Intelligent remote-control full-automatic subway construction vertical conveying system

A technology of remote control and conveying system, applied in the directions of transportation and packaging, trolley cranes, load hanging components, etc., can solve the problem of tunnel slag and segment conveying system backward supporting equipment, tunnel slag and segment conveying Problems such as poor safety and increasing energy-intensive movements of mechanical facilities can achieve the effect of reducing on-site operations and ground cooperating personnel, promoting safe production, and changing energy-intensive movements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

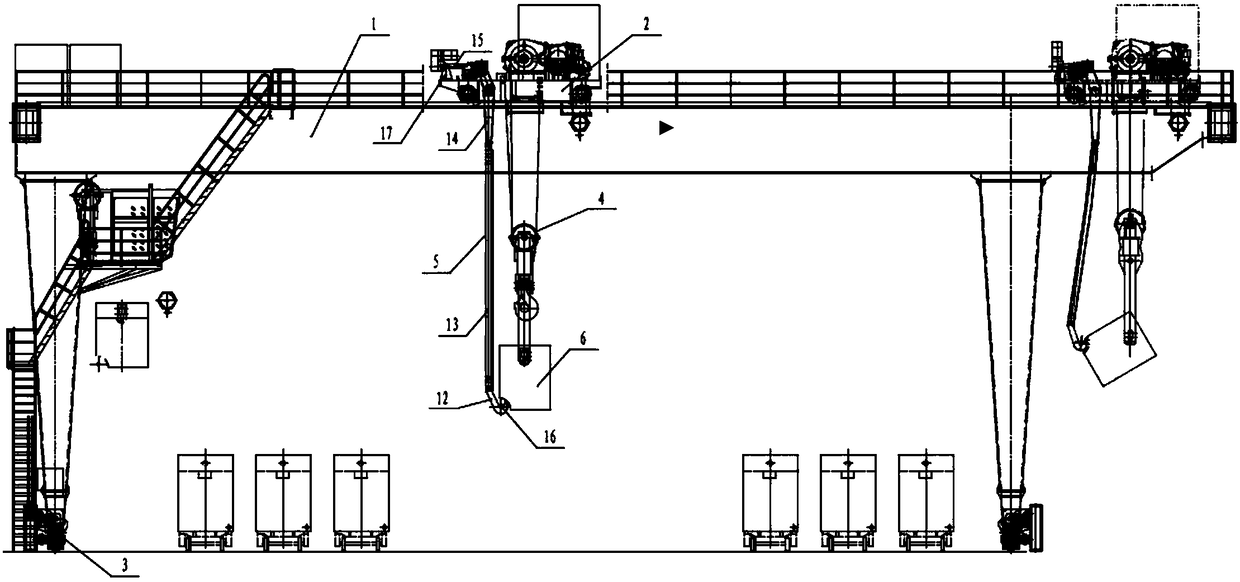

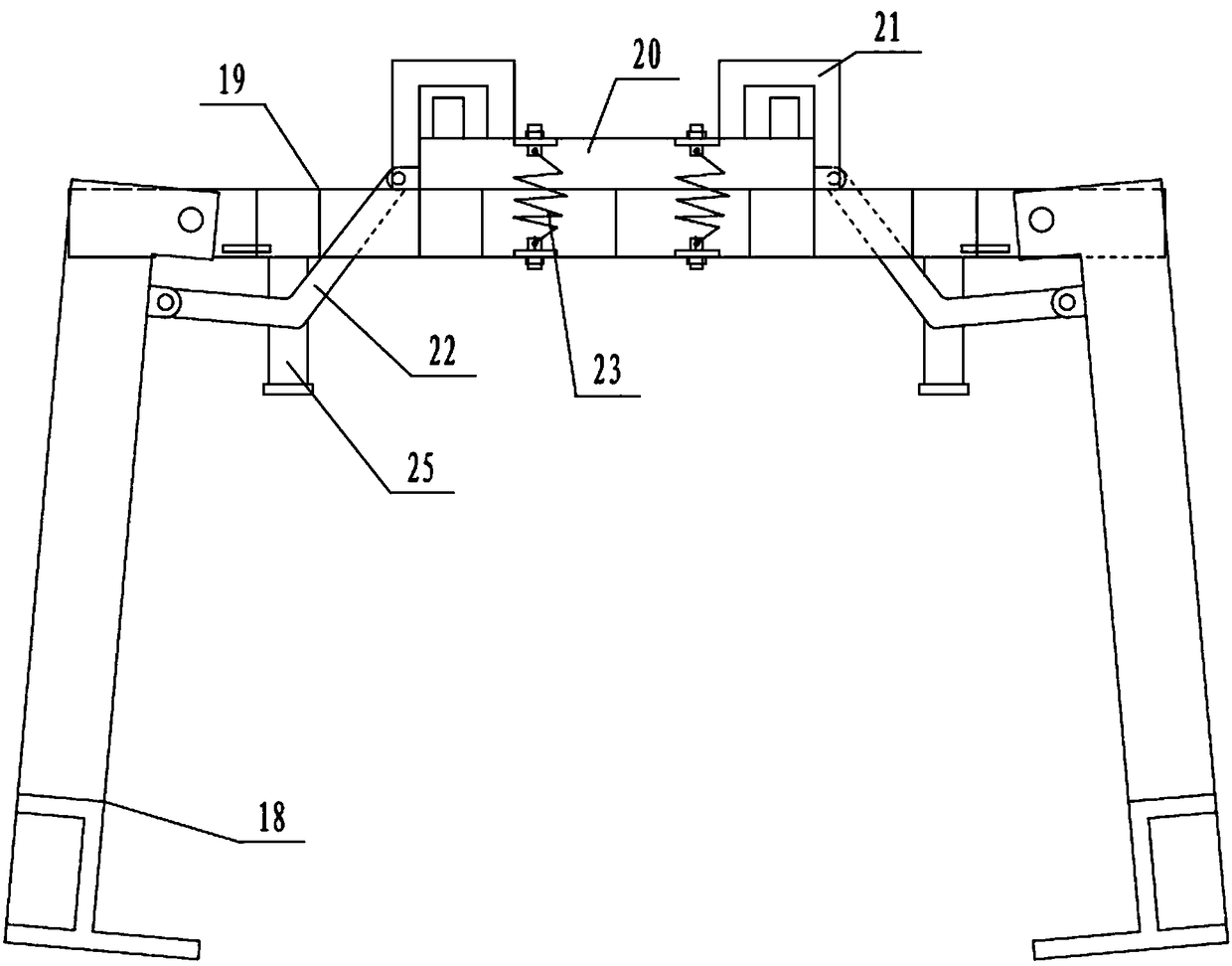

[0025] Embodiment 1: as Figure 1-Figure 6 As shown, the intelligent remote control fully automatic subway construction vertical conveying system includes a gantry 1, a trolley traveling mechanism 2 is arranged on the top of the gantry 1, a cart traveling mechanism 3 is arranged on the bottom, and a lifting mechanism 4 and a lifting mechanism 4 are installed on the trolley traveling mechanism 2. The slag turning device 5 and the lifting mechanism 4 are detachably connected to the slag box 6, and the slag turning device 5 drives the slag box 6 to turn material.

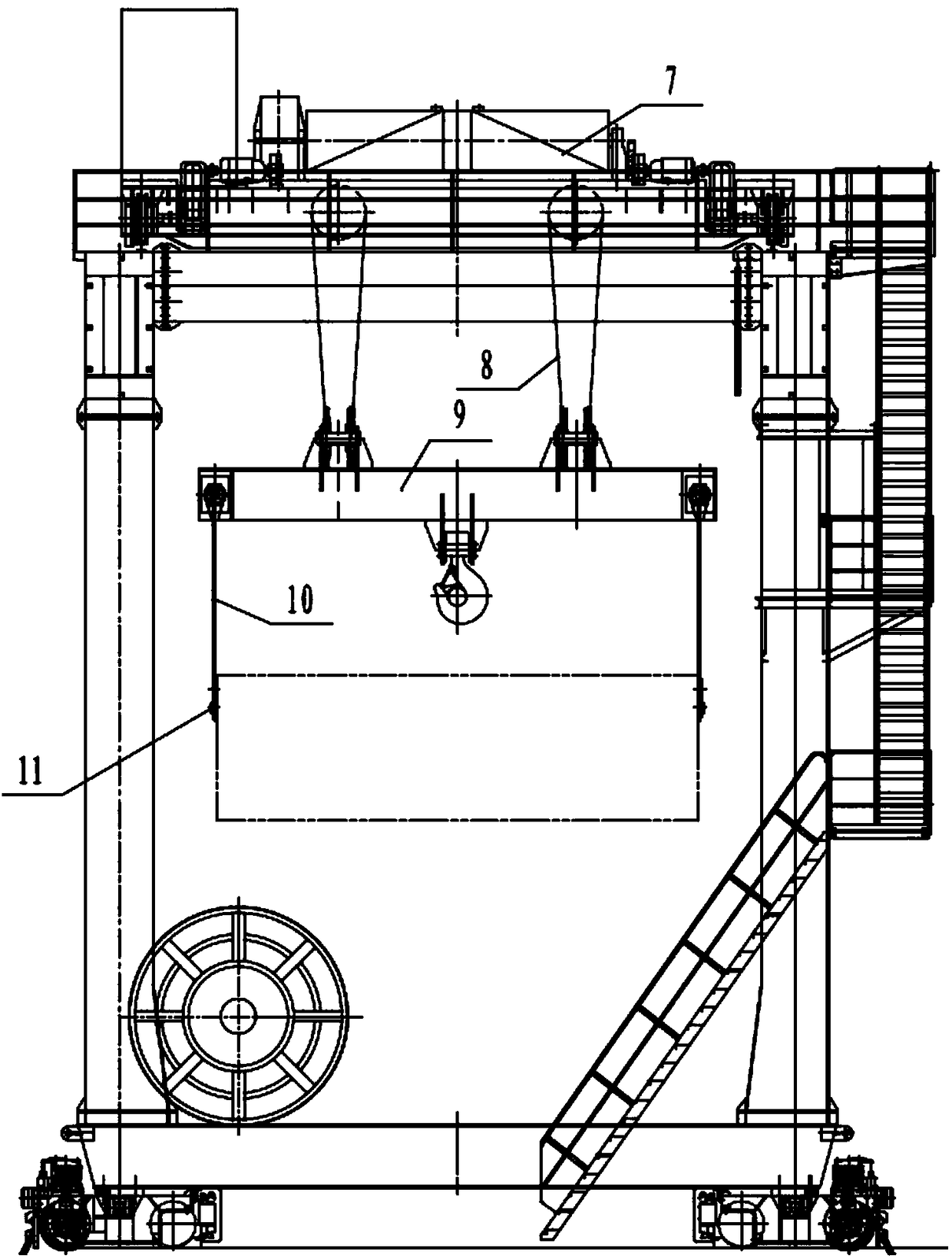

[0026] Preferably, the lifting mechanism 4 includes a hoist 7, a wire rope 8, a beam 9 and a spreader hook 10, the hoist 7 is fixedly connected to the traveling mechanism 2 of the trolley, and the beam 9 is connected to the hoist through a fixed pulley 11 through which the wire rope 8 passes. 7, the crossbeam 9 is perpendicular to the moving direction of the trolley running mechanism 2, and the two ends are connected w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com