Air separation cooling box layering haling method

A technology of cold box and sand removal, which is applied in the direction of refrigeration, liquefaction, liquefaction, solidification, etc. It can solve the problems that it is difficult to control the pearlescent sand flying with the wind, unfavorable steel pipe installation pearlescent sand flow, and damage to the internal equipment pipes of the cold box, etc., to achieve Easy to install and move up and down, shorten tooling preparation time, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

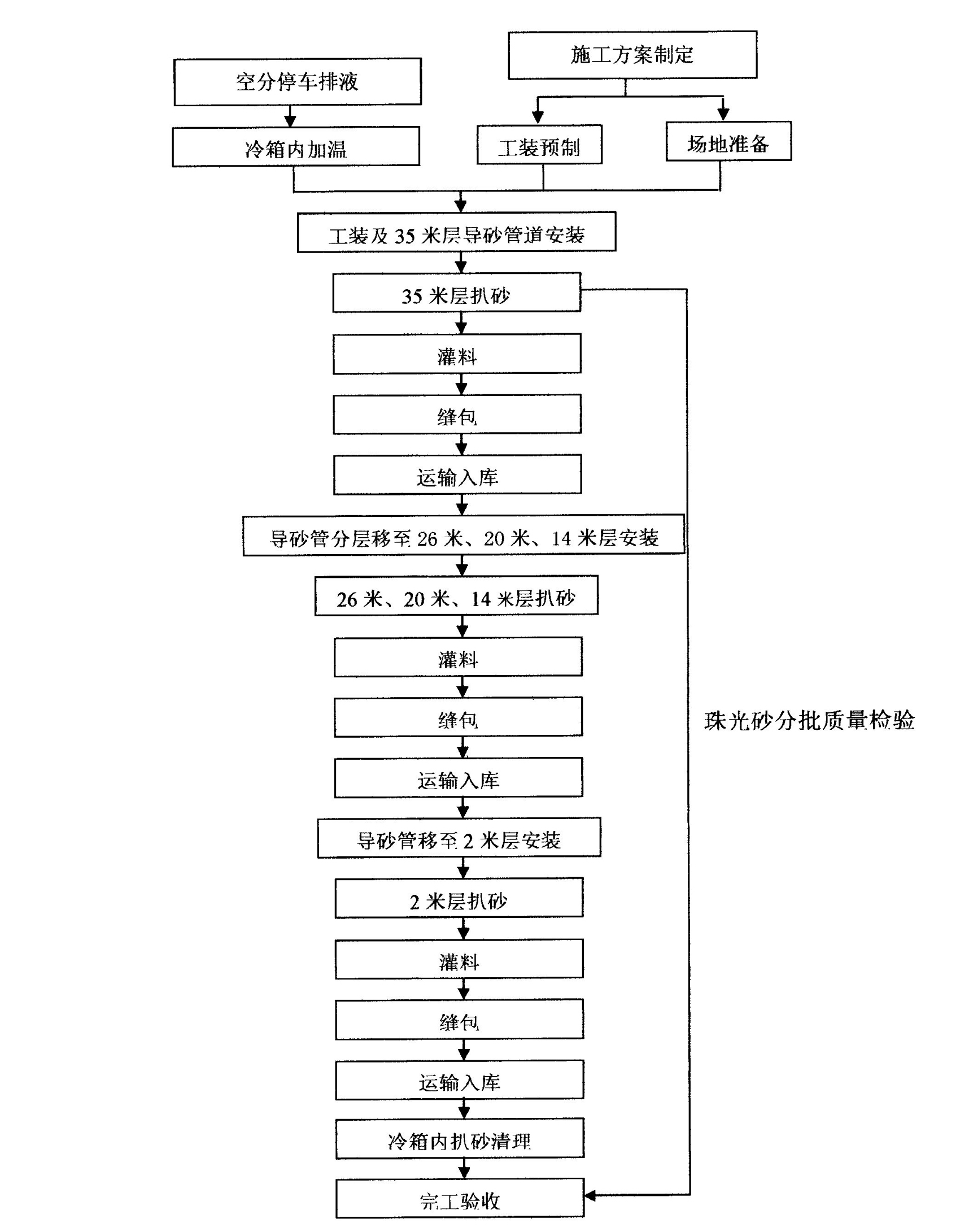

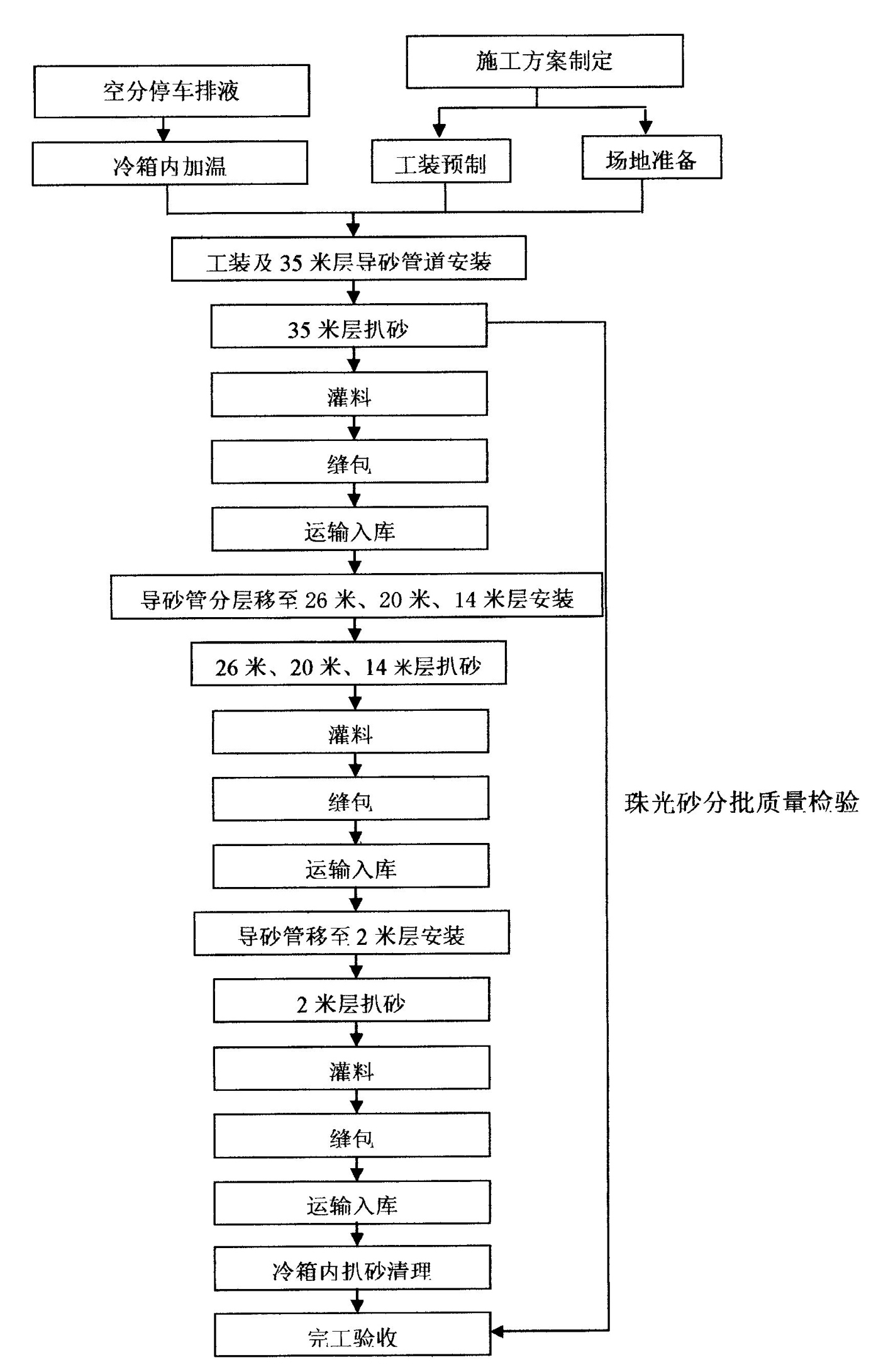

Image

Examples

specific Embodiment

[0031] 1. Pre-treatment of the cold box before sand removal: the pre-treatment of the cold box includes parking and drainage of the cold box and heating inside the cold box:

[0032] 1) Parking and draining: During the draining process, the operation must be slow to prevent frostbite of low-temperature liquid and accumulation of oxygen, nitrogen, and argon concentrations, and prevent explosion and suffocation. When discharging liquids, liquid air, liquid oxygen, liquid nitrogen, and liquid argon are discharged at high altitude in sequence. When discharging, fire and open flames are strictly prohibited within 25 meters around the cold box.

[0033] 2) Heating: Heating the fractionation tower and strictly implementing the equipment operating procedures, especially when the liquid leaks from the cold box, more attention should be paid to it. The heating time should be ensured, generally not less than 36 hours. When heating, the amount of sealing gas in the cold box should be prop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com