Section-adjustable rectangular column framework assembly

A rectangular column and formwork technology, which is applied to formwork/formwork/work frame, on-site preparation of building components, construction, etc., can solve the problems of occupying construction sites, inconvenient building construction, and time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

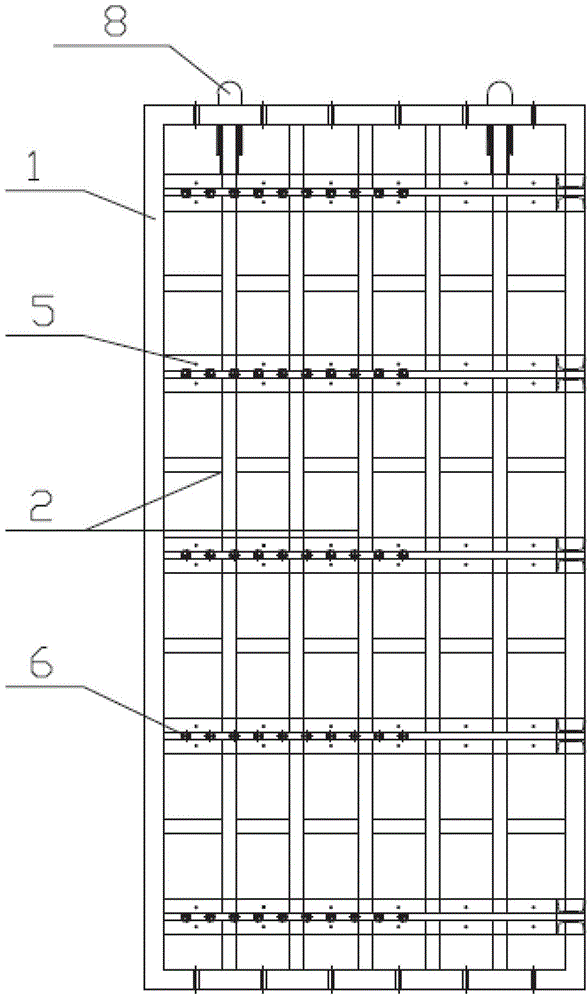

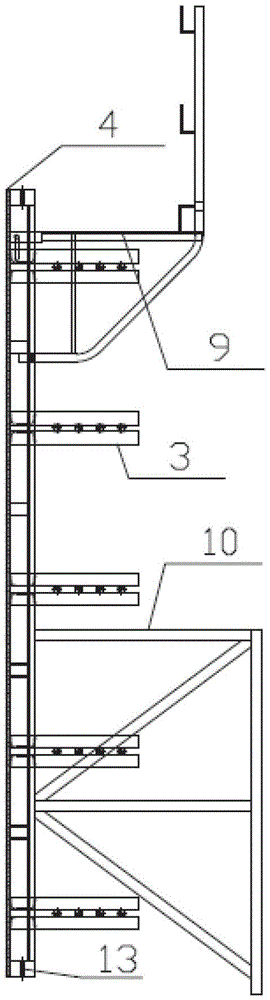

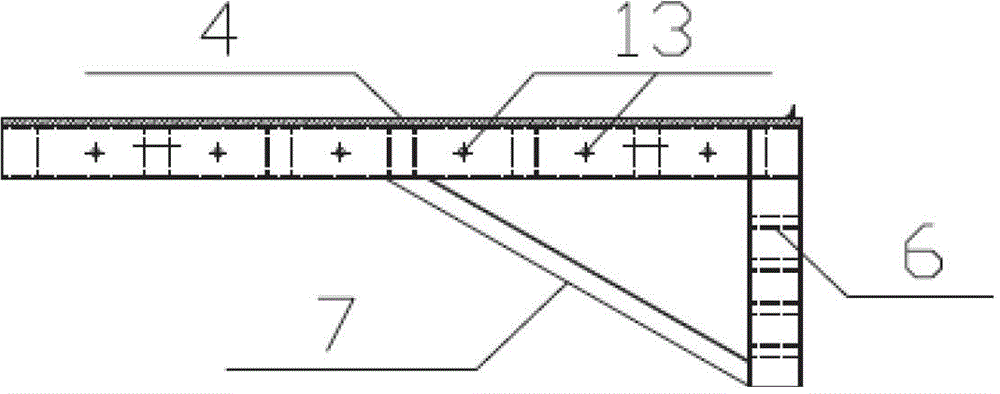

[0019] Specific embodiments of the present invention will be described below with reference to the drawings. The adjustable section steel frame plywood rectangular column formwork assembly of this embodiment includes four detachable rectangular formworks, the structure of each formwork is as follows figure 1 , figure 2 As shown, it is composed of a plywood panel 4 fixed on the inner surface of the plate frame, and the plate frame is composed of a rectangular outer frame 1 and an inner frame 2 of a sash structure therein. A number of channel-steel horizontal corrugated strips 5 distributed at intervals above and below are fixed in the plate frame, and the plate frame at the end of each horizontal corrugated strip is respectively welded and fixed to the channel-steel vertical corrugated strips perpendicular to it to form an L-shaped back corrugated strip 3 . The horizontal corrugated bar and the vertical corrugated bar respectively have bolt holes 6 distributed at intervals. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com