Process for constructing underground structural walls without linings

A construction technology and underground structure technology, applied in underwater structures, infrastructure engineering, artificial islands, etc., can solve the problems of irregular water seepage on the wall surface, easy to trap mud, and difficult to guarantee the quality of the wall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

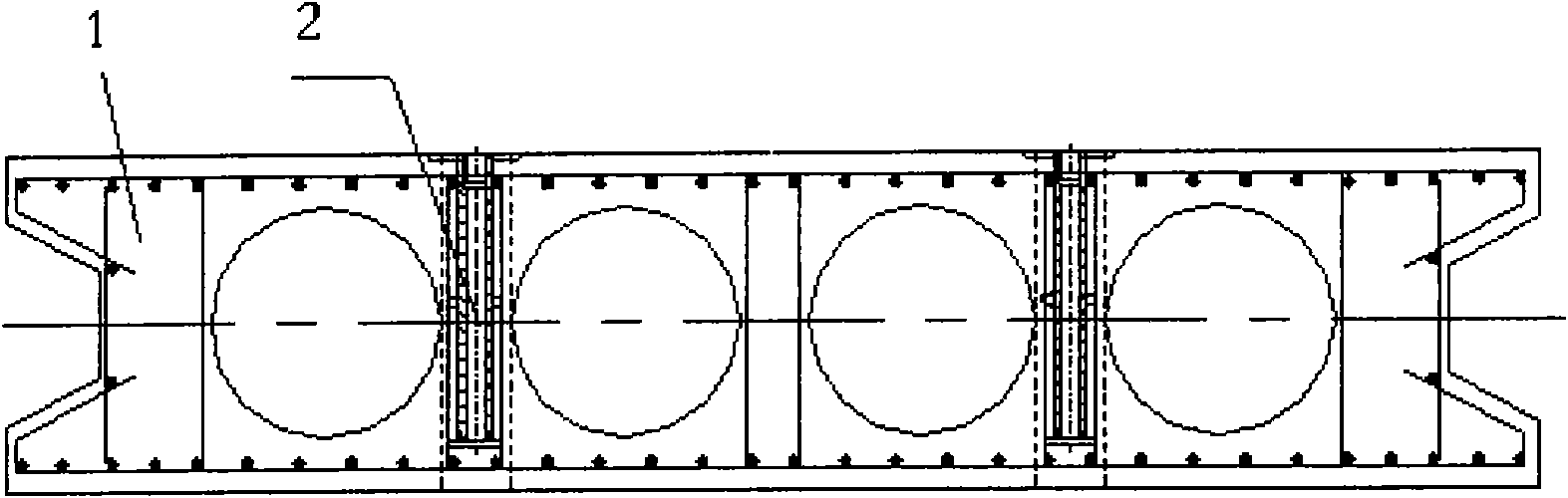

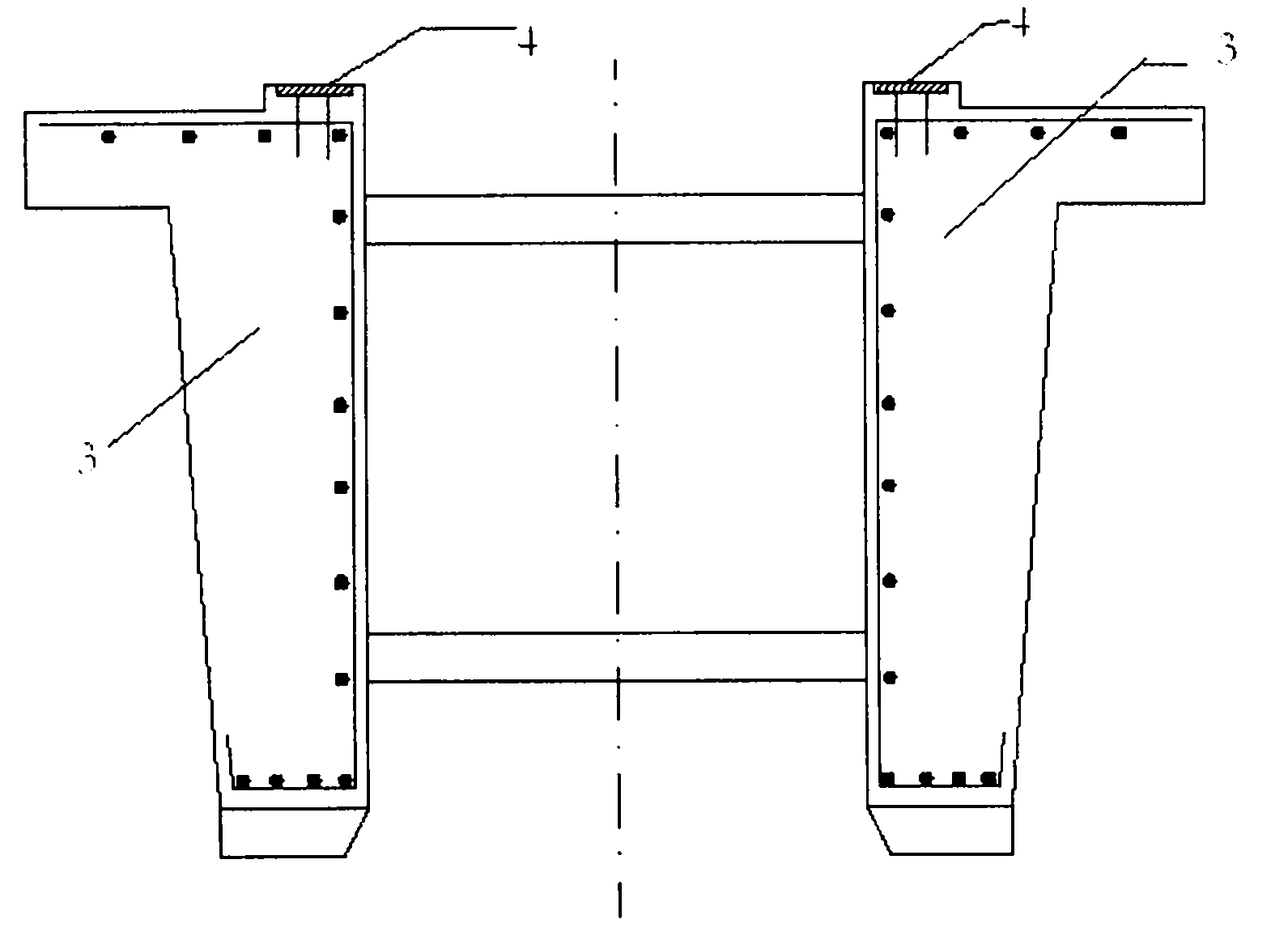

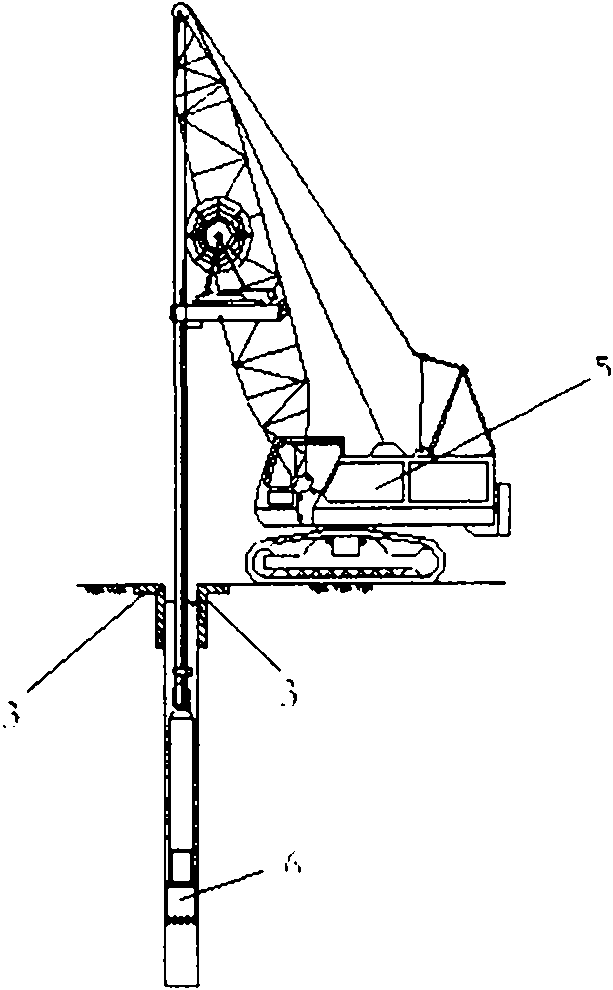

[0011] Specific implementation methods: (1) Prefabrication of underground structural wall panels, (2) Transportation of underground structural wall panels, (3) Grooving and hoisting of underground structural walls, (4) Joint piles between underground structural wall sections Construction, (5) Treatment of wall toes and joints of underground structural walls. It is characterized in that: the prefabrication of the underground structure wall panel described in the step (1) is as follows: ground concrete base formwork, measurement and lofting, after acceptance, laying isolation film, binding steel bars, filling foam plastics in the inner holes of the structural bottom plate, and installing inserting bars , connectors, waterstops, grouting pipes, inclinometer pipes and other embedded parts, install wall side forms, carry out concealed engineering acceptance, pour concrete below the bottom of the inner hole, install rubber airbags in the inner hole below the structural bottom plate, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com