Patents

Literature

54 results about "E resources" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

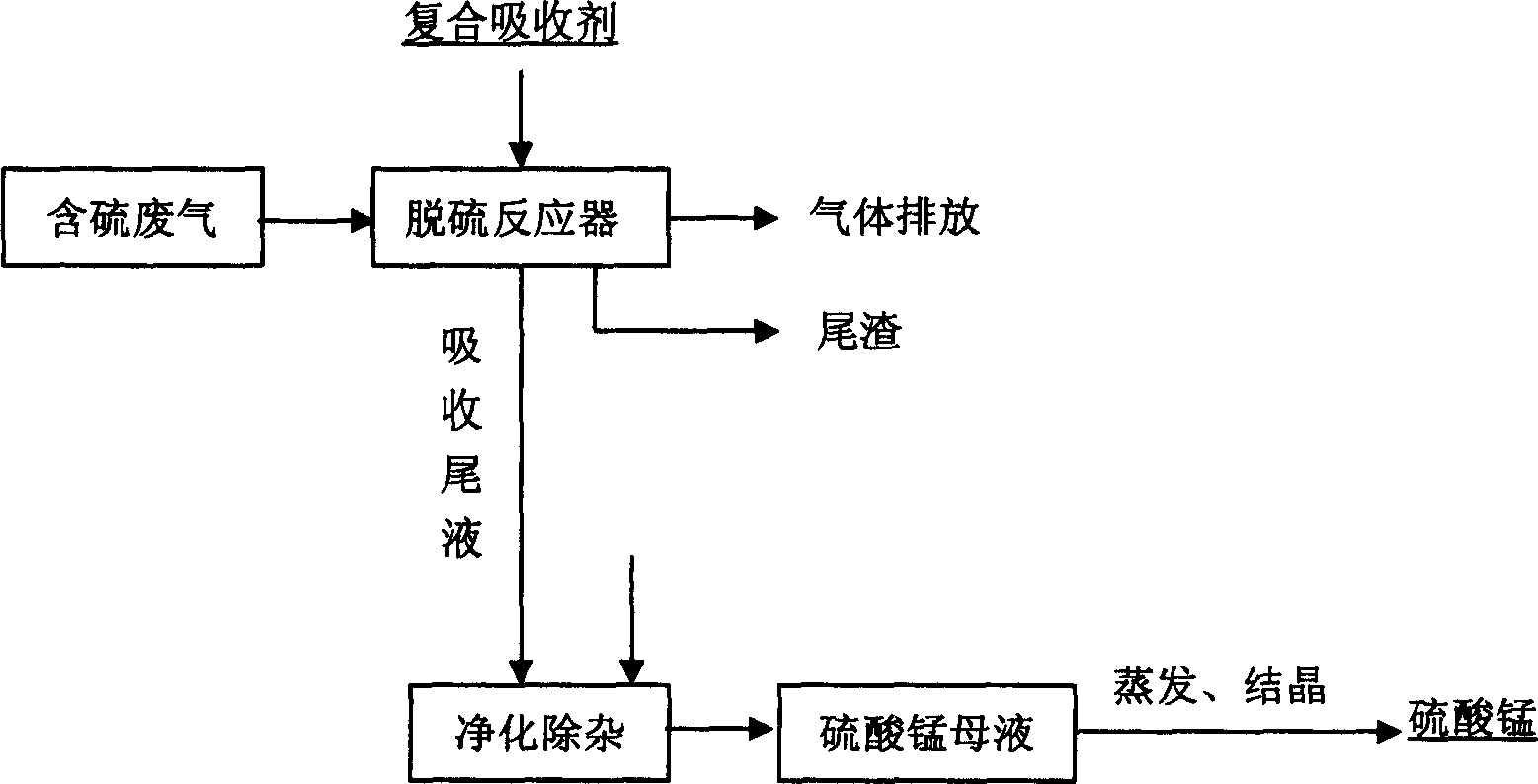

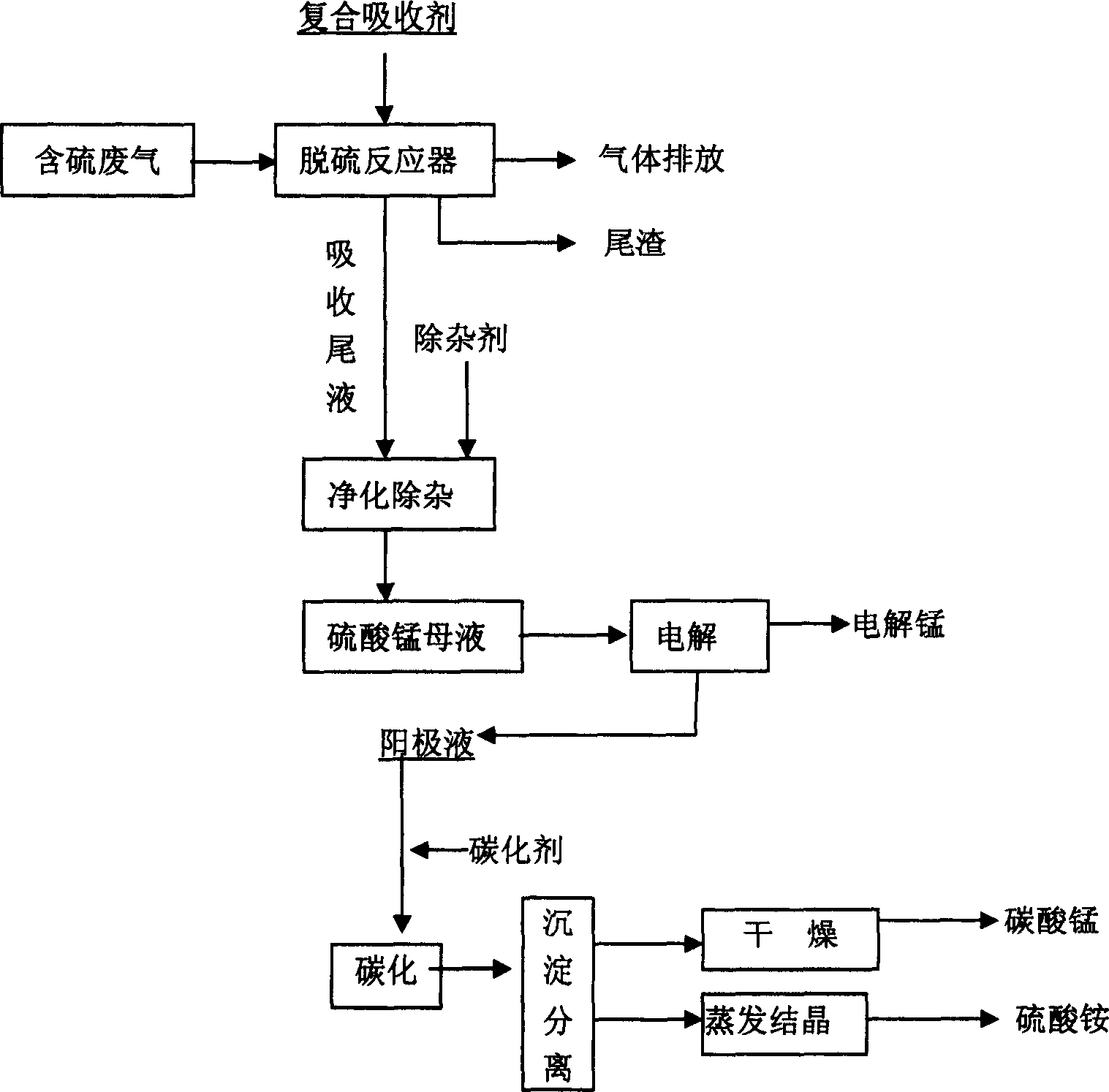

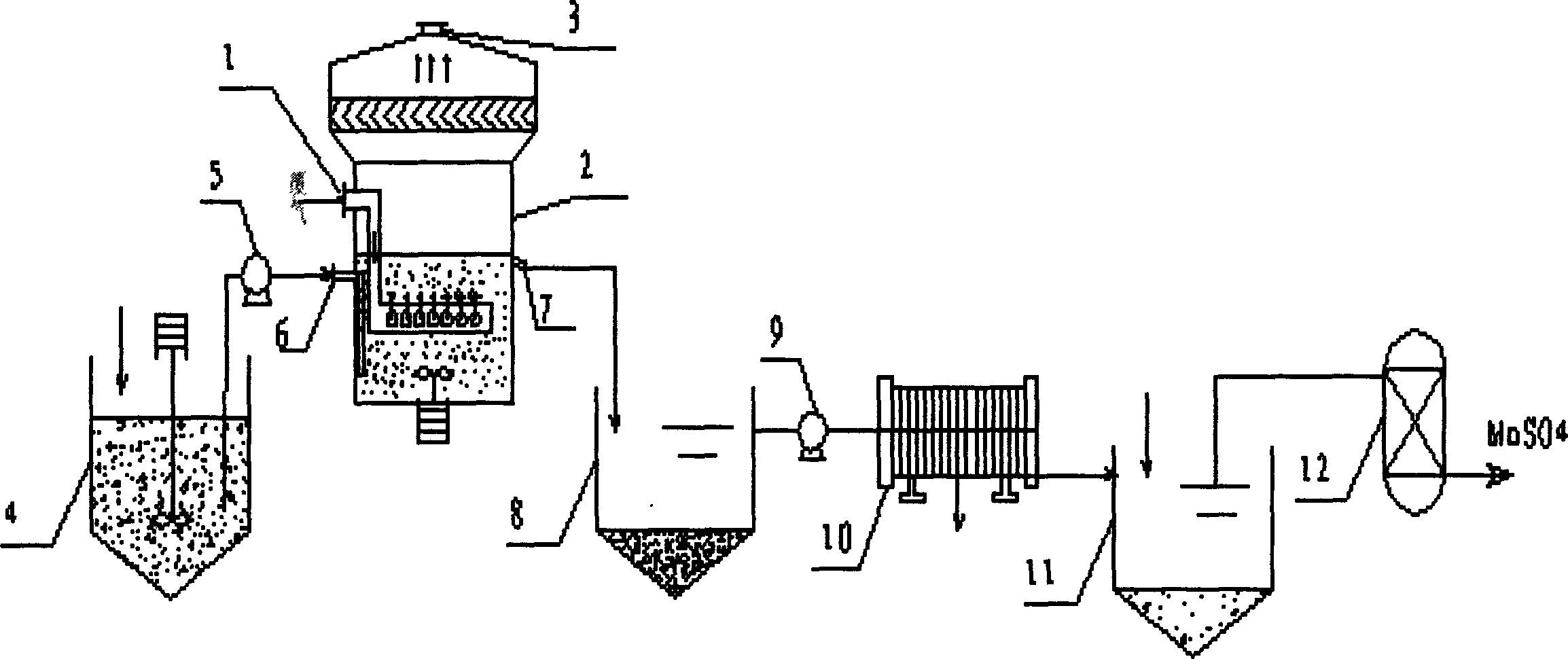

Waste gas desulfurizing method with composite absorbant comprising pyrolusite and pH buffering agent

ActiveCN1772345ARich reservesLow pricePhotography auxillary processesDispersed particle separationPyrolusiteElectrolysis

The present invention is method of comprehensively utilizing waste SO2 gas resource and pyrolusite, and the method includes utilizing the composite absorbent comprising pyrolusite slurry and pH buffering agent to produce oxidation-reduction and neutralizing reaction with waste SO2 gas to eliminate SO2 from the waste gas, purifying the absorbed tail liquid to obtain manganese sulfate product through direct evaporating crystallization or metal manganese product through DC electrolysis, and treating the anode liquid to obtain high purity manganese carbonate product and ammonium sulfate product. The present invention realizes treatment of waste with waste to recover sulfur resource and comprehensively utilize pyrolusite. The method of the present invention is reasonable and has no secondary pollution.

Owner:SICHUAN UNIV

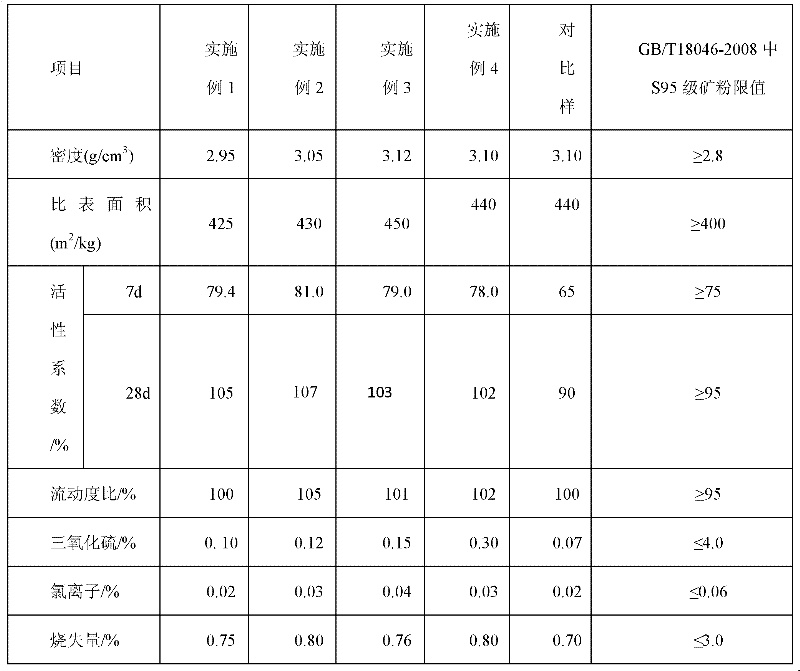

Modified steel slag composite admixture and preparation method thereof

InactiveCN102491664AOvercoming stability issuesImprove early activitySolid waste managementWork performanceSlag

The invention discloses a modified steel slag composite admixture and a preparation method thereof. The modified steel slag composite admixture comprises 55-75wt% of micro mineral slag powder, 20-40wt% of micro steel slag powder, and 1-5wt% of sintering desulphurization slag. Concrete prepared by mixing the modified steel slag composite admixture of the invention with cement has the following characteristics: the seven day active index is greater than 75%, the twenty-eight day active index is greater than 100%, the specific surface area is equal to or greater than 400m<2> / kg, the sulfur trioxide content is equal to or less than 4.0%, the chloride ion content is equal to or less than 0.06%, the ignition loss amount is equal to or less than 3.0%, and the autoclaving stability is qualified. The modified steel slag composite admixture which allows a low early strength disadvantage of steel slag composite admixtures to be overcome, working performances of concrete to be effectively improved, the strength and the endurance of concrete to be improved, and energy consumption required by slag grinding to be effectively reduced and is in favor of the low carbon economy realization, is a resource use type concrete admixture.

Owner:SHANGHAI BAOTIAN NOVEL BUILDING MATERIALS

Method for removing antibiotics in water

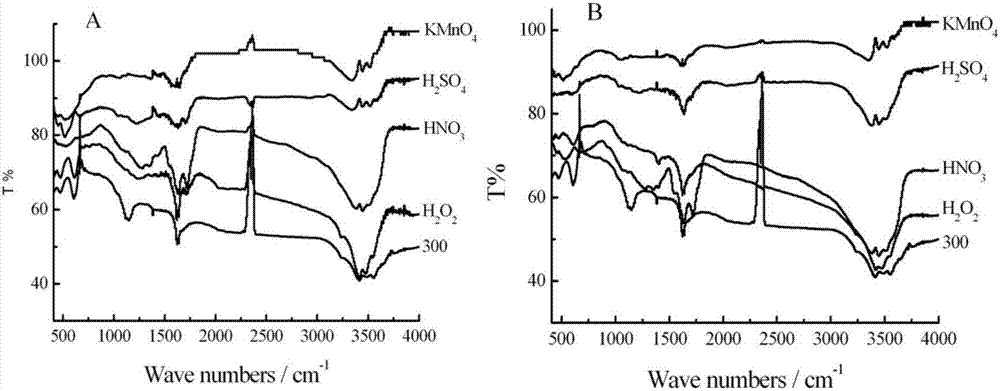

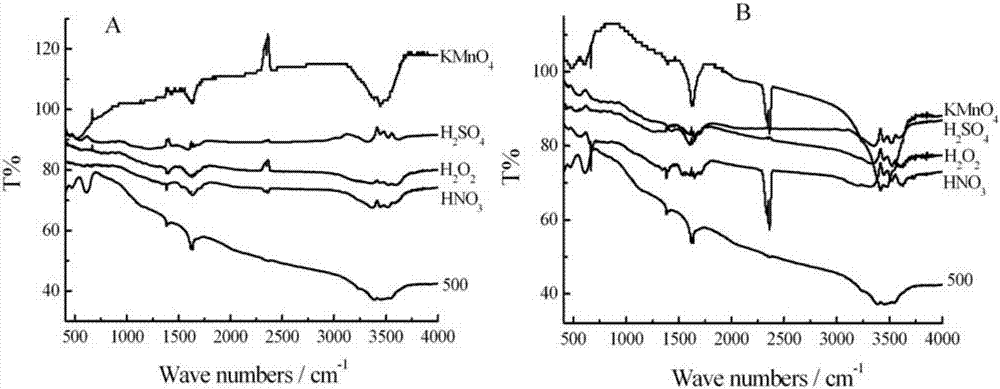

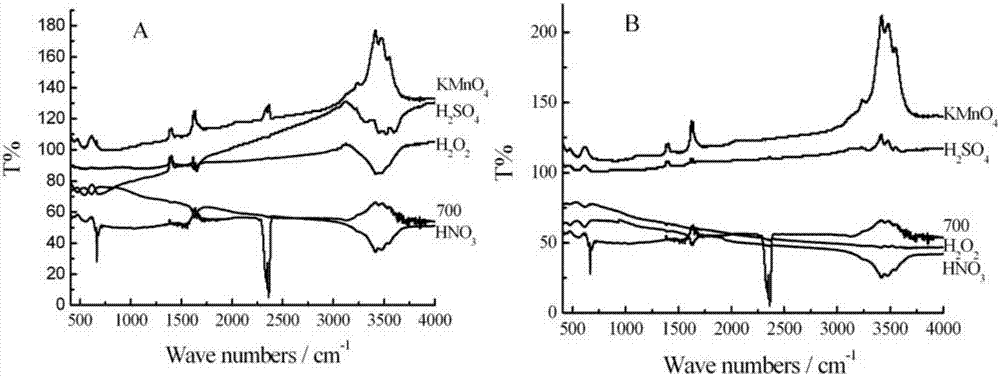

InactiveCN106995224AGood removal effectImprove adsorption capacityOther chemical processesWater contaminantsCarbonizationAntibiotic Y

The invention discloses a method for removing antibiotics in water. The method comprises the following steps: 1) pretreating collected sugarcane bark, and placing the pretreated sugarcane bark into a tubular carbonization furnace for burning to obtain sugarcane activated carbon; 2) adding a modifier into the sugarcane activated carbon for modifying; 3) removing antibiotics in water by using the modified sugarcane activated carbon. By adopting the method, the yield of biomass charcoal is about 31 percent, the yield is about 89 percent after ultrasonic impregnation modification of 30-percent hydrogen peroxide, and the produced biomass charcoal can efficiently absorb sulfonamide antibiotics in water, and has higher adsorption capacity for sulfonamide antibiotics such as sulfamethoxazole, thiazole, methylpyrimidine and dimethylpyrimidine under the adsorption condition that pH is equal to 4 and the temperature is 35 DEG C; in particular, the activated carbon has a best removing effect after being burned at the temperature of 500 DEG C and being subjected to modification with the 30-percent hydrogen peroxide and ultrasonic impregnation modification; a good way for recycling resources is provided by taking bagasse as a raw material for preparing the biomass charcoal; the biomass charcoal can absorb the antibiotics in water, and has a very good application prospect in the aspect of removal of other pollutants.

Owner:SOUTH CHINA INST OF ENVIRONMENTAL SCI MEP

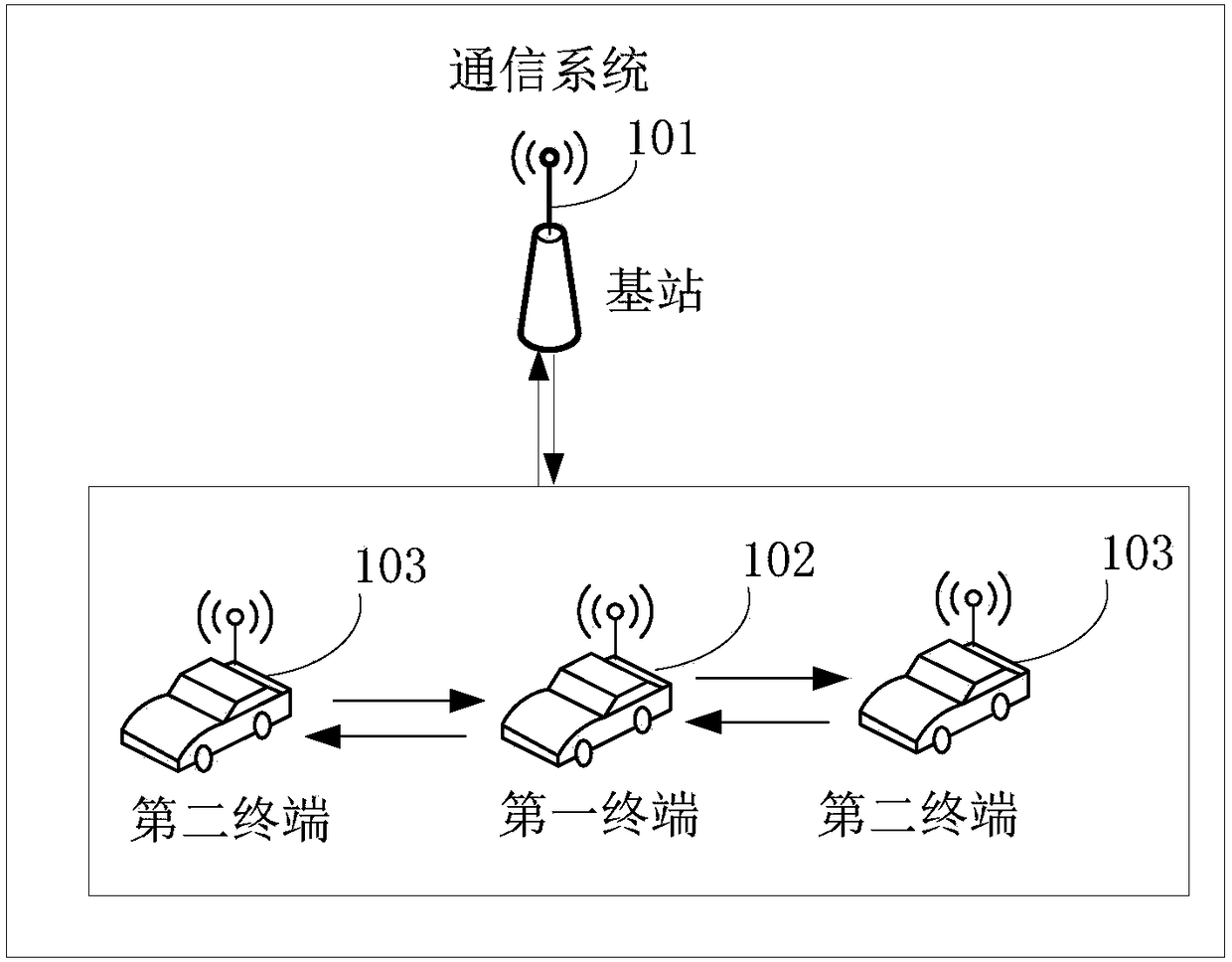

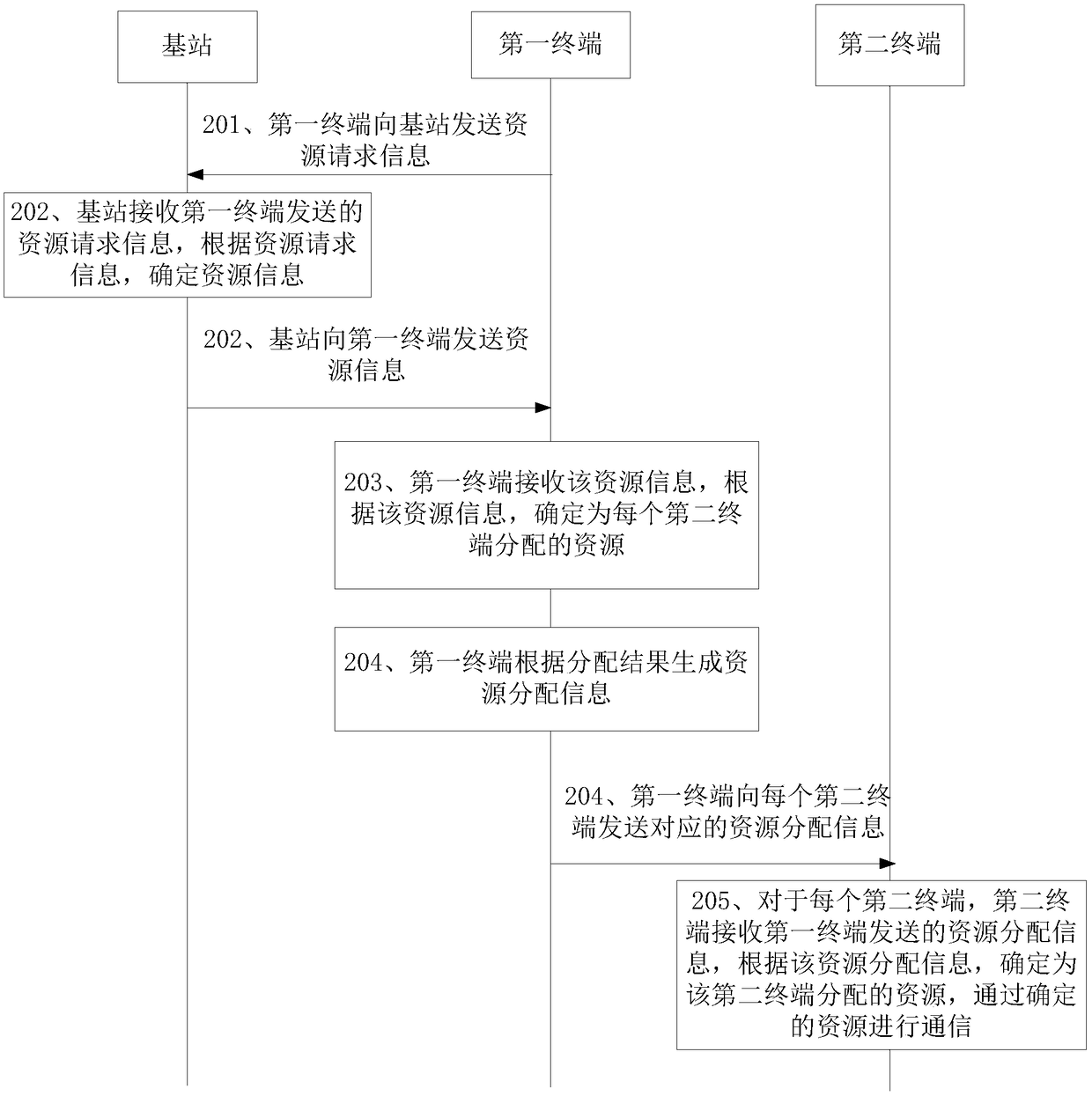

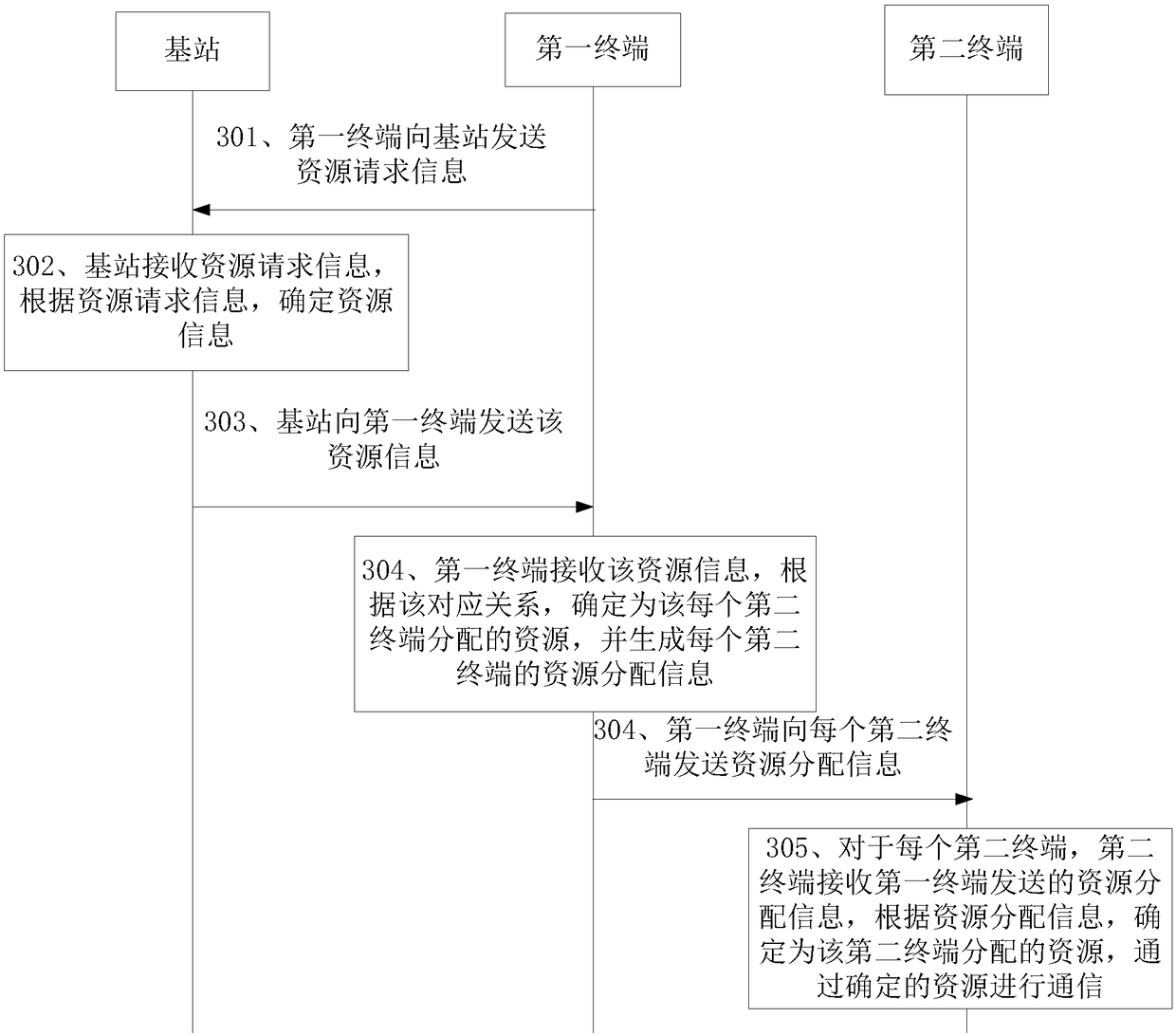

Resource allocation method and device

PendingCN108347772AEnsure normal communicationImprove reliabilityWireless communicationResource informationResource allocation

The invention discloses a resource allocation method and device and belongs to the technical field of a network. The method comprises the steps that a first terminal receives resource information sentby a base station and determines resources allocated to at least one second terminal according to the resource information; the first terminal generates resource allocation information according to an allocation result, and each second terminal in the at least one second terminal determines the resources allocated to the second terminal through the resource allocation information; and the first terminal sends corresponding resource allocation information to each second terminal, so each second terminal carries out communication through the determined resources. According to the method and thedevice, the resource allocation is uniformly carried out by the first terminal or the base station, a resource conflict can be avoided, the communication reliability is improved, and the normal communication of each second terminal is ensured.

Owner:HUAWEI TECH CO LTD

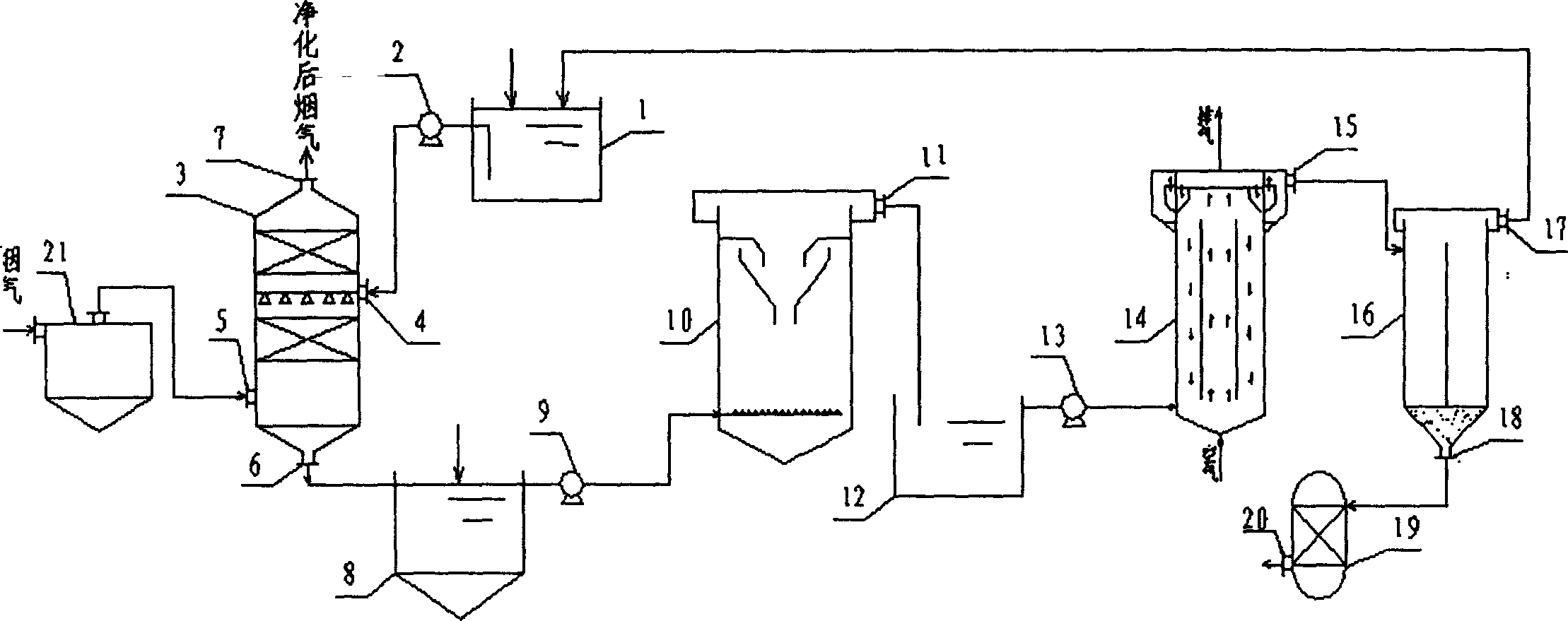

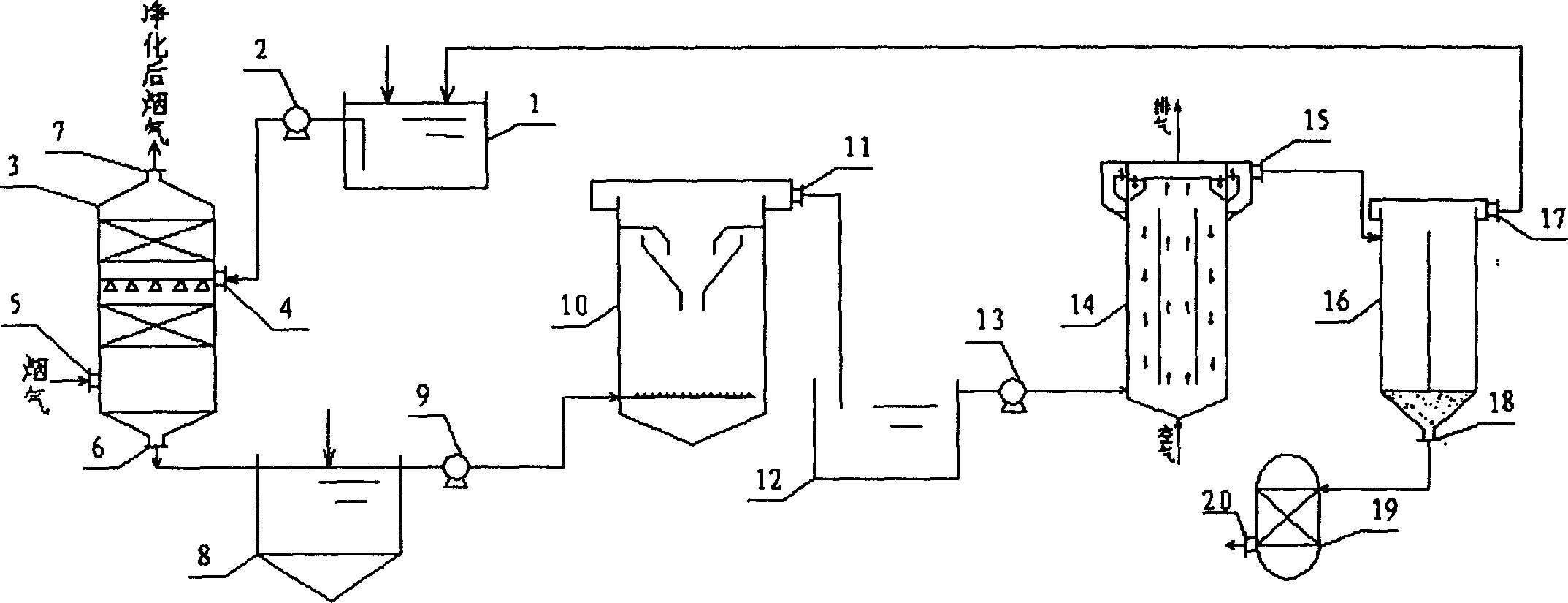

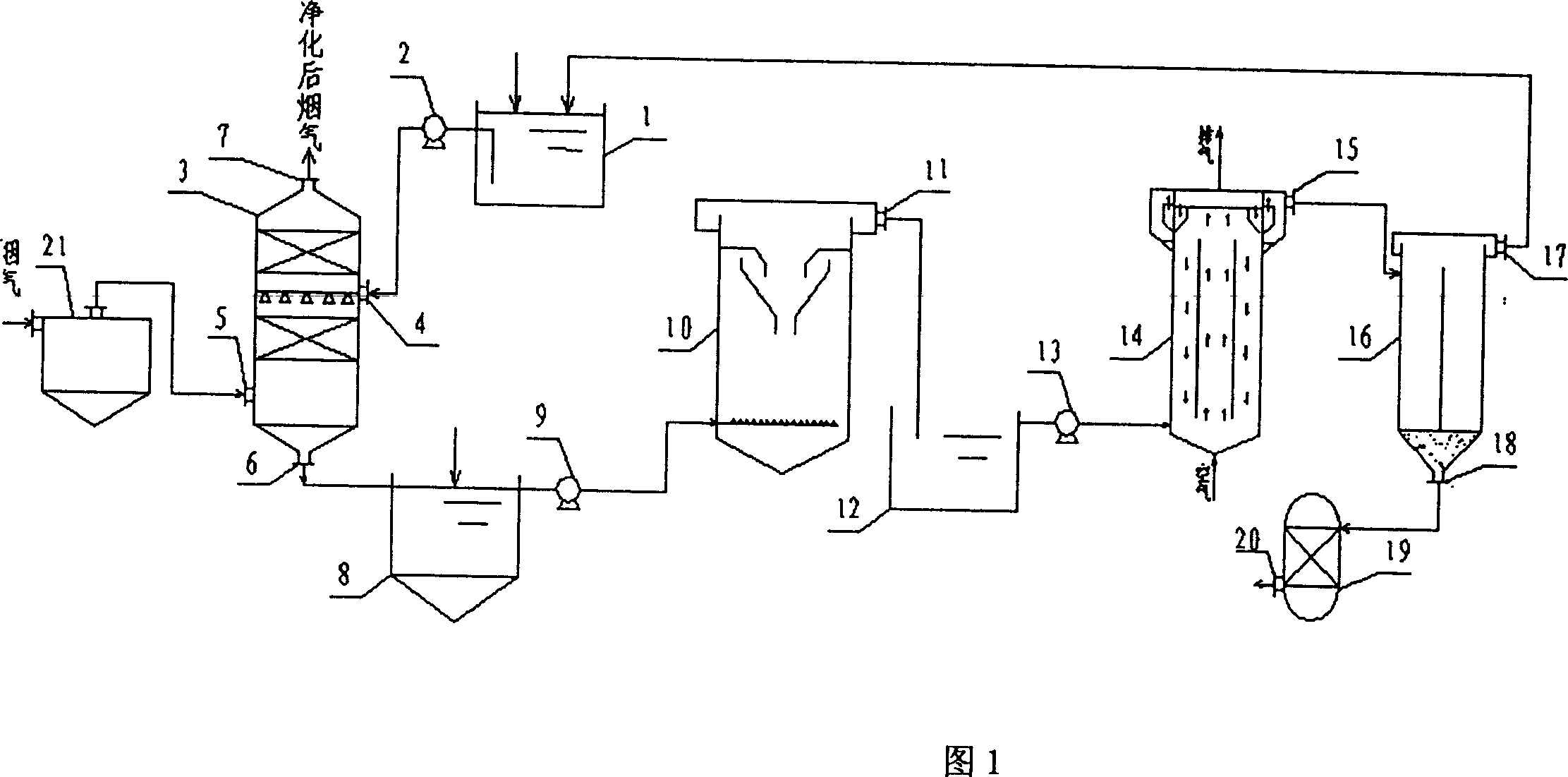

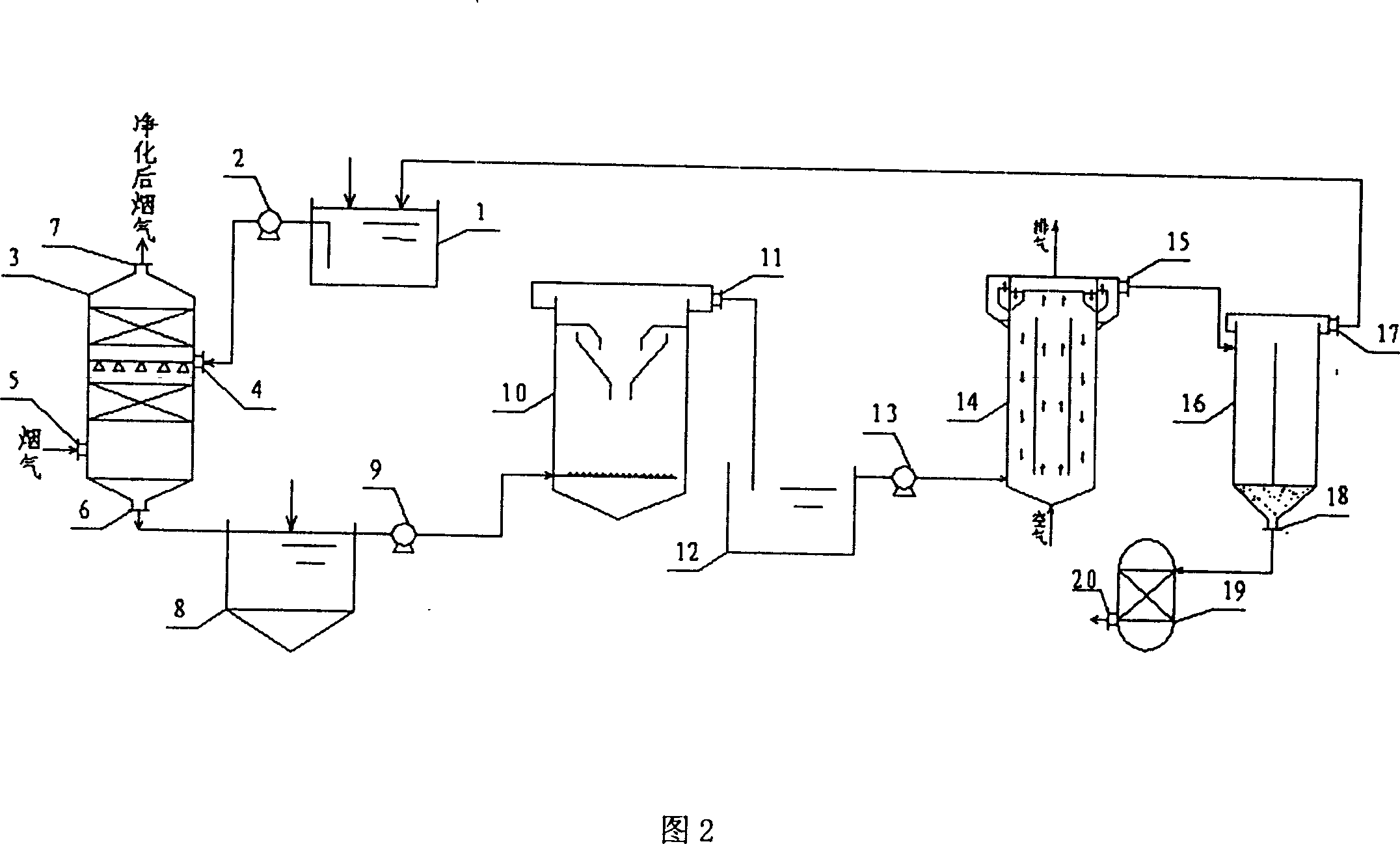

Waste gas control method by removing sulfur dioxide for resource utilization

InactiveCN1736557AReasonable workmanshipMild desulfurization reaction conditionsDispersed particle separationResource utilizationSulfur

The invention provides a method for desulfurization of SO2 waste gas. A basic absorption liquid neutralizes the SO2- laden waste gas to eliminate SO2, discharge the purified gas when the content of SO2 reaches the standard; microbe reduces the desulfurizing absorption tail liquid (containing sulfite group, bisulphate group, or sulfuric group), then microbe oxygenizes the liquid, and the SO2 contained is recovered as a existent of elemental sulfur. The liquid treated by microbe is basic, and it can return directly to the desulfurizing absorption unit and be reused as a basic absorption liquid. And it realizes the aim of eliminating waste and recycling sulfur resource. The method for waste gas treatment is easy to operate and leads to none secondary pollution.

Owner:SICHUAN UNIV

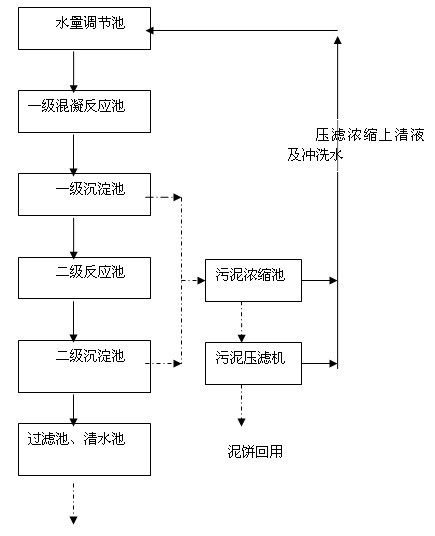

Method for treating manganese-containing wastewater generated during electrolytic manganese processing

InactiveCN102115284ALow costGuarantee sustainable developmentSludge treatment by de-watering/drying/thickeningWater contaminantsManganeseEmission standard

The invention discloses a method for treating manganese-containing wastewater generated during electrolytic manganese processing. The method comprises the following steps of: firstly, pretreating manganese-containing wastewater; adding sodium hydroxide to adjust the pH value to be 9.3+0.10; adding carbonate capable of undergoing a displacement reaction with Mn<2+> to generate a MnCO3 sediment; then, adding a flocculant and fully stirring, wherein the addition amount of the flocculant is 0.12-0.35 percent of the wastewater amount; leading the wastewater to enter a primary sedimentation tank, standing still, sedimenting MnCO3 and separating the MnCO3 from liquid; then, adding sodium hydroxide to adjust the pH value to 9.7+0.10; adding perhydrol and the flocculant; and leading the wastewater enter a secondary sedimentation tank and standing still to generate a Mn(OH)2 sediment; and adding an acid or alkali substance to adjust the pH value of the Mn(OH)2 sediment so that related indexes can reach an emission standard. The method disclosed by the invention is a production type treatment method for resource recycling, can be used for recycling manganese resources, has lower treatment cost and is beneficial to decrease of the costs of enterprises for treating the manganese-containing wastewater.

Owner:重庆武陵锰业有限公司

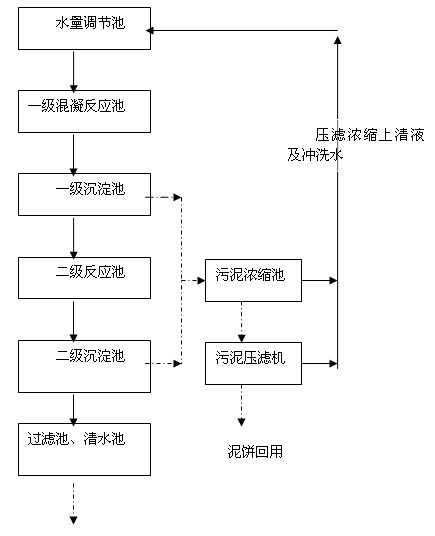

Modification technology of iron reduction and component reconstruction for molten slag

InactiveCN102796833AEfficient use ofIncrease added valueManufacturing convertersRecycling and recovery technologiesMolten saltIron reduction

The invention relates to the field of metallurgy waste residue treatment, particularly relates to a modification technology of iron reduction and component reconstruction for molten slag, comprising the following steps: adding a modified material in molten slag, wherein the modified material comprises coke and SiO2, the weight ratio of coke to SiO2 to the molten slag is 0.08-0.12:0.10-0.12:1; heating up the molten slag after mixing to 1500-1700 DEG C; after fully reaction of the modified material and the molten slag, separating molten iron from the molten slag, and then discharging the molten iron. The technology has simple process, is a short flow technology of modification and regeneration of resources, has no need for new devices, can be used directly in on line production, is a supplement for existing steel smelting technology, and only needs auxiliary production technologies.

Owner:SHANGHAI MCC ENVIRONMENTAL ENG TECH CO LTD +1

Preparation method for ammonium rhenate from waste high temperature alloy enriched material

InactiveCN103436721AEfficient recyclingAchieve recyclingProcess efficiency improvementRheniumIon exchange

The invention discloses a preparation method for ammonium rhenate from a waste high temperature alloy enriched material. The method comprises the following steps: subjecting a waste high temperature alloy to melting, atomization and powder injection and leaching nickel and cobalt to obtain a tungsten-molybdenum-rhenium enriched material; then subjecting the tungsten-molybdenum-rhenium enriched material to acid leaching, alkali treatment and the like so as to obtain a solution containing tungsten, molybdenum and rhenium; carrying out ion exchange by using a certain resin so as to obtain a solution rich in rhenium; and carrying out concentration and crystallization so as to prepare pure ammonium rhenate. A raw material used in the invention is a material rich in tungsten, molybdenum and rhenium obtained after earlier-stage pretreatment of the waste high temperature alloy; the preparation method is convenient for large scale production, is a sustainable green and environment-friendly process cyclically using resources and discharging no harmful exhaust gas and has good practicality, economic benefits and social benefits.

Owner:SINO PLATINUM METALS CO LTD

Seedling culturing method of ground cover bamboo

The invention discloses a seedling culturing method of ground cover bamboo, and belongs to the technical field of bamboo culturing. The seedling culturing method of the ground cover bamboo comprises the following steps: selecting primary bamboos, selecting bamboo rhizomes, cutting the bamboo rhizomes, processing rhizome sections, bagging the rhizome sections, managing a sprouting process, separating rhizome section seedlings, grading and screening the rhizome section seedlings, and planting the rhizome section seedlings. By of the technology, bamboo rhizome sections are seeds, plastic bags are seedling culturing containers, culture medium is not used, a seedling culturing field is largely saved, water management in the seedling culturing process is reduced, invalid seedling culturing of ground cover bamboo seeds is reduced, the seedling culturing time of the ground cover bamboo is shortened, the seedling culturing cost of the ground cover bamboo is lowered, good usable seedlings can be selected visually, the seedling culturing is rapid, economical and low-carbon, the ground cover bamboo can be transplanted and transported to another place conveniently, and therefore the seedling culturing method of the ground cover bamboo is energy-saving, environment-friendly, and suitable for popularization and application.

Owner:国家林业局竹子研究开发中心

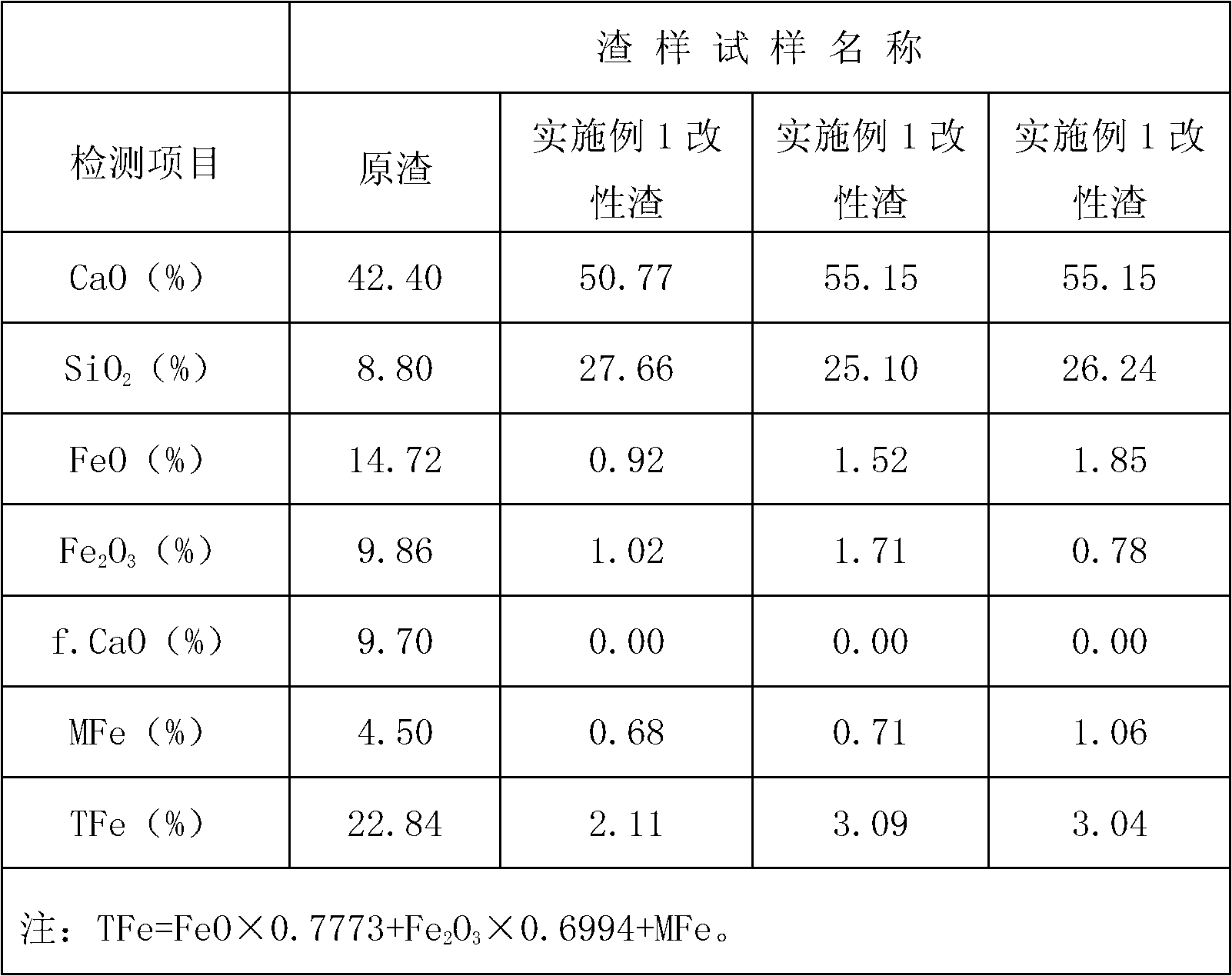

Comprehensive utilization method of slag iron concentrates of wet-type zinc smelting furnace

InactiveCN103695662AEffective dissolutionLeaching is effectiveProcess efficiency improvementResource utilizationMaterials science

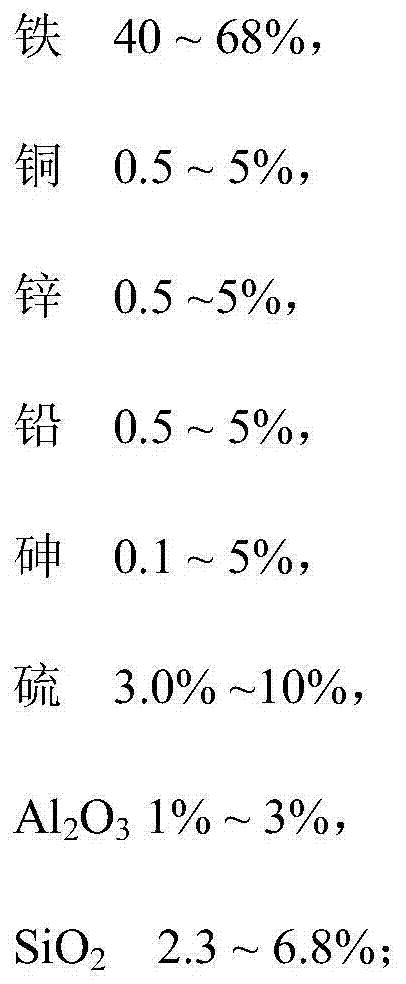

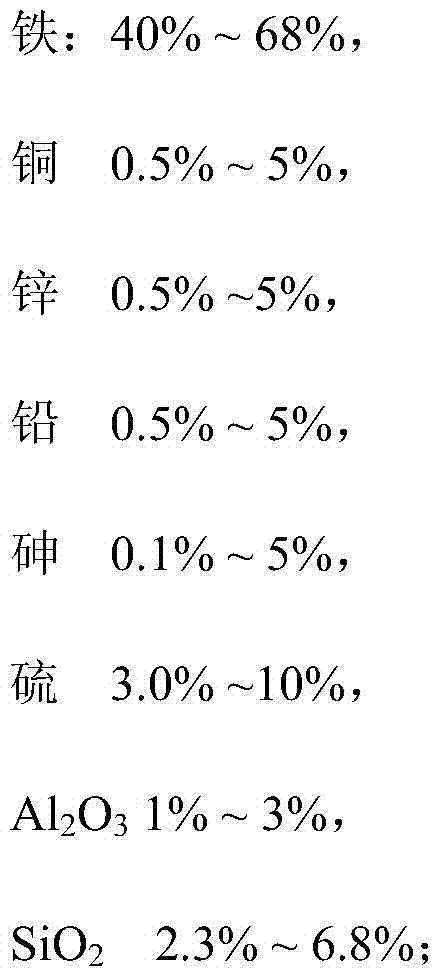

The invention relates to a comprehensive utilization method of slag iron ore concentrates of a wet-type zinc smelting furnace and belongs to the technical field of metallurgy. The method comprises the following steps: performing two-section counterflow leaching on raw material (slag iron ore concentrates in the wet-type zinc smelting furnace) in the presence of a hydrochloric acid aqueous solution serving as a leaching agent so that valuable metals such as iron, silver, copper, lead, zinc and arsenic in the slag iron ore concentrates enter a leachate; purifying the leachate by utilizing processes of metal iron powder replacement, control over pH (Power Of Hydrogen) value, arsenic sedimentation, sulfuration precipitation and the like, separating the valuable metals such as copper, silver, lead, zinc and arsenic, wherein the purified leachate is a pure FeCl2 aqueous solution; performing thermal decomposition on the pure FeCl2 aqueous solution in a spraying manner so as to obtain Fe2O3 powder; and absorbing the generated HCL gas with water so as to regenerate hydrochloric acid which returns to the leaching process. By the method, the valuable elements in the slag iron ore concentrates of the wet-type zinc smelting furnace are comprehensively separated and recycled; and the hydrochloric acid taken as a leaching agent can be recycled, so that the method realizes resource conservation and is friendly to the environment. During the whole process, the discharge of three wastes is basically avoided; all the resources are utilized to the greatest extent; and obtained products are convenient for subsequent treatment and processing. The method has the advantages of environmental friendliness, economical performance, energy conservation and high resource utilization rate, thereby being convenient for industrial production.

Owner:CENT SOUTH UNIV

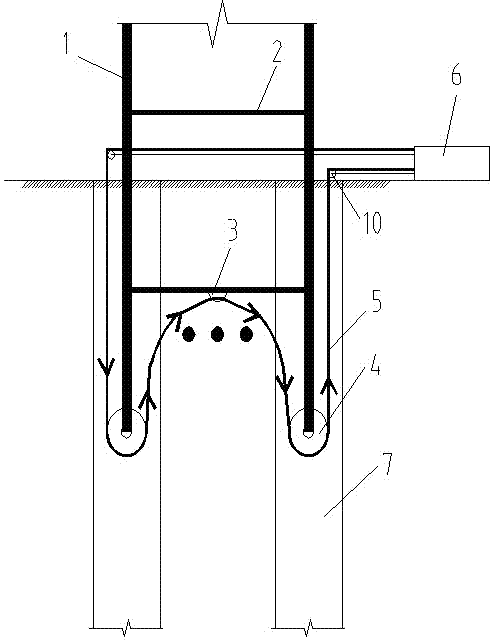

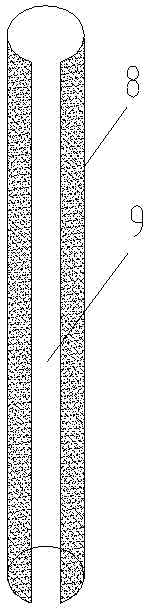

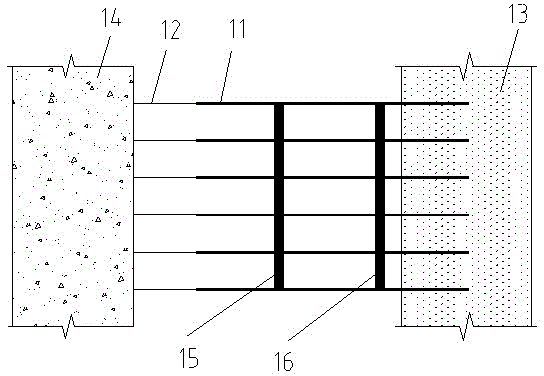

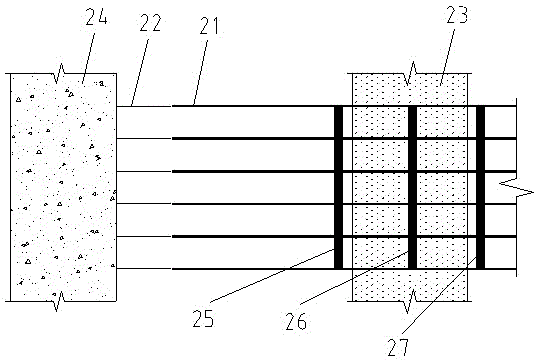

Construction method of cutting underground obstacle with wire saw

The invention discloses a construction method of cutting an underground obstacle with a wire saw. The construction method comprises the following steps of a, determining a cutting point by referring to the position relationship between the underground obstacle and the construction interval according to a drawing; b, drilling on the two sides of the cutting point of the obstacle symmetrically with a drilling rig to form two drilling holes, and placing a circular tube into each drilling hole to protect the wall, wherein each circular tube is provided with a notch extending in the length direction, and the notches in the two circular tubes are arranged in opposite; c, assembling the wire saw; d, putting down a support component slowly, and starting a drive device until the obstacle is cut off. In the way, the construction method has the advantages of being safe and reliable, economical and reasonable and convenient in construction, the time limit for a project can be effectively reduced, and the impact exerted on the surrounding environment is small, so the construction method is resource-saving and environment-friendly.

Owner:JIANGSU DINGDA BUILDING NEW TECH +1

Aliphatic acid lubricant for petroleum drilling fluid

InactiveCN102311722AImprove the lubrication effectReduce dosageDrilling compositionWater basedPetroleum

The invention discloses an aliphatic acid lubricant for petroleum drilling fluid and a preparation technology of the aliphatic acid lubricant, which are of a recycling technology and belong to the field of environment-friendly oilfield chemical new materials. The aliphatic acid lubricant for petroleum drilling fluid is characterized by being prepared by adopting industrial and agricultural byproducts and residua as main materials through a unique processing technology. The aliphatic acid lubricant for petroleum drilling fluid is used for lubricating a drill and a drilling rig, capable of reducing friction coefficient with the well wall and effectively improving quality of a water-based drilling fluid mud cake, and has anti-seize and fluid loss reducing capacities. The aliphatic acid lubricant for petroleum drilling fluid is applicable to preparation of various water based drilling fluids, in particular to various drilling fluid systems and high-density drilling fluid systems constructing under low temperature. The aliphatic acid lubricant for petroleum drilling fluid comprises the following components in parts by weight: natural mixed aliphatic acid 7-10%, rice bran oil 85-90% and polyol and amine compound 3-5%.

Owner:HARBIN JIELIWO GASOLINEEUM TECH

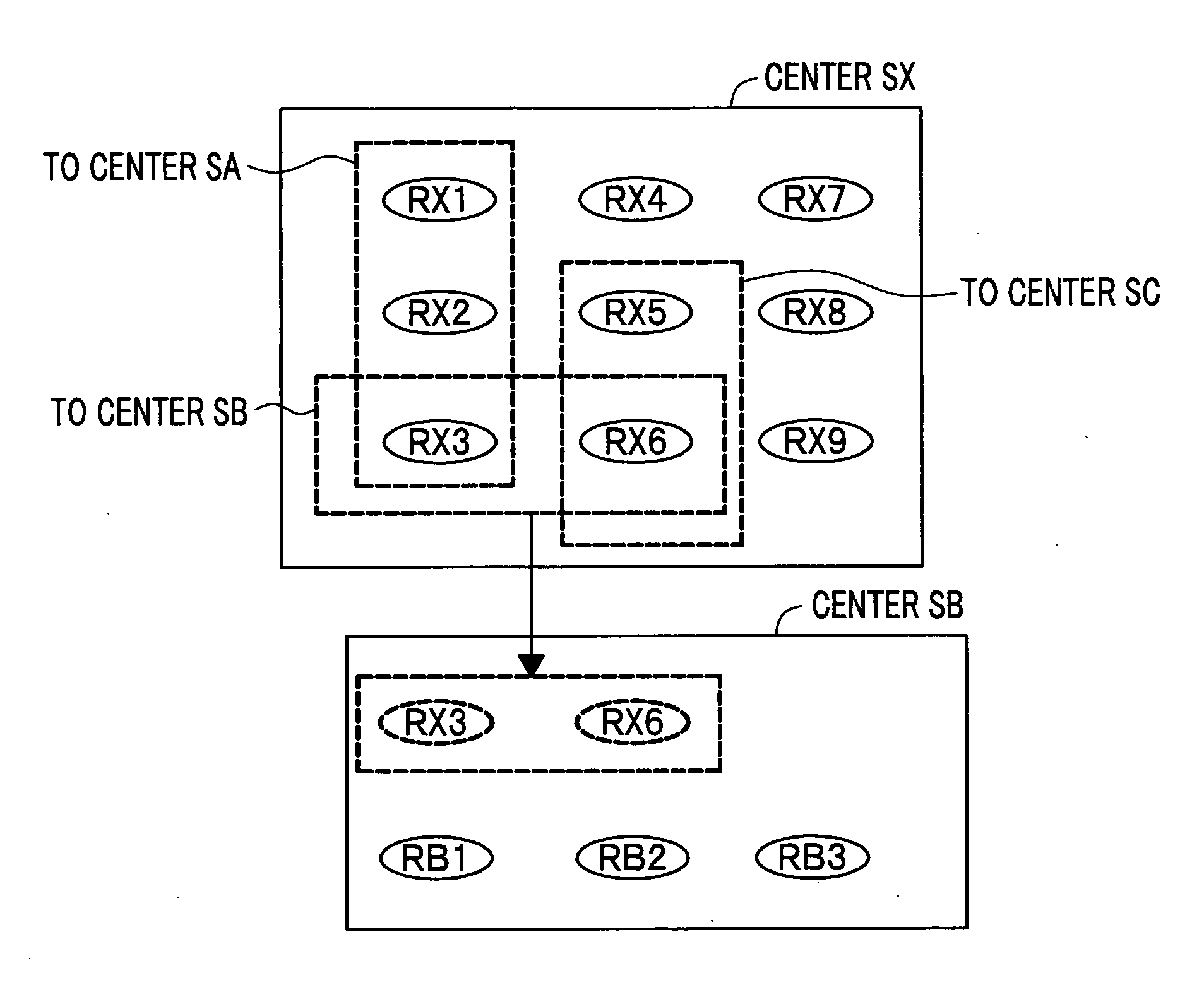

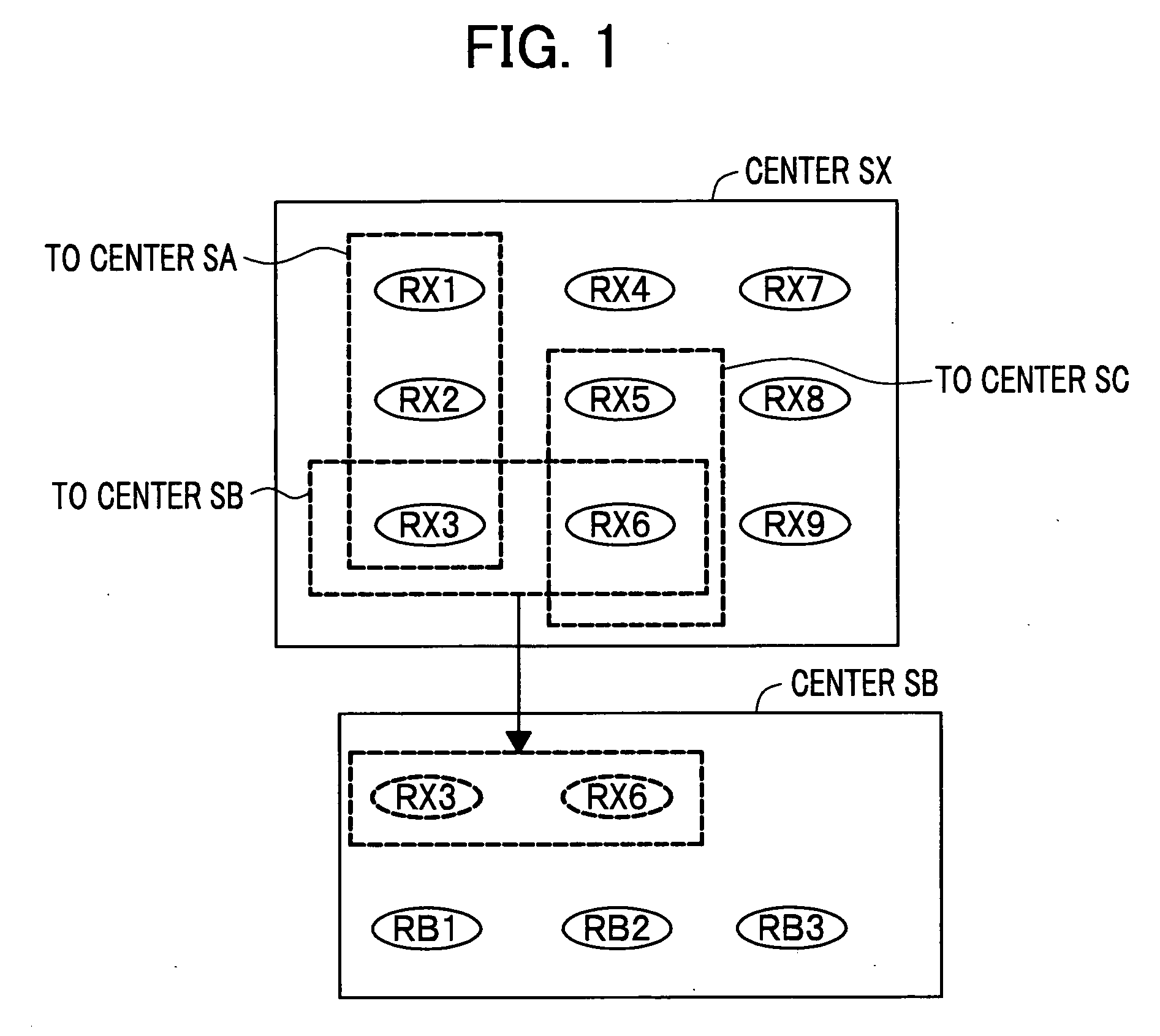

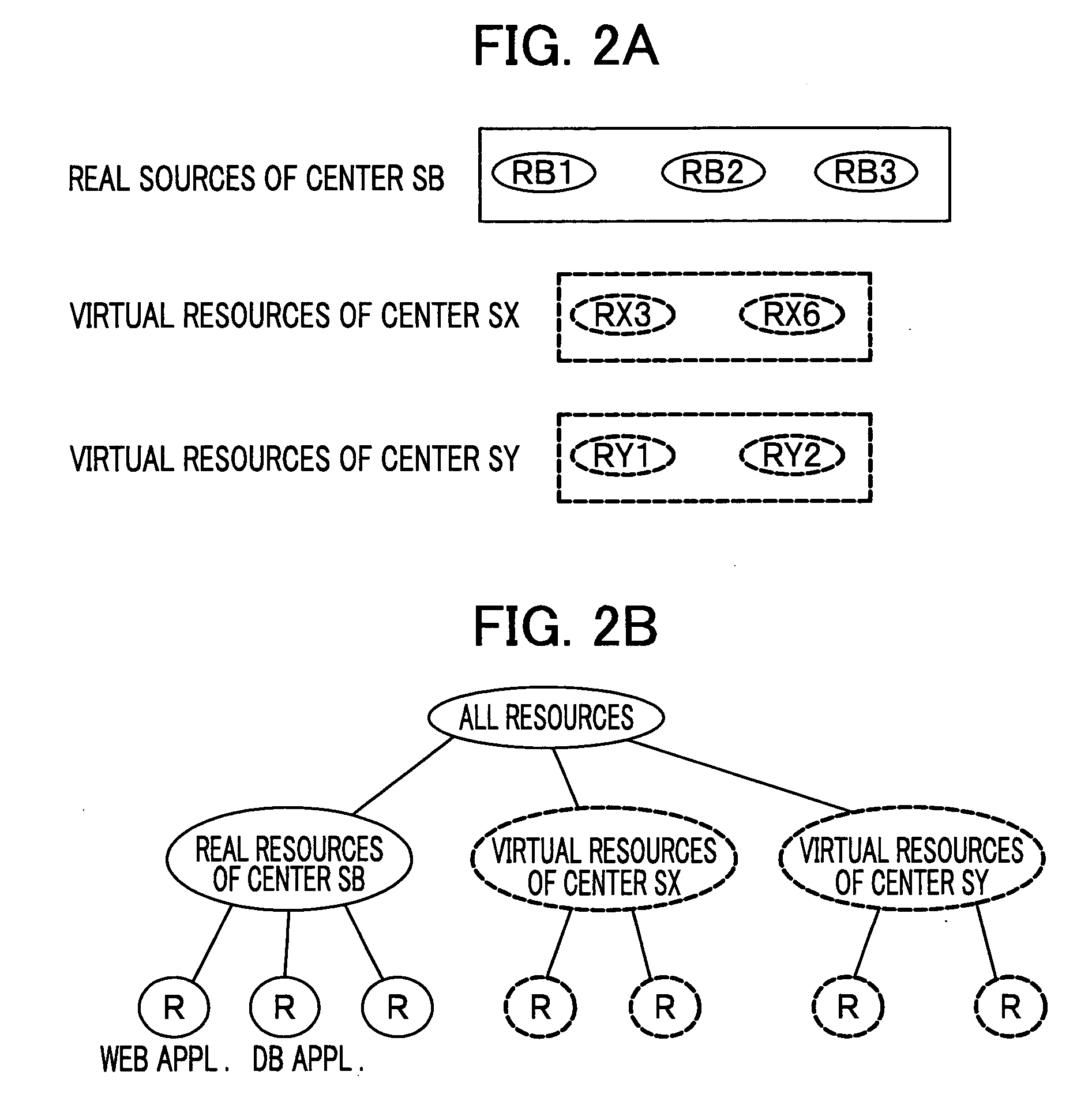

Method and system for managing computer resource in system

InactiveUS20060210051A1Increase costLow costManual exchangesAutomatic exchangesComputer resourcesResource information

Disclosed is a resource management method by which one or more lender center apparatuses each lend one or more computer's resources to a borrower center apparatus, and which is executed by the borrower center apparatus. The method includes the step of receiving, from each of the lender center apparatuses, resource information on one or more resources, and registering the resource information to a management table, the step of detecting a shortage of one or more computer's resources in the borrower center apparatus, and pinpointing a bottleneck causing the shortage, the step of searching through the management table for one or some of the resources which can resolve the bottleneck, and creating a center list of one or some of the lender center apparatuses which possess the searched resources, and the step of requesting the lender center apparatuses on the center list to lend the searched resources.

Owner:HITACHI LTD

Method for enriching and recycling niobium and tantalum from waste high-temperature alloy

InactiveCN104164567AEfficient recyclingAchieve recyclingProcess efficiency improvementRheniumNiobium

The invention discloses a method for enriching and recycling niobium and tantalum from a waste high-temperature alloy. The method comprises the following steps: smelting, atomizing and spraying the waste high-temperature alloy, and leaching nickel, cobalt, tungsten, molybdenum and rhenium out to obtain materials; and then, carrying out alkali fusion, water leaching and acid treatment to obtain a niobium-tantalum-containing oxide. The raw materials related in the method are the materials obtained after the nickel, the cobalt, the tungsten, the molybdenum and the rhenium of the waste high-temperature alloy are leached out at the early stage, and thus, the method is a sustainable green environment-friendly process which can realize resource cyclic utilization, is free of harmful waste gas and wastewater, and has very good practicability, economic benefits and social benefits.

Owner:SINO PLATINUM METALS CO LTD

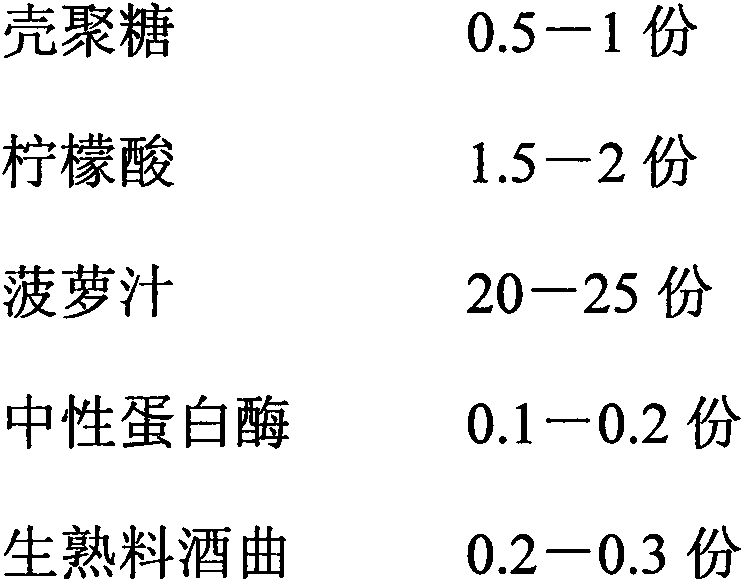

Fen-flavor liquor second-batch distiller grain refermentation technology

ActiveCN105039076ASolve the reuse problemSolve the problem of poor wine qualityAlcoholic beverage preparationMicroorganism based processesFlavorAlcohol

The invention aims at providing a fen-flavor liquor second-batch distiller grain refermentation technology. The refermentation liquor producing technology, namely, a resource reusing technology is performed on second-batch distiller grains by mixing mouldy bran and fen-flavor daqu. According to the fen-flavor liquor second-batch distiller grain refermentation technology, 3% of white qu, 5% of black qu, 3% of the yeast mouldy bran and 2% of the fen-flavor daqu are adopted to referment the second-batch distiller grains, edible alcohol is quantificationally added to improve the bouquet, fermentation temperature changes follow the principles that the temperature is quickly risen in the early stage, the temperature is invariable in the middle stage, and the temperature is slowly lowered in the late stage, the fermentation cycle is 15 days, and the liquor yield can reach 24%-26%. The produced fen-flavor liquor is clear in bouquet, pure, pure sweet, soft, natural, harmonious and refreshing and clean in remaining taste, and can reach the level of superior liquor. Accordingly, a new method and way is supplied for improving company benefits and achieving resource reuse, and the important realistic significance is achieved.

Owner:SHANDONG TIAN DI YUAN LIQUIR

Clearing construction method for underground obstacle

The invention discloses a clearing construction method for an underground obstacle. The method comprises the following steps of a, looking up the position relation between an underground obstacle anchoring section and a construction interval according to a blueprint; b, grooving to the obstacle position at the upper part of the underground obstacle anchoring section by a grooving machine, grooving at least two grooves and forming at least two groove areas; c, cutting off the underground obstacle in part of the groove areas by a cutting machine, and separating the part, positioned in the construction interval, of the underground obstacle from the underground obstacle body; d, pulling the underground obstacle from the other groove areas by a mechanical device; e, backfilling the groove areas. By the mode, the clearing construction method has the advantages of safety, reliability, economy, reasonability and convenience in construction, the duration can be effectively saved, the influence to peripheral environment is small, and the clearing construction method belongs to a resource-saving and environment-friendly construction method.

Owner:JIANGSU DINGDA BUILDING NEW TECH +1

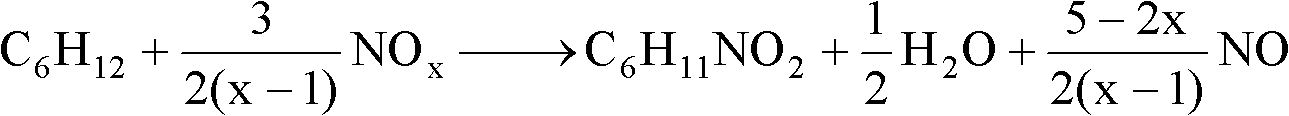

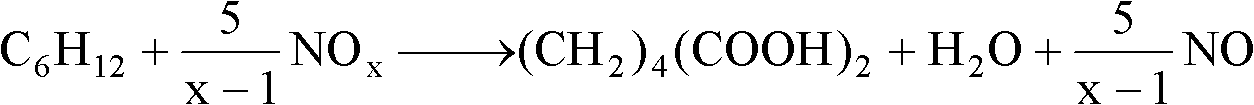

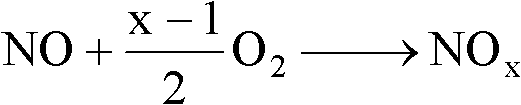

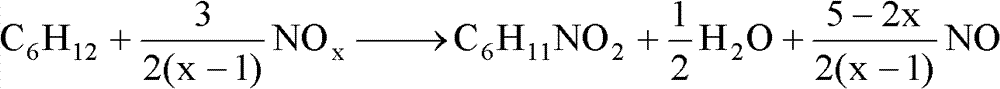

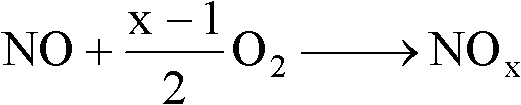

Method for high-selectivity co-production of nitrocyclohexane and adipic acid

InactiveCN101781217AHigh selectivityReduce generationOrganic compound preparationCarboxylic compound preparationGas phaseConcentration ratio

The invention relates to a method for the high-selectivity co-production of nitrocyclohexane and adipic acid, which adopts nitrogen oxide NOx as the nitrating and oxidizing agent, carrys out continuous gas-phase catalysis or non-catalytic nitration and oxidation reaction on cyclohexane. By effectively setting the conditions of the concentration ratio, the reaction temperature and the reaction time of the reactants and optimizing the reaction pressure as well as catalysts and assistants, the invention realizes the simultaneous high-selectivity co-production of the nitrocyclohexane and the adipic acid of different ratios, and the reduction product NO generated by the nitration and oxidation reaction can be recycled for cyclic utilization. The method of the invention has high resource efficiency, less waste generation, simple process flow and device and low production cost, and is an environment-friendly synthetic method.

Owner:XIANGTAN UNIV

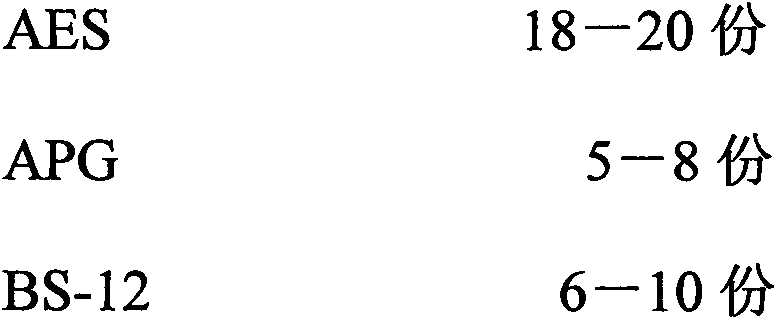

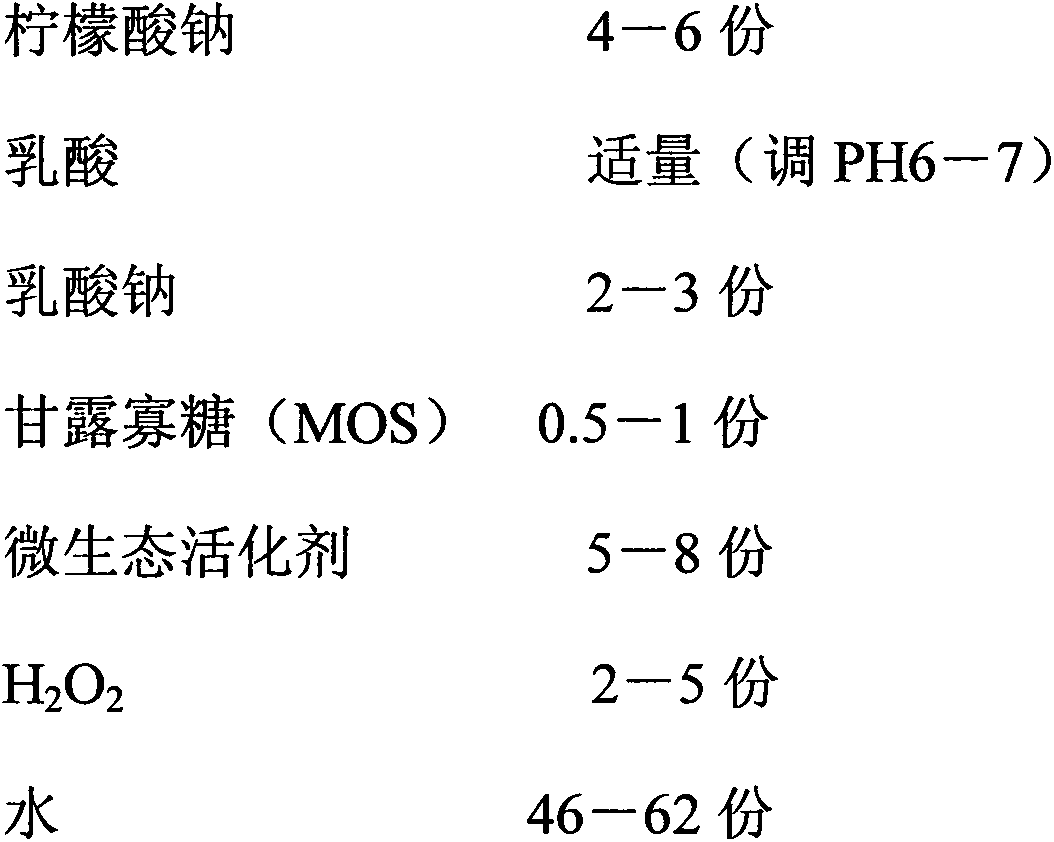

Preparation and process of functional sugar active enzyme biological scouring agent

InactiveCN104342296AIncreased sugar activityGood biocompatibilityOrganic detergent compounding agentsSurface-active detergent compositionsSodium lactateActive enzyme

The invention relates to preparation of a functional sugar active enzyme biological scouring agent which is composed of AES, APG, BS-12, sodium citrate, lactic acid, sodium lactate, mannan oligosaccharides (MOS), a micro ecological activator, H2O2 and water. The functional sugar active enzyme biological scouring agent resists bacteria and virus, has high enzyme activity, allows soaked clothes in summer to be not stink, can rapidly purify sewage, and is friendly to environment; the functional sugar active enzyme biological scouring agent has good biocompatibility, easily degrade clothes dirt, and saves water and electricity; and compared with chemical scouring agents, the functional sugar active enzyme biological scouring agent enables washing water to be saved by 50%, is a resource-saving environmental-friendly green ecological scouring agent, and has a broad market development prospect.

Owner:黄庆禄 +1

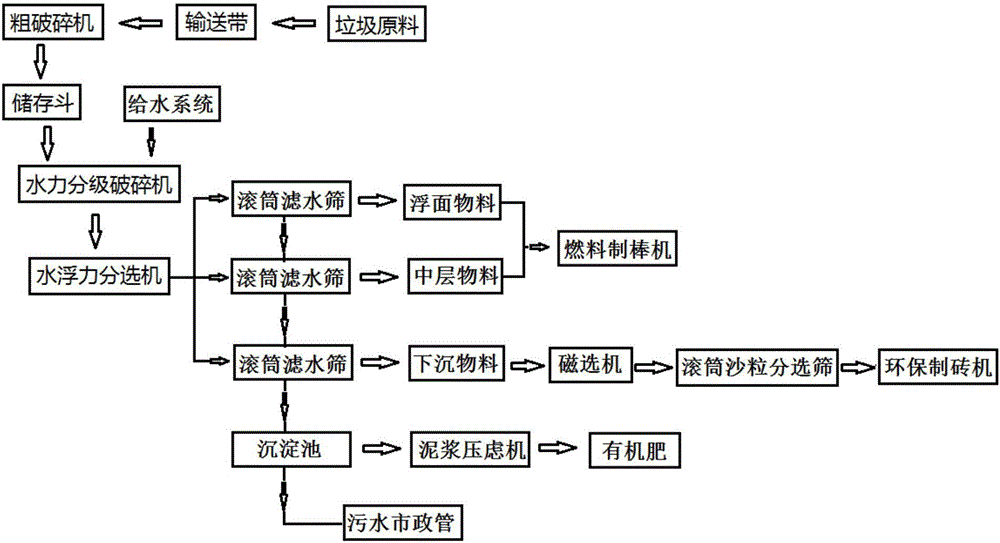

Method for water treatment of household garbage

The invention discloses a method for water treatment of household garbage. The household garbage is subjected to crushing, hydrolyzing, automatic water buoyancy sorting and other manners to be classified and decomposed, different kinds of garbage are recycled in a targeted manner, organic matter and soil obtained through decomposition are used as organic fertilizer raw materials, and meanwhile dirt water generated in the treatment process is subjected to innocent treatment. In the whole process, no manpower is needed, full-automatic sorting is achieved, energy consumption is low, and the resource utilization rate is high. The hazard caused by irrational utilization of the garbage to the environment is reduced more effectively, and a preferred embodiment for garbage resourceful treatment and sorting is achieved.

Owner:中山市万泰环境科技有限公司

Formula of plastic pencil holder

InactiveCN108359188AReduce weightReduce manufacturing costNon-propelling pencilsNib holdersResource savingHuman health

The invention discloses a formula of a plastic pencil holder. The formula comprises materials including high impact polystyrene (modified polystyrene), general purpose polystyrene (transparent polystyrene), wood flour, butadiene styrene rubber, talc powder, calcium stearate, zinc stearate, a foaming agent and toner. A little wood flour is added to the pencil holder produced with the formula, the cutting effect of the plastic pencil holder is enhanced while the weight of the pencil holder is reduced, and particularly, the freight can be saved in large-batch transportation. The plastic pencil holder is a novel material which is resource-saving, environmentally friendly, beneficial to human health and capable of substantially reducing the labor strength.

Owner:大连爱森文教用品有限公司

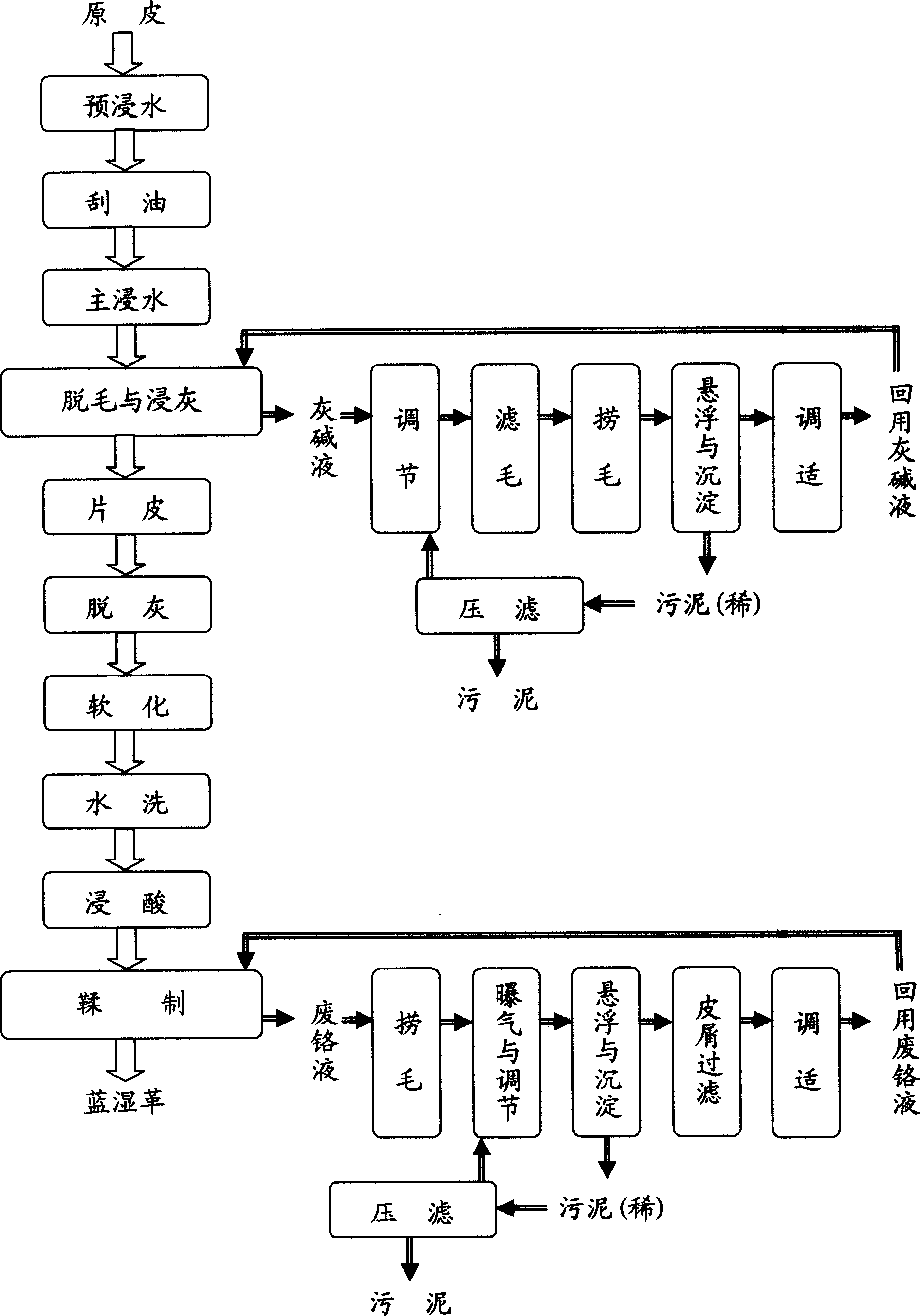

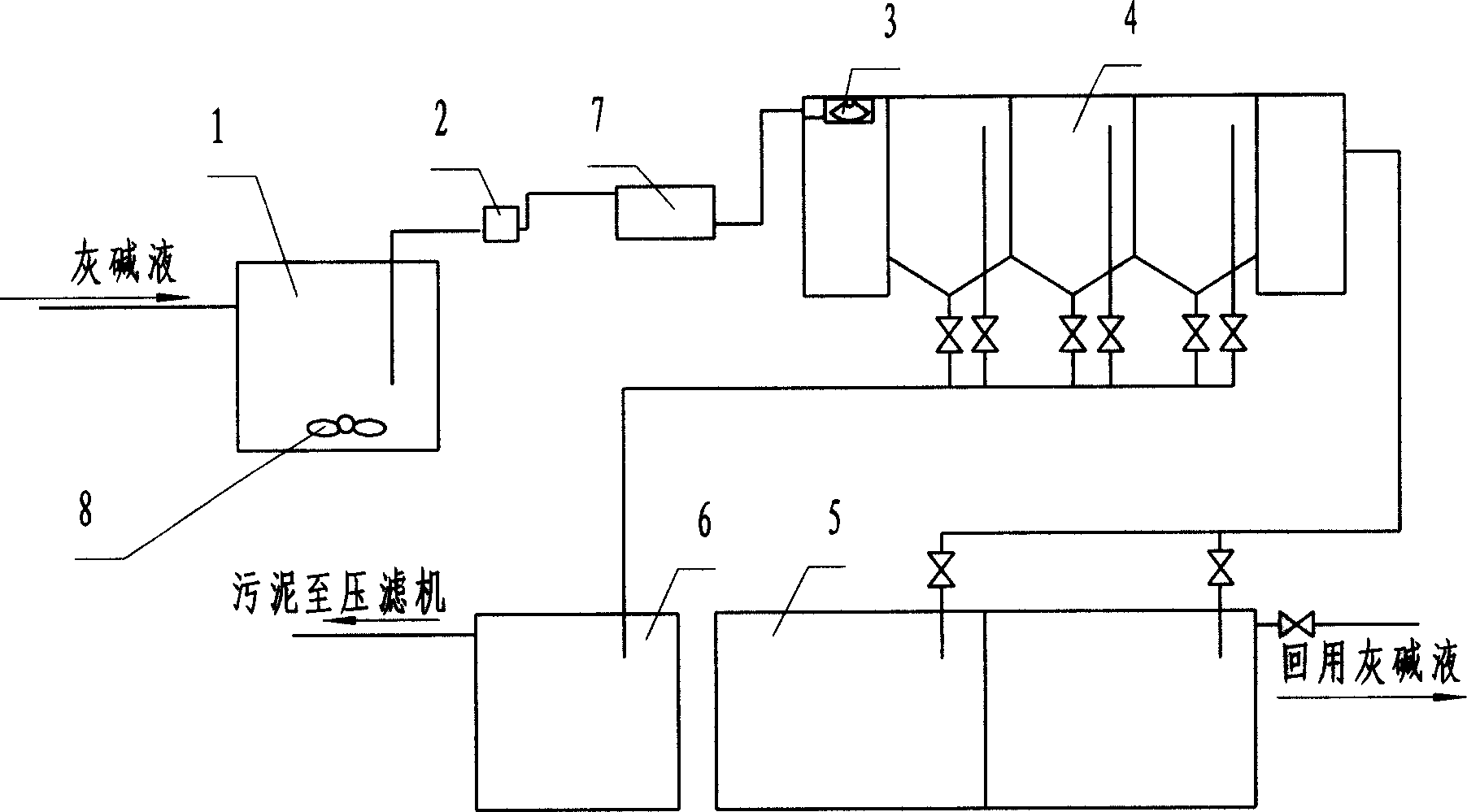

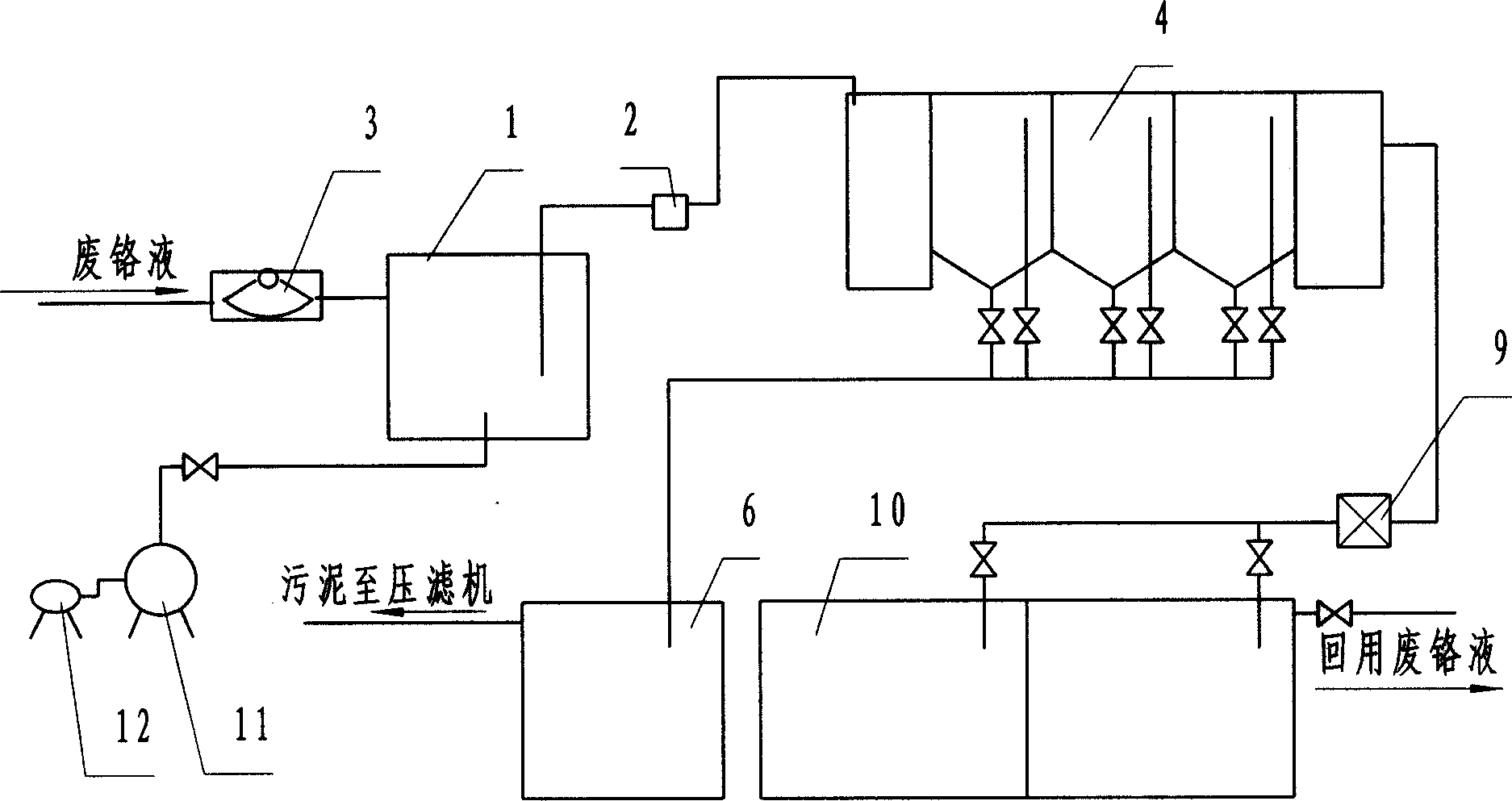

Tanning technology for treatment and reuse of waste chrome liquor of bate without discharge and its treatment device

InactiveCN1654371AReasonable designEasy to operateWater aerationMultistage water/sewage treatmentWater resourcesDepilations

The present invention provides one kind of tanning technology treating lixivium and waste chrome tannage liquid to realize zero exhaustion. The tanning process includes water soaking, scraping oil, depilation, liming, softening, water washing, pickling, tanning, treating lixivium, treating waste chrome tannage liquid and other steps. The lixivium treatment includes regulation, fishing hair, filtering, suspending and depositing, and modification; and the waste chrome tannage liquid treatment includes fishing hair, aeration and regulating, suspending and depositing, filtering, and modification. The present invention also provides the treating apparatus for treating lixivium and treating waste chrome tannage liquid. The present invention can save water resource and chemical material and lower production cost.

Owner:HAINING SENDE LEATHER

Method for high-selectivity co-production of nitrocyclohexane and adipic acid

InactiveCN101781217BHigh selectivityReduce generationOrganic compound preparationCarboxylic compound preparationGas phaseConcentration ratio

The invention relates to a method for the high-selectivity co-production of nitrocyclohexane and adipic acid, which adopts nitrogen oxide NOx as the nitrating and oxidizing agent, carrys out continuous gas-phase catalysis or non-catalytic nitration and oxidation reaction on cyclohexane. By effectively setting the conditions of the concentration ratio, the reaction temperature and the reaction time of the reactants and optimizing the reaction pressure as well as catalysts and assistants, the invention realizes the simultaneous high-selectivity co-production of the nitrocyclohexane and the adipic acid of different ratios, and the reduction product NO generated by the nitration and oxidation reaction can be recycled for cyclic utilization. The method of the invention has high resource efficiency, less waste generation, simple process flow and device and low production cost, and is an environment-friendly synthetic method.

Owner:XIANGTAN UNIV

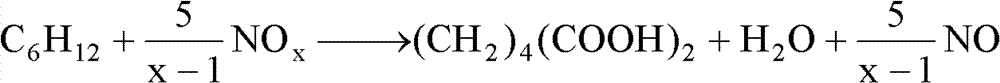

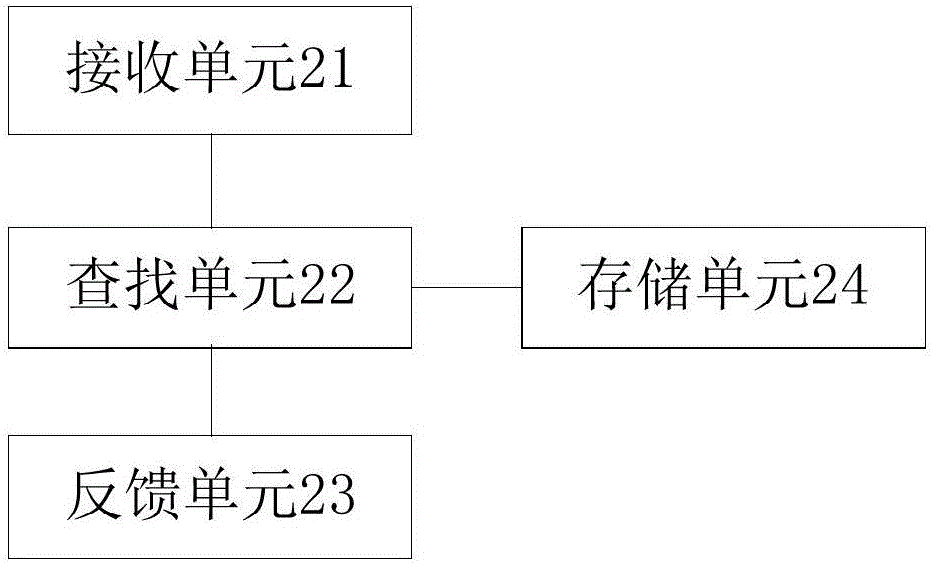

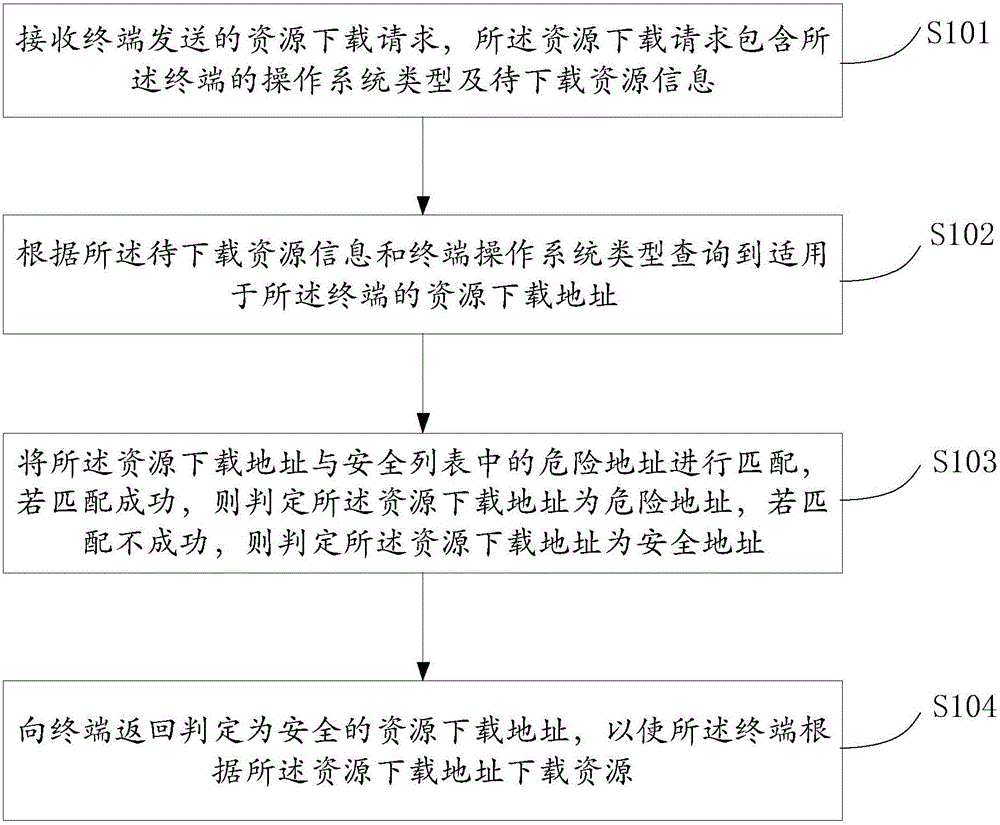

Resource downloading method and device

InactiveCN106302639AAvoid unavailableTransmissionNetwork data managementOperational systemResource information

The invention relates to the computer technology, and especially relates to a resource downloading method and device. The method comprises the steps of receiving a resource download request transmitted by a terminal, wherein the resource download request comprises an operating system type of the terminal and information of a resource to be downloaded; inquiring a resource actual download link applicable to the terminal according to the information of the resource to be downloaded and the operating system type of the terminal; and returning the resource actual download link to the terminal, so as to enable the terminal to download the resource according to the actual download link. The resource downloading method and device provided by the invention can avoid the situation of unavailability after the terminal downloads the resource, thereby improving the resource download effectiveness.

Owner:韦春

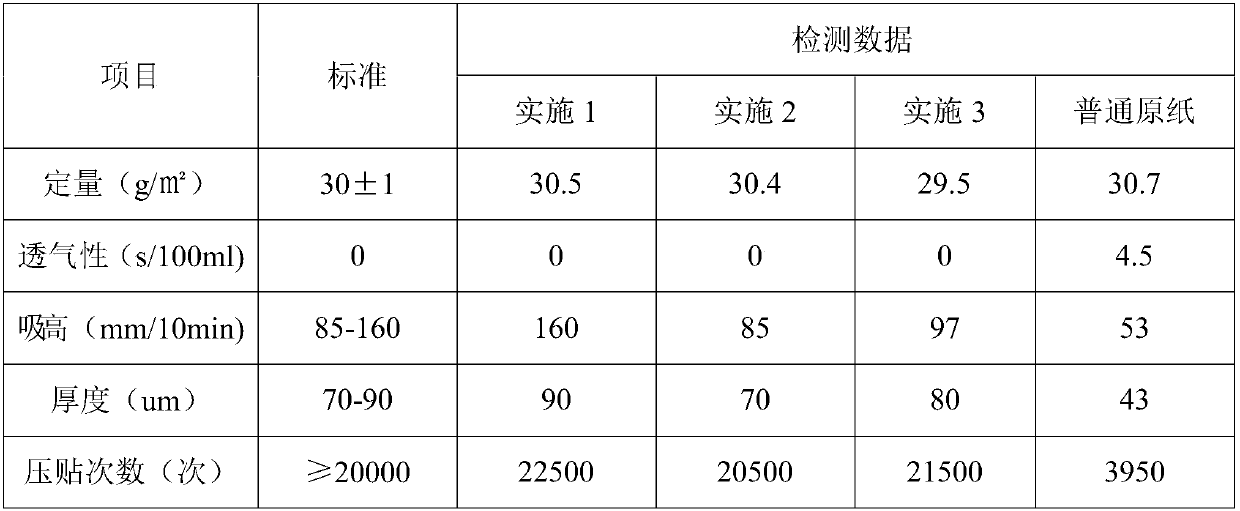

High-definition high-bulk wear-resistant paper and preparation method thereof

InactiveCN109629316AEliminate damage of varying degreesEliminate destructionReinforcing agents additionPaper/cardboardWear resistantResource saving

The invention belongs to the technical field of surface wear-resistant paper, and particularly relates to high-definition high-bulk wear-resistant paper and a preparation method thereof. The raw materials comprise, by mass, the following components: 40-85% by dry component of wood pulp, 10-50% of a filler and 5-10% of an auxiliary agent; wherein the filler is aluminum oxide, and the aluminum oxideis a mixture of aluminum oxide with the particle diameters of 90-130um and the particle diameters of 60-90um. The high-definition high-bulk wear-resistant paper has the advantages of good permeability, high air permeability, high uniformity, high sizing amount and high bulk, and is prepared into a reinforced wood floor after being impregnated with glue and pressed and pasted at high temperature,the wood floor has the advantages of high brightness, high definition and stable wear-resistant revolution, the definition reaches the effect that common wear-resistant paper cannot be simulated, andthe hot pressing frequency of the formwork is 5 times of that of common wear-resistant paper, the wear resistant paper is a resource-saving and environment-friendly product.

Owner:ZIBO OU MU SPECIAL PAPER

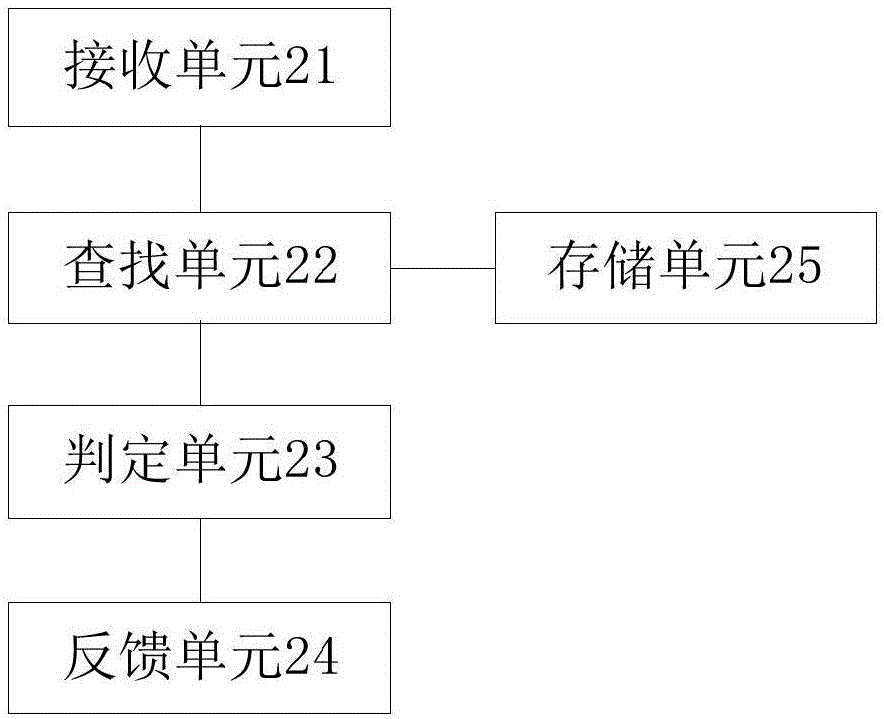

Resource secure downloading method and device

InactiveCN106254432AAvoid unavailableAvoid infectionTransmissionOperational systemResource information

The invention relates to computer technology, in particular to a method and device for safely downloading resources. The method includes: receiving a resource download request sent by a terminal, the resource download request including the operating system type of the terminal and resource information to be downloaded; querying the resource information applicable to the terminal according to the resource information to be downloaded and the terminal operating system type The resource download address of the terminal; match the resource download address with the dangerous address in the safety list, if the match is successful, then determine that the resource download address is a dangerous address, if the match is unsuccessful, then determine that the resource download address is A safe address: returning a resource download address determined to be safe to the terminal, so that the terminal downloads the resource according to the resource download address. The invention can avoid the situation that the resource is unavailable after the terminal downloads the resource, and improves the effectiveness and safety of the resource download.

Owner:郝芊雨

Waste gas control method by removing sulfur dioxide for resource utilization

InactiveCN100360212CReasonable workmanshipMild desulfurization reaction conditionsDispersed particle separationResource utilizationSulfur

The invention provides a method for desulfurization of SO2 waste gas. A basic absorption liquid neutralizes the SO2- laden waste gas to eliminate SO2, discharge the purified gas when the content of SO2 reaches the standard; microbe reduces the desulfurizing absorption tail liquid (containing sulfite group, bisulphate group, or sulfuric group), then microbe oxygenizes the liquid, and the SO2 contained is recovered as a existent of elemental sulfur. The liquid treated by microbe is basic, and it can return directly to the desulfurizing absorption unit and be reused as a basic absorption liquid. And it realizes the aim of eliminating waste and recycling sulfur resource. The method for waste gas treatment is easy to operate and leads to none secondary pollution.

Owner:SICHUAN UNIV

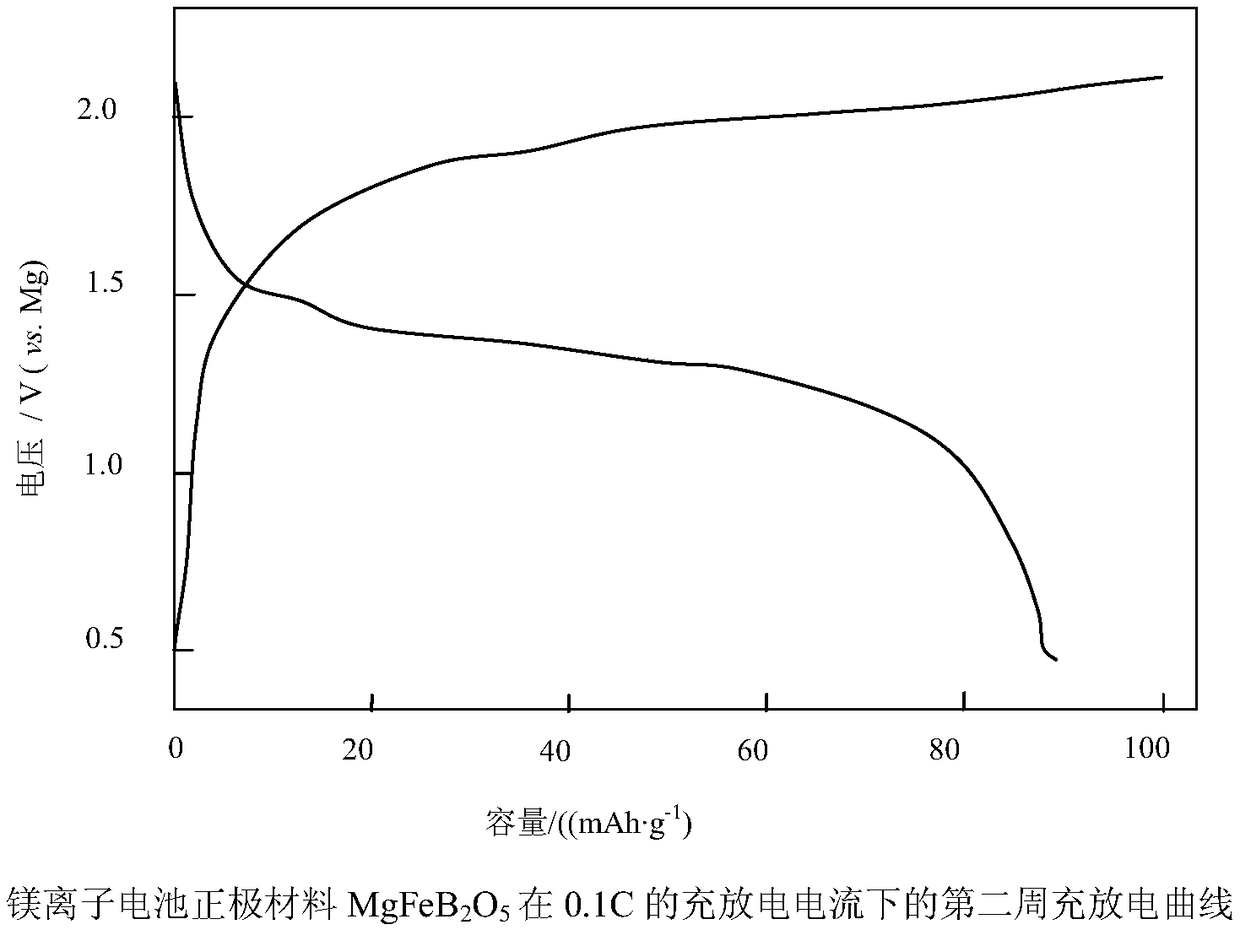

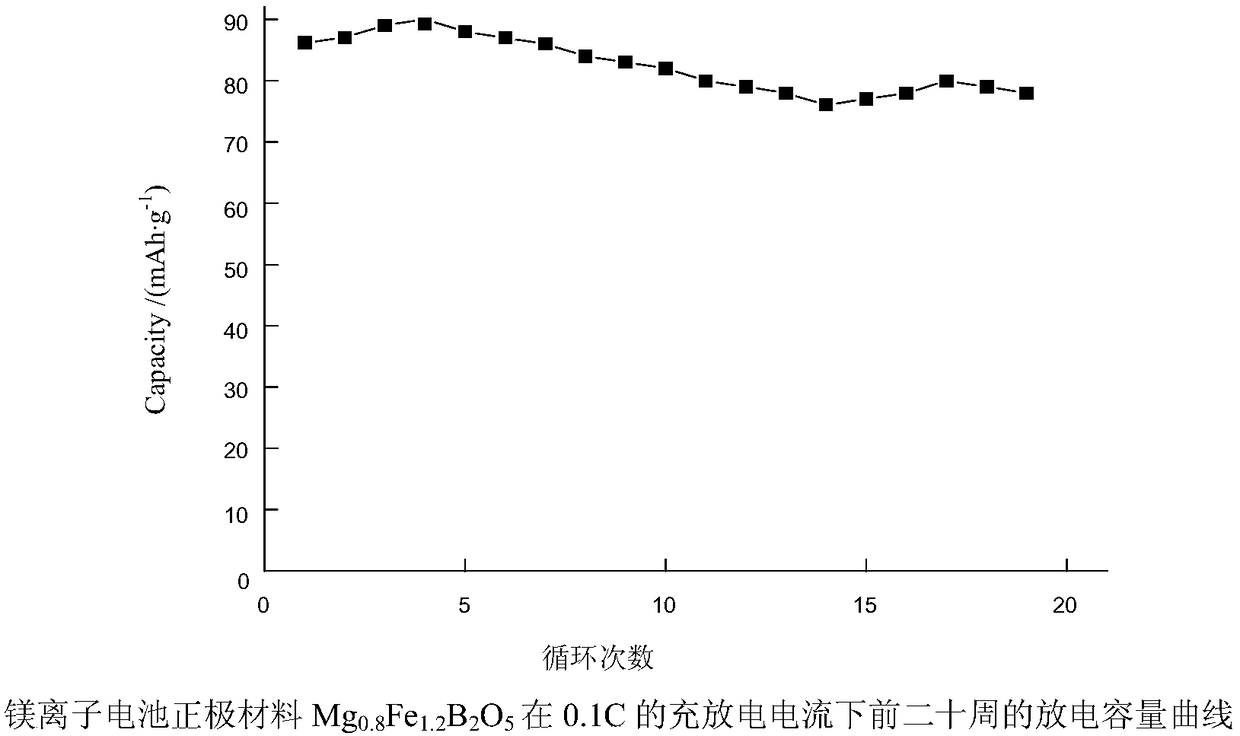

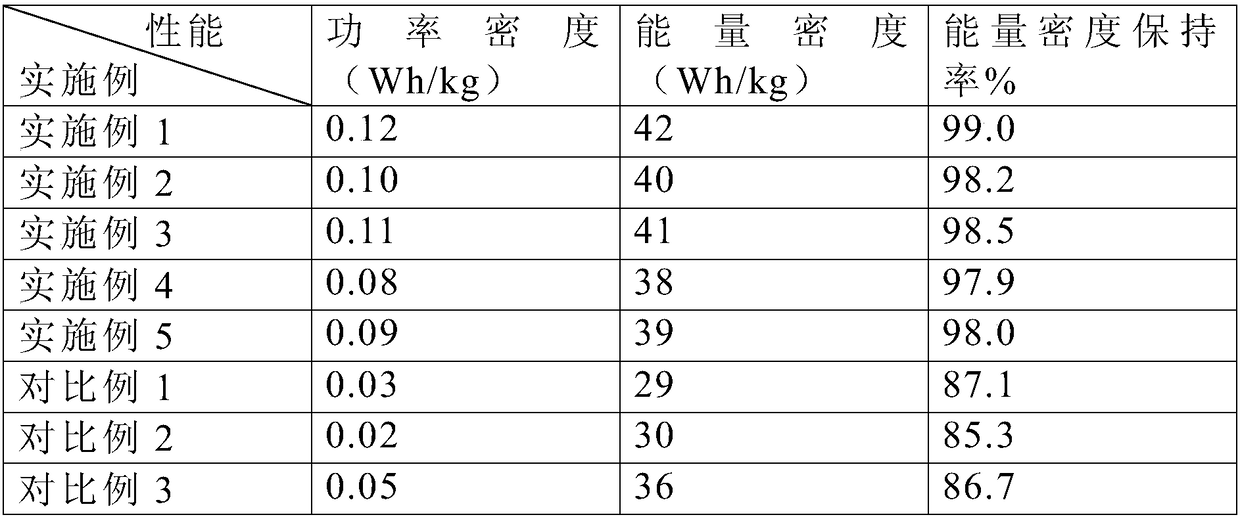

Method for preparing magnesium ion battery positive electrode material

The invention belongs to the technical field of battery materials, and concretely relates to a method for preparing a magnesium ion battery positive electrode material. The magnesium ion battery positive electrode material is carbon coated magnesium ferrous borate, wherein the magnesium ferrous borate mainly comprises a magnesium source compound, a ferrous source compound and a borate radical compound. The magnesium ferrous borate synthesized from common raw materials in the invention is a novel magnesium ion battery positive electrode material having an extremely rich source and an excellentapplication prospect. Compared with currently widely studied phosphate polyanion compound magnesium ion battery positive electrode materials, the positive electrode material in the invention achievesa higher theoretic specific capacity by replacing a phosphate radical having a large mole with a borate radical having a small mole from structural analysis. The electric conduction capability of ferrous borate is stronger than that of ferrous phosphate, the volume change rate of the ferrous borate before and after discharge is lower than that of the ferrous phosphate before and after discharge and is less than half of that of the ferrous phosphate, so the magnesium ferrous borate positive electrode material has good rate performances and a good cycle stability.

Owner:NINGBO POLYTECHNIC

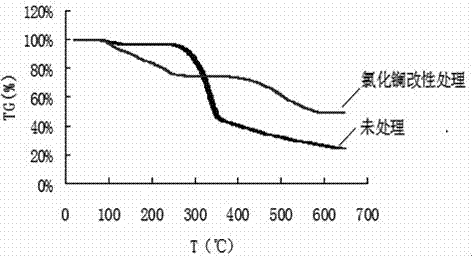

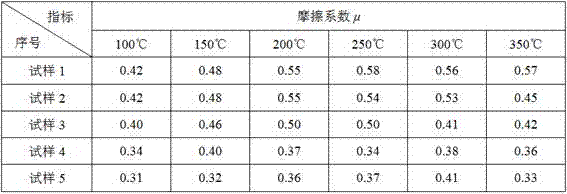

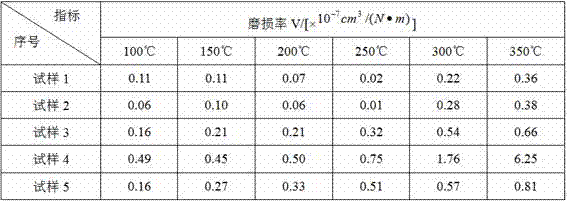

Natural fiber modified by rare earth chloride and application of natural fiber to preparing automobile brake materials

ActiveCN107163498AAddressing Poor Tribological PerformanceSolve the problem of poor high temperature performanceFriction liningActuatorsHeat resistanceResin matrix

The invention provides a natural fiber modified by rare earth chloride and application of the natural fiber to preparing automobile brake materials. The natural fiber and the application have the advantages that the natural fiber is modified by rare earth chloride modifiers, accordingly, the interfacial bond properties of the natural fiber and resin matrixes can be effectively improved, and the heat resistance of the natural fiber can be greatly improved; hot press molding is carried out on the obtained modified natural fiber, phenolic resin and friction property modifiers to obtain the resource-saving automobile brake materials with excellent friction and wear properties; processes are simple, the natural fiber is low in cost, each resin-based brake material prepared from the natural fiber modified by rare earth is excellent in friction and wear property and is a resource-saving brake friction material, and accordingly the natural fiber has an excellent application prospect.

Owner:FUZHOU UNIV

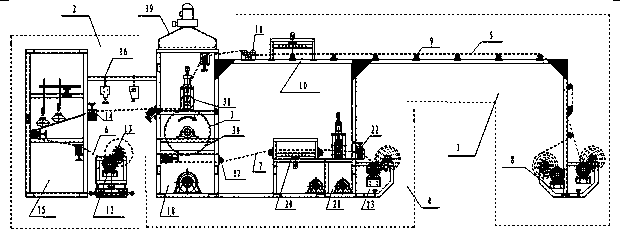

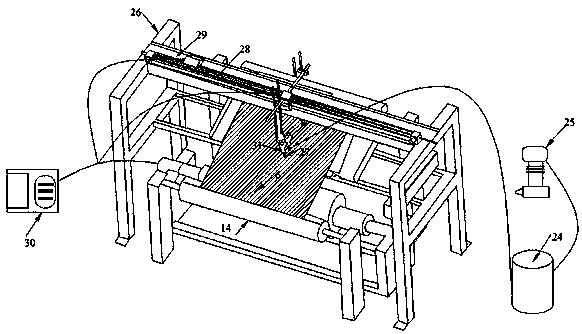

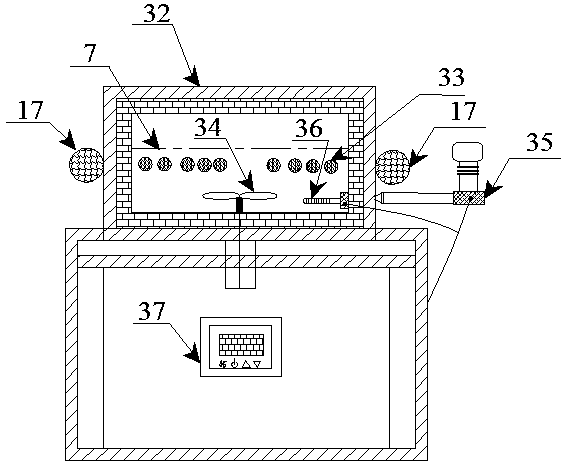

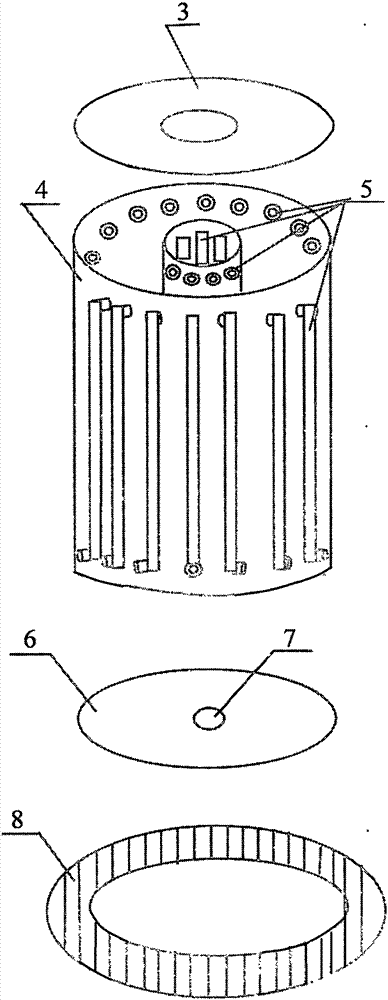

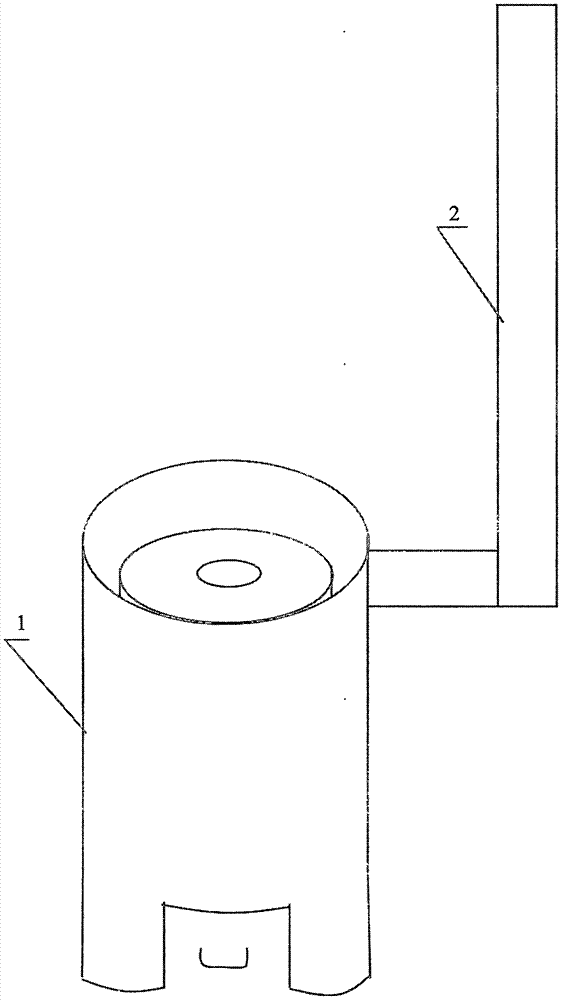

Special reflective layer production system for a long heat transmission network

PendingCN110202912ALow application costImprove protectionLamination ancillary operationsNon-macromolecular adhesive additivesGlass fiberHeat transmission

The invention discloses a special reflective layer production system for a long heat transmission network, the special reflective layer production system comprises a glass fiber cloth conveying device1, an aluminum foil conveying device 2, a pressing device 3 and a finished product conveying device 4, the glass fiber cloth conveying device 1 and the aluminum foil conveying device 2 are respectively arranged on two sides of the pressing device 3. The pressing device 3 comprises rolling a guide roller 38 and a rolling roller 39 which are arranged up and down. And after glass fiber cloth 5 conveyed by the glass fiber cloth conveying device 1 and an aluminum foil 6 conveyed by the aluminum foil conveying device 2 are pressed by the pressing device 3 to form a high-temperature resistant reflective layer 7, and the high-temperature resistant reflective layer 7 is conveyed from the pressing device 3 to a winding device 23 for storage. The special reflective layer production system is beneficial to improving the adhesiveness of the high-temperature resistant reflective layer, the production efficiency can be improved by 3-6 times, and meanwhile, the usage amount of high-temperature glue is reduced, and the special reflective layer production system is a resource-saving and environment-friendly production method.

Owner:JIANGSU LONGYING PIPELINE NEW MATERIAL

Farmyard homemade gas stove

The invention discloses a farmyard homemade gas stove. The farmyard homemade gas stove is characterized by comprising a stove body; the stove body comprises a chimney and a fire grate; and a coal storage tank comprises a smoke guide pipe and upper and lower end covers. In winter, in particular, in northern rural areas, each family ignites a coal furnace for warming; and because of limitations of a homemade furnace, coals are burnt insufficiently to generate the phenomenon of a lot of smoke, resources are wasted, and the environment is polluted. After the farmyard homemade gas stove is used, the coals can be converted to gas for combustion, so that the coals can be fully burnt, and the environmental pollution is reduced.

Owner:李 俊杰 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com