Method for water treatment of household garbage

A domestic garbage and water treatment technology, applied in grain treatment, biofuel, solid waste removal, etc., can solve the problems of high operating cost, large investment, regional limitations, etc., and achieve the effect of reducing environmental hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

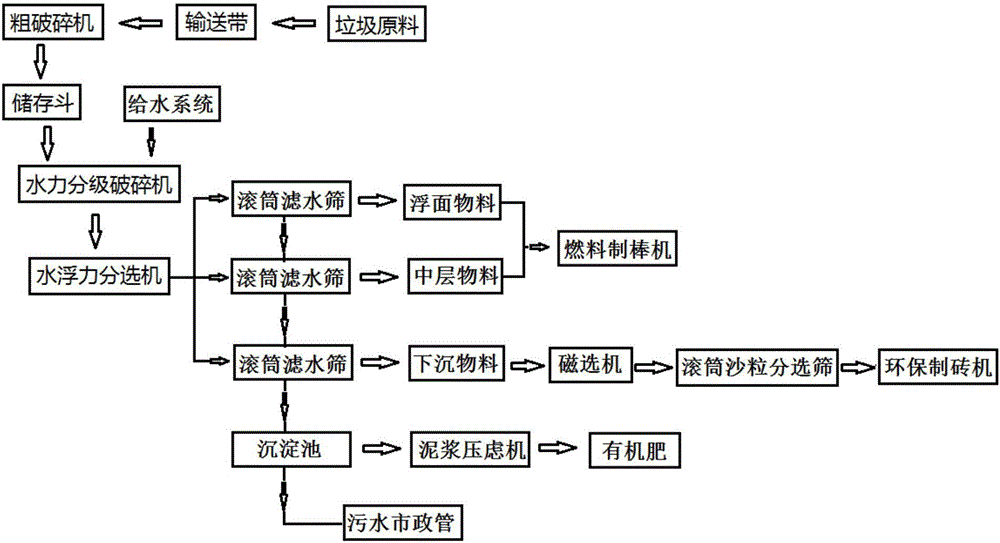

[0033] A method for domestic waste water treatment, comprising the following steps:

[0034] A. The domestic waste enters the coarse crusher through the conveyor belt and is then stored in the storage hopper;

[0035] B. The quantitative feeder performs quantitative feeding according to the production output requirements and the capacity of the hydraulic classifier, and the maximum feeding amount cannot exceed 10% of the capacity of the hydraulic classifier each time to avoid affecting the crushing effect and damaging the machine;

[0036] C. The material stored in the storage hopper enters the hydraulic classification pulverizer through the quantitative feeder. The hydraulic classification pulverizer is fed with water by the water supply system at the same time and starts the water flow to drive the motor to make the domestic garbage suspend in the water body according to its own weight with the water flow, and control it. The direction of the water flow is opposite to the di...

Embodiment 2

[0045] In the described step F, the recyclable materials sorted by the water buoyancy separator are recycled, and the specific recycling scheme is as follows:

[0046] The floating material is removed by a water filter and then sent to the production workshop by a conveyor belt to be made into fuel rods or packaging supplies.

[0047] The material in the middle layer is filtered through a rolling water sieve and then sent to the production workshop by a conveyor belt to be made into fuel rods or directly sold for processing.

[0048] After the sinking material is extracted into the water filter screen, the sand and gravel particles and other materials are separated by the drum sieve and the magnetic separation device. Other materials are collected and processed uniformly.

Embodiment 3

[0050] In the described step G, the treatment scheme of the sewage is as follows:

[0051]The sludge after the sewage is settled in the sedimentation tank is pumped to the mud high pressure filter by a mud pump for extrusion. After extrusion, the water content of the mud is about 50%-55% of the mud block, and the mud block is sent to the organic The fertilizer production workshop adds an appropriate amount of bacteria and other organic materials according to the ingredients of the mud block, and then ferments and produces the finished organic fertilizer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com