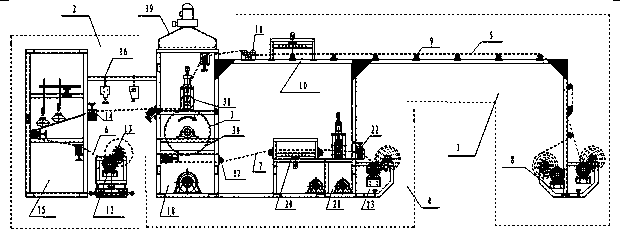

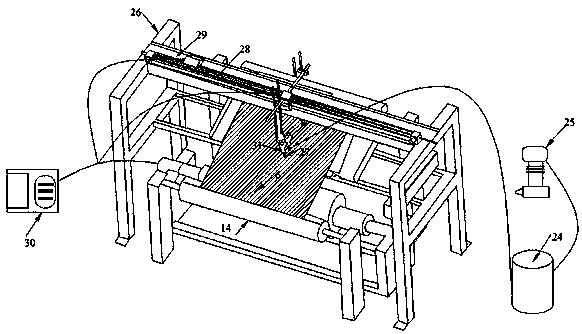

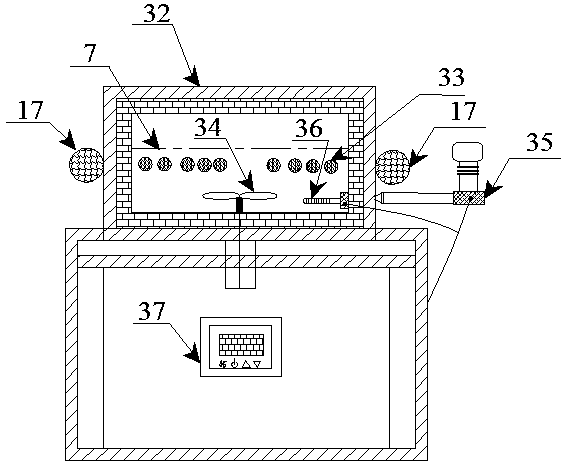

Special reflective layer production system for a long heat transmission network

A production system and reflective layer technology, applied in the direction of layered products, lamination, lamination equipment, etc., can solve the problems of slow drying speed of glue, poor product performance, and failure of glue bonding, so as to reduce application cost, Obvious energy-saving effect and excellent thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Through the test in the heat network test device, when the central temperature of the DN400 steam pipeline is 420 °C and the ambient temperature is 25 °C, the reflective layer mass-produced by the company with patent authorization publication number ℃N205579044U is used. The temperature difference between the front and back of the reflective layer is about 5 °C. After the test, the adhesive of the reflective layer disappeared completely, and the aluminum foil and the glass fiber cloth were separated.

Embodiment 2

[0042] like Figure 4 As shown, through the test in the heat network test device, when the central temperature of the DN400 steam pipeline is 420 ° C and the ambient temperature is 25 ° C, the high temperature resistant reflective layer provided by the present invention is used, and the thickness of the high temperature resistant flame retardant adhesive 3 is 0.5mm. , The temperature difference between the front and back of the reflective layer is about 21 °C, and the reflective layer is not damaged after the test.

Embodiment 3

[0044] like Figure 4 As shown, through the test in the heat network test device, when the central temperature of the DN400 steam pipeline is 420 ° C and the ambient temperature is 25 ° C, the high temperature resistant reflective layer provided by the present invention is used, wherein the thickness of the high temperature resistant flame retardant adhesive 40 is 0.7 mm, the temperature difference between the front and back of the reflective layer is about 26 °C, the reflective layer is not damaged after the test, and the energy saving effect is remarkable.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com