Patents

Literature

32results about How to "Control spray volume" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

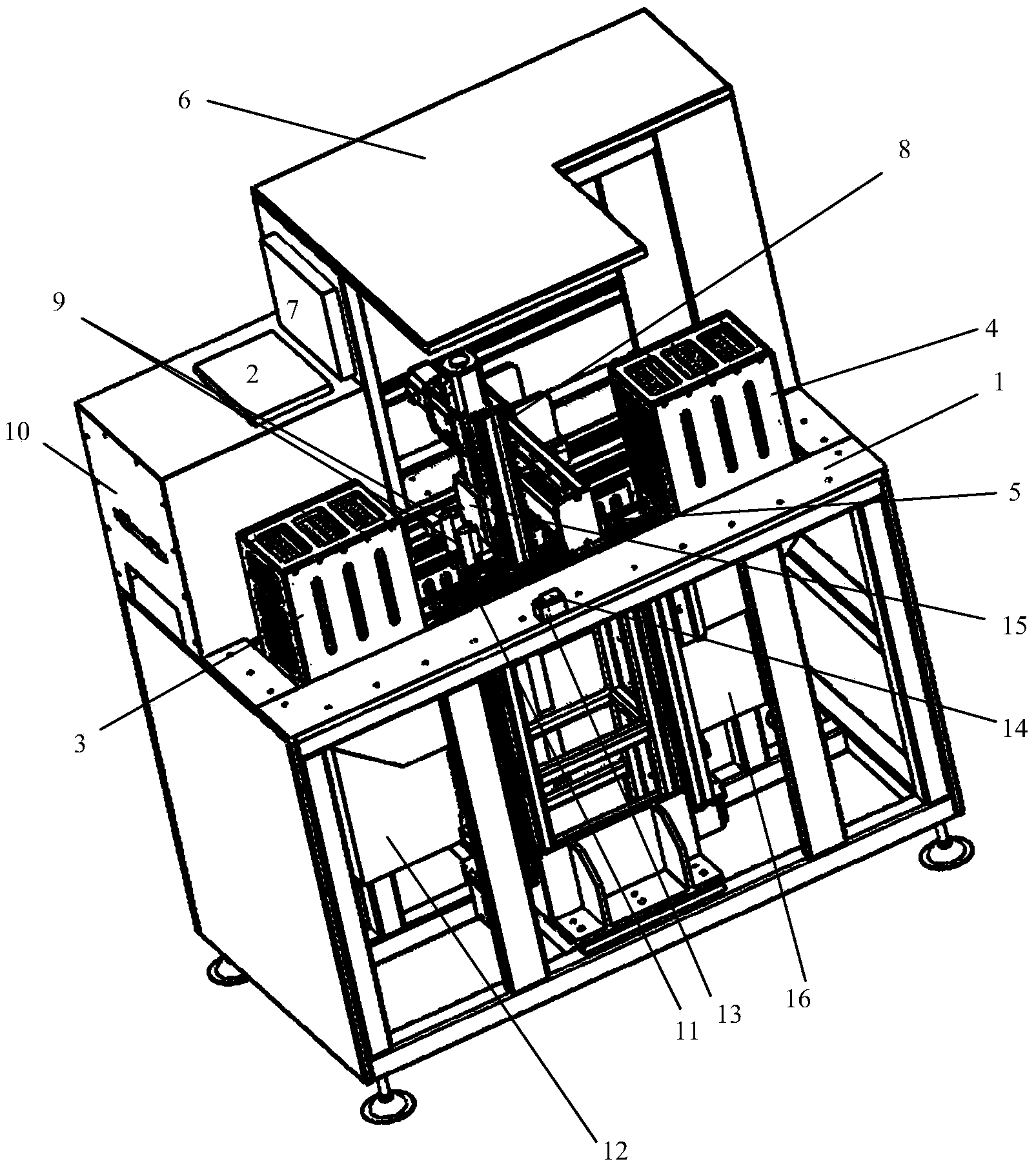

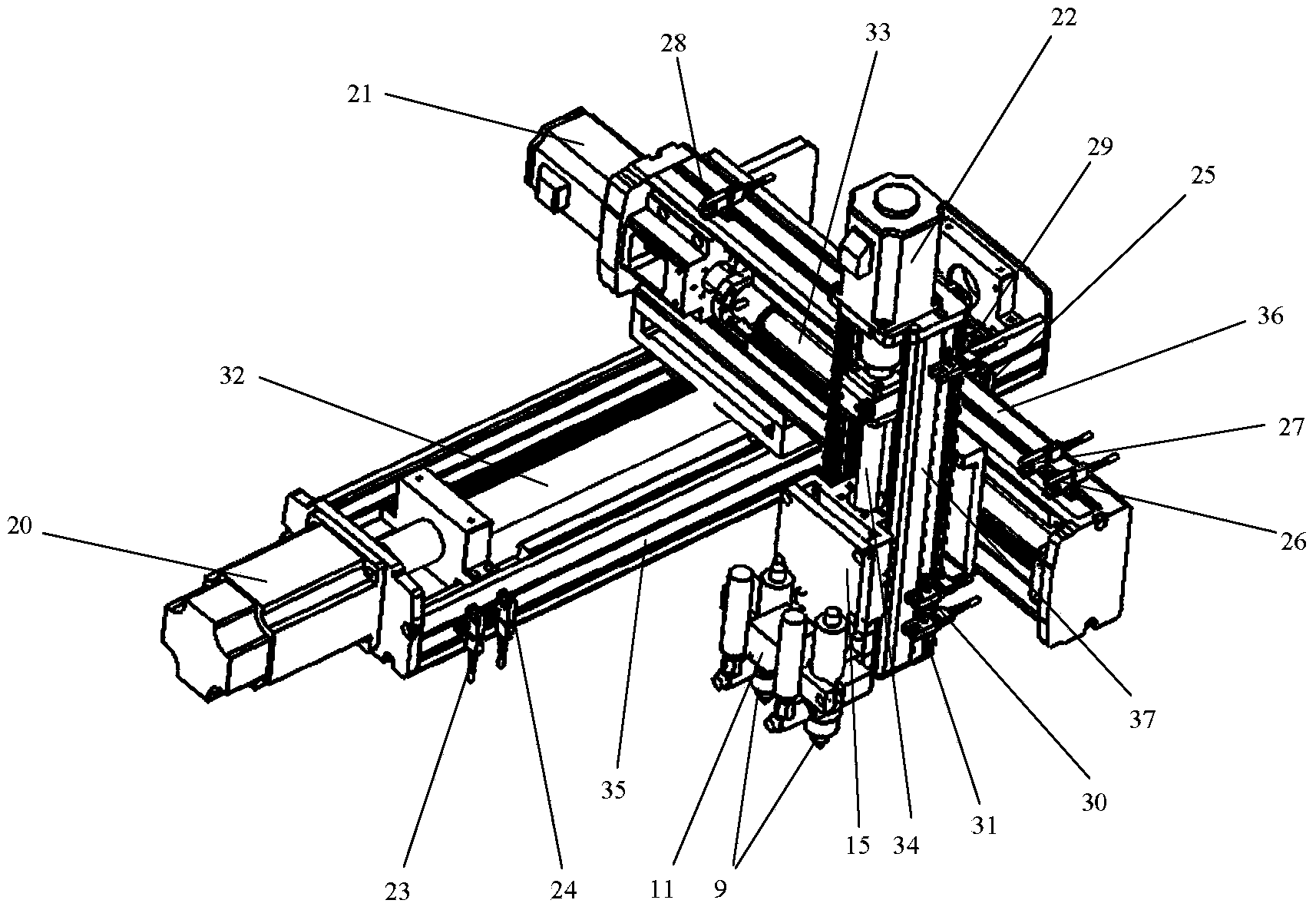

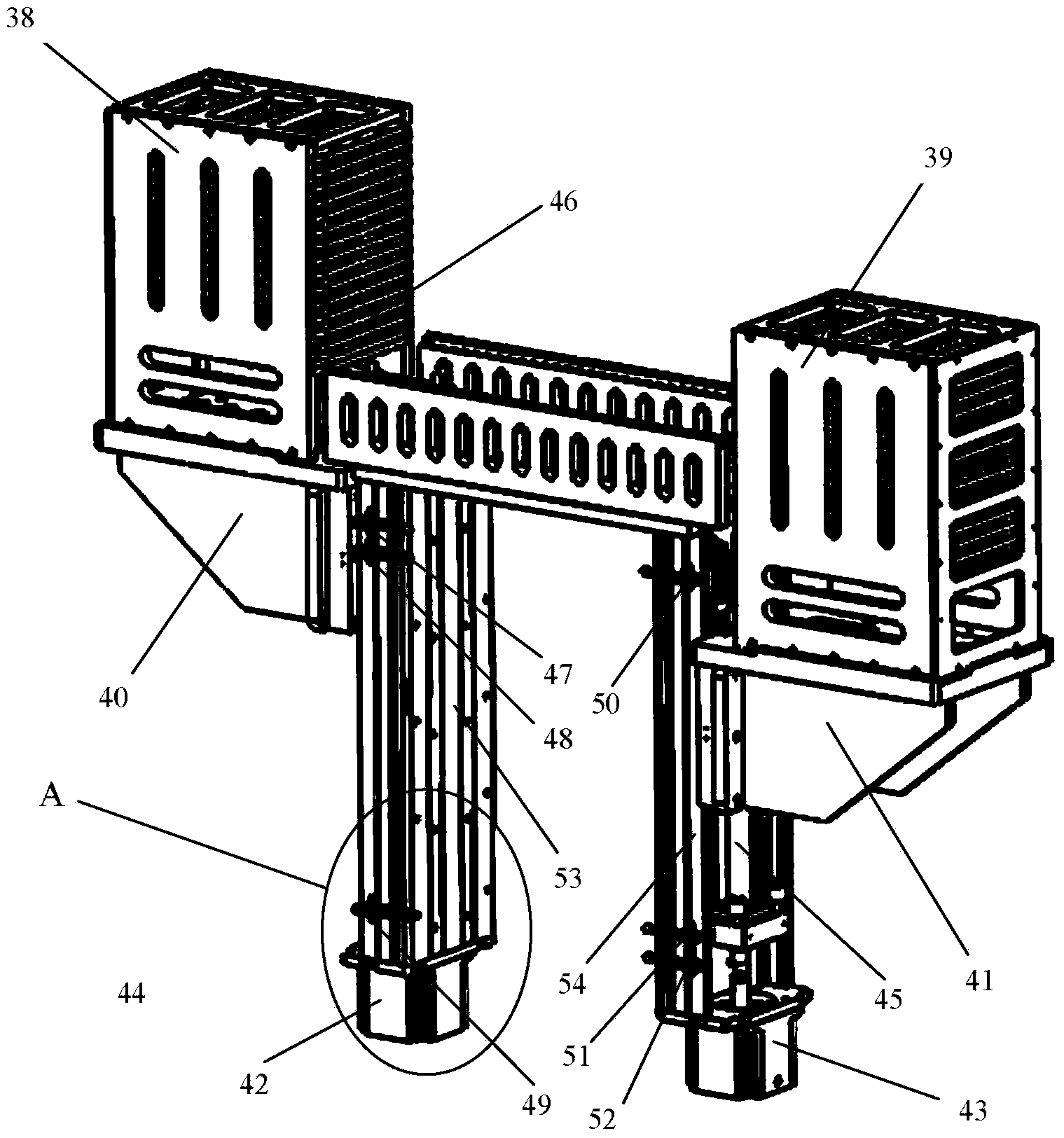

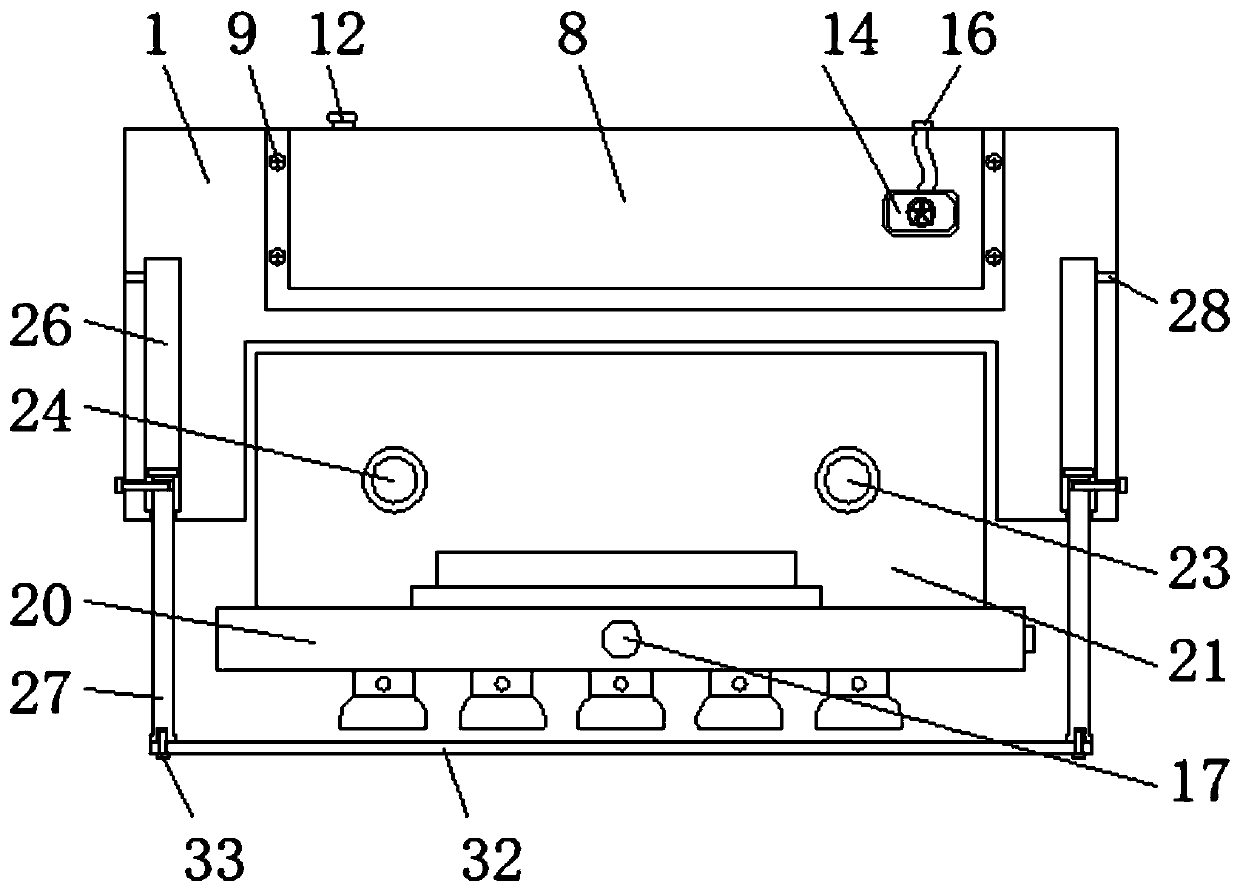

Fully-automatic LED phosphor coating apparatus and control method thereof

ActiveCN103817052AReduce typesReduce manufacturing costCoatingsSpecial surfacesPhosphorFully automatic

The invention discloses a fully-automatic LED phosphor coating apparatus and a control method thereof. The phosphor coating apparatus comprises a frame, a main control box and an industrial control computer main engine are fixed below the frame, the top end of the frame is provided with an XYZ-axial motion platform, a tray dragging mechanism, a nozzle control box, a waste box and a cleaning sponge, a control circuit is installed in the main control box, the Z-axial moving sliding block of the XYZ-axial motion platform is provided with a spraying device and an image acquisition device, an industrial control computer keyboard and an industrial control computer display screen are fixed over the nozzle control box, and the control circuit and the image acquisition device are respectively connected with the industrial control computer main engine. The apparatus has a simple and compact structure, and the control method is also used to improve the execution efficiency of system resources, so the fully-automatic material feeding, blanking and LED phosphor coating of an LED support can be completed, and the problems of low efficiency, non-uniform phosphor coating surface and the like of manual material feeding can be solved.

Owner:SOUTH CHINA UNIV OF TECH

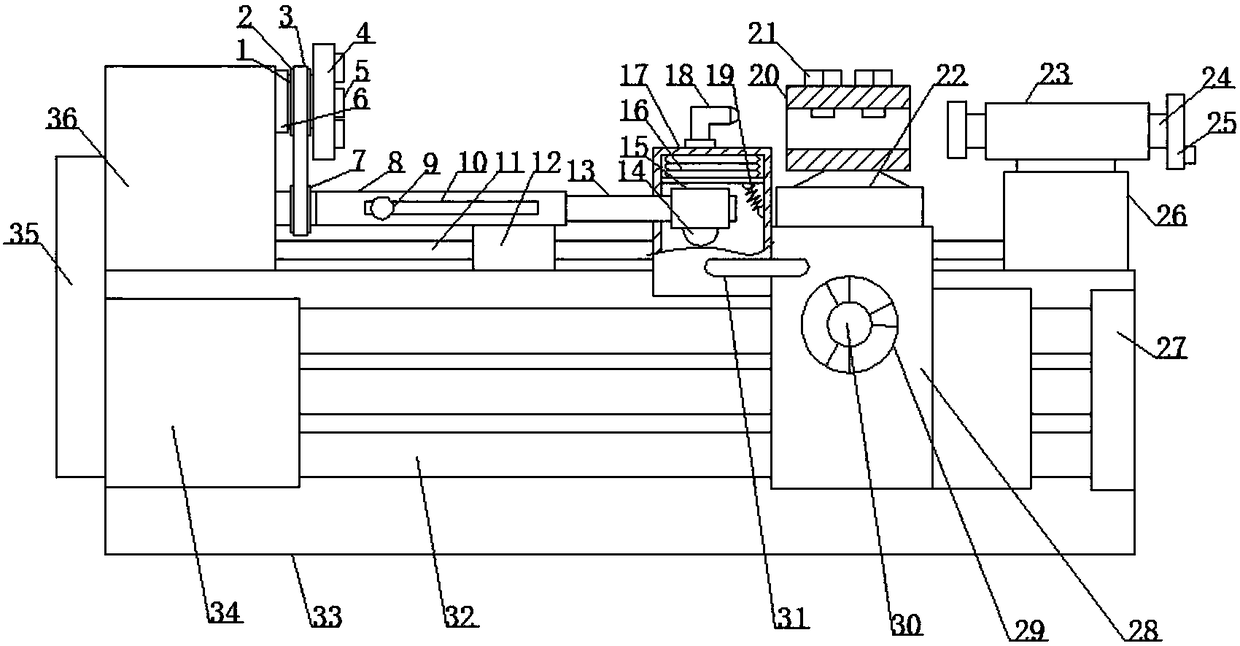

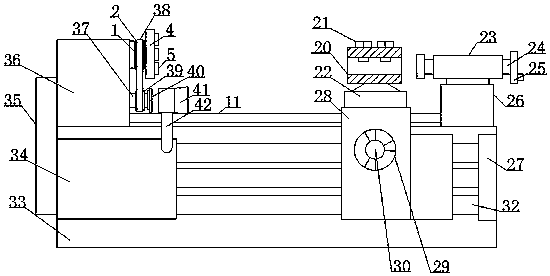

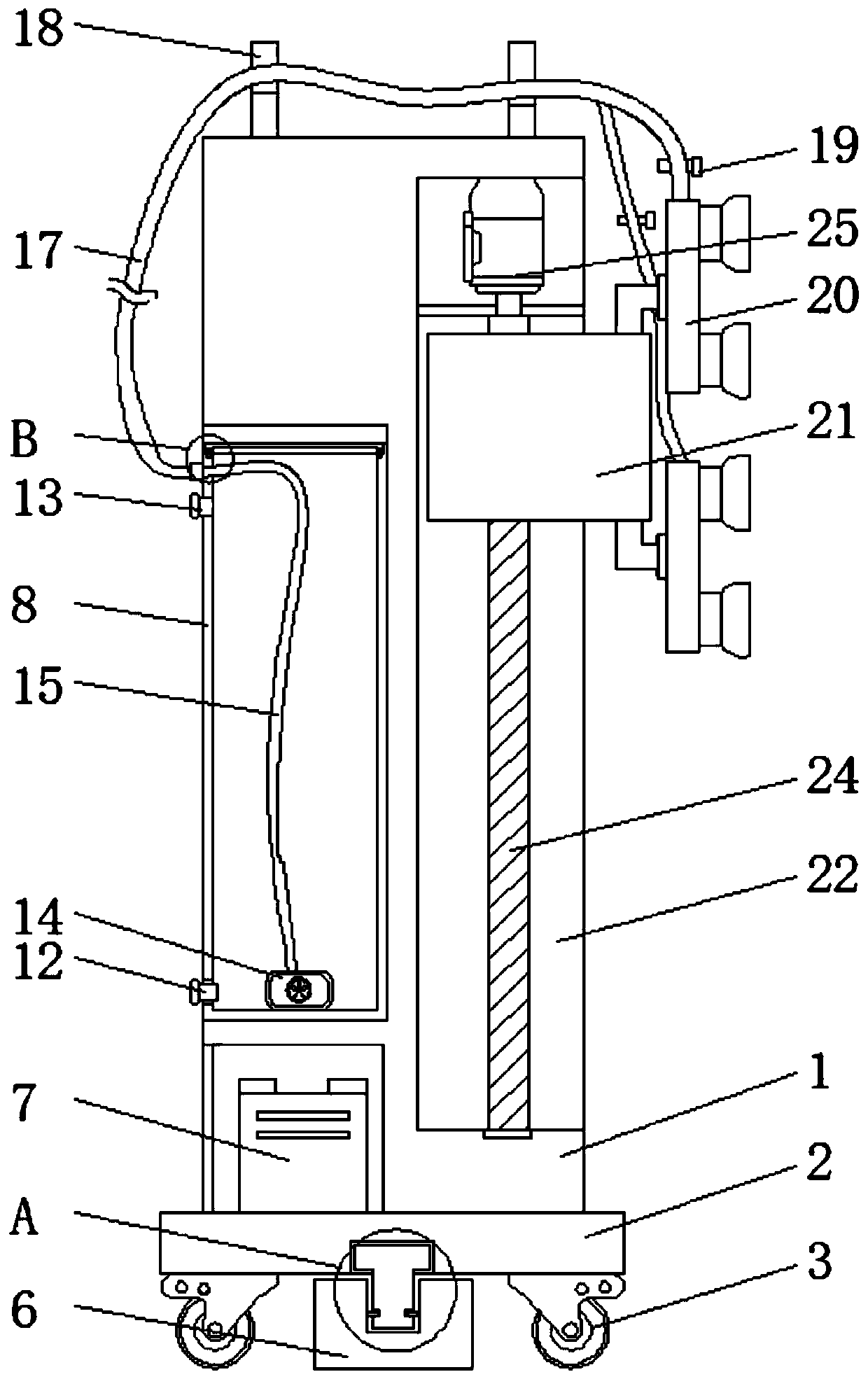

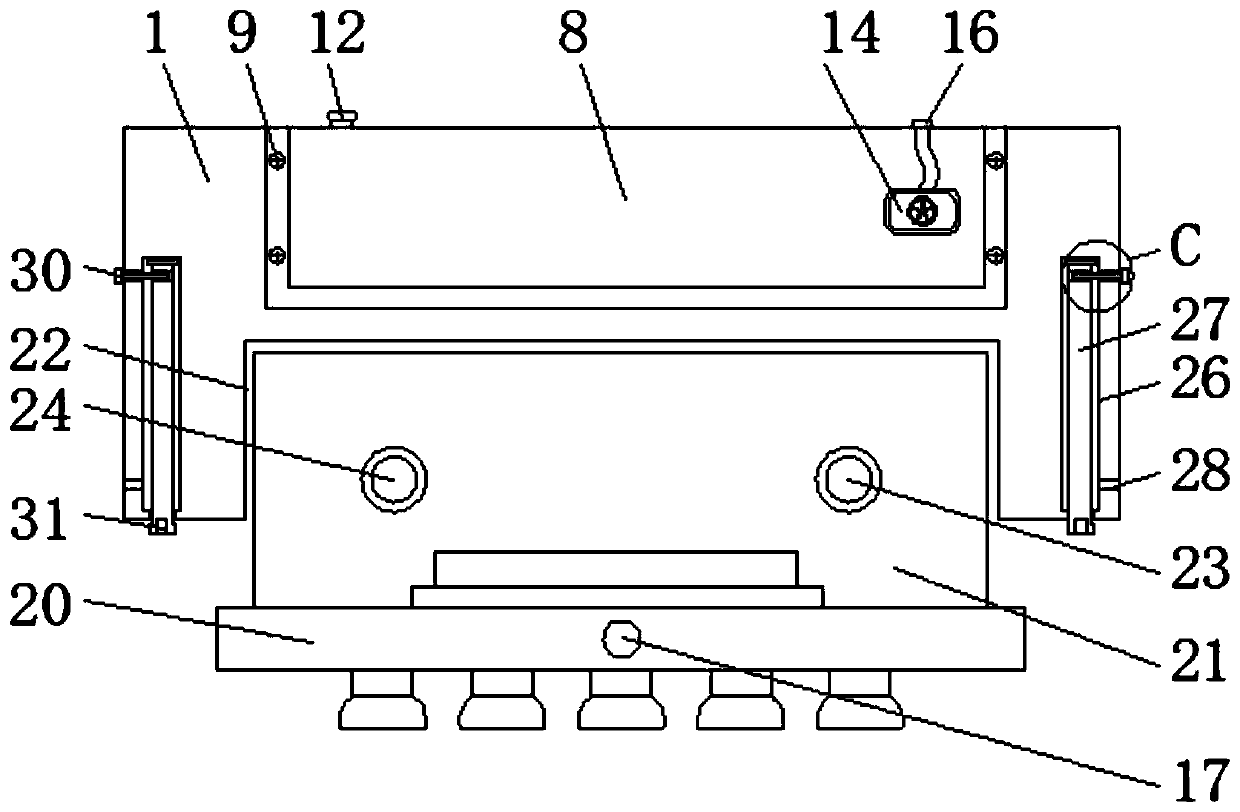

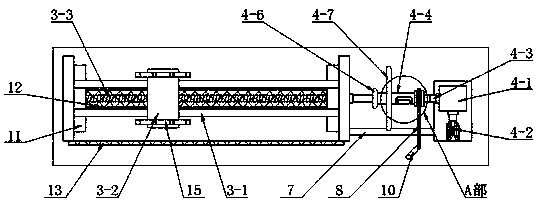

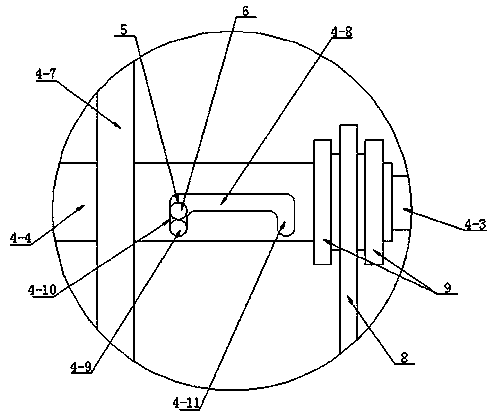

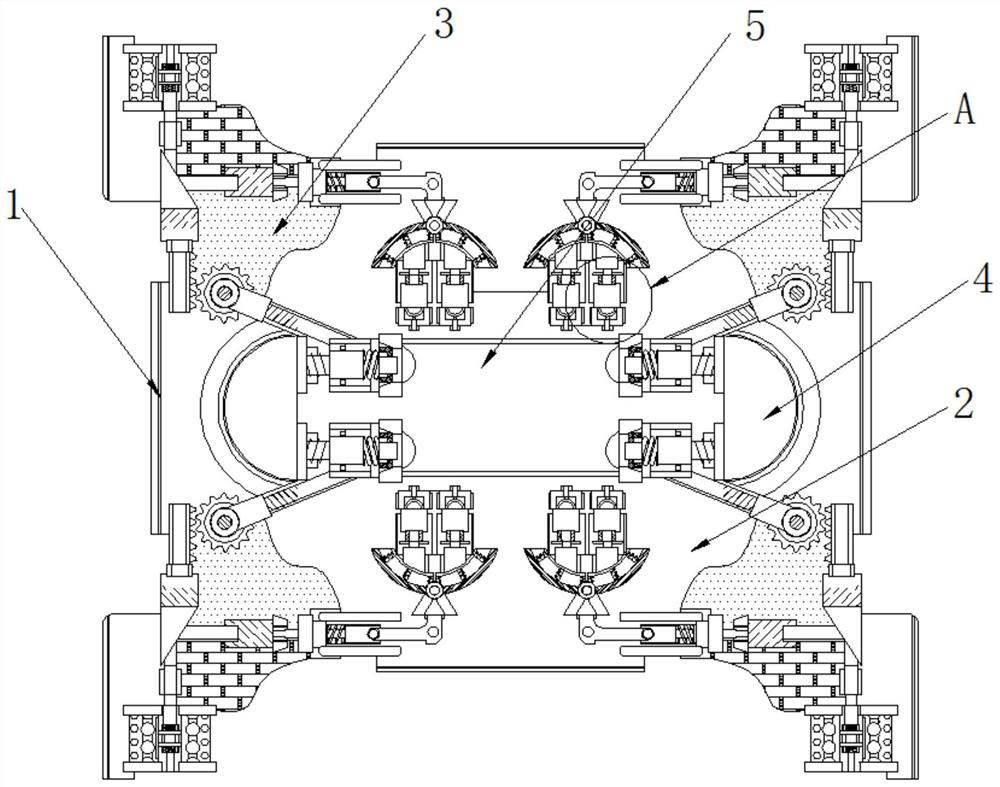

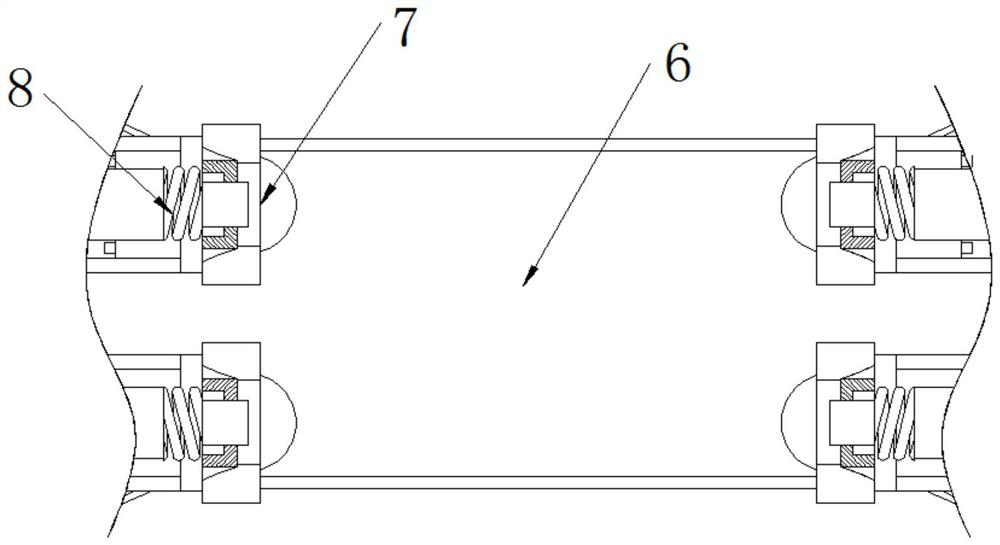

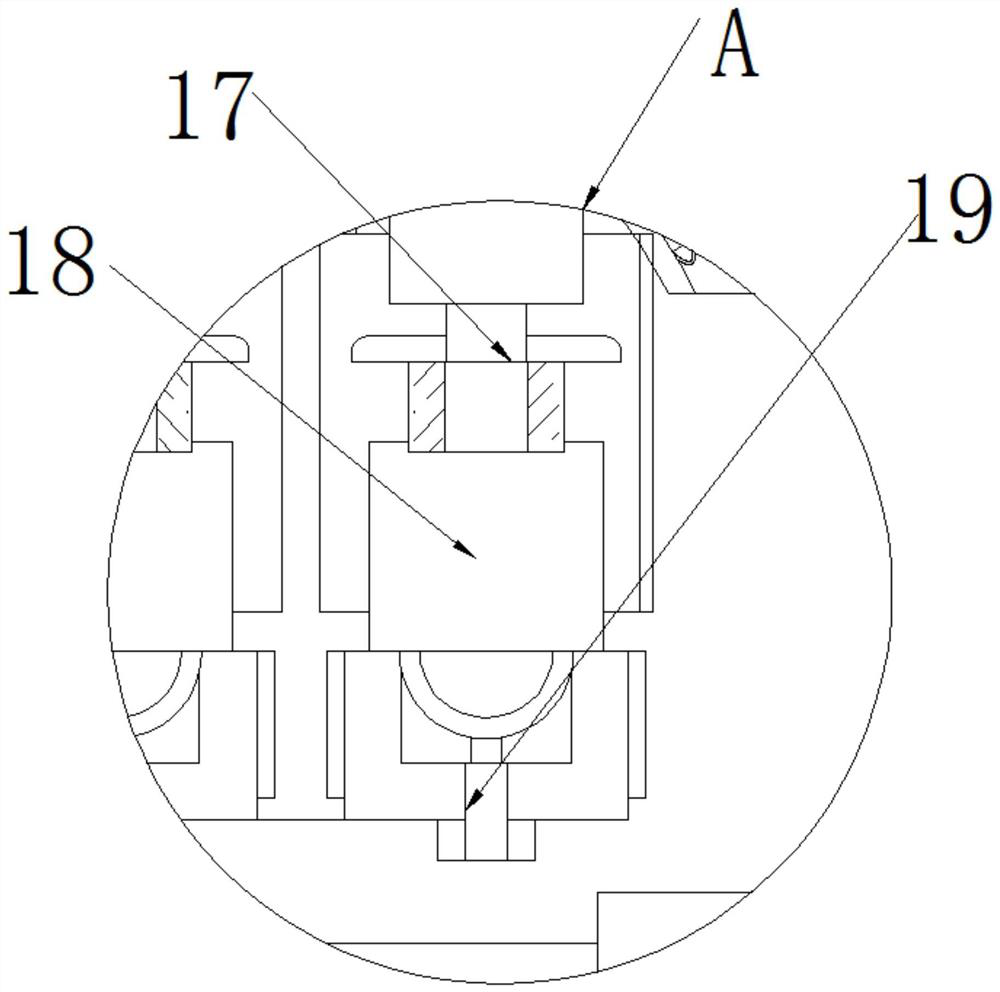

Automatic cooling and cleaning integrated device for machine tool cutting machining process

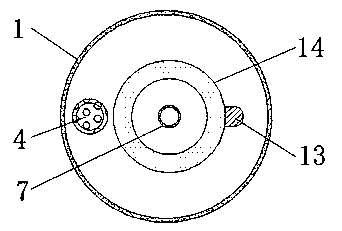

InactiveCN108058060AEasy to processSmooth rotationPositioning apparatusMaintainance and safety accessoriesCoil springEngineering

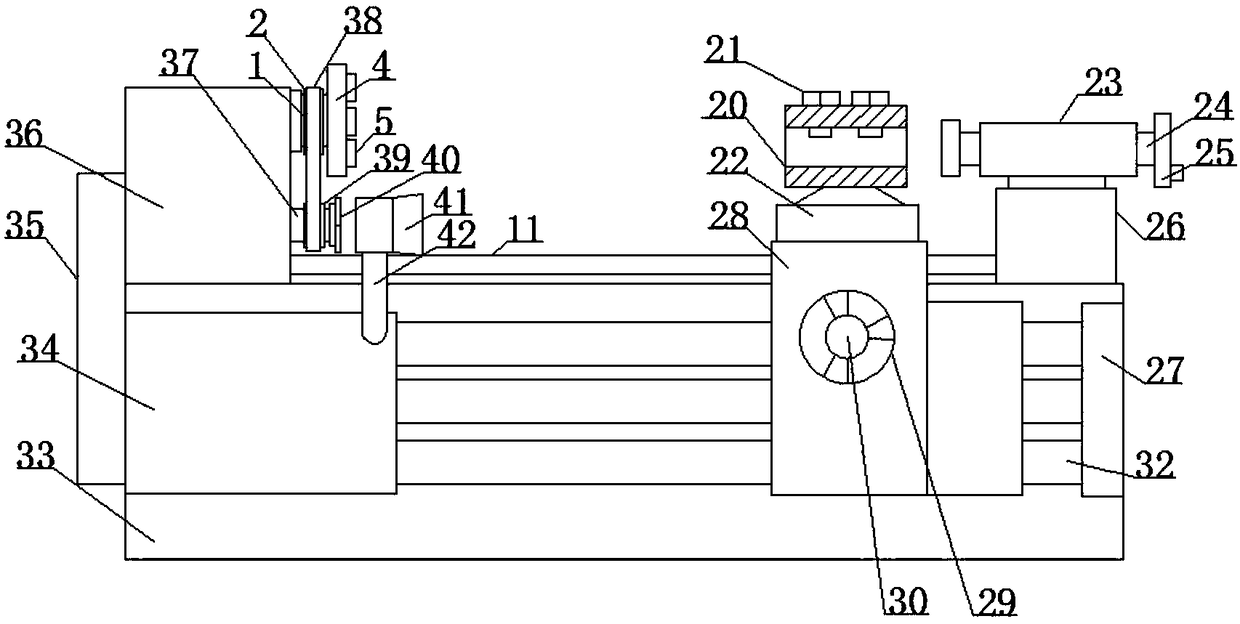

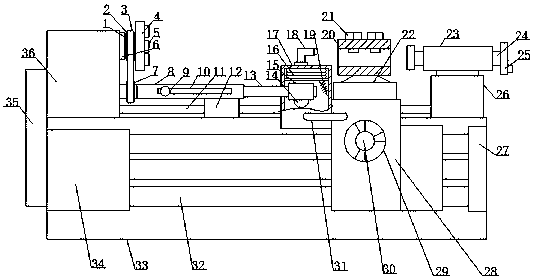

The invention aims to solve the problem that an existing machine tool cannot conveniently spray cooling liquid along with the rotation speed of workpieces, and discloses an automatic cooling and cleaning integrated device for the machine tool cutting machining process. The automatic cooling and cleaning integrated device comprises a first rotary shaft, a first rotary wheel, a first belt, a chuck,a gripper, a sleeve ring, a second rotary wheel, a sleeve pipe, a slide block, a guide groove, a guide rod, a supporting block, a slide rod, a push block, a connection block, a telescopic airbag, a connection box, a discharging pipe, a spiral spring, a knife rest, fastening screws, a supporting table, a guide pipe, a positioning rod, a first rotary disc, a positioning table, a positioning plate, asliding box, a second rotary disc, a first screw rod, a connection rod, second screw rods, a machine table, a feeding box, a connection plate, a spindle box, a second rotary shaft, a second belt, a third rotary wheel, a fan, an air guide cover and a supporting rod. According to the automatic cooling and cleaning integrated device, the sleeve pipe is driven by the second rotary wheel to rotate, accordingly, cooling liquid is sprayed out through the discharging pipe, the cooling liquid can be conveniently sprayed onto the surface of a workpiece automatically in the machine table operation process, and the workpiece is cooled.

Owner:李京帅

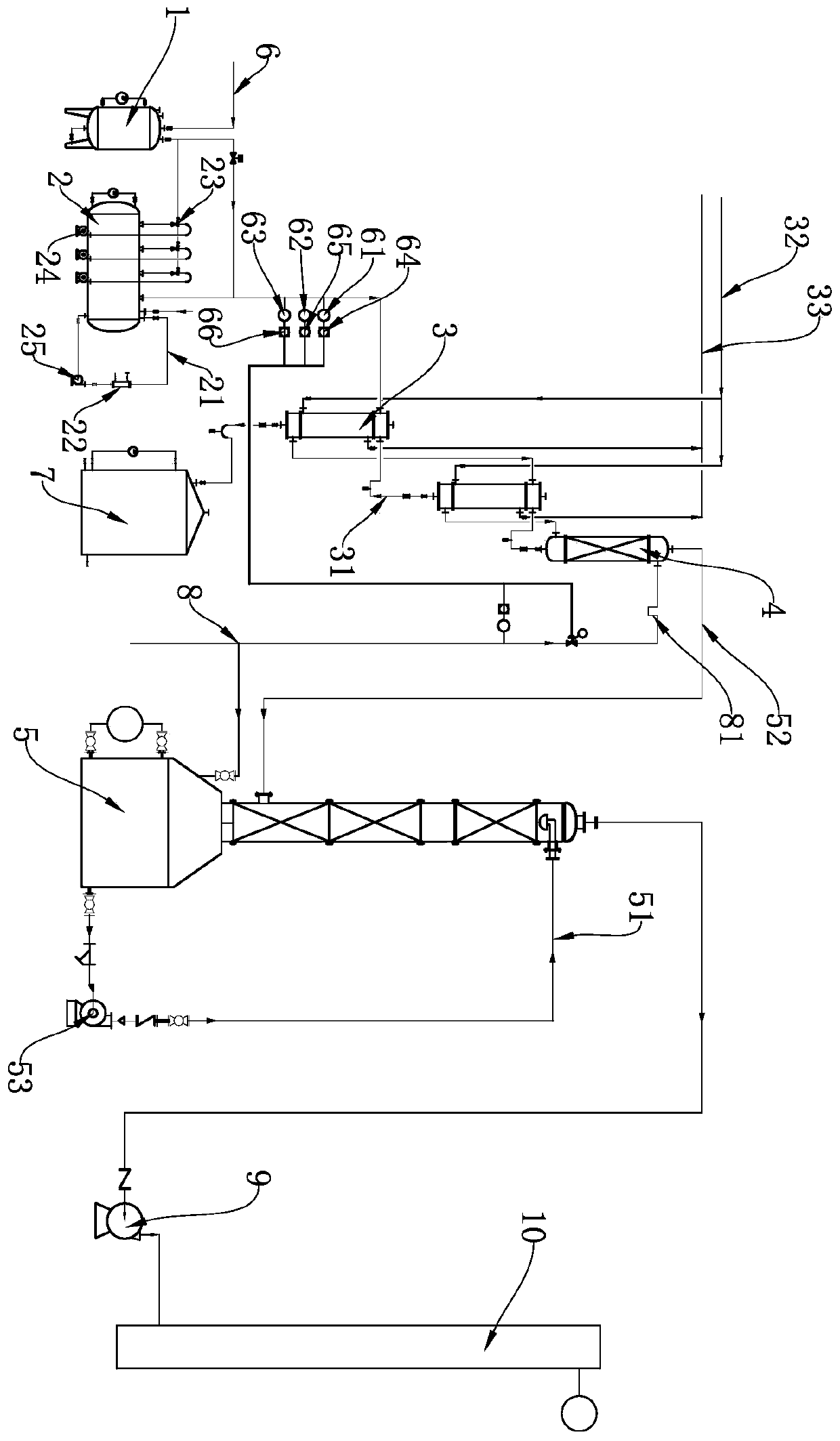

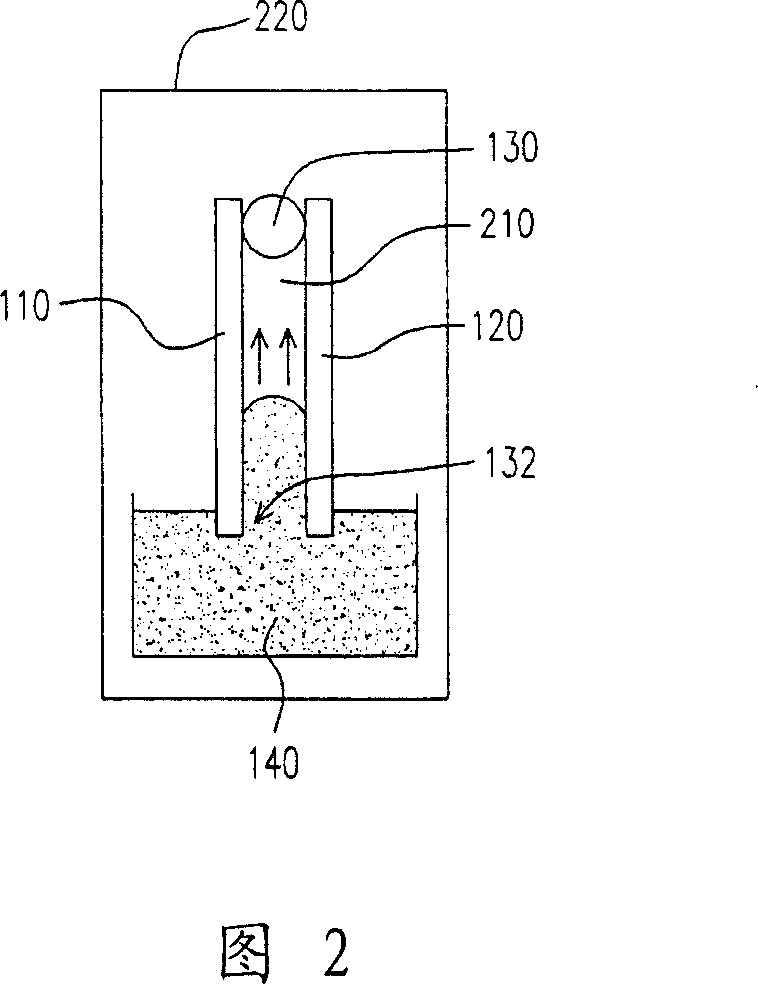

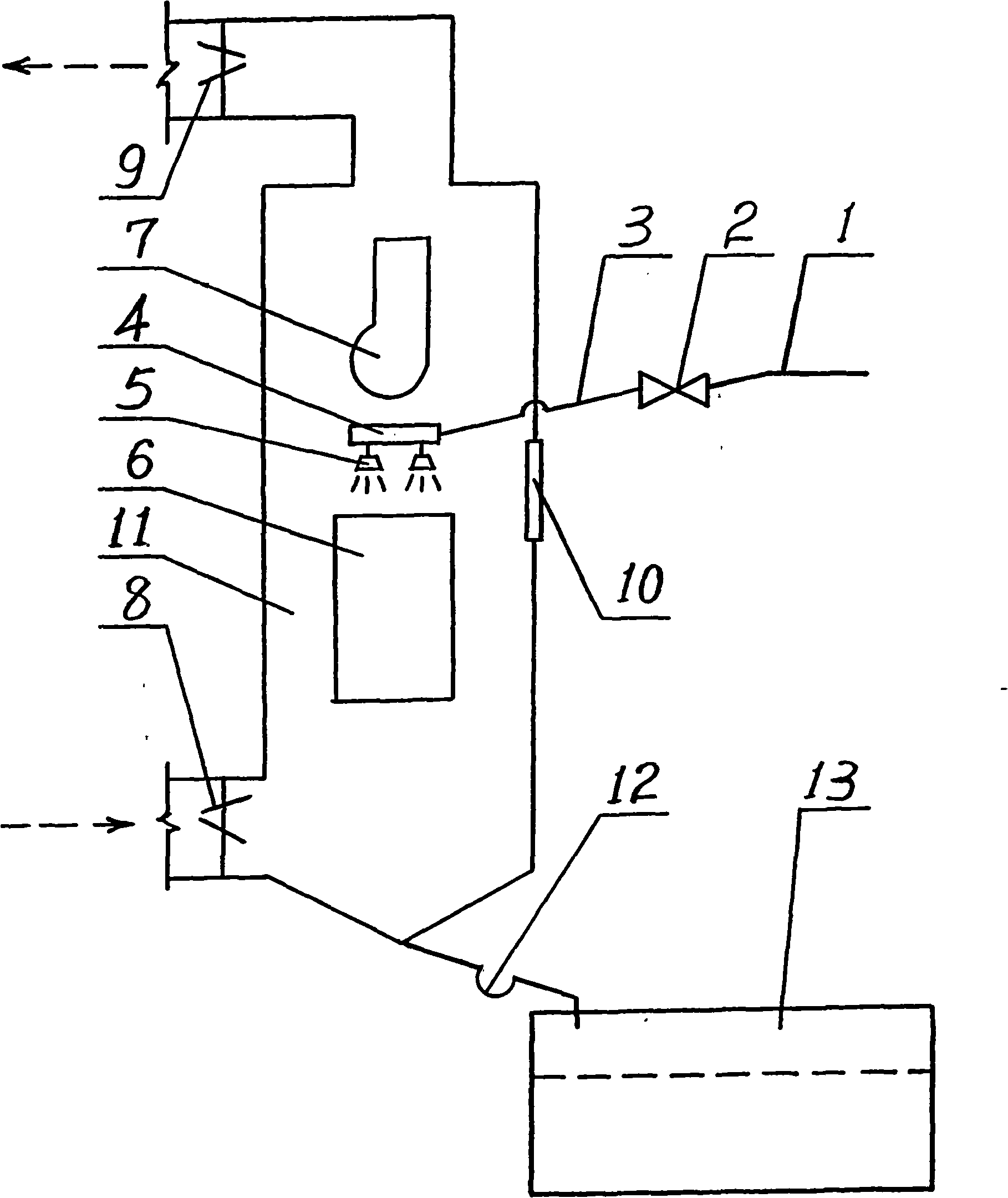

Continuous absorption method for byproduct hydrogen chloride gas in chlorination reaction

PendingCN111068465ACost savingsSave running costsChlorine/hydrogen-chloride purificationDispersed particle separationPhysical chemistryWater chlorination

The invention discloses a continuous absorption method of byproduct hydrogen chloride gas in a chlorination reaction, which comprises the following steps: allowing impurity-containing hydrogen chloride gas generated in the chlorination reaction to pass through a concentrated hydrochloric acid washing tank, sufficiently mixing the gas with concentrated hydrochloric acid, and washing to remove impurities; continuously feeding the washed hydrogen chloride gas into at least two stages of falling film absorption towers which are arranged in series, spraying and absorbing stage by stage, and feedingthe gas into a packing absorption tower for further absorption; allowing fresh absorption water to enter from the top of the packing absorption tower and sequentially flow through the packing absorption tower and the at least two stages of falling film absorption towers in a countercurrent mode, and feeding hydrochloric acid after absorption into a hydrochloric acid storage tank; allowing gas discharged from the top of the packing absorption tower to enter a spray tower again so that the gas is sprayed and absorbed by fresh absorption water and residual hydrogen chloride gas is further absorbed and then discharging at high altitude. According to the method, continuous absorption can be realized, no water-soluble impurities exist in the hydrochloric acid after absorption, and the absorption efficiency is high.

Owner:山东旭锐新材股份有限公司 +1

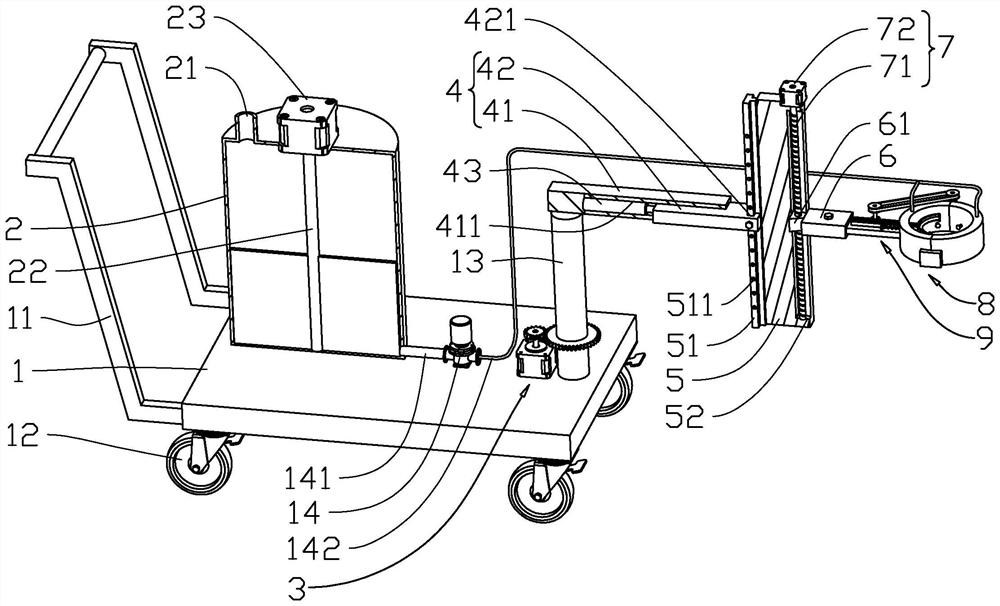

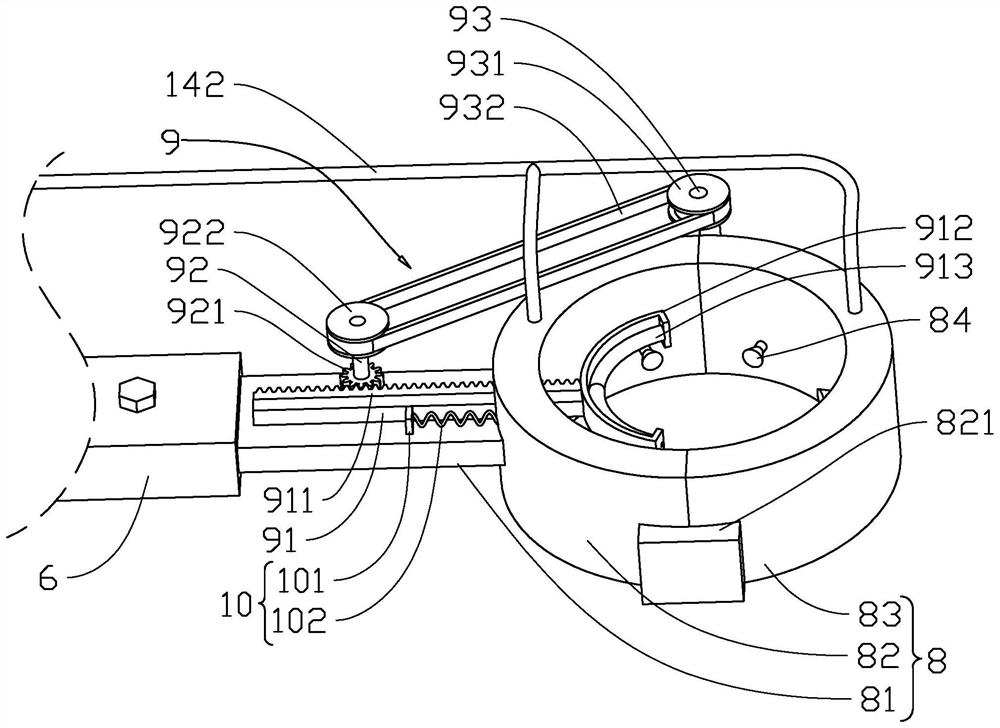

Automatic cooling and cleaning integrated device for cutting process of machine tool

InactiveCN109202517AEasy to processSmooth rotationMaintainance and safety accessoriesCoil springAirbag

In order to solve the problem that the existing machine tool is not easy to follow the rotation speed of a workpiece to spray cooling liquid, the invention discloses an automatic cooling and cleaningintegrated device for the cutting process of the machine tool. The automatic cooling and cleaning integrated device comprises a first rotating shaft, a first rotating wheel, a first belt, a chuck, a gripper, a lantern ring, a second rotating wheel, a sleeve pipe, a sliding block, a guide groove, a guide rod, a supporting block, a sliding rod, a push block, a connecting block, a telescopic airbag,a connecting box, a discharging pipe, a spiral spring, a knife rest, fastening screws, a supporting platform, a guide pipe, a positioning rod, a first rotary table, a positioning platform, a positioning plate, a sliding box, a second rotary table, a first screw rod, a connecting rod, a second screw rod, a machine, a feeding box, a connecting plate, a spindle box, a second rotating shaft, a secondbelt, a third rotating wheel, a fan, an air director and a supporting rod. The sleeve pipe is driven to rotate by the second rotating wheel, and therefore the cooling liquid is sprayed through the discharging pipe. Thus, the automatic cooling and cleaning integrated device is convenient to automatically spray the cooling liquid on the surface of the workpiece for cooling the workpiece in the operation process of the machine.

Owner:HANDAN COLLEGE

Liquid crystal filling device and method

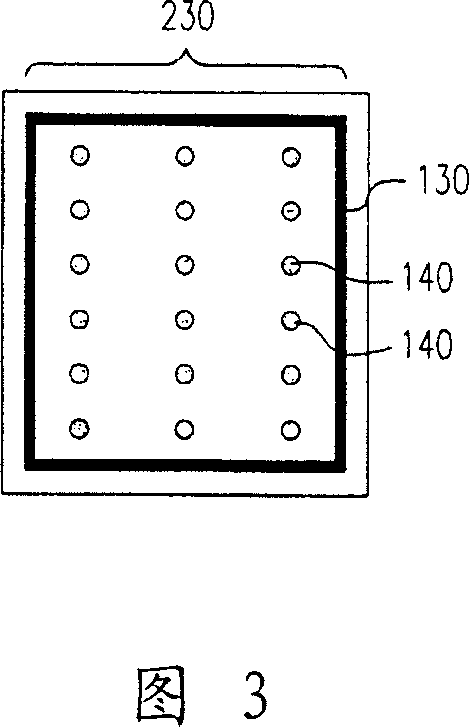

Owner:UNITED MICRODISPLAY OPTRONICS CORP

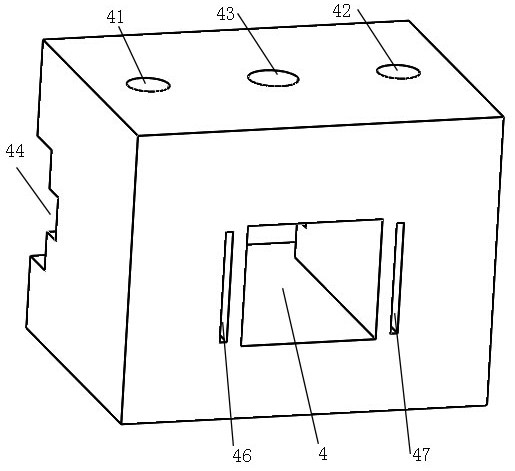

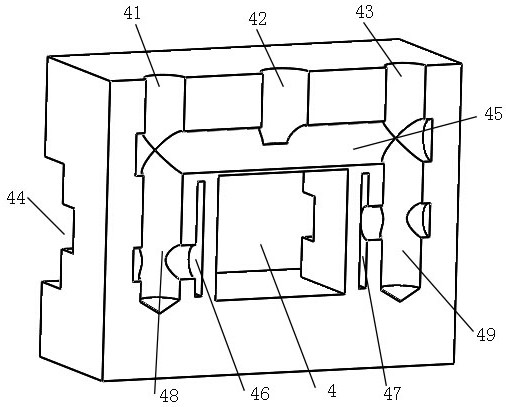

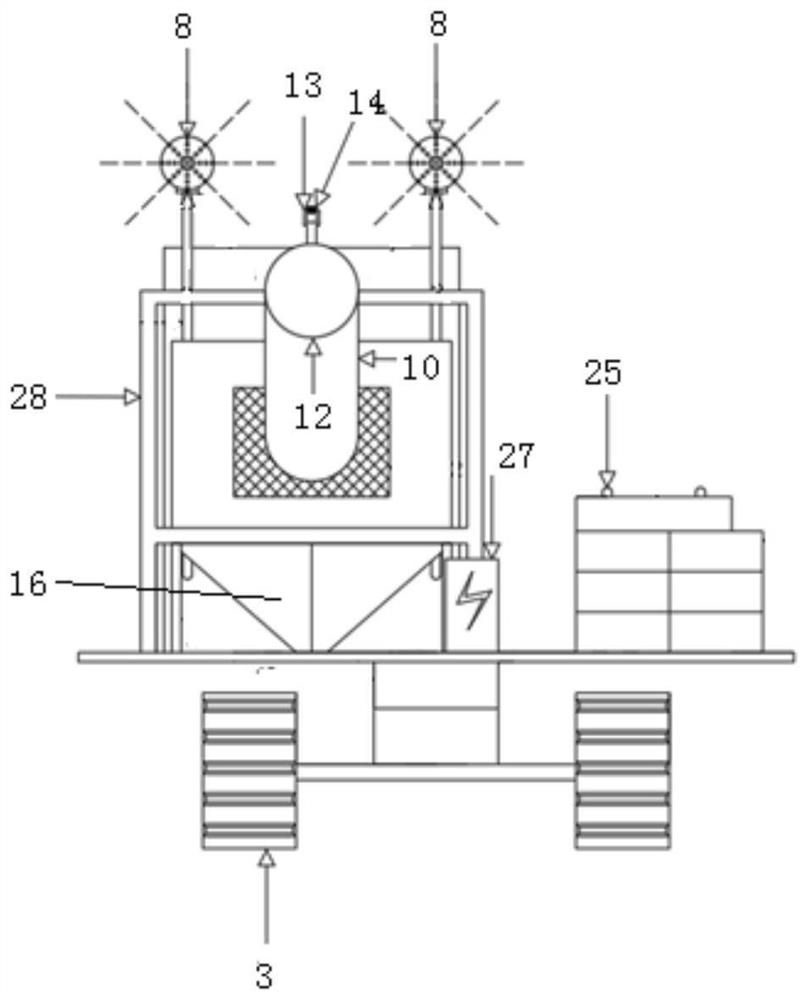

Intelligent coating equipment

InactiveCN110369178AControl spray volumeClean thoroughlyLiquid spraying apparatusAgricultural engineeringSelf locking

The invention discloses intelligent coating equipment. The intelligent coating equipment comprises a machine body, a sliding groove, a first fixing hole, a third bolt and a fourth bolt. A base is fixed below the machine body, and a pulley is rotatably connected to a limiting block; a tank cover is fixed on the top of a storage tank through a second bolt; a joint is fixed on the storage tank, and adistributing pipe is clamped in a limiting buckle; the end, which is away from the joint, of the distributing pipe is connected with a spray head; the spray head is fixed on the front side surface ofa moving block, and the sliding groove is formed in the front side surface of the machine body; first fixing holes are formed in the left side surface and the right side surface of the machine body;the third bolt penetrates through the first fixing holes and is connected with a second fixing hole; and the fourth bolt penetrates through a template and is connected with a third fixing hole. According to the intelligent coating equipment, structures such as a power supply box and the storage tank are arranged in the machine body in an embedded mode, the whole device is compact in structure andsmall in size, and by arrangement of self-locking wheels, and the device moves conveniently.

Owner:江苏纵湖涂装设备产业研究院有限公司

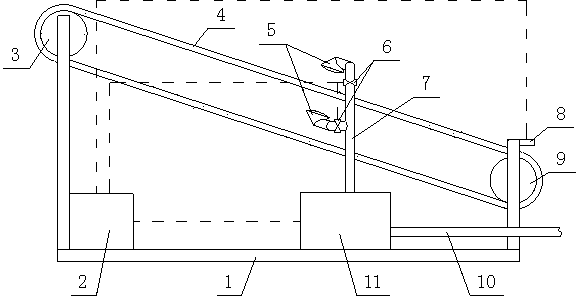

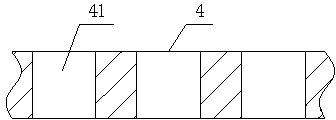

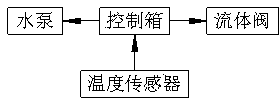

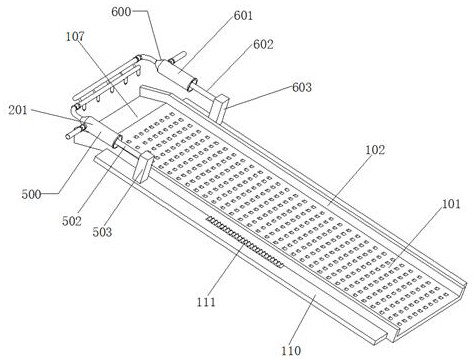

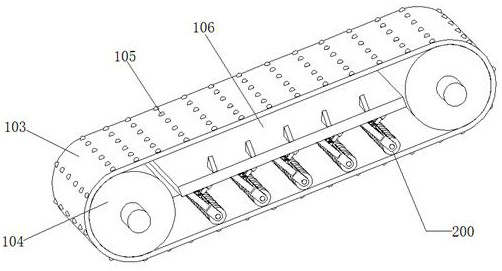

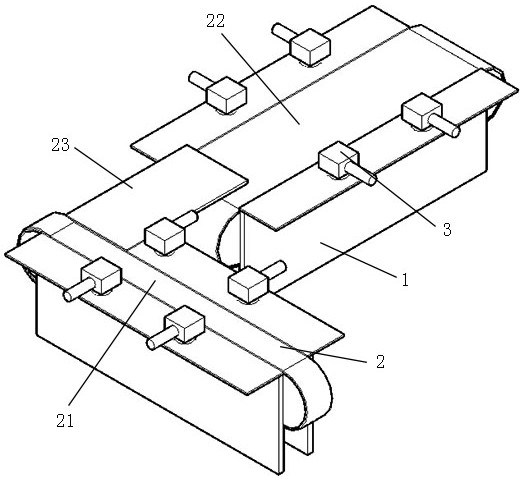

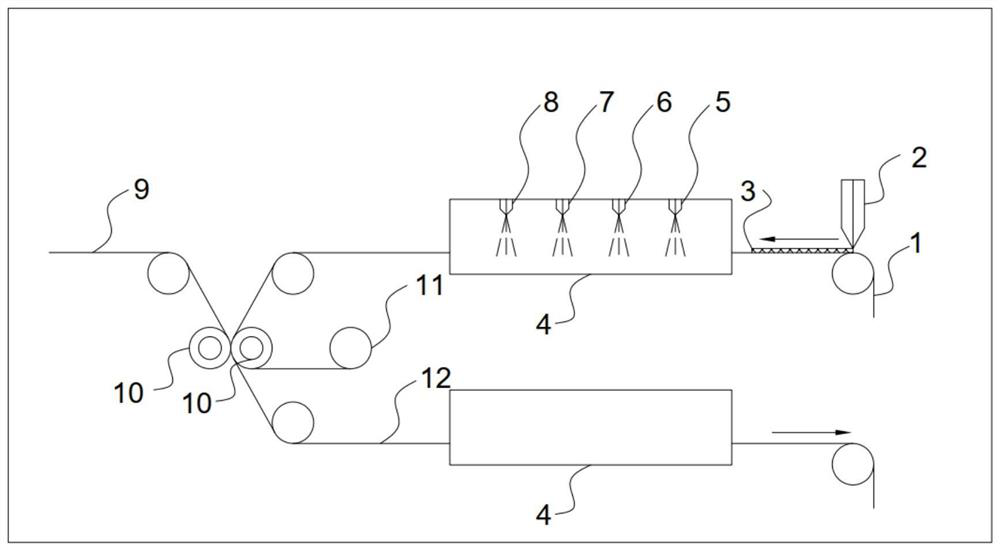

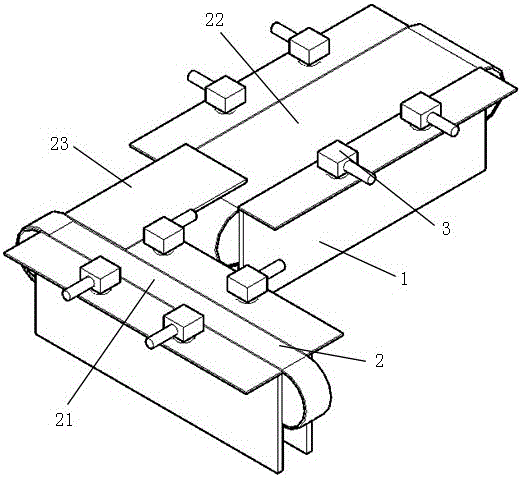

Intelligent spraying system in fresh leaf conveyor belt

PendingCN104171074AQuality assuranceQuality improvementPre-extraction tea treatmentEngineeringConveyor belt

The invention particularly relates to improvement of an intelligent spraying system in a fresh leaf conveyor belt, and aims at providing an intelligent spraying system in a fresh leaf conveyor belt, which is capable of rapidly reducing the temperature of fresh leaves and keeping water of the fresh leaves. The intelligent spraying system comprises a conveyor belt, a spraying device, a temperature sensor and a control box, wherein the spraying device comprises nozzles and a water pump, the nozzles are arranged corresponding to the conveyor belt, and are connected with a water outlet of the water pump by virtue of a pipeline, the temperature sensor is arranged at the input end of the conveyor belt, the control box is connected with the water pump and the temperature sensor, and the control box controls the water pump to be turned on by virtue of a signal of the temperature sensor. According to the intelligent spraying system, the water pump is controlled to be turned on by inducing the temperature of the fresh leaves, water mist is sprayed to the fresh leaves by virtue of the nozzles so that the fresh leaves are rapidly cooled, the water mist is capable of replenishing the water for the fresh leaves so that the water of the fresh leaves is prevented from losing, and the quality of finished tea in the subsequent processing is ensured.

Owner:BAOSHAN CHANGNING HONG TEA GRP

Vehicle spraying device with spraying amount convenient to control

ActiveCN110449298AControl spray volumeControl the direction of rotationSpraying apparatusEngineeringSpur gear

The invention discloses a vehicle spraying device with the spraying amount convenient to control, and relates to the technical field of automobile maintenance equipment. A first guiding rod is fixedlyarranged on a support, and a sliding block is slidably arranged on the first guiding rod; a mounting frame is fixedly arranged on the sliding block, and a screw nut is fixedly arranged on the lower surface of the sliding block; a screw rod is arranged in the screw nut in a threaded manner, and a gearbox is fixedly arranged on the support; a transmission rod is fixedly arranged on the output shaftof the gear box; a guiding sleeve is movably arranged on the transmission rod in a sleeving manner, and a spur gear is fixedly arranged at the left end of the guiding sleeve; a transmission gear is fixedly arranged at the right end of the screw rod, the spur gear is engaged with the transmission gear, and a ring gear is fixedly arranged on the guiding sleeve; and by controlling the traveling speed of a spray gun, the spraying amount per unit area is controlled, the vehicle spraying device can be cooperatively used with equipment such as an existing spray gun, and the equipment updating cost is low.

Owner:江苏长虹机械设计院有限公司

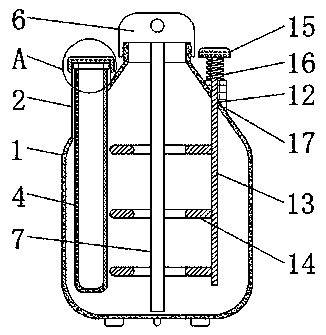

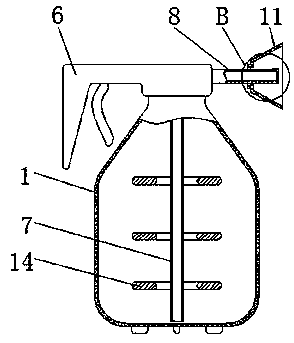

Spraying device for kapok dyes

InactiveCN109225710ASolve the problem of being vulnerable to collision damage,Solve operational problemsSingle-unit apparatusDye injectionStorage tank

The invention discloses a spraying device for kapok dyes. The spraying device comprises a storage tank and a spraying gun. An injection opening is embedded in the left side wall of the storage tank. Afilter screen penetrating through the injection opening is installed at the lower end of a bearing block. The spraying gun is fixed to the top end of the storage tank through threaded connection. Anoutput pipe is arranged on the rear side of the spraying gun. A shielding cover is installed on the outer side of a connecting block. A spraying nozzle is detachably installed at the tail end of the output pipe. A limiting hole is formed in the right side of the storage tank. A stirring plate is fixedly installed on the left side of a limiting rod. The lower surface of a pressing block is fixedlyconnected with the upper end of a spring sleeving the outside the limiting rod. The spraying device solves the problems that a spraying gun of an existing spraying device for kapok dyes is prone to collision damage and complicated in operation in the dye injection process, the dyes in the storage tank precipitate and the spraying effect can be poor.

Owner:JIANGSU DELIHENG COTTON

Bromomethane impurity removal process adopting weak base

InactiveCN112047807AReduce decompositionReduce loss rateHalogenated hydrocarbon preparationPhysical chemistryAtomic physics

The invention relates to a bromomethane impurity removal process adopting weak base, which belongs to the field of bromomethane purification. The process comprises the following steps: step 1, introducing bromomethane into a tower from the bottom of a first absorption tower, spraying a weak base solution with the pH value of 8-10 from the top of the first absorption tower, and neutralizing bromomethane; and step 2, introducing the bromomethane obtained in the step 1 into the tower from the bottom of a second absorption tower, spraying a sulfuric acid solution from the top of the second absorption tower, and drying the bromomethane, the weak base solution being prepared from weak base and water. The process has the effects of reducing the loss rate of bromomethane and improving the impurityremoval yield of bromomethane.

Owner:临海市建新化工有限公司

Cold storage water defrost and defrosting water as well as defrosting water recycle apparatus

ActiveCN101303188BControl areaControl spray pressureLighting and heating apparatusDefrostingWater dischargeTap water

The invention discloses a device of cold-storage water defrosting and deforesting water and foresting water reusing, which relates to the technical field of cold-storage defrosting. The supply pipe of tap water and a cut-off valve, the cut-off valve and a water-carrying pipe, the water-carrying pipe and a spray pipe, the spray pipe and a nozzle are all connected through screw threads; the enclosing case of an evaporator is fixedly and respectively connected with an evaporator fan, the spray pipe, an evaporator and a glass observing window through a fastener; the wind-returning passage of the enclosing case of the evaporator and a wind-returning door, the wind-feeding passage of the enclosing case of the evaporator and a wind-feeding door are all connected by a rotating shaft in a movable way; the bottom of the enclosing case of the evaporator is connected with a water-sealing drain pipe in a flange connection way; the periphery of the enclosing case of the evaporator is provided with a circulation water storing pool, and the water discharge end of the water-sealing drain pipe extends to the upper part of the circulation water storing pool. The device of the invention is applied tocold-storage defrosting with good effect, can reuse deforesting water and foresting water and the cold of frost layers, and saves water resource and electric energy.

Owner:GUANGXI ZHUANG AUTONOMOUS REGION ACAD OF AGRI SCI

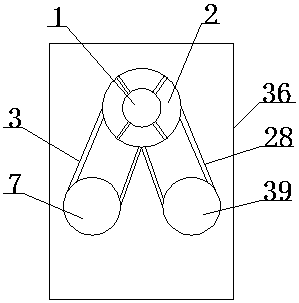

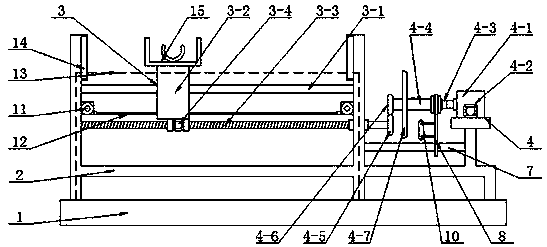

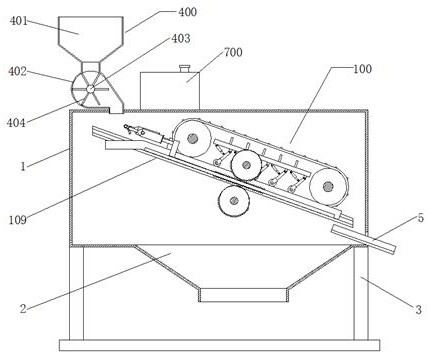

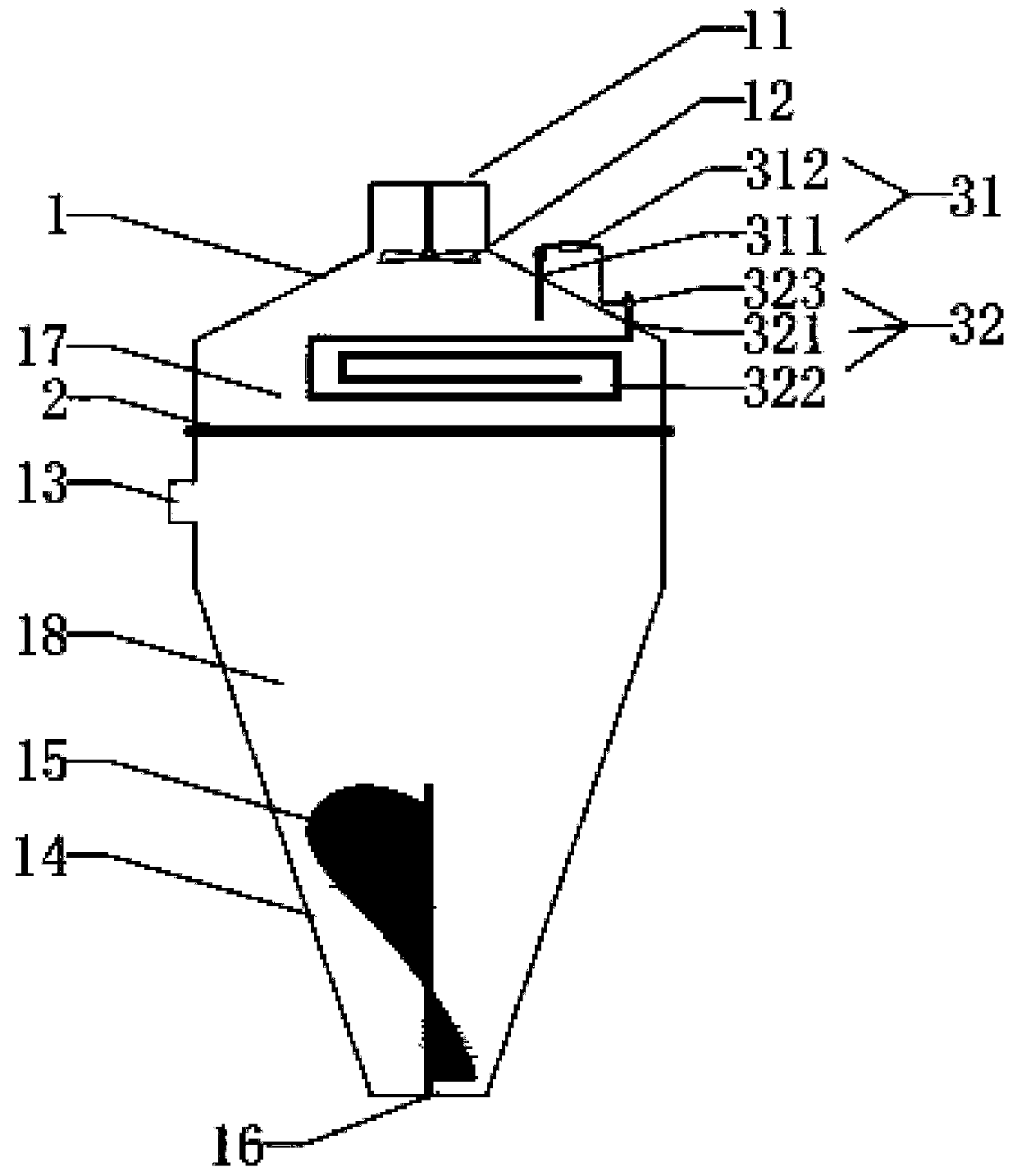

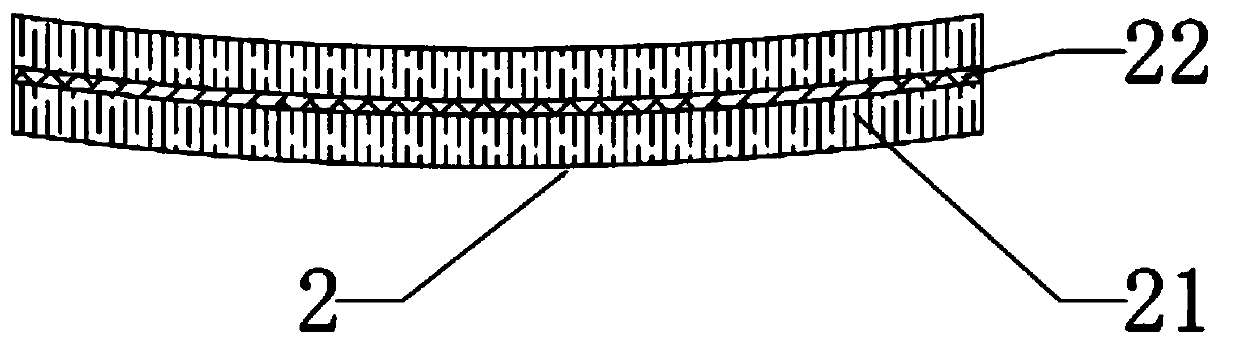

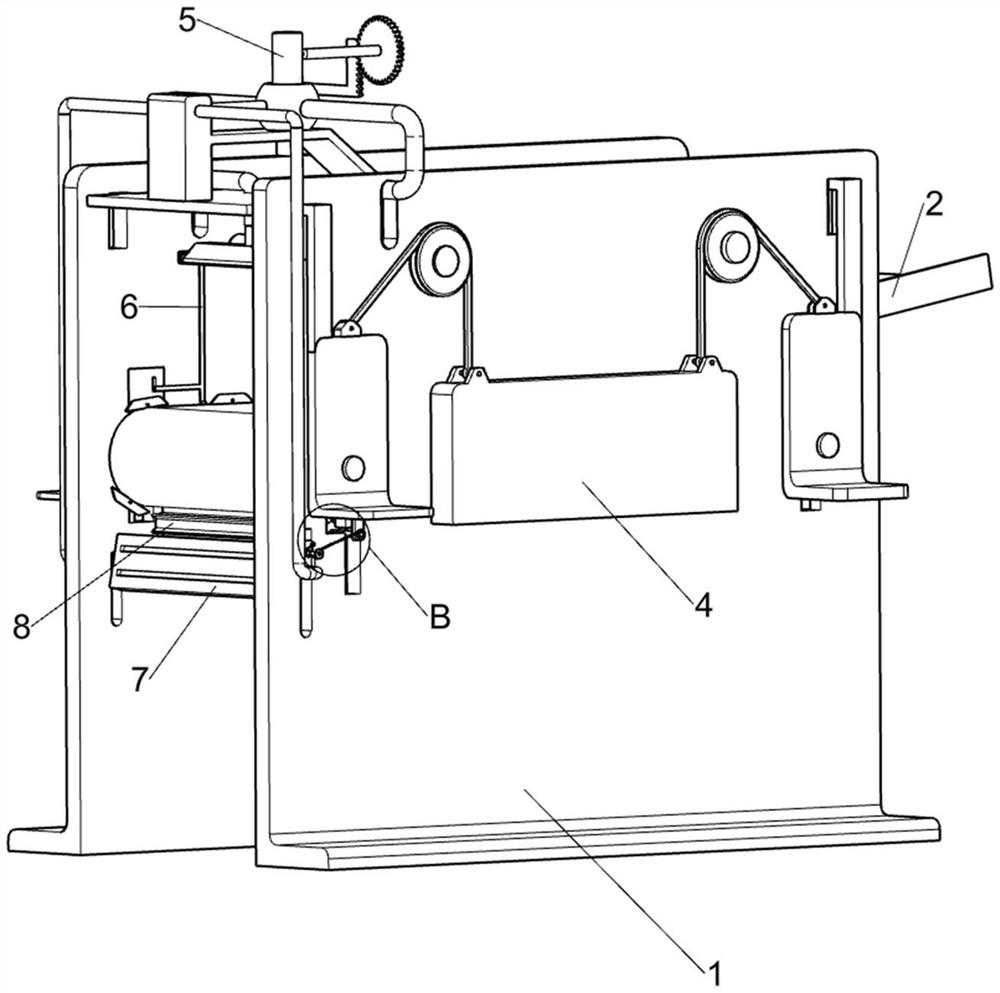

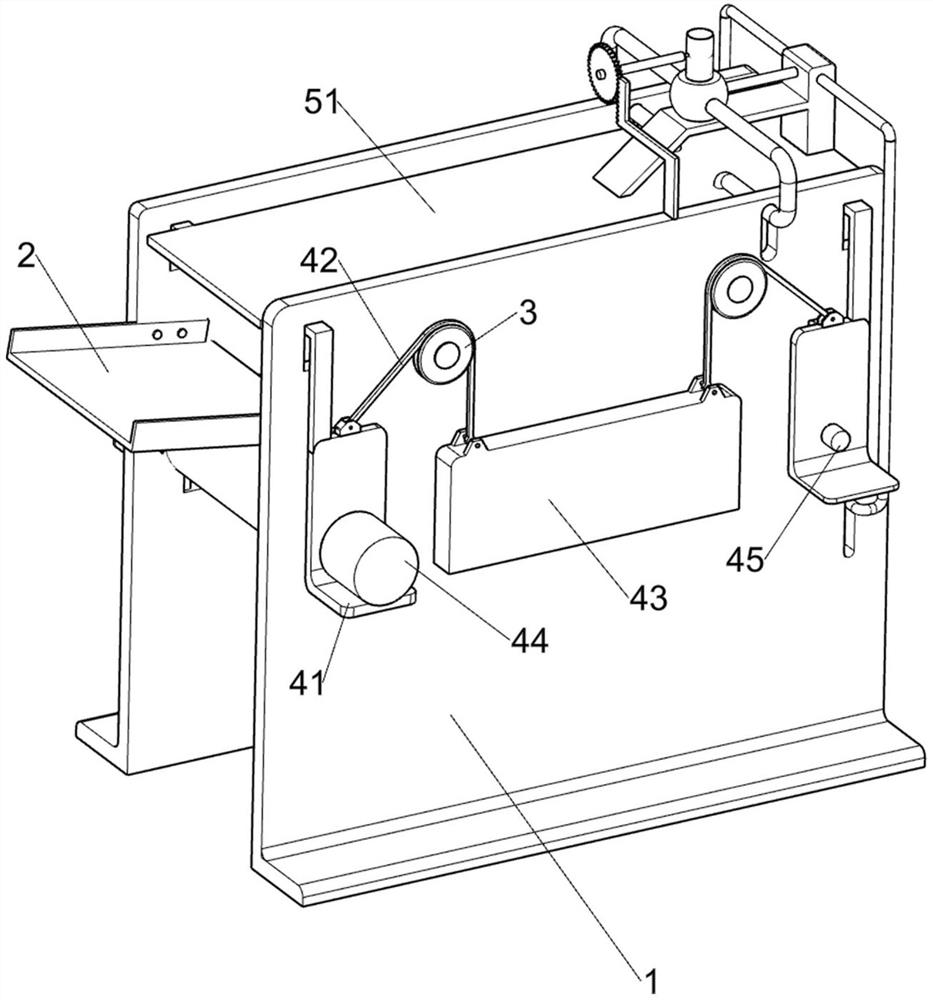

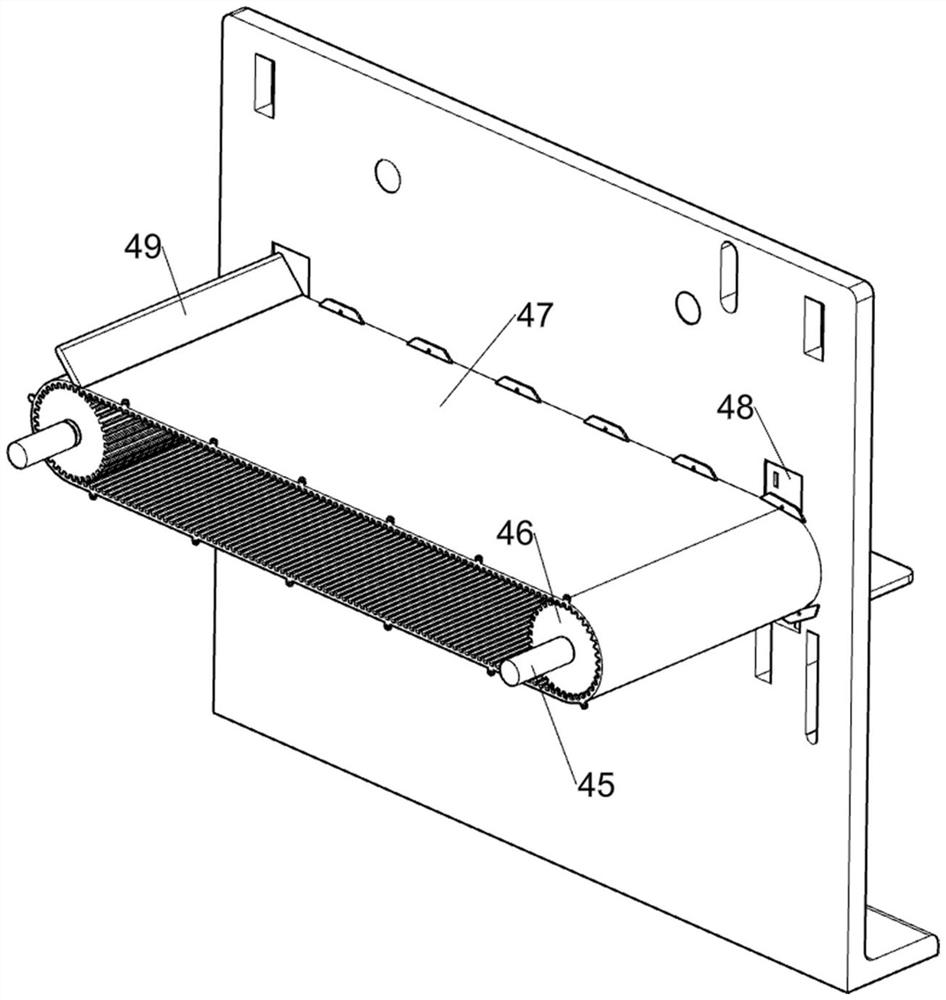

Polishing device for rice production

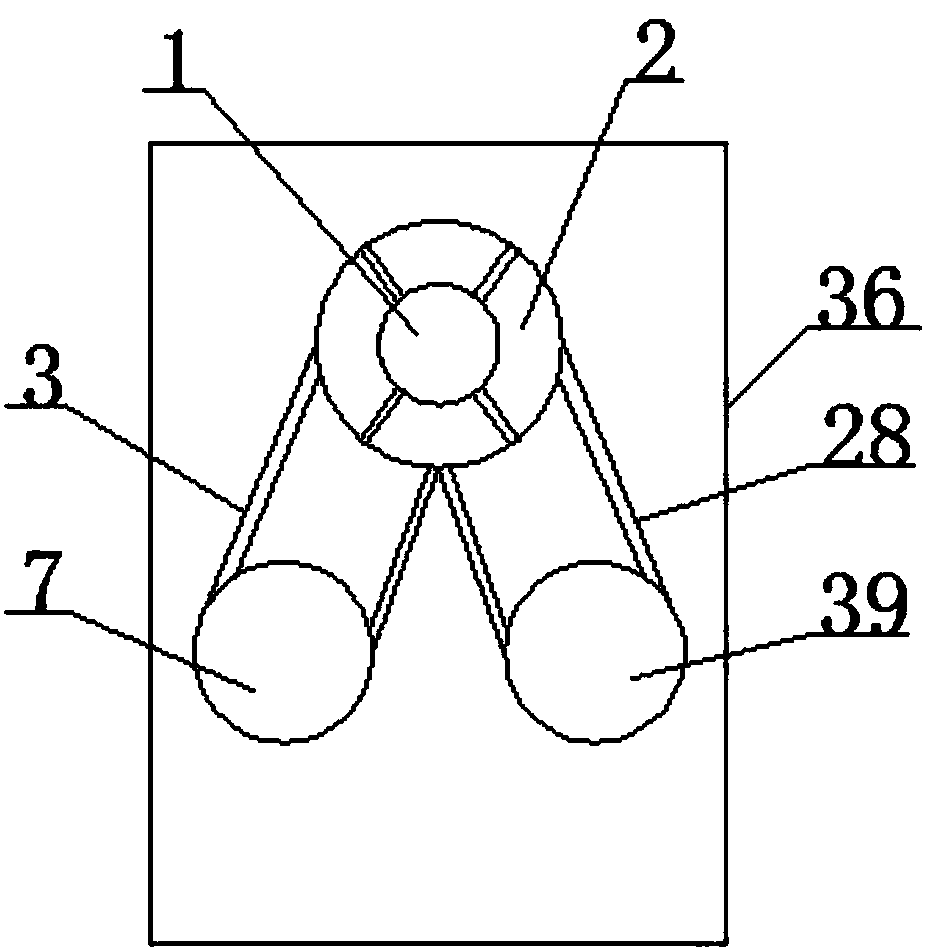

InactiveCN113680417AReduce broken rice rateGuaranteed polishing effectGrain huskingGrain polishingBroken riceMechanical engineering

The invention relates to the technical field of rice processing equipment, and particularly discloses a polishing device for rice production. The polishing device comprises a machine box and a feeding device, wherein a screen panel which is obliquely arranged downwards is arranged in the machine box, the upper end of the screen panel is connected with a material receiving plate which is right opposite to the feeding device, a discharging channel is formed in the position, located below the screen panel, of the machine box, two transmission rollers are arranged in the position, located above the screen panel, of the machine box, a flexible polishing belt is arranged between the two transmission rollers, a large number of polishing balls are embedded in the outer surface of the flexible polishing belt, a fixing plate fixedly connected with the inner wall of the machine box is arranged in the inner ring of the flexible polishing belt, the fixing plate is parallel to the screen panel, and a plurality of buffering pressing devices are connected to the lower surface of the fixing plate. According to the polishing device for rice production, on the premise that the rice polishing effect is guaranteed, the broken rice rate in the polishing process can be greatly reduced, and the rice polishing effect of the whole polishing device is quite excellent.

Owner:安徽省东博米业有限公司

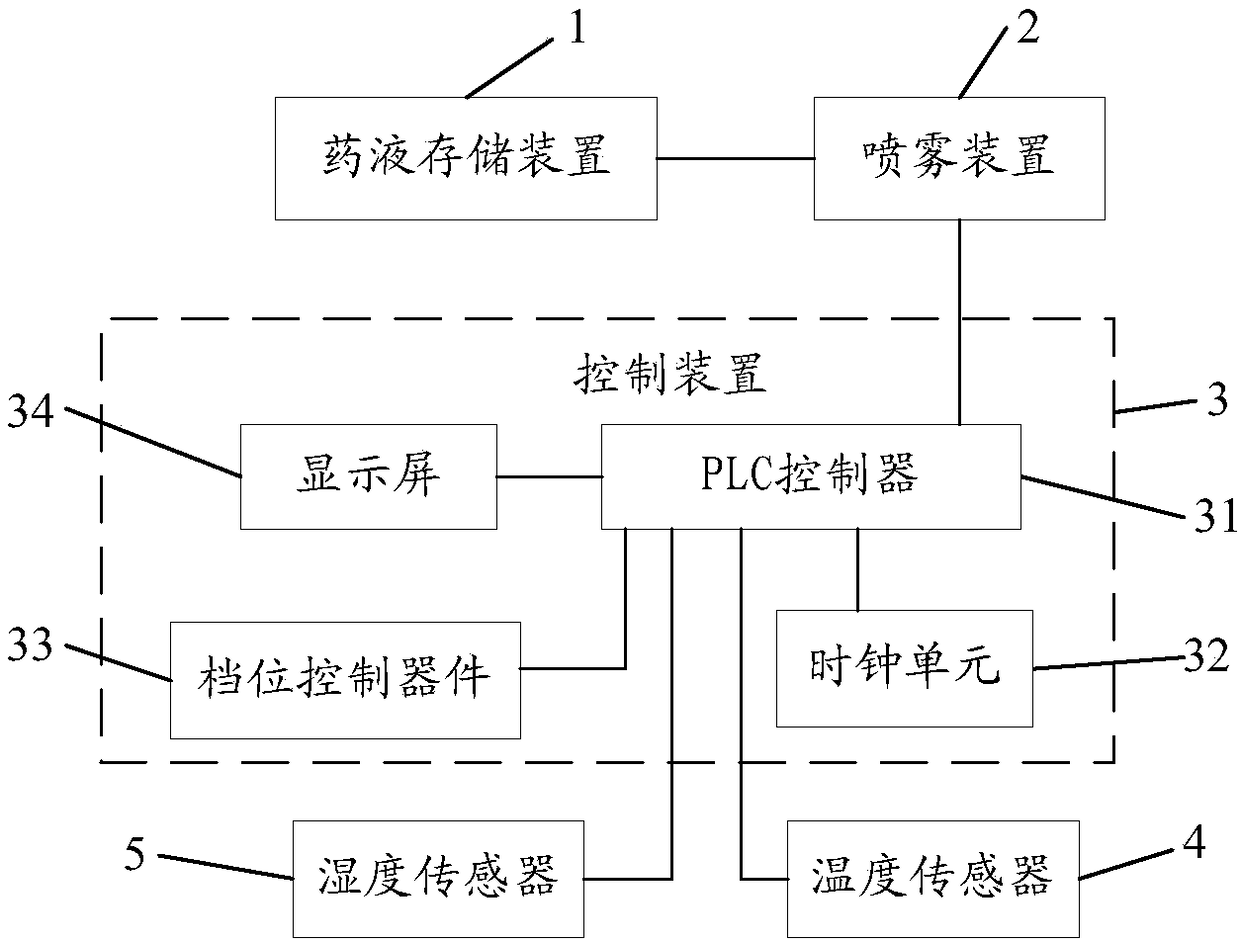

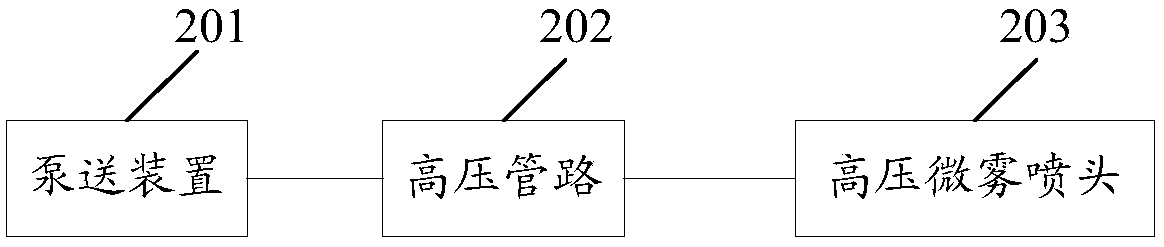

Spraying system for casting workshop

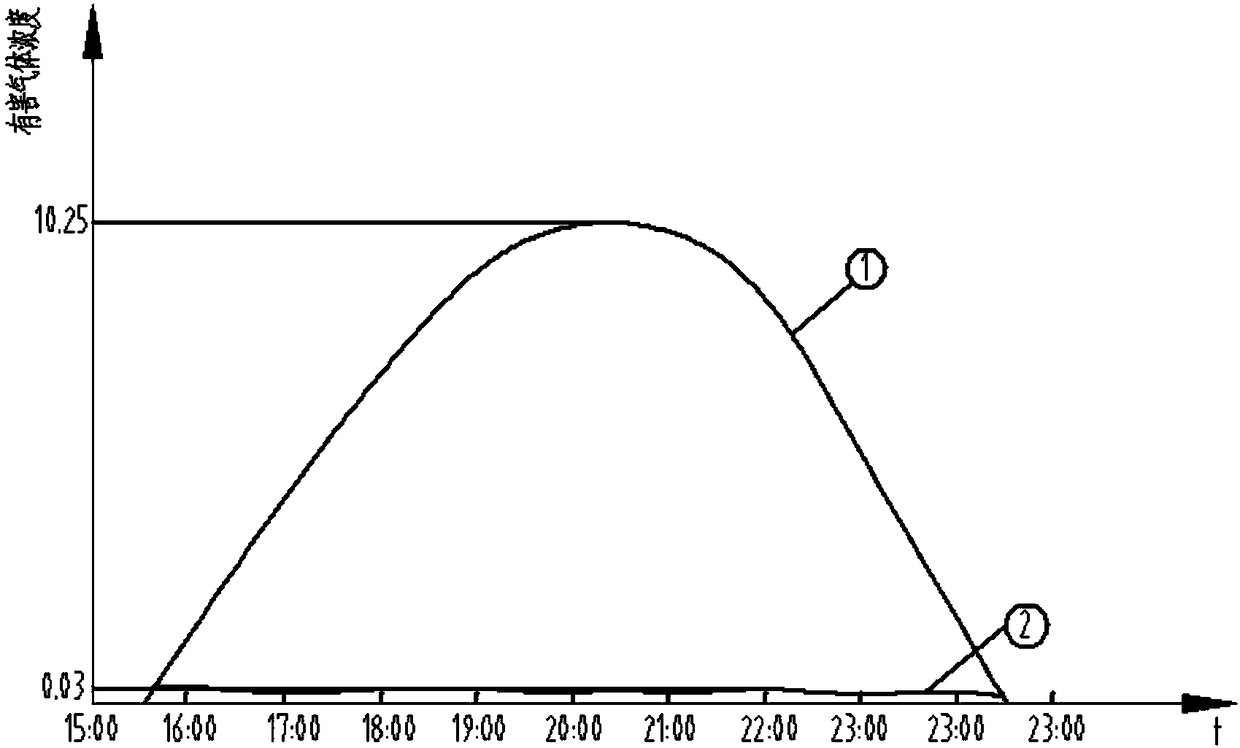

PendingCN108296474ATo achieve the effect of removing harmful gasesTo achieve the purpose of cooling and humidifyingCasting apparatusElectric controlElectrical and Electronics engineering

The invention discloses a spraying system for a casting workshop, and belongs to the technical field of casting. The system comprises a medicine liquid storage device, a spraying device and a controldevice; an outlet of the medicine liquid storage device is connected with an inlet of the spraying device; the spraying device is mounted at the middle upper part of the casting workshop for sprayingthe whole casting workshop; the control device comprises an electric control cabinet, a PLC arranged in the electric control cabinet, and a clock unit and a gear control device arranged in the PLC; acontrol end of the PLC is connected with the spraying device; and after the gear control device is communicated, the PLC controls the spraying device to repeat actions according to present time of theclock unit and according to a mode of intermitting by a certain of time length after spraying by a certain of time length. The system can reduce the temperature and remove the dust and harmful gas atthe same time, can accurately control the spraying quantity, and is simple in structure and low in cost.

Owner:济南圣泉环保科技有限公司

A spraying process of release agent in banburying workshop

ActiveCN105728248BGood water solubilityPrevent subsidencePretreated surfacesCoatingsEngineeringWater jacket

The invention relates to a lower auxiliary system and a spraying process for a mixing workshop separant. The lower auxiliary system comprises a cooling section, a separant spraying section and a drying section which are arranged in sequence, wherein each of the cooling section, the separant spraying section and the drying section is provided with a conveying device; the cooling section comprises a cooling pond and a first draught fan arranged at the discharging end of the cooling pond; the drying section is provided with a second draught fan; and the separant spraying section comprises a separant pond, wherein the separant pond comprises a separant pond body, the outside of the separant pond body is sleeved by a condensed water jacket, a condensed water inlet and a condensed water outlet are formed in the condensed water jacket, an ultrasonic generator is arranged in the separant pond body, and separant nozzles are respectively arranged above and below the separant pond. Three rows of separant nozzles are arranged above the separant pond, three rows of separant nozzles are arranged below the separant pond, and three separant nozzles are arranged in each row. A graphene oxide water solution is suitable for use as a separant, so that the cost can be reduced, and the separating effect can be improved.

Owner:JIANGSU GENERAL SCI TECH

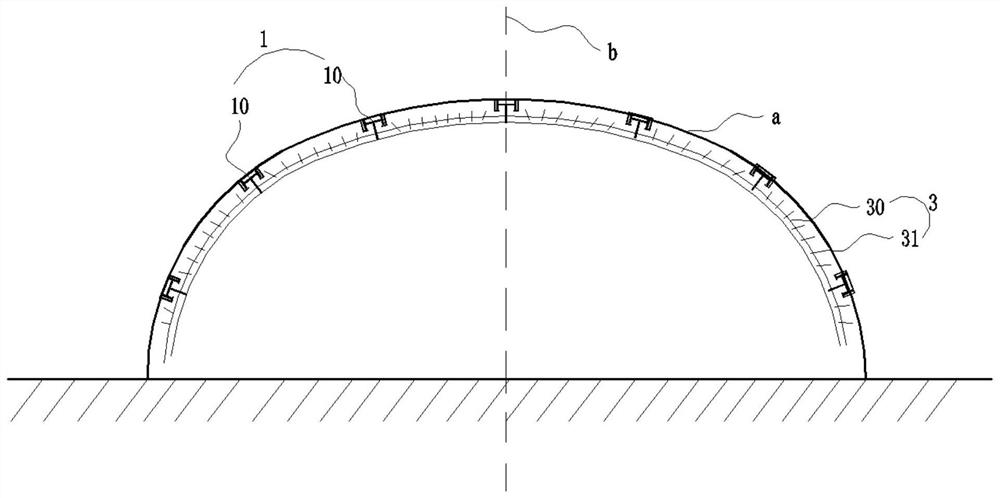

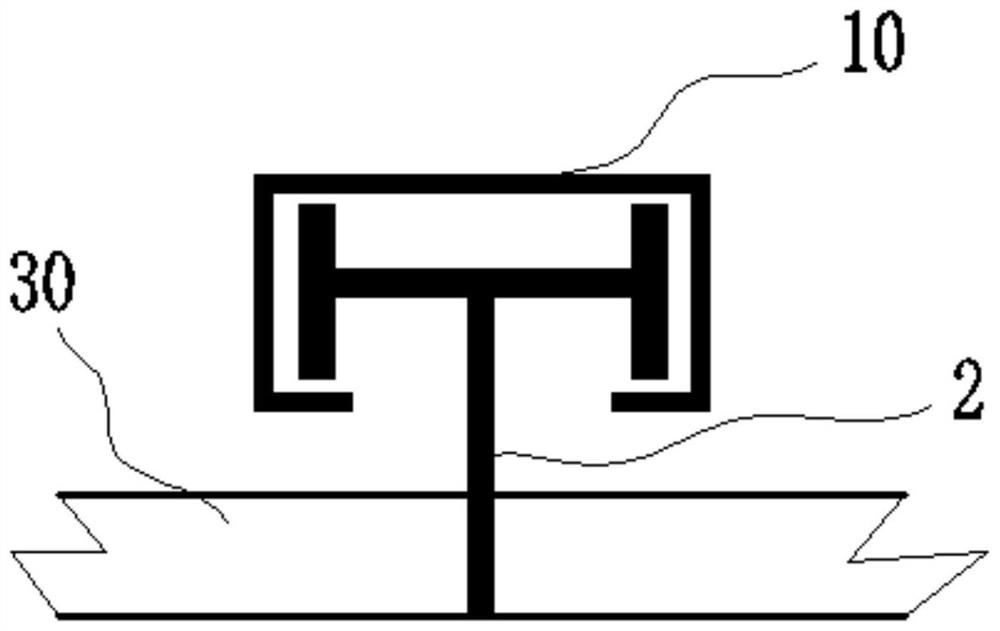

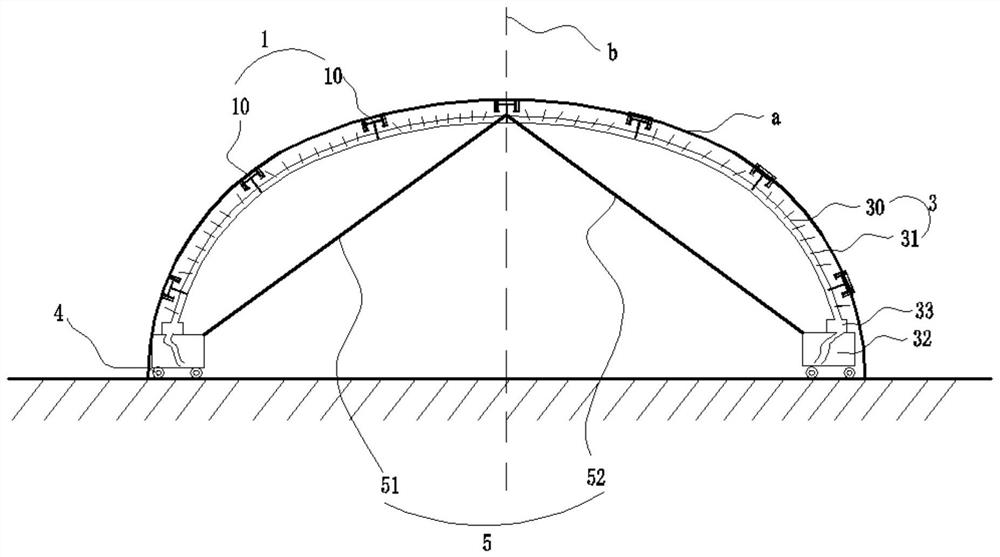

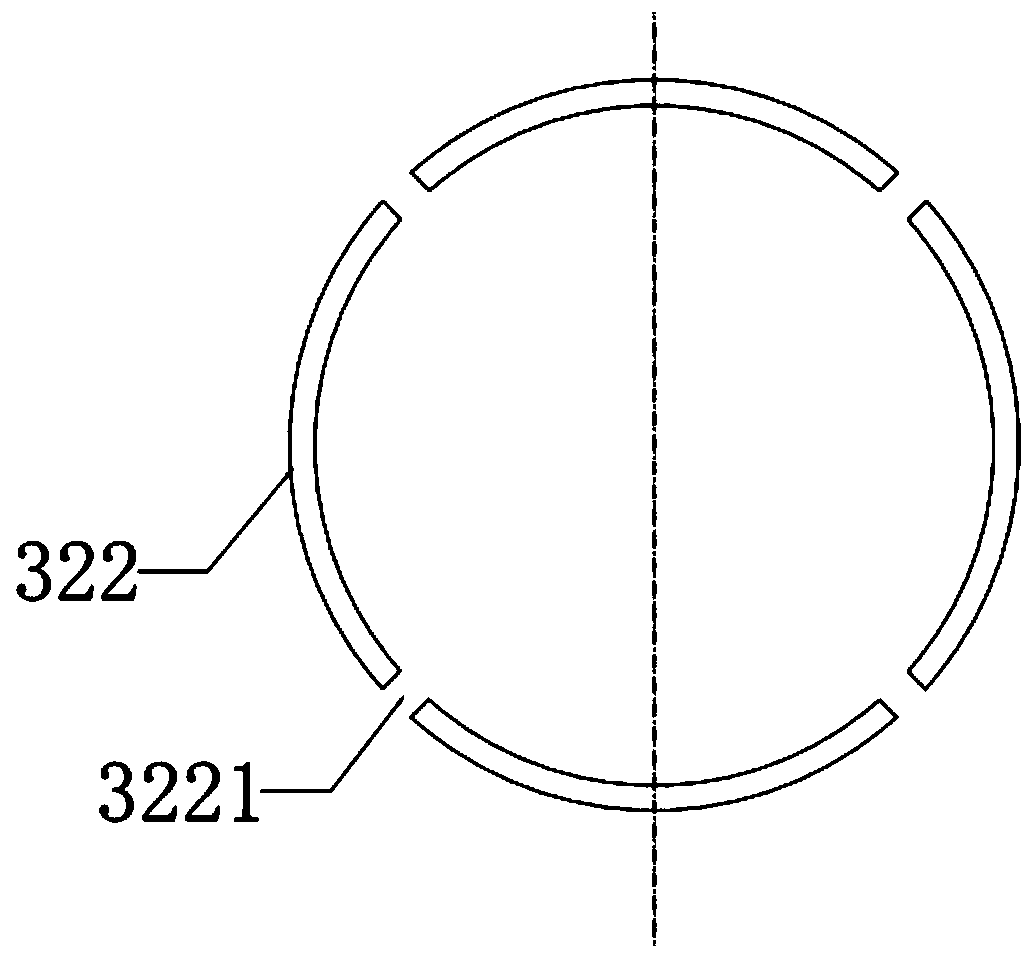

Concrete curing system for tunnel with super-large cross section

PendingCN114183171ARealize fully automatic spraying operationLabor savingUnderground chambersMovable spraying apparatusArchitectural engineeringStructural engineering

The invention discloses a concrete curing system for a tunnel with an ultra-large cross section. The concrete curing system comprises a curing track, a sliding device connected with the curing track and a spraying device connected with the sliding device. Wherein the spraying device comprises an arc-shaped spraying pipeline, the spraying pipeline is arranged in the arc-shaped direction of the tunnel and connected with the sliding device, a plurality of spraying units are arranged on the spraying pipeline, and when liquid is introduced into the spraying pipeline, the spraying units spray the tunnel face. According to the concrete curing system for the tunnel with the super-large cross section, the curing track is fixedly connected to the concrete tunnel face where pouring is completed, then the spraying pipeline is connected with the curing track, spraying is conducted along the concrete tunnel face where pouring is completed, and full-automatic spraying operation is achieved; and manual walking on the maintenance rack is replaced for spraying, so that the labor force is reduced, and the potential safety hazard of manual operation can be effectively avoided.

Owner:中铁隧道局集团建设有限公司

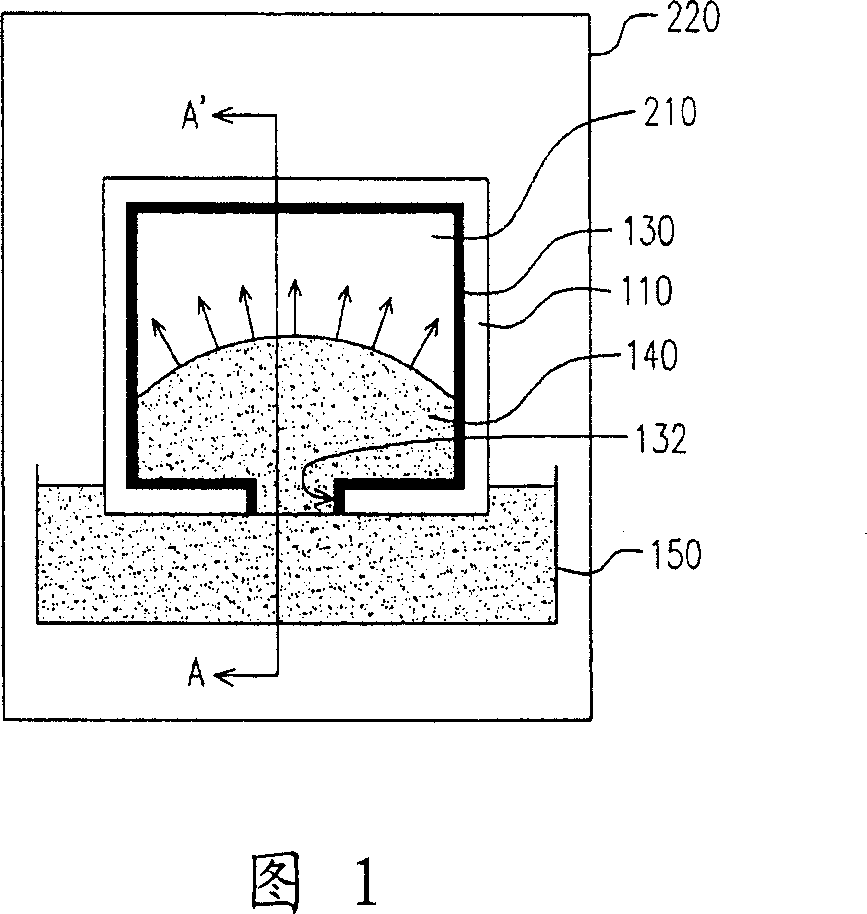

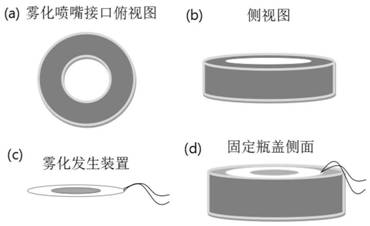

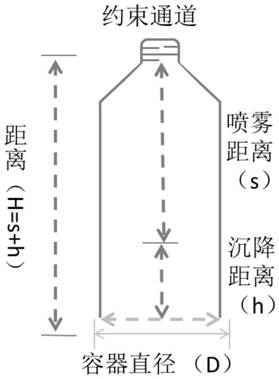

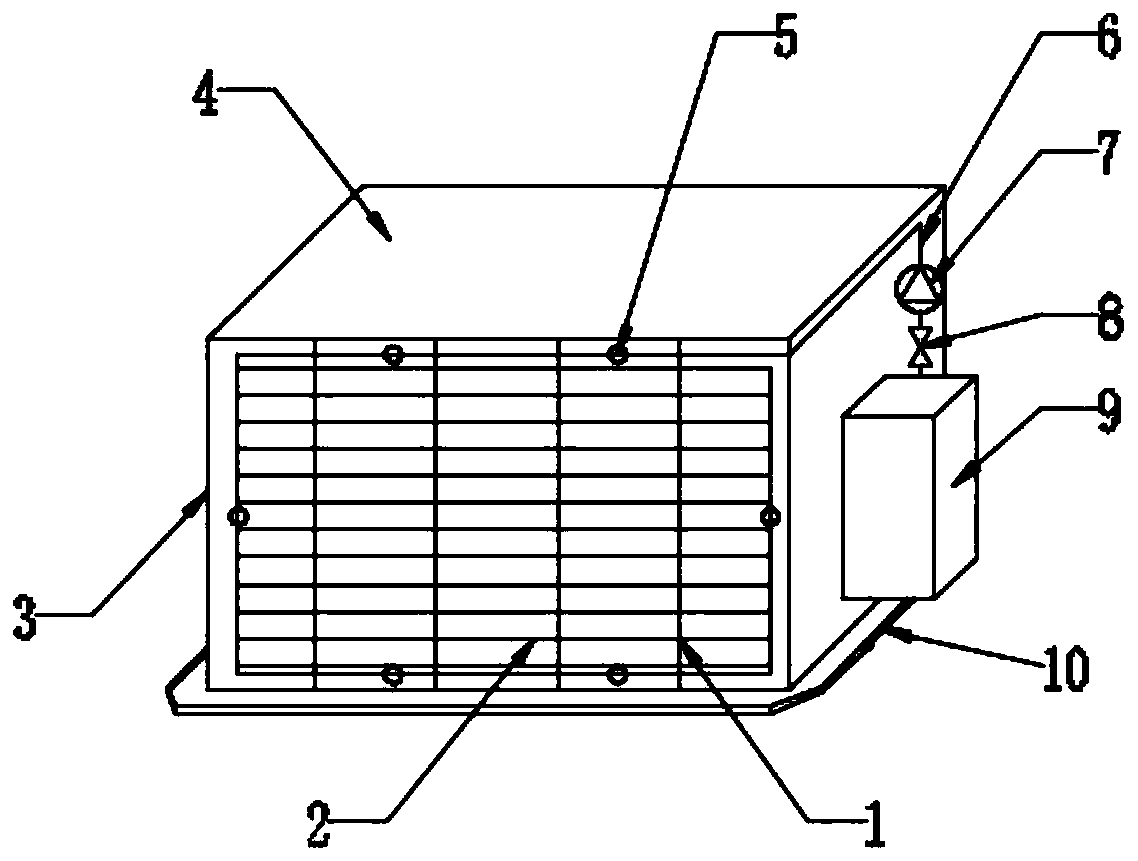

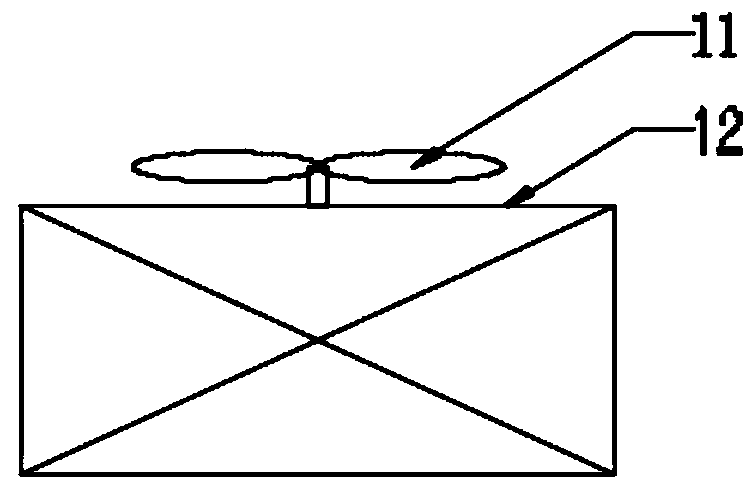

A device for rapid preparation of high-throughput droplet arrays based on spray assistance

ActiveCN112473500BEfficient collectionEffective preservationTransportation and packagingMixing methodsMicro fabricationAerosolize

The invention belongs to the field of biological analysis and micro-manufacturing, and discloses a spray-assisted high-throughput droplet array rapid preparation device, which includes from top to bottom: an aerosol droplet generating device for atomizing liquid To form aerosol droplets, specifically, it is formed by connecting the atomizer and the base; the aerosol droplets restrict the settling channel, which is used to restrict the settlement and diffusion area of the aerosol droplets, so that the settlement of the droplets and the collection area are controlled; the droplet collection interface is used to accept the droplets obtained after settling, and collect the droplet array. And it may be preferred to keep the droplets in air for at least seven days by means of a temperature differential supply assembly. The present invention can effectively solve the problems of liquid droplet array preparation, control and further storage by improving the arrangement of each component in the device and the corresponding working mode, and is a spray-assisted ultra-high-flux liquid droplet array ultra-fast forming device.

Owner:HUAZHONG UNIV OF SCI & TECH

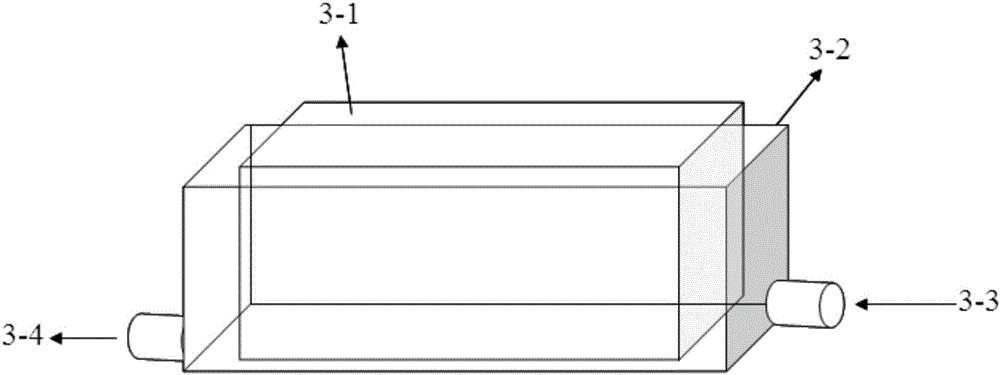

Self-frost-inhibition heat exchanger using condense substances

InactiveCN109780757AControl spray volumeHigh densityEvaporators/condensersCorrosion preventionLiquid storage tankVolumetric Mass Density

The invention belongs to the technical field of refrigeration, and relates to a self-frost-inhibition heat exchanger using condense substances. The heat exchanger comprises fins, heat exchange pipes,a side plate, a top plate, a front cover plate, a fan, an atomization nozzle, a spraying hose, an electromagnetic valve, a plunger pump, a liquid storage tank and a water receiving disc. The condensesubstances are used for lowering the frost crystal forming temperature and increasing the frost layer density to reduce the heat resistance; an alcohol spraying and frost inhibiting unit is added on the basis of a common heat exchanger structure; and the spraying quantity of the condense substances is controlled under the frosting condition to achieve the frost inhibiting purpose by using condensed temperatures of the condense substances with different concentrations according to actual use conditions of the heat exchanger. The heat exchanger is reasonable in design and compact in structure, effectively controls the frosting quantity under the working conditions of low temperature and high humidity, guarantees efficient system operation, has the advantages of high efficiency, low cost, safe operation and convenience to use, and is suitable for such application fields as aerospace.

Owner:DALIAN UNIV OF TECH

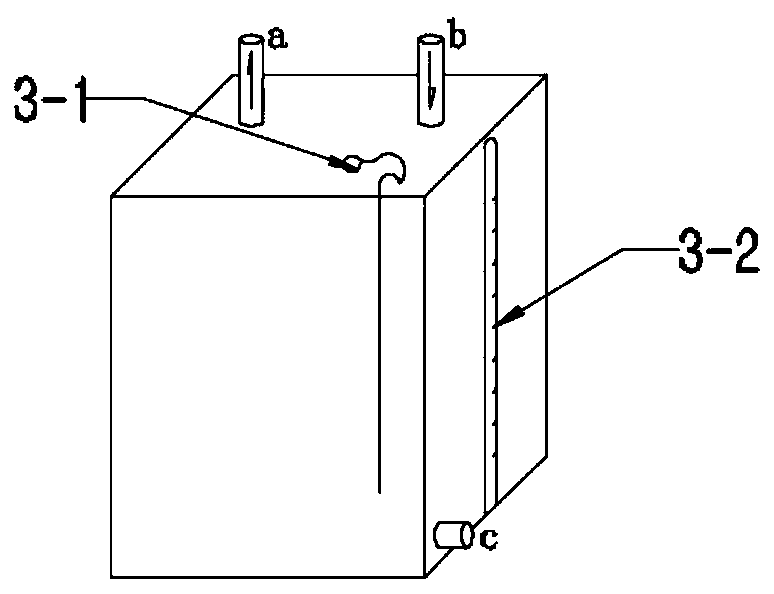

An industrial ceramic dust removal device

ActiveCN107051046BAchieve dust removalNo gapCombination devicesDispersed particle filtrationEngineeringTime control

The invention discloses an industrial ceramic dust removal device, which comprises a tank body, a filtering mechanism and a pneumatic spraying mechanism. The filtering mechanism is arranged in the inner cavity of the tank, and divides the inner cavity of the tank into a first cavity and a second cavity; the pneumatic spraying device includes a pneumatic component and a spraying component. Among them, the pneumatic components include pressure gauges and controllers; the spray components include water inlets, spray pipes, and quick-cut valves. The industrial ceramic dust removal device with this structure, the filter mechanism is sealed and connected with the inner wall of the tank, there is no gap, and the dust removal efficiency is high; the dust or glaze on the filter mechanism is automatically removed through the linkage of the pneumatic component and the spray component, realizing continuous operation and equipment utilization. High efficiency and large production capacity; and according to the degree of dust or glaze deposition on the filter mechanism, the opening of the quick-cut valve can be controlled in real time, saving spray liquid and reducing dust removal costs, especially suitable for dust contained in dusty gas at different times Or the case of uneven glaze concentration.

Owner:JINGDEZHEN CERAMIC UNIV

A vacuum adsorption type floor spraying equipment

ActiveCN106622782BLow bottomImprove the effect of spray paintLiquid spraying apparatusStructural engineeringTransfer mechanism

The invention relates to the technical field of floor processing equipment, in particular to a vacuum adsorption type floor painting equipment. A vacuum adsorption type floor painting equipment, comprising a frame, a floor transmission mechanism arranged on the frame, a plurality of painting mechanisms symmetrically arranged on the frame on both sides of the floor transmission mechanism in the transmission direction, and A paint liquid recovery mechanism connected to the paint spraying mechanism; each of the paint spraying mechanisms includes a paint spray mold, a height adjustment member for adjusting the height of the paint spray mold, and a horizontal position adjustment member for adjusting the distance between the paint spray mold and the floor ; The floor transfer mechanism includes a long-side floor spraying transfer mechanism and a floor short-side spraying transfer mechanism, and a transfer transition part is arranged between the floor long-side spraying transfer mechanism and the floor short-side spraying transfer mechanism. The invention can automatically control the amount of paint spraying, and draw back the excess paint for reuse, which not only protects the environment, but also improves the spray painting effect of the floor.

Owner:湖州涂邦自动化设备科技有限公司

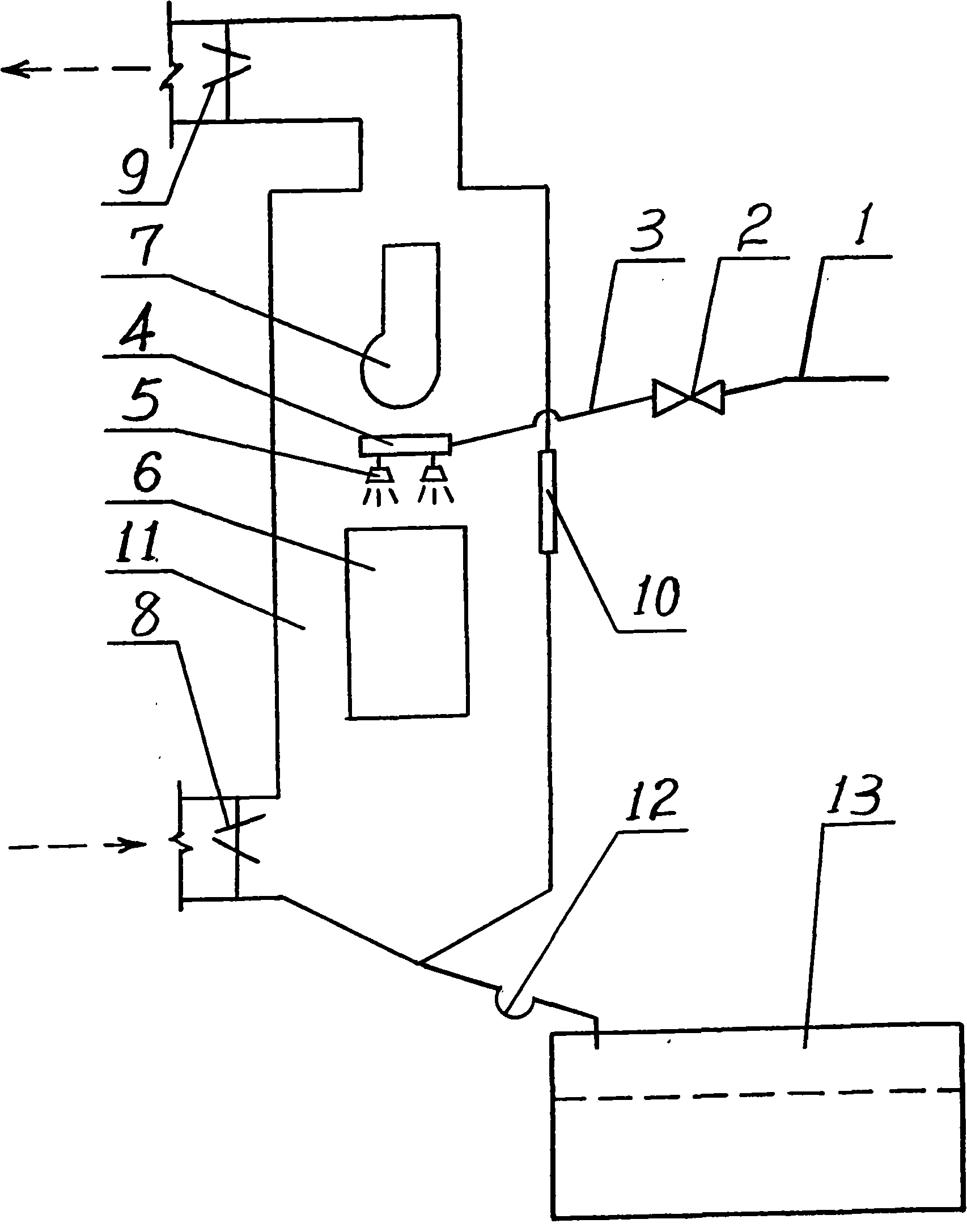

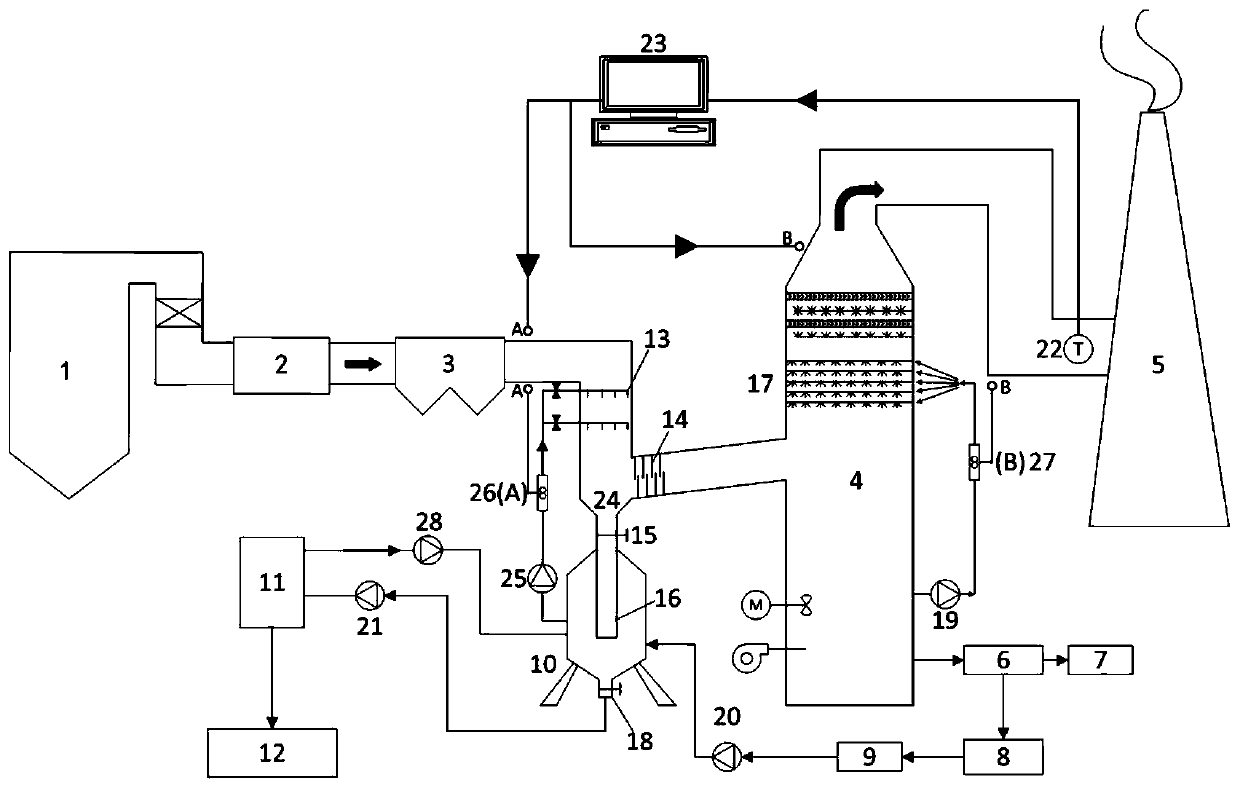

Method and device for coupling treatment of desulfurization wastewater zero discharge and flue gas white elimination for coal-fired power plant

InactiveCN110433609AControl spray volumeSimple processDispersed particle separationWater/sewage treatmentComputer control systemWater vapor

The invention discloses a method and a device for coupling treatment of desulfurization wastewater zero discharge and flue gas white elimination for a coal-fired power plant. The method comprises thefollowing steps that (1) feeding desulfurization wastewater into a water outlet tank to adjust the total water inlet amount of the desulfurization wastewater, and pumping the wastewater into a concentration tank through a water inlet pump, wherein a water collecting pipe is inserted deeply into the concentration tank by at least 1.2 m to prevent flue gas from being poured into the concentration tank; (2) pumping the wastewater in the concentration tank into a spraying device positioned in a vertical flue: (3) enabling sprayed liquid drops to be in direct contact with the low-temperature flue gas behind the electric precipitator for heat exchange, enabling evaporated wastewater steam to enter a desulfurizing tower along with the flue gas, and enabling unevaporated wastewater to enter the concentration tank again; and 4) filtering and separating the solid-liquid mixed salt solution at the bottom of the concentration tank through a membrane separation system, feeding the filtrate back tothe concentration tank again, and transporting the crystallized mixed salt outside for landfilling. The device comprises an air pre-heater, an electric dust remover, a concentration spraying part, anabsorption tower, a chimney, a dehydration system, a water outlet tank, a microfiltration separation system and a computer control system.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Automobile spare part coating device capable of automatically controlling coating quantity according to sizes of spare parts

ActiveCN113414025AAutomatic control of spray volumeControl spray volumeSpray boothsRatchetGear wheel

The invention relates to the technical field of automobile spare parts, and discloses an automobile spare part coating device capable of automatically controlling the coating quantity according to the sizes of the spare parts. The device comprises a mounting mechanism and a placing mechanism, wherein the mounting mechanism comprises a supporting seat; the outer surface of the supporting seat is movably connected with an annular plate; the outer surface of the supporting seat is fixedly connected with a limiting seat; the placing mechanism comprises a placing frame; a jacking plate is movably connected to the interior of the placing frame, an elastic pressing rod is movably connected to the surface of the jacking plate; the device further comprises a coating mechanism; the coating mechanism comprises a connecting rod; one end of the connecting rod is movably connected with a movable gear; and a ratchet frame is movably connected to the outer surface of the movable gear. According to the different sizes of different spare parts, the moving distances of the elastic pressing rod and the connecting rod are different, then the different moving distances of a piston rod in a coating base are indirectly controlled, the spray amount is indirectly controlled, and waste is avoided.

Owner:中技佳智能装备科技(广州)有限公司

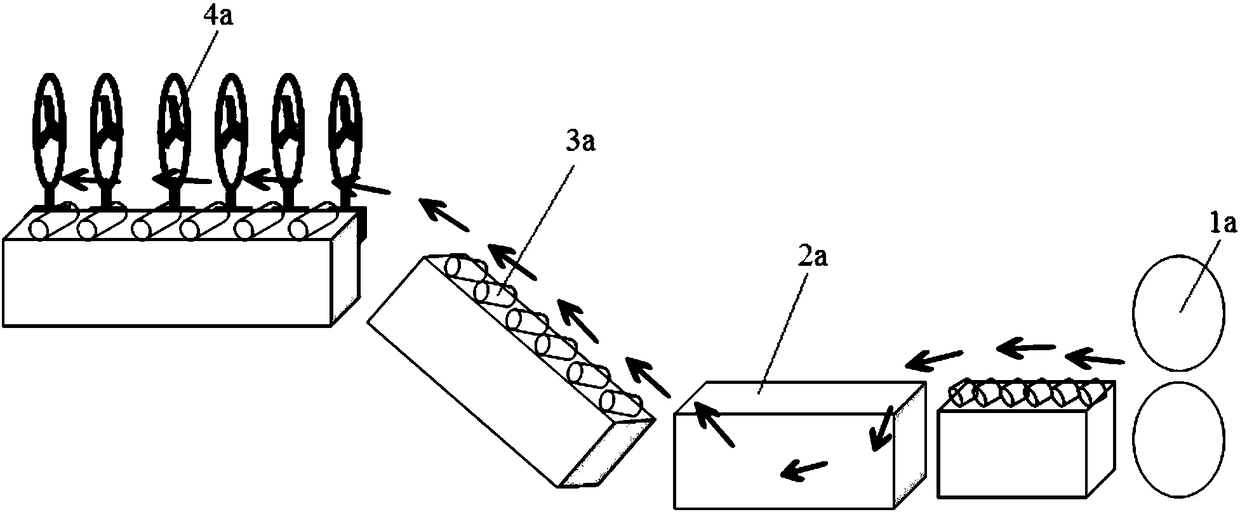

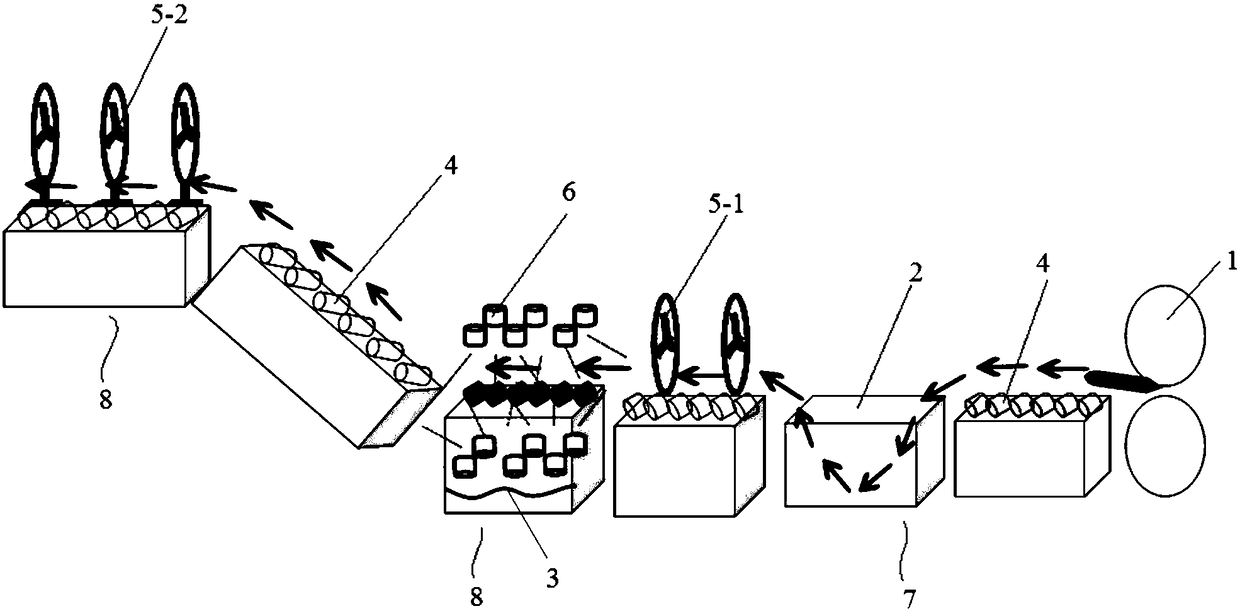

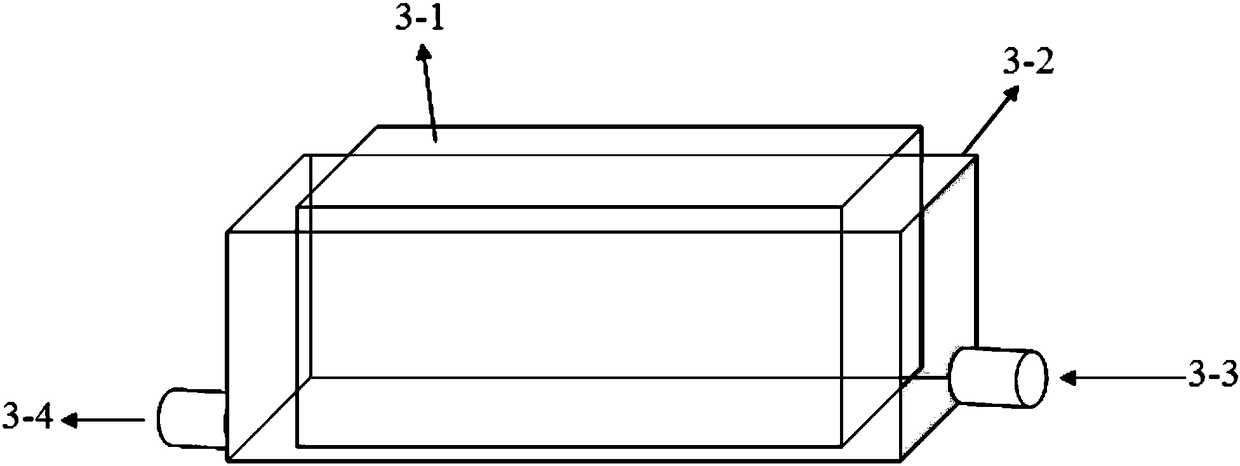

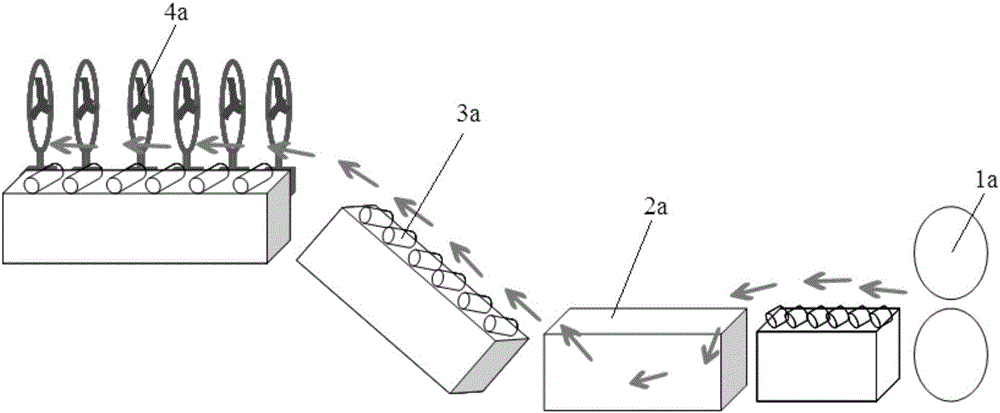

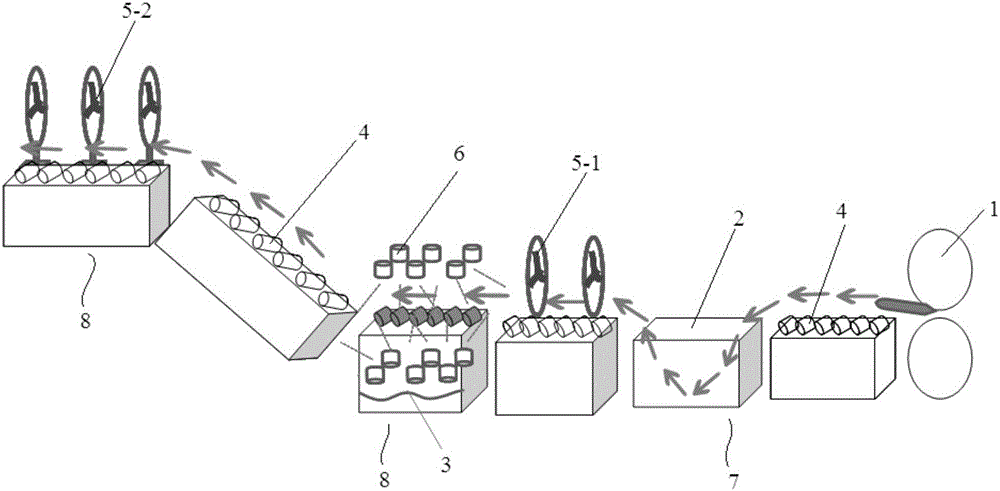

A high-yield fuel cell catalytic electrode coating production method and equipment thereof

ActiveCN112599791BQuality assuranceGood adhesionLiquid surface applicatorsCell electrodesPtru catalystPhysical chemistry

The invention discloses a high-yield fuel cell catalytic electrode coating production method and equipment thereof. The method includes the following steps: S1. Add solid catalyst particles and perfluorosulfonic acid resin solution into deionized water and low-boiling alcohol A kind of solvent and slow drying agent, disperse and defoam to obtain catalyst slurry; S2, select the first preset process to apply to one side of the proton exchange membrane, and completely dry to form catalytic layer A; S3, apply catalyst slurry on on the support, and make it through multi-channel functionalized spraying treatment to form a support complex with a gel state layer; S4, hot-press the support complex with a gel state layer and the other side of the proton exchange membrane Transfer, transfer the gel state layer on the support complex to the other side of the proton exchange membrane to obtain a catalytic electrode; the membrane electrode of the present invention solves the swelling of the proton exchange membrane and the removal of the catalytic layer by means of hot pressure transfer during the preparation process. Problems such as falling, and the yield is high, and the electrochemical performance of the catalytic layer is excellent.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

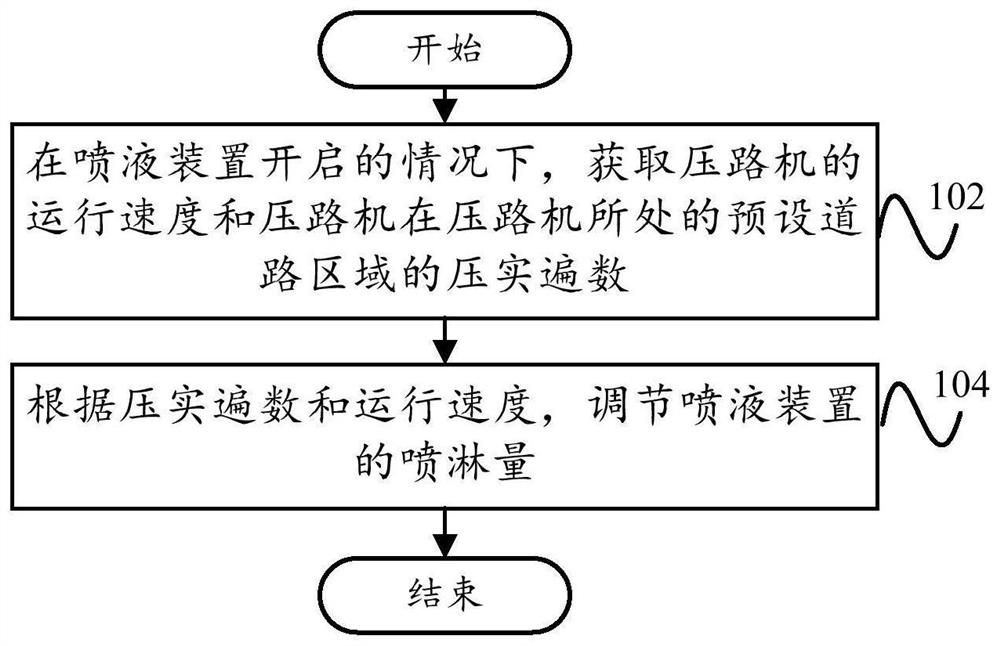

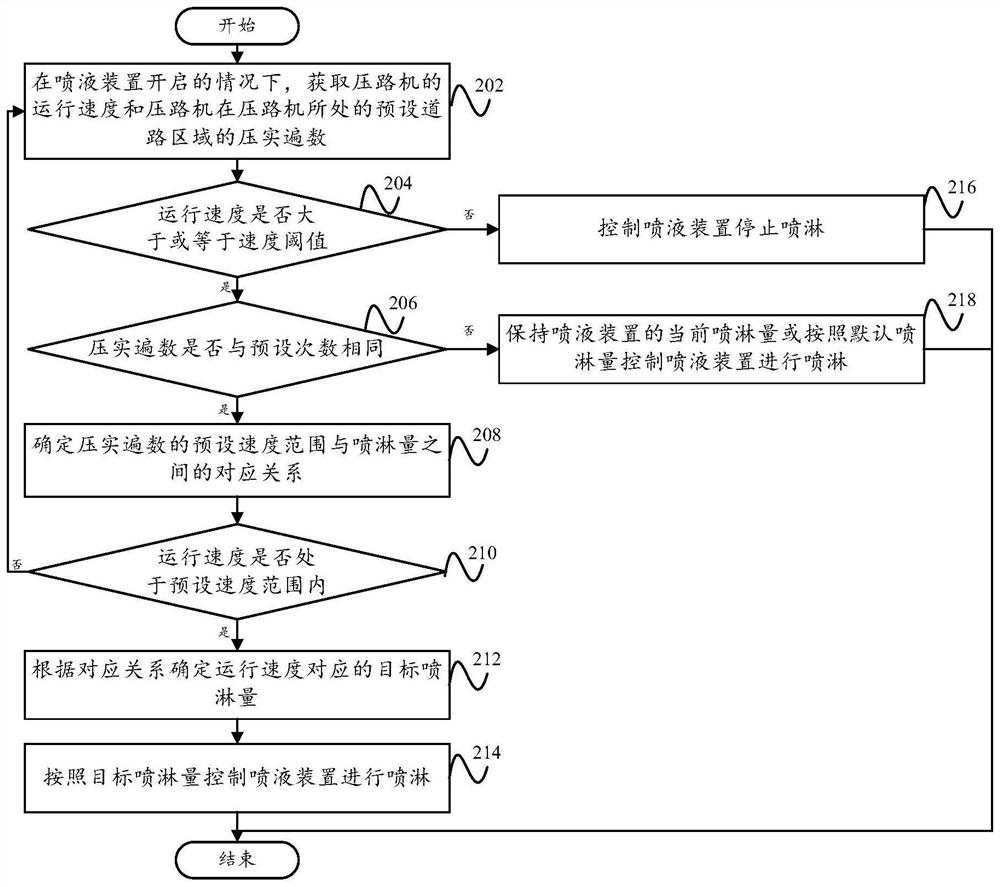

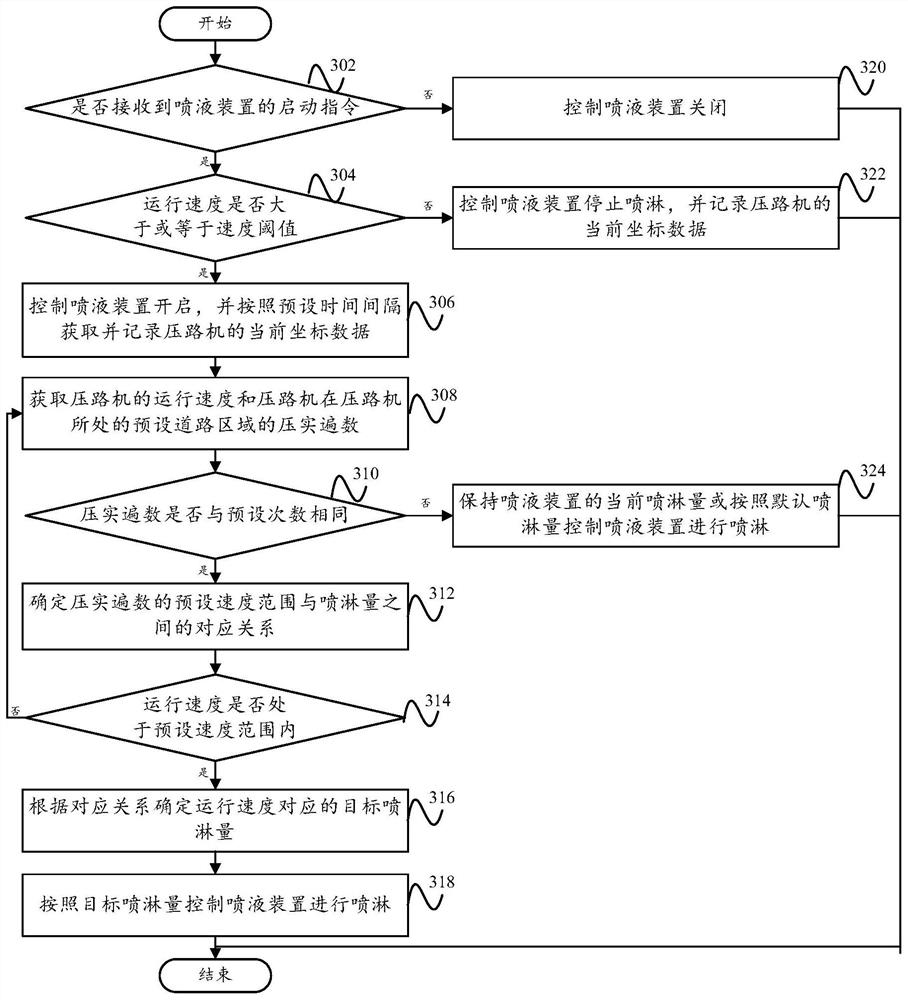

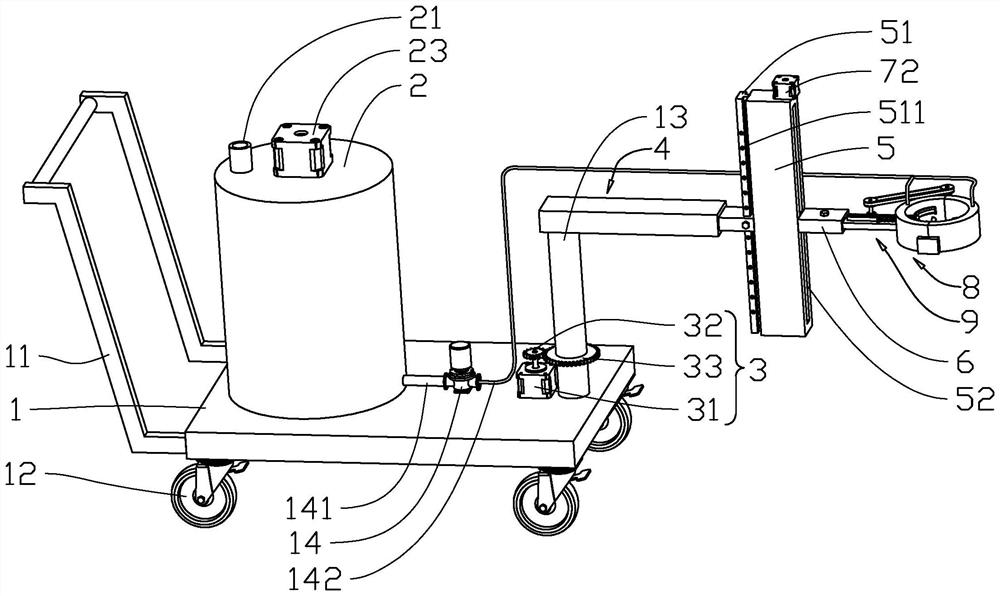

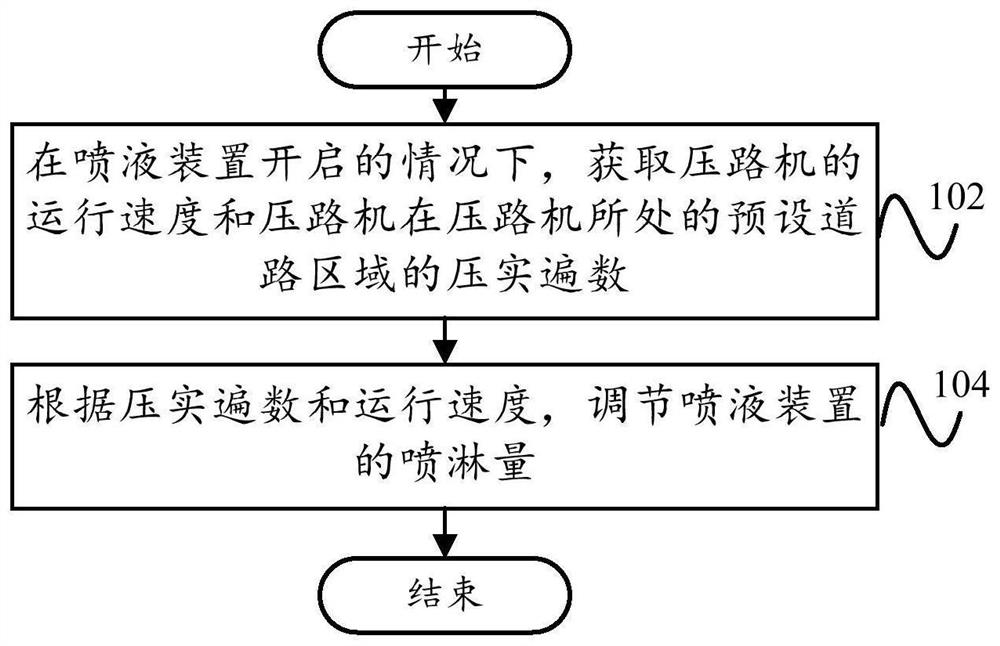

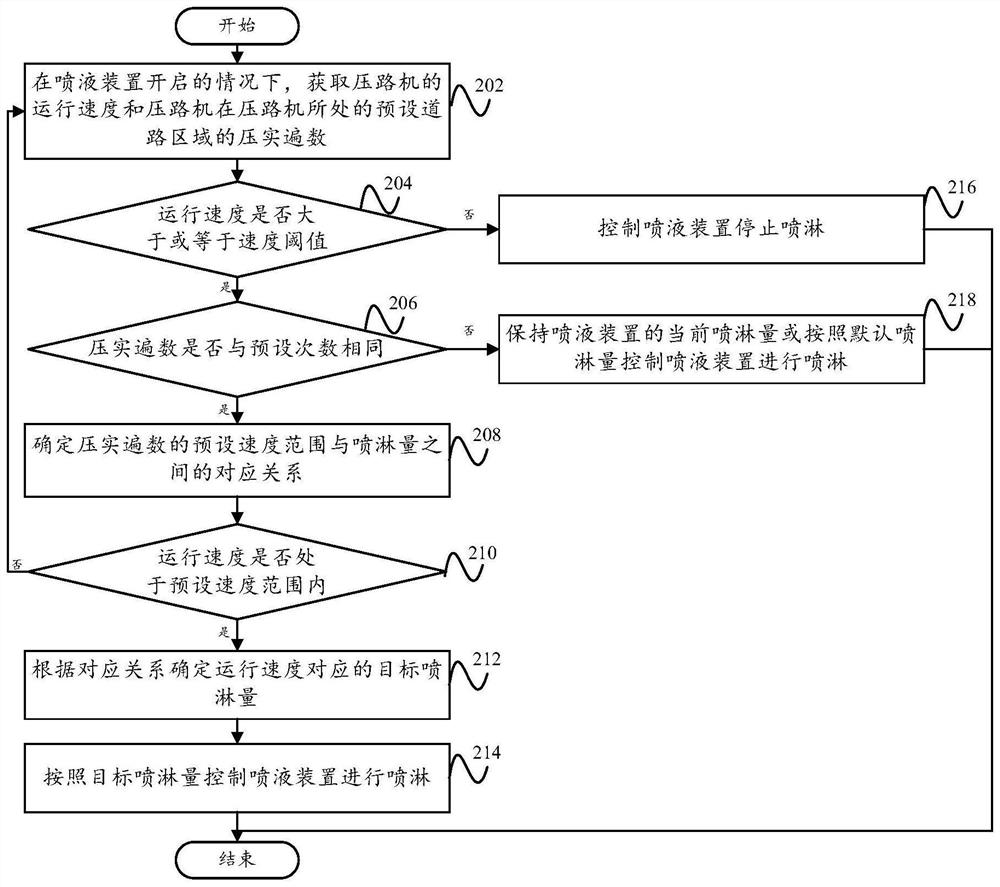

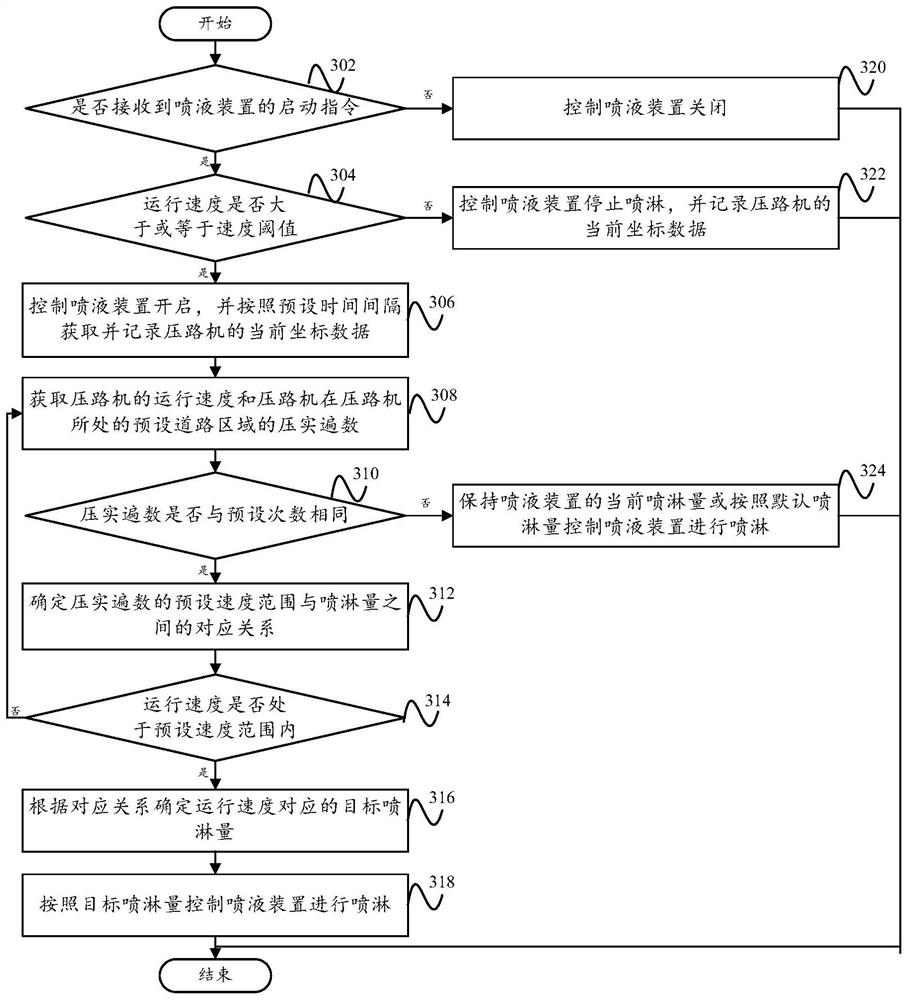

Road roller liquid spraying control method and system, road roller and readable storage medium

ActiveCN113389109AControl spray volumeLow structural requirementsRoads maintainenceControl engineeringRoad surface

The invention provides a road roller liquid spraying control method and system, a road roller and a readable storage medium. The method comprises the steps: under the condition that a liquid spraying device is started, acquiring the running speed of the road roller and the number of times of compaction of the road roller in a preset road area where the road roller is located; and adjusting the spraying amount of the liquid spraying device according to the compaction times and the operation speed. On one hand, the automatic liquid spraying device does not need to wipe water or oil along with the machine manually, the labor cost is reduced, and most importantly, the use safety risk of oil / water wiping of the road roller can be greatly reduced, and then safety accidents are avoided. On the other hand, the spraying amount self-adaptive control strategy is optimized, so that the road roller can meet the spraying amount requirements of different running speeds and construction times in the road compacting process, the wheel sticking phenomenon of the road roller is prevented, meanwhile, resource waste is greatly reduced, the situation that too much liquid pollutes the road surface can be avoided, the working quality of the whole machine is improved, and the use cost of the whole machine is reduced.

Owner:HUNAN SANY ROAD MACHINERY

Tree spraying device for municipal greening

PendingCN114405714AImprove work efficiencyImprove butt strengthSpraying apparatusPlant protectionAgricultural engineeringStructural engineering

The invention discloses a tree spraying device for municipal greening, and belongs to the field of municipal greening equipment, the tree spraying device for municipal greening comprises a base and a storage barrel arranged on the base and used for containing materials, universal wheels are arranged at four corners of the bottom surface of the base, a mounting table is arranged on the base, a spraying assembly is arranged on the mounting table, and the spraying assembly is arranged on the mounting table. The spraying assembly comprises a connecting plate arranged on the mounting table, a first arc-shaped plate fixedly connected to the connecting plate and a second arc-shaped plate hinged to the first arc-shaped plate, and the first arc-shaped plate and the second arc-shaped plate are each provided with a plurality of spraying heads used for spraying materials. The first arc-shaped plate is provided with a driving assembly used for driving the second arc-shaped plate to rotate. The tree spraying device has the effect of improving the working efficiency of the tree spraying device.

Owner:芜湖萃艺园林绿化有限公司

Methyl bromide impurity removal process adopting strong base

PendingCN112047806AHigh yieldEfficient removalHalogenated hydrocarbon preparationPhysical chemistrySodium hydroxide

The invention relates to a methyl bromide impurity removal process adopting strong alkali, which belongs to the field of methyl bromide purification. The process comprises the following steps: (1), performing neutralization treatment: introducing methyl bromide gas into alkali liquor for neutralization treatment; and (2), performing drying treatment: introducing bromomethane obtained in the step (1) into a sulfuric acid solution for drying treatment. The alkali liquor is a sodium hydroxide solution with the mass concentration of 15-26%. The process disclosed by the invention has the effects ofsimple operation, low energy consumption and high purity of the obtained bromomethane.

Owner:临海市建新化工有限公司

Lower auxiliary system and spraying process for mixing workshop separant

ActiveCN105728248AGood water solubilityIncrease single layer rateLiquid surface applicatorsCoatingsEngineeringWater jacket

The invention relates to a lower auxiliary system and a spraying process for a mixing workshop separant. The lower auxiliary system comprises a cooling section, a separant spraying section and a drying section which are arranged in sequence, wherein each of the cooling section, the separant spraying section and the drying section is provided with a conveying device; the cooling section comprises a cooling pond and a first draught fan arranged at the discharging end of the cooling pond; the drying section is provided with a second draught fan; and the separant spraying section comprises a separant pond, wherein the separant pond comprises a separant pond body, the outside of the separant pond body is sleeved by a condensed water jacket, a condensed water inlet and a condensed water outlet are formed in the condensed water jacket, an ultrasonic generator is arranged in the separant pond body, and separant nozzles are respectively arranged above and below the separant pond. Three rows of separant nozzles are arranged above the separant pond, three rows of separant nozzles are arranged below the separant pond, and three separant nozzles are arranged in each row. A graphene oxide water solution is suitable for use as a separant, so that the cost can be reduced, and the separating effect can be improved.

Owner:JIANGSU GENERAL SCI TECH

Road roller spraying liquid control method, system, road roller and readable storage medium

ActiveCN113389109BControl spray volumeLow structural requirementsRoads maintainenceAgricultural engineeringEnvironmental engineering

The invention provides a road roller spray liquid control method, a system, a road roller and a readable storage medium. Wherein, the method includes: when the liquid spraying device is turned on, obtaining the running speed of the road roller and the number of compaction times of the road roller in the preset road area where the road roller is located; adjusting the speed of the liquid spraying device according to the number of compaction times and the running speed Spray volume. On the one hand, the automatic liquid spraying device does not need to manually apply water or oil to the machine, which reduces labor costs. Most importantly, it can greatly reduce the safety risk of oiling / watering the road roller, thereby avoiding safety accidents. On the other hand, optimizing the self-adaptive control strategy of spray volume enables the road roller to take into account the spray volume requirements of different operating speeds and construction times during the road compaction process, which greatly reduces the waste of resources while preventing the wheel from sticking to the road roller, and It can also avoid excessive liquid pollution on the road surface, thereby improving the working quality of the whole machine and reducing the cost of using the whole machine.

Owner:HUNAN SANY ROAD MACHINERY

Uniform spraying device for liquid feed additive

InactiveCN114308444AControl spray volumeLarge amount of sprayFeeding-stuffSpraying apparatusThermodynamicsEngineering

The invention relates to the field of feed processing, in particular to a liquid feed additive uniform spraying device which comprises a supporting plate, a feeding plate, a movable wheel, a weight fluctuation assembly and the like. A feeding plate is jointly and fixedly connected between the two supporting plates, the upper portions of the supporting plates are rotationally connected with a pair of movable wheels, and weight fluctuation assemblies are arranged on the supporting plates. When the feed conveyed on the conveying belt is less, the liquid additive sprayed on the surface of the feed on the conveying belt is less; when a large amount of feed is conveyed on the conveying belt, a large amount of liquid additive is sprayed on the surface of the feed on the conveying belt, so that the spraying amount of the liquid additive is adaptively controlled according to the amount of the feed conveyed on the conveying belt.

Owner:山东炎辰生物科技有限公司

Vacuum adsorption floor paint spraying device

ActiveCN106622782ALow bottomImprove the effect of spray paintLiquid spraying apparatusAutomatic controlEngineering

The invention relates to the technical field of floor processing devices, in particular to a vacuum adsorption floor paint spraying device. The vacuum adsorption floor paint spraying device includes a rack, a floor conveying mechanism arranged on the rack, a plurality of paint spraying mechanisms which are symmetrically arranged on rack and positioned on two sides of the conveying direction of the floor conveying mechanism, and a paint recovery mechanism connected to the paint spraying mechanisms; each paint spraying mechanism includes a paint spraying die, a height adjustment member for adjusting the height of the paint spraying die, and a horizontal position adjustment member for adjusting the distance between the paint spraying die and the floor; and the floor conveying mechanism includes a floor long edge paint spraying conveying mechanism and a floor short edge paint spraying conveying mechanism, wherein a conveying transition part is arranged between the floor long edge paint spraying conveying mechanism and the floor short edge paint spraying conveying mechanism. The vacuum adsorption floor paint spraying device can automatically control the paint spraying amount, can reuse excess paint, can protect the environment, and can improve the paint spraying effect of the floor.

Owner:湖州涂邦自动化设备科技有限公司

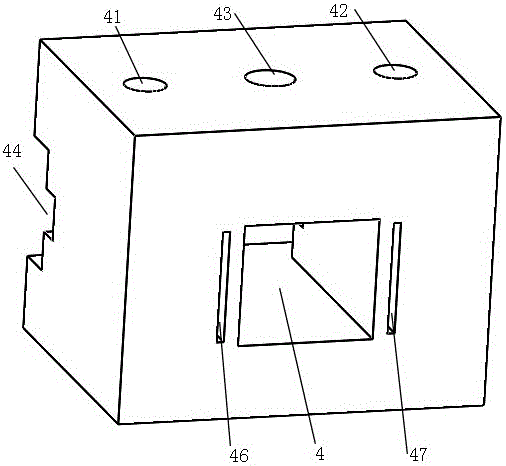

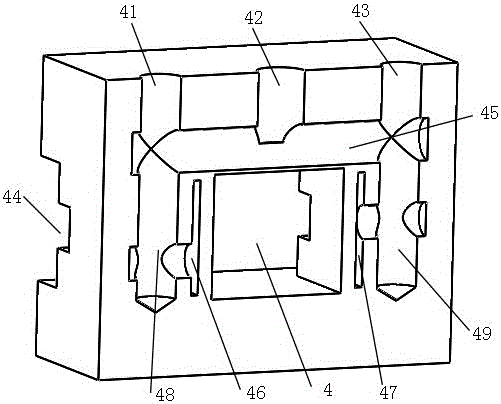

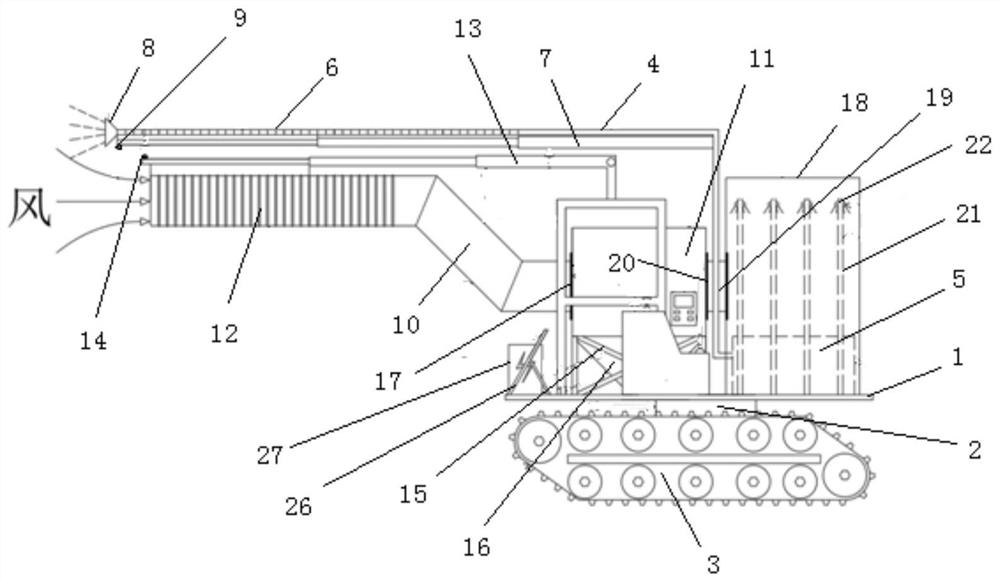

A tunnel dust removal vehicle

ActiveCN111005752BImprove dust removal effectImprove economyDust removalFire preventionDust controlStructural engineering

Owner:SHANDONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com