Automobile spare part coating device capable of automatically controlling coating quantity according to sizes of spare parts

A technology for auto parts and painting, applied in the direction of spraying devices, spray booths, etc., can solve the problems affecting the processing of auto parts, the trouble of controlling the amount of coating, and low intelligence, so as to speed up the coating effect, avoid waste, and accelerate molding Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

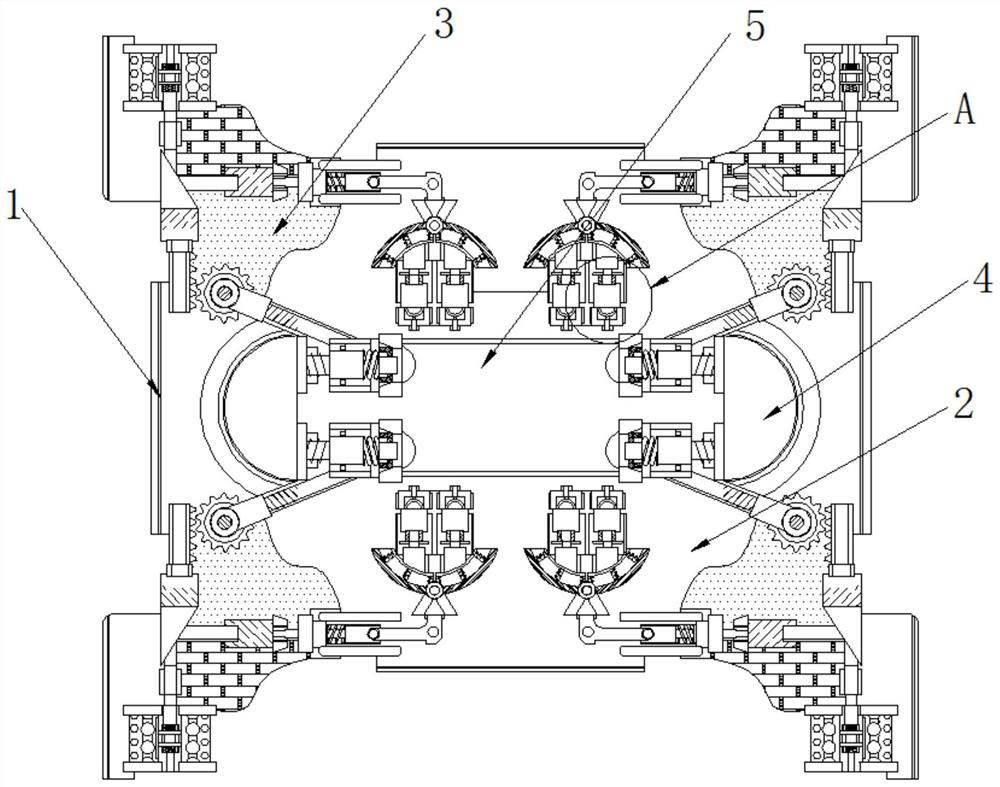

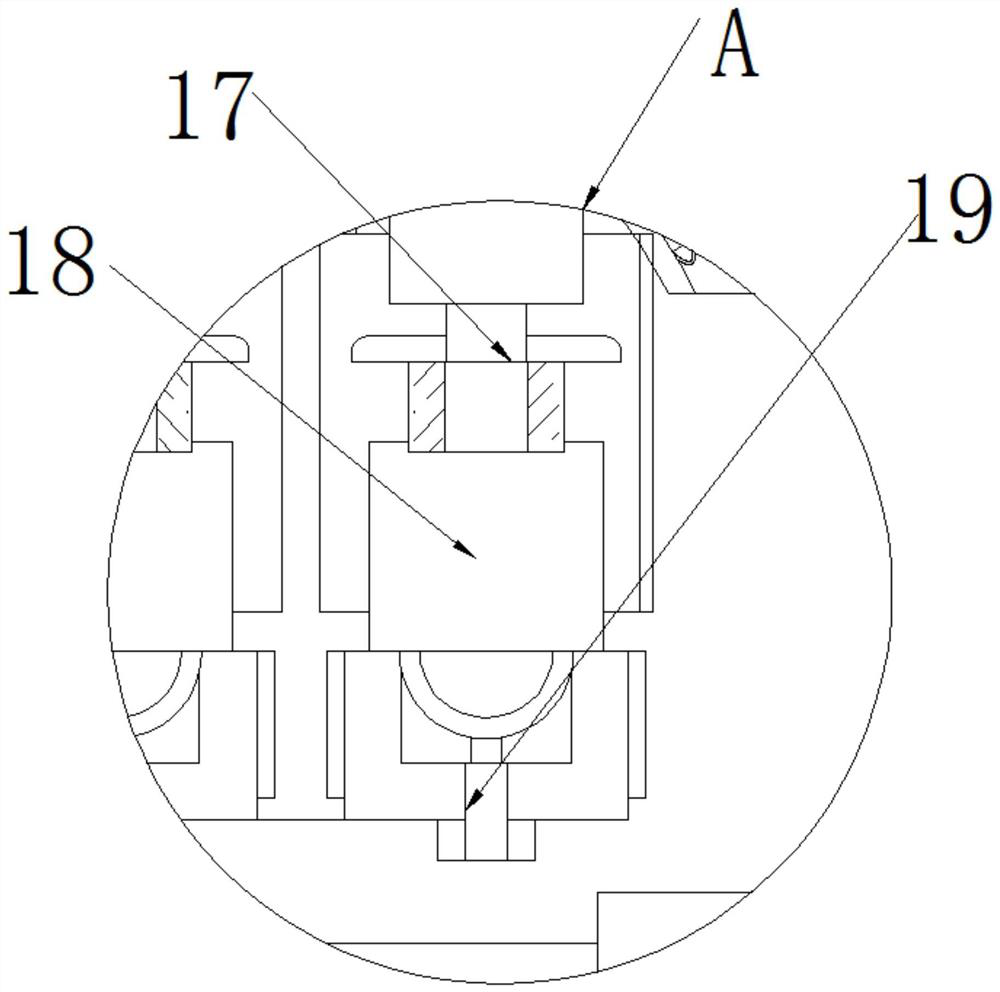

[0021] as attached figure 1 to attach Figure 4 Shown:

[0022] A coating device for auto parts that can automatically control the amount of coating according to the size of the parts, including a mounting mechanism 1 and a placement mechanism 2, the mounting mechanism 1 includes a support seat 3, the outer surface of the support seat 3 is movably connected with an annular plate 4, and the support seat The outer surface of 3 is fixedly connected with limit seat 5.

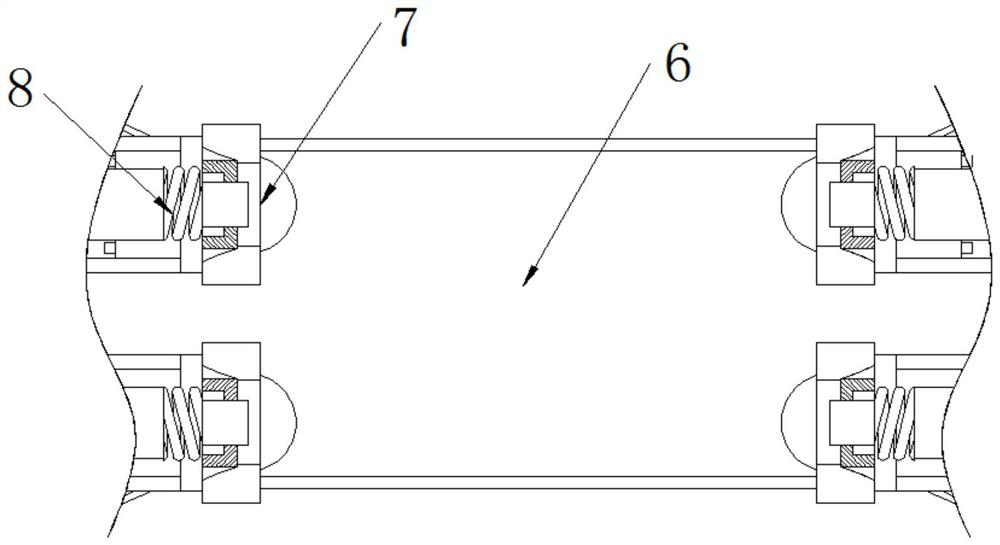

[0023] The placing mechanism 2 includes a placing frame 6 , the inside of the placing frame 6 is movably connected with a holding plate 7 , and the surface of the holding plate 7 is movably connected with an elastic pressure rod 8 .

[0024] Further, it also includes a coating mechanism 9, the coating mechanism 9 includes a connecting rod 10, one end of the connecting rod 10 is movably connected with a movable gear 11, and the outer surface of the movable gear 11 is movably connected with a ratchet frame 12, and ...

specific Embodiment approach 2

[0026] as attached Figure 4 to attach Figure 5 Shown:

[0027] A coating device for auto parts that can automatically control the amount of coating according to the size of the parts, including a mounting mechanism 1 and a placement mechanism 2, the mounting mechanism 1 includes a support seat 3, the outer surface of the support seat 3 is movably connected with an annular plate 4, and the support seat The outer surface of 3 is fixedly connected with limit seat 5.

[0028] Further, it also includes a sizing mechanism 20, the sizing mechanism 20 includes a cylindrical rod 21, one end of the cylindrical rod 21 is movably connected with a bag seat 22, and the inside of the bag seat 22 is movably connected with an extension spring seat 23, and the outer surface of the bag seat 22 is An air blowing pipe 24 is movably connected, and one side of the air blowing pipe 24 is movably connected with an air collecting seat 25 .

[0029] During the movement of the corner seat 13 driven ...

specific Embodiment approach 3

[0030] as attached figure 1 to attach Figure 5 Shown:

[0031] A coating device for auto parts that can automatically control the amount of coating according to the size of the parts, including a mounting mechanism 1 and a placement mechanism 2, the mounting mechanism 1 includes a support seat 3, the outer surface of the support seat 3 is movably connected with an annular plate 4, and the support seat The outer surface of 3 is fixedly connected with limit seat 5.

[0032] The placing mechanism 2 includes a placing frame 6 , the inside of the placing frame 6 is movably connected with a holding plate 7 , and the surface of the holding plate 7 is movably connected with an elastic pressure rod 8 .

[0033] The coating mechanism 9 includes a connecting rod 10, one end of the connecting rod 10 is movably connected with a movable gear 11, the outer surface of the movable gear 11 is movably connected with a ratchet frame 12, and one end of the ratchet frame 12 is fixedly connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com