Uniform spraying device for liquid feed additive

A technology of spraying device and liquid feed, which is applied in the direction of spraying device, feed, food science, etc. It can solve the problems of affecting feed quality, insufficient liquid additives, control, etc., and achieve the effect of avoiding excessive spraying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

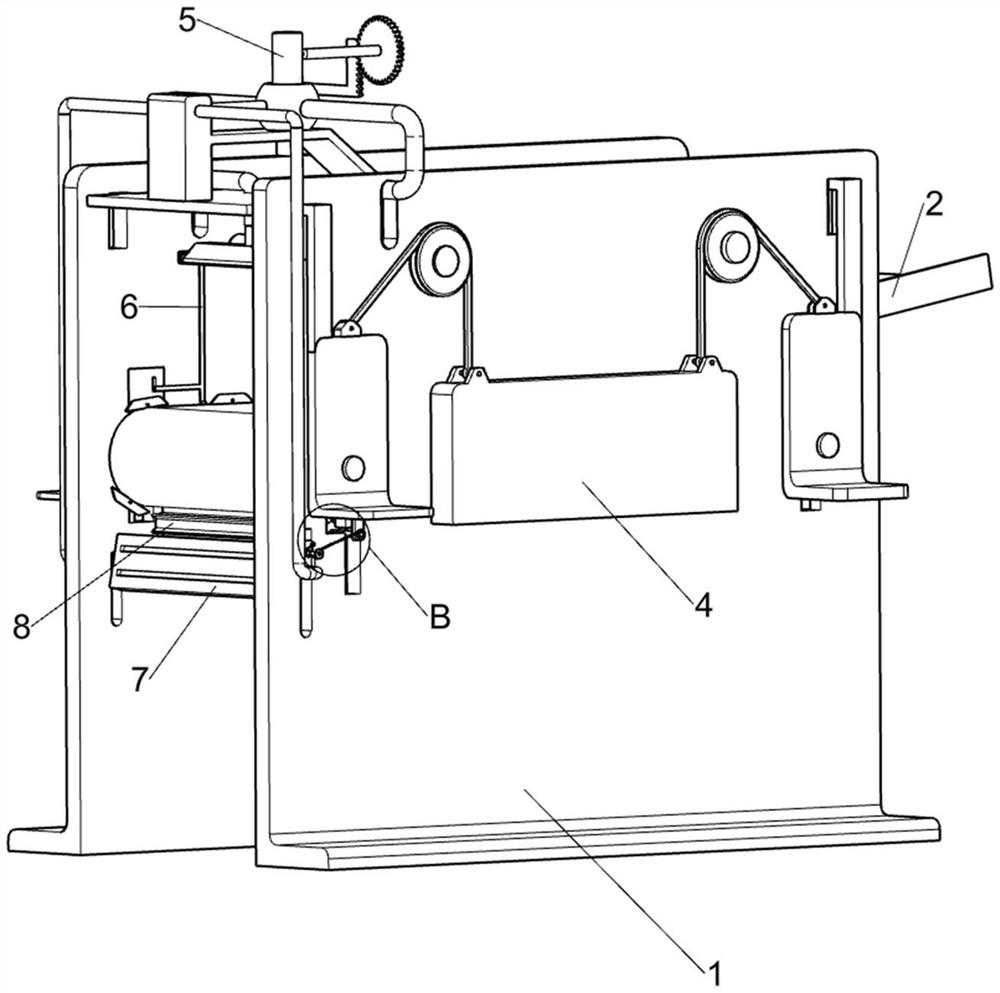

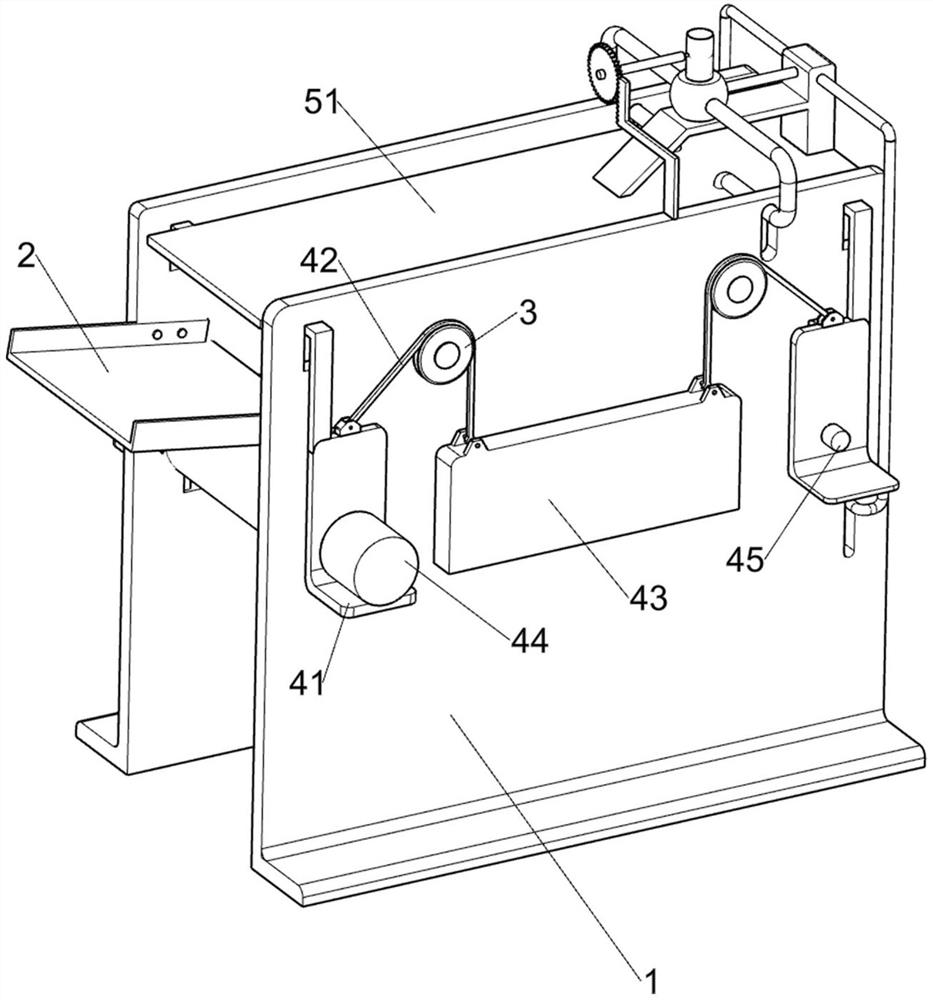

[0034] A uniform spraying device for liquid feed additives, such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 As shown, it includes a support plate 1, a feed plate 2, a movable wheel 3, a weight fluctuation component 4, a spray volume control component 5 and an intermittent spray component 6, and a feed plate is fixed between the two support plates 1 2. A pair of movable wheels 3 are rotatably connected to the upper part of the support plate 1. The support plate 1 is provided with a weight fluctuation component 4, and the support plate 1 is provided with a spray volume control component 5. The spray volume control component 5 is used to adjust the amount of feed To control the spraying amount of the liquid additive, the weight fluctuation component 4 is provided with an intermittent spraying component 6, which is used for intermittently spraying the liquid additive.

[0035]The weight fluctuation assembly 4 includes a sliding bearing...

Embodiment 2

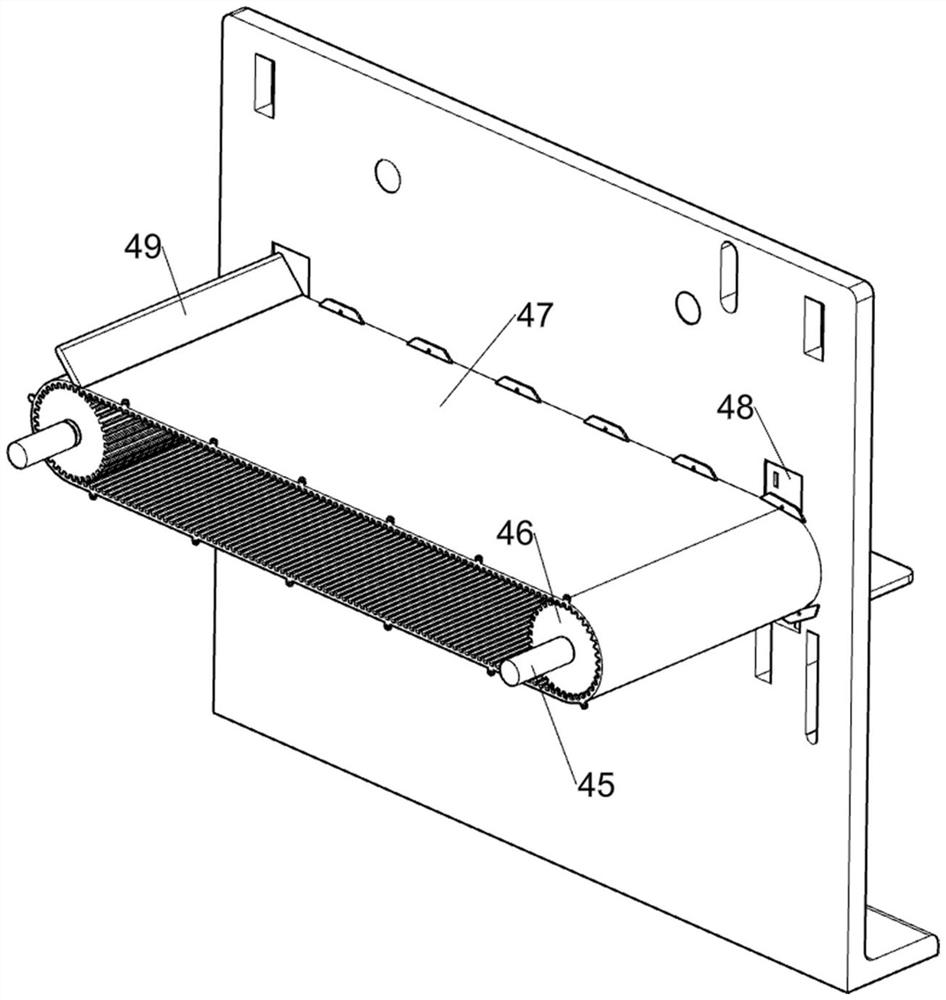

[0042] On the basis of Example 1, such as Figure 8 and Figure 9 As shown, the bottom atomization assembly 7 is also included, and the bottom atomization assembly 7 is arranged on the support plate 1 on the front side. , water wheel rotation shaft 74, transverse shaft 75, bevel gear 76, dial 77 and tension spring 2 78, the left side of the external valve seat 53 is connected with a shunt pipe 71, part of the liquid additive will flow down through the shunt pipe 71, the shunt pipe 71 passes through the trapezoidal seat 52, the shunt pipe 71 is fixedly connected to the trapezoidal seat 52, the shunt pipe 71 passes through the support plate 1, and the bottom of the shunt pipe 71 is fixed with an atomizer 72, which is used to atomize and spray the liquid additive On the feed, the atomizer 72 communicates with the shunt pipe 71. The atomizer 72 is located on the left side below the conveyor belt 47. The front support plate 1 is slidably connected with a sliding plate 711. The fro...

Embodiment 3

[0045] On the basis of Example 2, such as Figure 9 As shown, it also includes an anti-sticking component 8, which is located on the sliding support 41 on the left side of the front side. The anti-sticking component 8 includes a fixed plate 801, a scraper shaft 81, a rotating disk 82, a connecting Rod 83 and scraping swivel frame 84 are connected with fixed plate 801 by bolts under the sliding support 41 on the left side of the front side, and fixed plate 801 is connected with scraping shaft 81 in a rotating manner, and scraping shaft 81 passes through the front side. Support plate 1, a turntable 82 is fixedly connected to the front side of the scraping shaft 81, and a turntable 82 is also connected to the front side of the transverse shaft 75 by welding, and a connecting rod 83 for transmission is connected between the two turntables 82 in a co-rotating manner. The shaft 81 is provided with a scraping carousel 84, the scraping carousel 84 is located below the conveyor belt 47...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com