Vacuum adsorption floor paint spraying device

A painting equipment and vacuum adsorption technology, applied in the direction of spraying devices, liquid spraying devices, etc., can solve the problems of large amount of spraying paint, waste of paint, health hazards of staff, etc., and achieve the goal of saving paint costs, protecting the environment and improving the effect of spraying paint Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

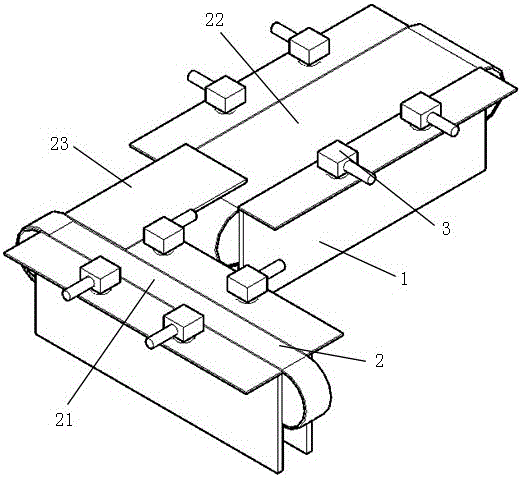

[0035] like figure 1 As shown, a vacuum adsorption type floor painting equipment includes a frame 1, and a floor transmission mechanism 2 arranged on the frame 1 is symmetrically arranged on both sides of the frame 1 in the transmission direction of the floor transmission mechanism 2. Several paint spraying mechanisms 3, and a paint liquid recovery mechanism connected with the paint spraying mechanism 3.

[0036] The floor transmission mechanism 2 includes a floor long-side painting transmission mechanism 21 and a floor short-side painting transmission mechanism 22, and a transmission transition part 23 is arranged between the floor long-side painting transmission mechanism 21 and the floor short-side painting transmission mechanism 22 . The floor transmission mechanism 2 can be a chain-plate tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com