Road roller liquid spraying control method and system, road roller and readable storage medium

A control method and control system technology, applied in the field of road rollers, can solve problems such as excessive fuel injection, road pollution, waste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

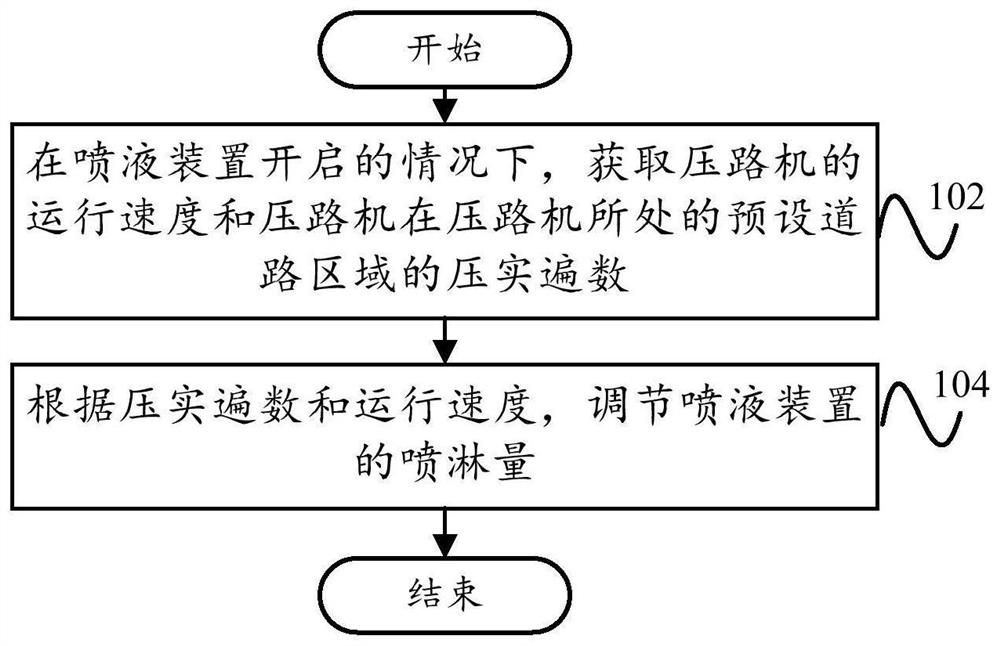

[0049] like figure 1 As shown, according to the first aspect of the present invention, a roller spray control method is proposed, including:

[0050] Step 102, in the case where the liquid discharge device is turned on, the compaction of the running speed of the roller and the compaction of the voltage roller at the roller is located;

[0051] Step 104, adjust the spray amount of the liquid liquid discharge device according to the number of compaction, the running speed.

[0052] In this embodiment, in the case where the liquid discharge device is activated, the operation speed of the roller is acquired, that is, the voltage carrier speed, and the compaction of the preset road area of the statistical roller at the roller, that is, the compact voltage is being Or the number of times that is about to pass through the road area. And on the basis of using the running speed control the spray amount of the liquid discharge device, further binding pressure is dynamically adjusted to th...

Embodiment 2

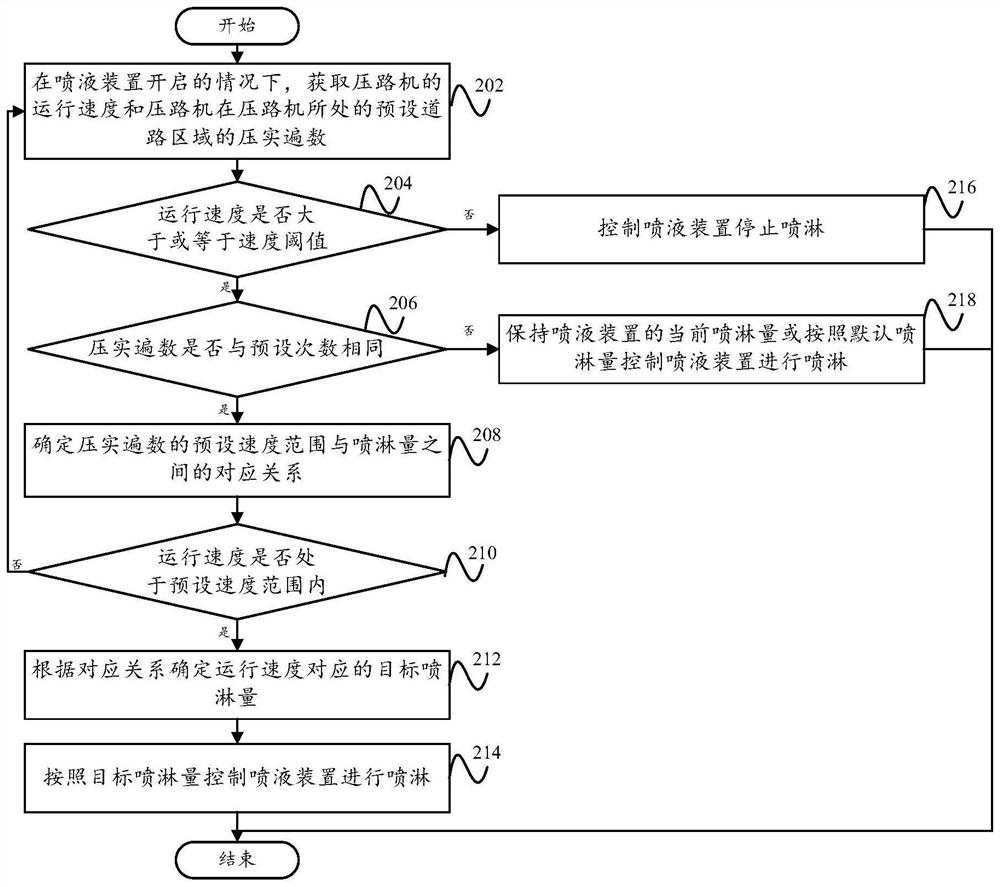

[0056] like figure 2 As shown, according to an embodiment of the present invention, a roller spray liquid control method is proposed, including:

[0057] Step 202, in the case where the liquid discharge device is turned on, the compaction of the running speed of the roller and the compaction of the voltage roller at the roller is located;

[0058] Step 204, whether the running speed is greater than or equal to the speed threshold, if yes, enter step 206, if, proceed to step 216;

[0059] Step 206, whether the compaction is the same as the number of defaults, if yes, enter step 208, if, enter step 218;

[0060] Step 208 determines the corresponding relationship between the preset speed range and the sprinkler of the compaction;

[0061] Step 210, whether the running speed is in the preset speed range, if yes, enter step 212, if, proceed to step 202;

[0062] Step 212, determine the target spur amount corresponding to the running speed according to the correspondence;

[0063] Step ...

Embodiment 3

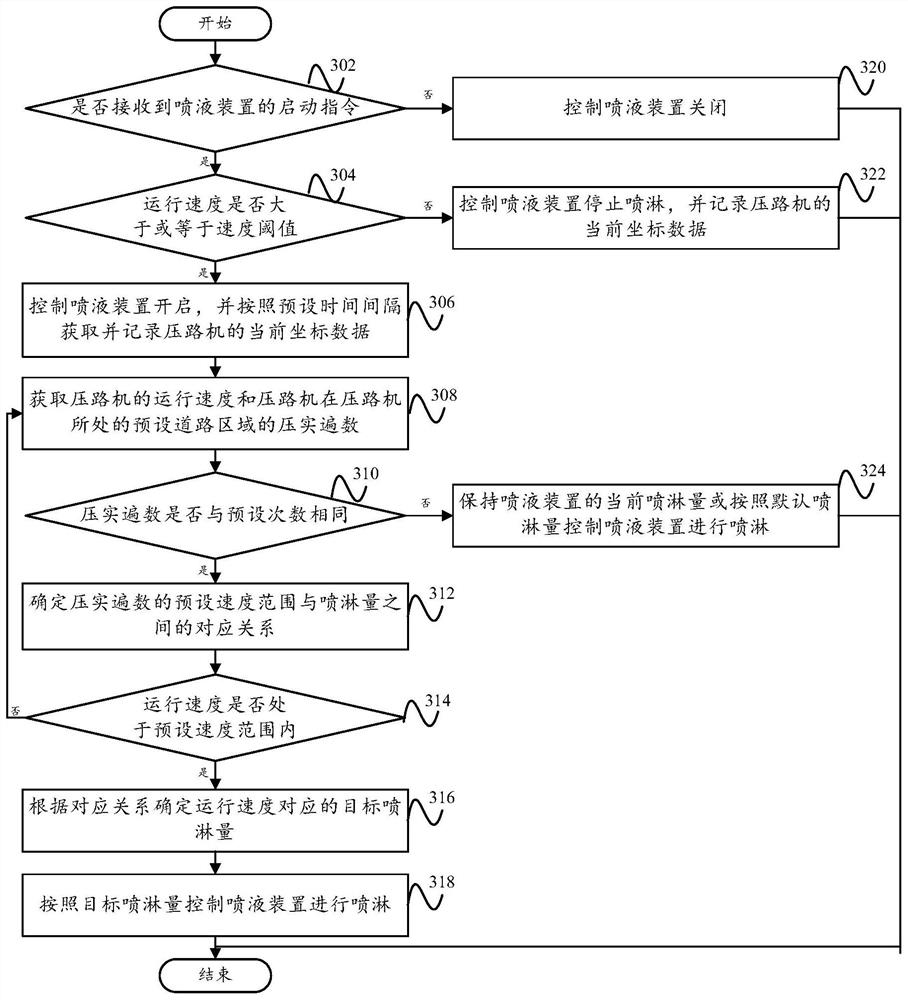

[0073] like image 3 As shown, according to an embodiment of the present invention, a roller spray liquid control method is proposed, including:

[0074] Step 302, whether or not the start command of the liquid discharge device is received, and if yes, enter step 304, if not, proceed to step 320;

[0075] Step 304, whether the operating speed is greater than or equal to the speed threshold, if yes, enter step 306, if, proceed to step 322;

[0076] Step 306: The control spray apparatus is turned on and the current coordinate data of the roller is acquired and recorded according to the preset interval;

[0077] Step 308, obtain the compaction of the running speed of the roller and the compaction of the voltage roller in the roller;

[0078] Step 310, whether the compaction is the same as the number of defaults, if yes, enter step 312, if, enter step 324;

[0079] Step 312, determine the corresponding relationship between the preset speed range and the sprinkler of the compaction;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com