Polishing device for rice production

A polishing device and rice technology, applied in application, grain finishing, grain processing and other directions, can solve the problem of high broken rice rate, and achieve the effect of reducing broken rice rate, ensuring quality and ensuring polishing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

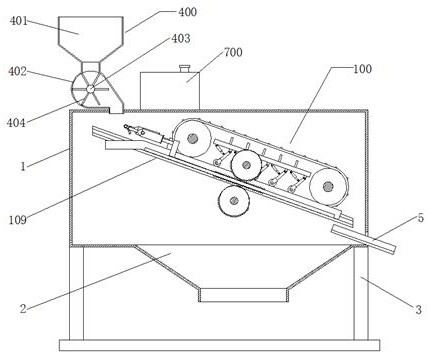

[0038] Embodiment 1 discloses a polishing device for rice production, referring to the attached figure 1 , the main body of the polishing device includes a chassis 1 and a polishing mechanism 100 disposed in the chassis 1 . The lower surface of the cabinet 1 is provided with a chaff dust collecting hopper 2, and a plurality of supporting feet 3 are connected to the lower surface of the cabinet 1 at the same time.

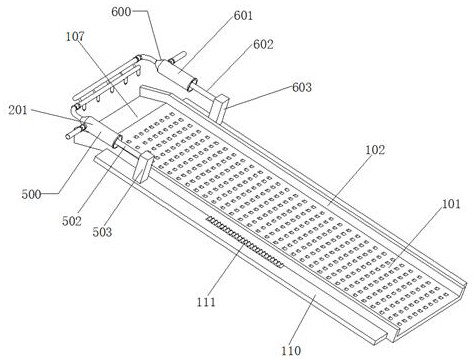

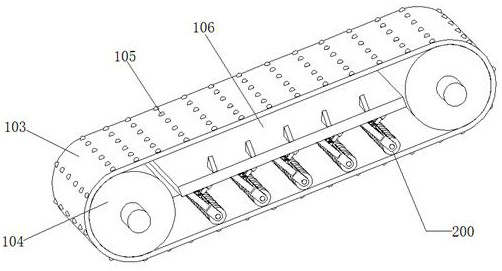

[0039] Reference attached figure 1 And attached figure 2 , the polishing mechanism 100 includes a sieve panel 101 arranged obliquely downward, and the sieve panel 101 is welded to the front and rear inner walls of the cabinet 1 . At the same time, the front and rear ends of the sieve panel 101 are provided with vertically upward edge strips 102 to prevent the rice on the sieve panel 101 from leaking from the front and rear ends of the sieve panel 101 during the polishing process. A material receiving plate 107 is connected to the upper end of the screen plate 10...

Embodiment 2

[0047] Embodiment 2 discloses an improved polishing device for rice production based on Embodiment 1, which mainly addresses the problem that the relatively short process of relative movement and relative friction of rice in the polishing gap may lead to a decrease in polishing effect.

[0048] The similarities between this embodiment 2 and embodiment 1 will not be described again, the difference is that the screen panel 101 in this embodiment 2 is movably arranged in the cabinet 1, and the front and rear inner walls of the cabinet 1 are welded with the screen panel 101 parallel inclined guide grooves 109, and then at the front and rear ends of the screen panel 101, smooth convex plates 110 matching the inclined guide grooves 109 are welded.

[0049] At the same time, a rack 111 is welded on the upper and lower surfaces of one of the smooth convex plates 110, and an incomplete gear 112 is respectively arranged on the upper and lower sides of the rack 111, and the number of teet...

Embodiment 3

[0052] Embodiment 3 discloses a polishing device for rice production improved on the basis of Embodiment 2. Since the rice heats up significantly when it is polished between the sieve plate 101 and the flexible polishing belt 103, it is necessary to cool down the rice during the polishing process to ensure that the rice is polished. rice quality.

[0053] Based on the above-mentioned technical problems, the front and rear ends of the cabinet 1 above the material receiving plate 107 in this embodiment 2 are respectively fixed with a piston pumping device 500 and a piston pumping device 600, and the piston pumping device and the piston pumping device form a mist The atomized spray mechanism sprays atomized water to the polished rice through the atomized spray mechanism to ensure that the temperature of the rice will not rise too high during the subsequent polishing process, and it can also increase the gloss of the polished rice.

[0054] Reference attached figure 1 And attache...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com