Rice processing method and equipment

A rice processing and rice technology, applied in the field of rice processing methods and equipment, can solve the problems of slow processing efficiency, complicated and tedious procedures, increased processing costs, etc., and achieve the effects of reducing one procedure, improving rice quality, and reducing processing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

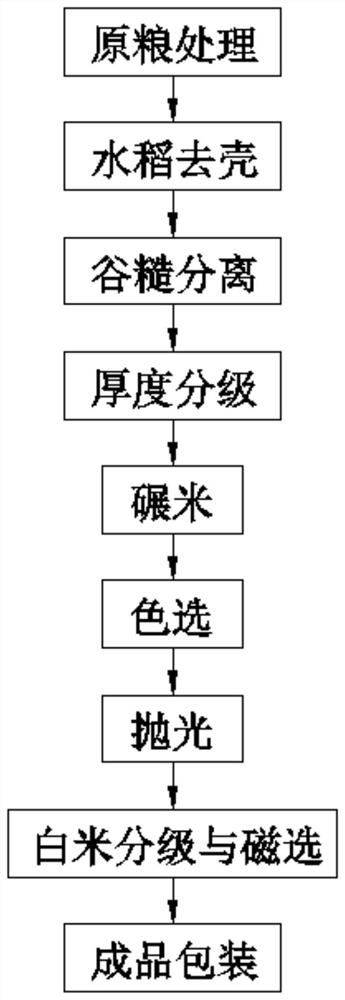

[0043] Embodiment: a kind of rice processing method, as figure 1 shown, including the following steps:

[0044] S1. Raw grain processing: The purchased rice is processed through a drum primary cleaning screen and a stone removal machine in order to remove impurities in the raw grain and obtain hulled rice;

[0045]S2. Rice husking: the husking process is carried out by the huller, and the gap between the rubber rollers in the huller is required to be no more than 2 mm, and the husking rate is greater than 75%;

[0046] S3. Separation of paddy and paddy: separate brown rice and paddy by paddy paddy separator, so that brown rice and unhulled paddy are separated, and the separation rate is required to be greater than 99%;

[0047] S4, thickness classification: classify by thickness classifier according to the grain size of brown rice, remove immature grains and broken grains, obtain A-grade brown rice, and remove immature grains and broken grains as B-grade brown rice;

[0048]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com