Novel rice milling emery roll

An emery roller, a new type of technology, is applied in the field of rice milling emery rollers, which can solve the problems of poor molding performance of the binder, short service life, and long production cycle, and achieve improved strength and impact resistance, reduced volume and weight, Effects that are cheap to manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

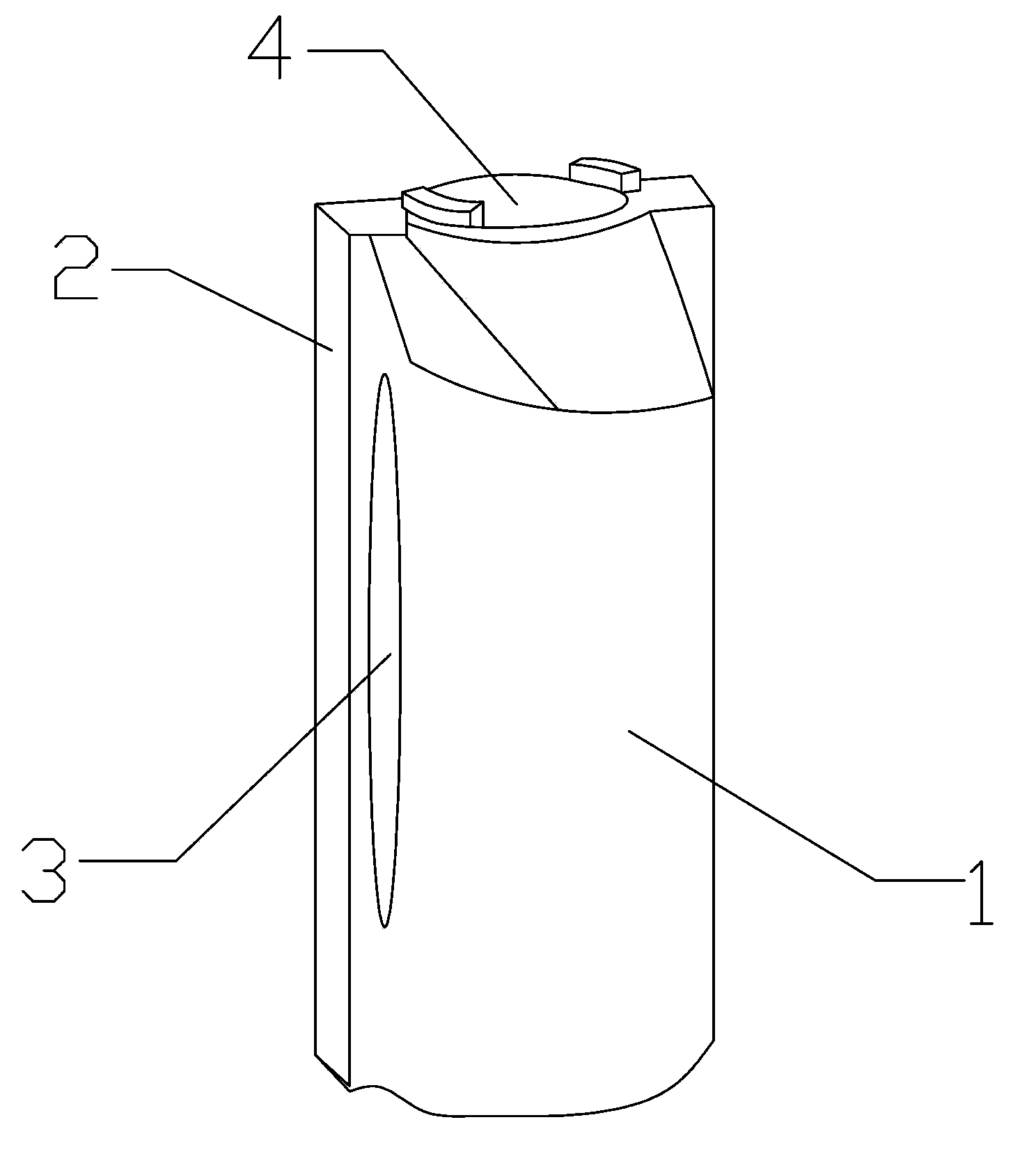

[0017] The present invention will be further described below in conjunction with drawings and embodiments. figure 1 Among them, the new type of rice milling emery roller consists of an emery roller body and a metal core sleeve 4 embedded in the hole in the emery roller body. It is characterized in that: the emery roller body is composed of a square part 1 and an arc part 2. The horizontal plane of the arc-shaped part 2 is connected with the square part 1, and its protruding surface faces outwards, and strip-shaped blowing holes 3 are respectively opened on both sides of the protruding arc-shaped part 2. The metal core sheath 4 is an iron core sheath.

[0018] The emery roller body is made by putting 4 metal core sets on the mould, then mixing 80 parts of corundum and 20 parts of bonding agent evenly, and then molding it at one time, then drying it at a low temperature of 60-100°, and then passing it through 80-200° Hardened at high temperature. Wherein the binding agent is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com