Unpolished rice tempering and enzyme deactivation equipment

A technology for tempering and brown rice, applied in food preparation, grain processing, grain milling, etc., can solve the problems of brown rice prone to cracks and cracks, and achieve the effects of easy moisture gradient balance, low burst rate, and fewer cracks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

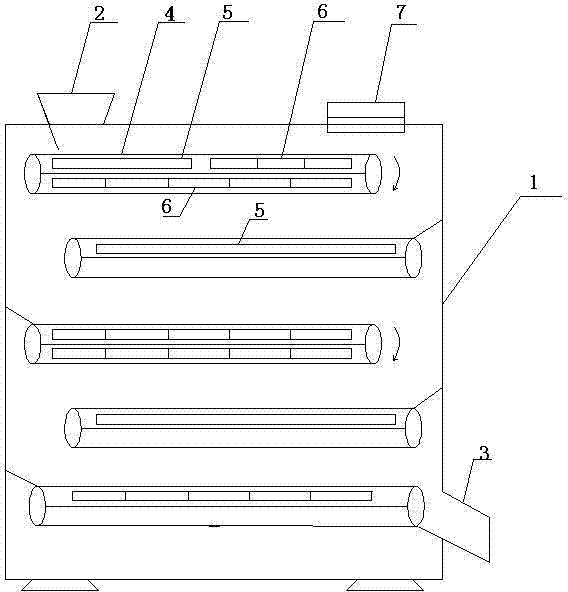

[0028] like figure 1 As shown, the brown rice tempering equipment includes a tempering box 1, a blanking port 2 and a discharge port 3 on the conditioning box, a conveyor belt 4 placed in the tempering box, a hot air square tube 5 below the conveyor belt 4 and Cold air square pipe 6; brown rice falls from the discharge port to the conveyor belt, and is transported to the discharge port 3 to be sent out. There are five layers of conveyor belts 4 in the tempering box, and the conveyor belts of each layer are arranged in a dislocation;

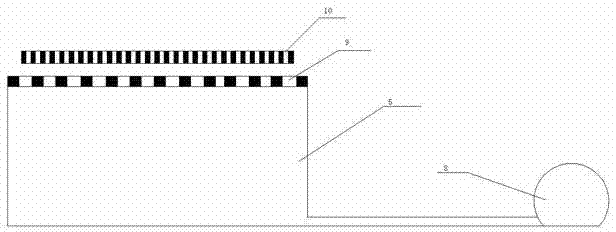

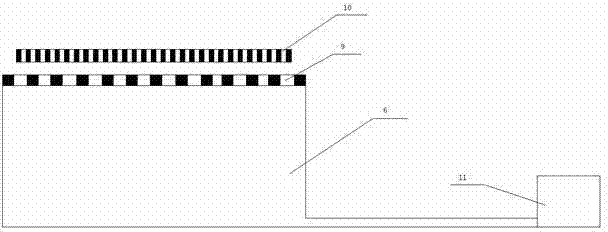

[0029] Hot-blast square pipes 5 and cold-blast square pipes 6 are arranged below every layer of conveyor belt 4, and hot-blast square pipes 5 are connected with saturated steam generator 8 through pipelines (as figure 2 ), the cold air square pipe is connected to the air cooler 11 through the pipe (such as image 3 );

[0030] The hot air square pipe 5 and the cold air square pipe 6 are distributed with air outlets 9;

[0031] The length of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com