Patents

Literature

43results about How to "Control the direction of rotation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

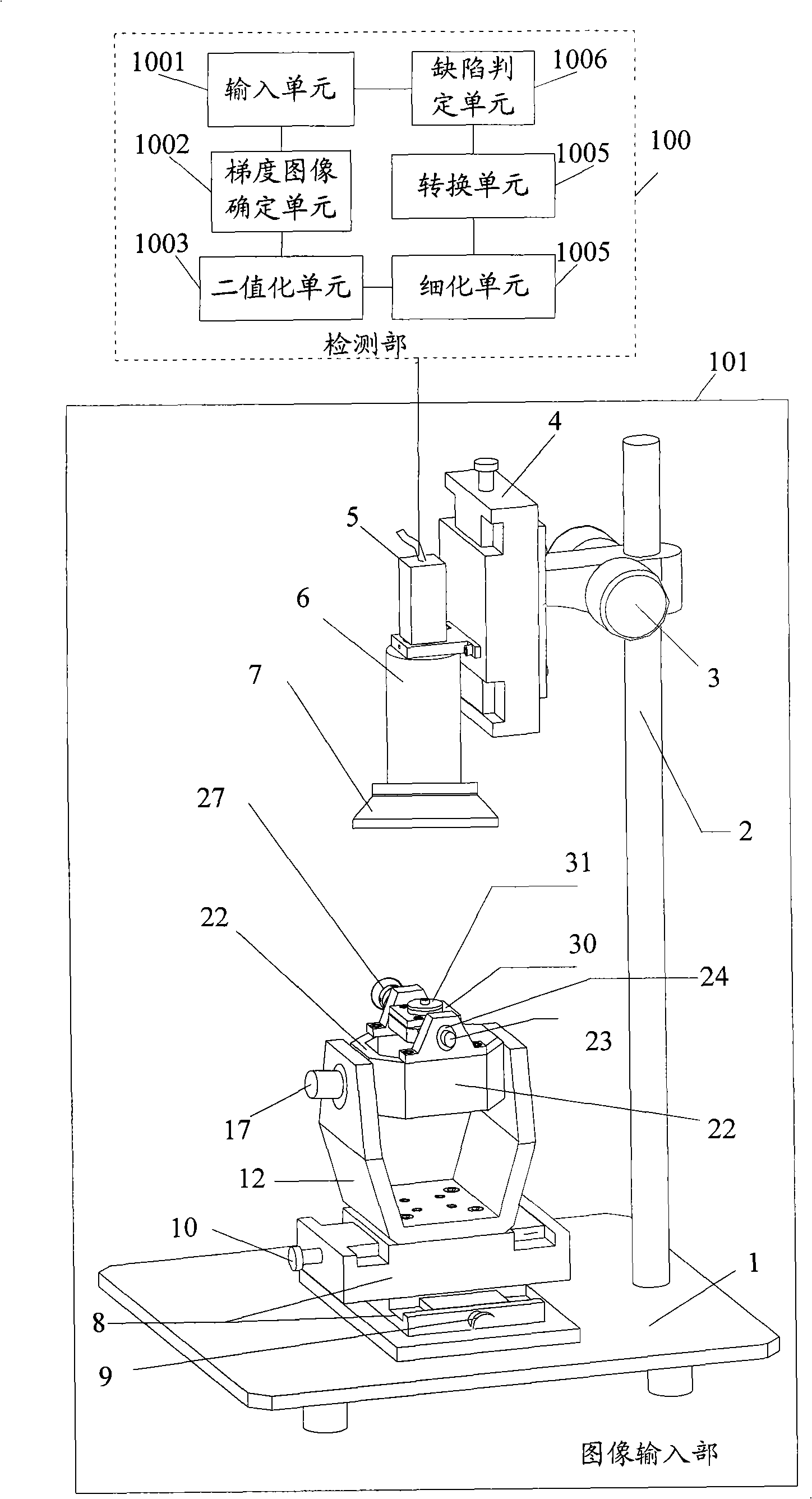

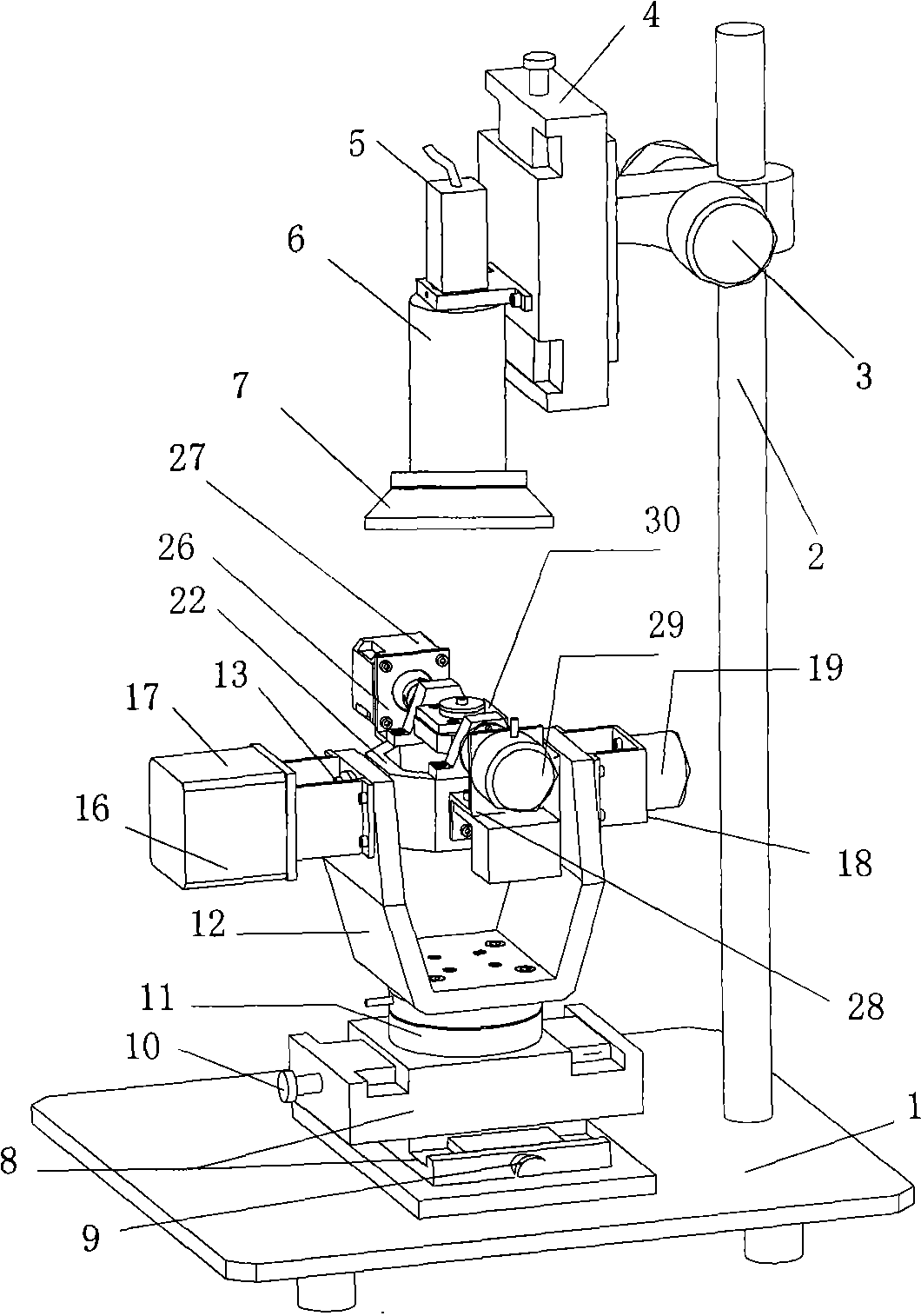

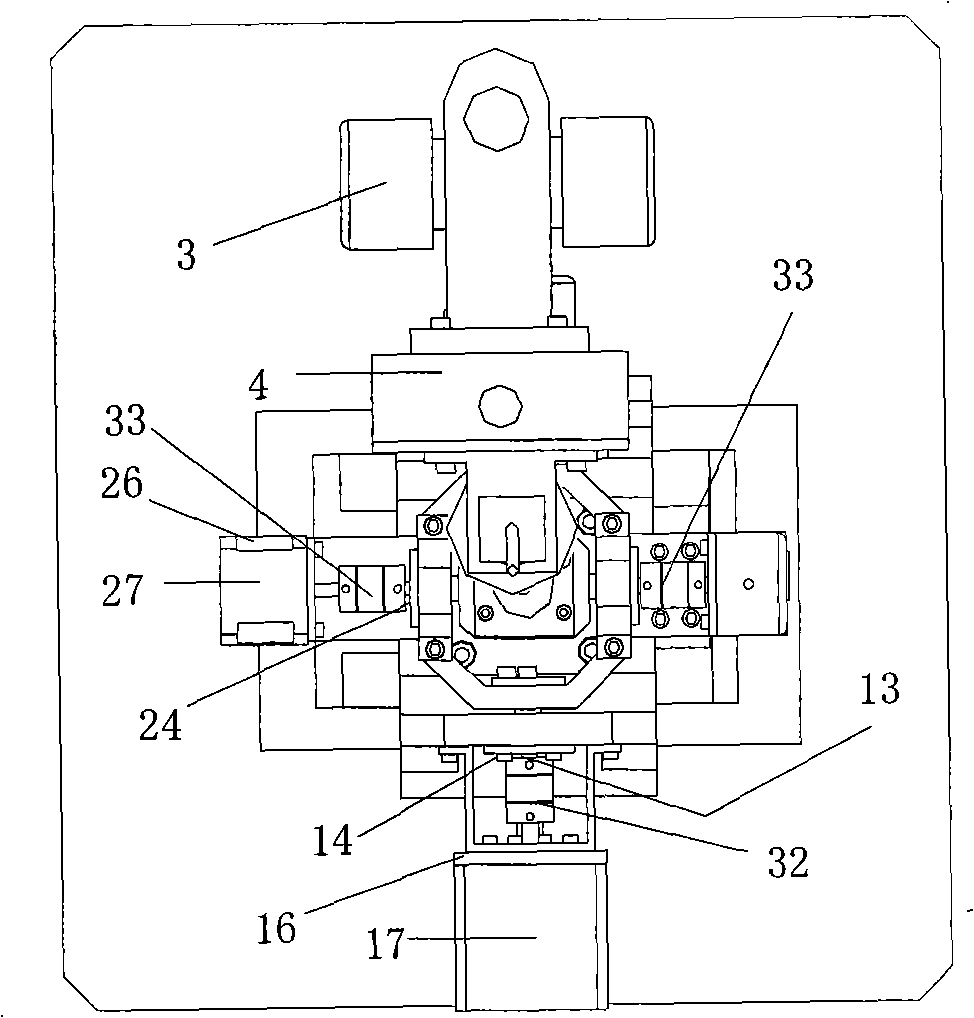

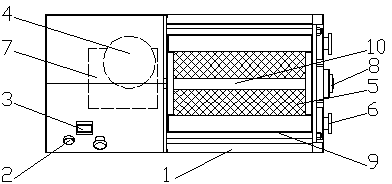

Surface flaw detection device

InactiveCN101261234AImprove detection efficiencyImplement automatic detectionImage analysisOptically investigating flaws/contaminationEngineeringImage capture

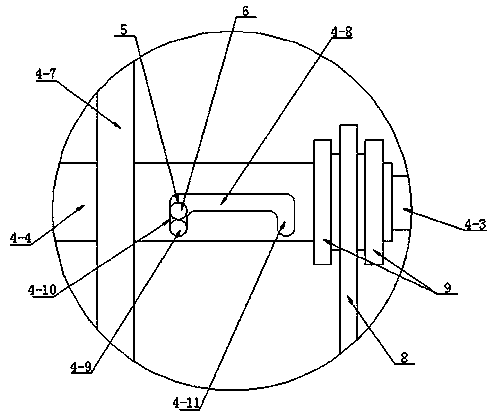

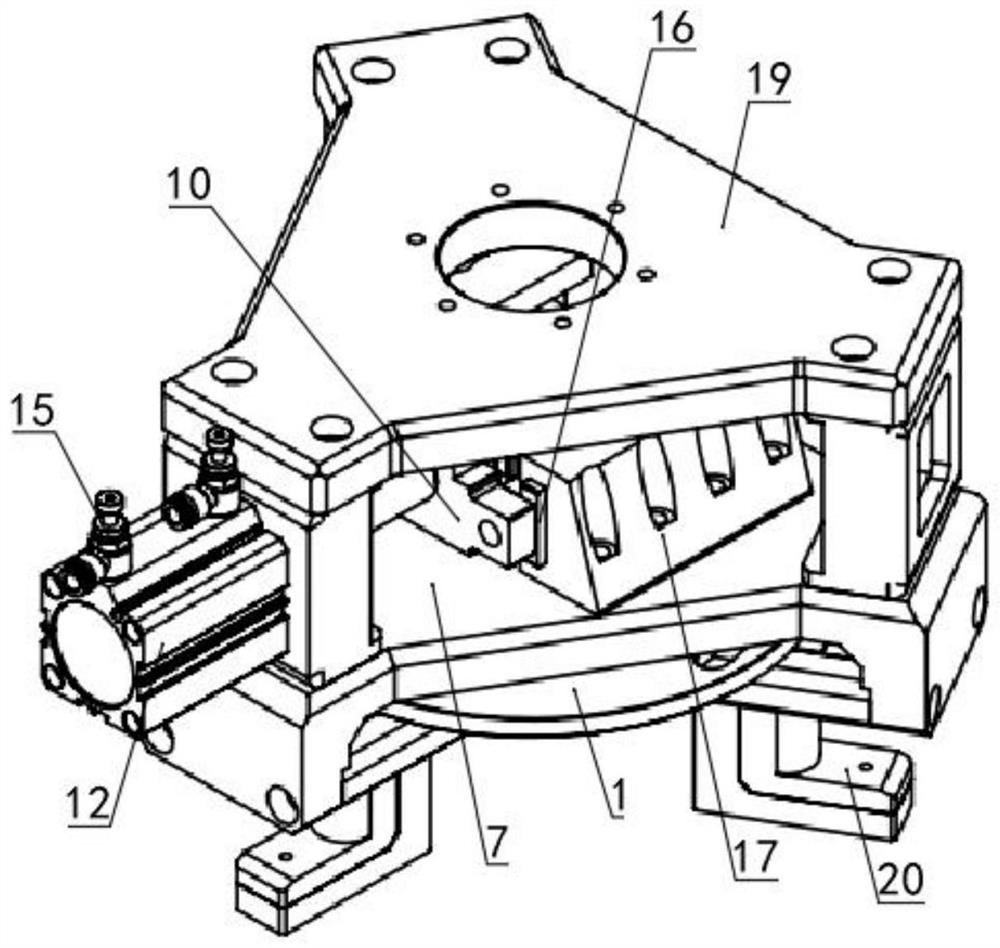

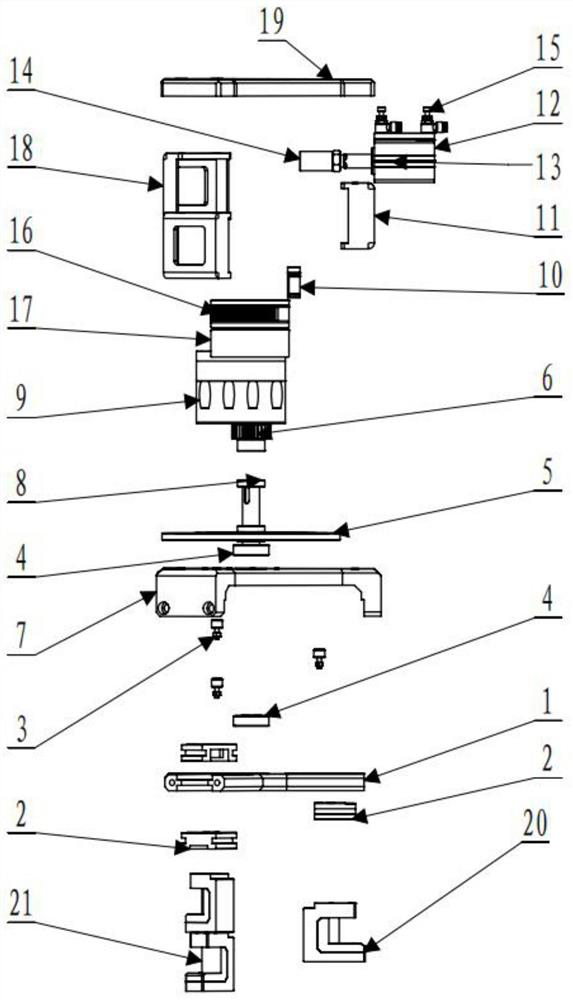

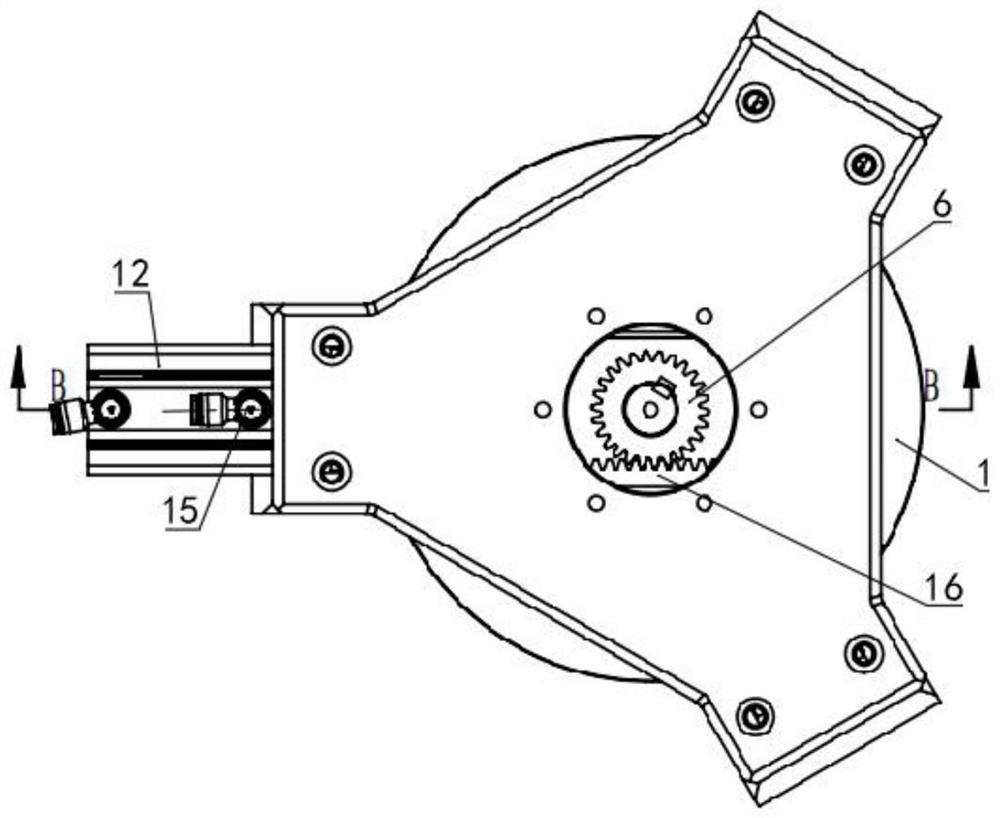

The invention relates to the detection field, disclosing a detection device of surface defects. The detection device of surface defects, which includes an image input part and a detection part, consists of a rolling mechanism and a pitching mechanism to drive an object stage to rotate towards four directions. A loading process can test a plurality of surfaces of a detected object; therefore, the device is convenient in use. Moreover, the coordination of a rolling motor, a pitching motor and a control circuit leads the device to conveniently control the rotation direction, swing angle and speed of the object stage and to collect images of the detected object in various angles, thus being beneficial to the detection part to detect comprehensively the defect according to the original image taken from various input angles and beneficial to improving the defect detection accuracy. In addition, the device can automatically adjust and finish the image capture of the detected objects from various angles as well as image detection, obviously, the device is favorable to improving automatic detection and detection efficiency.

Owner:INST OF IND TECH GUANGZHOU & CHINESE ACADEMY OF SCI +1

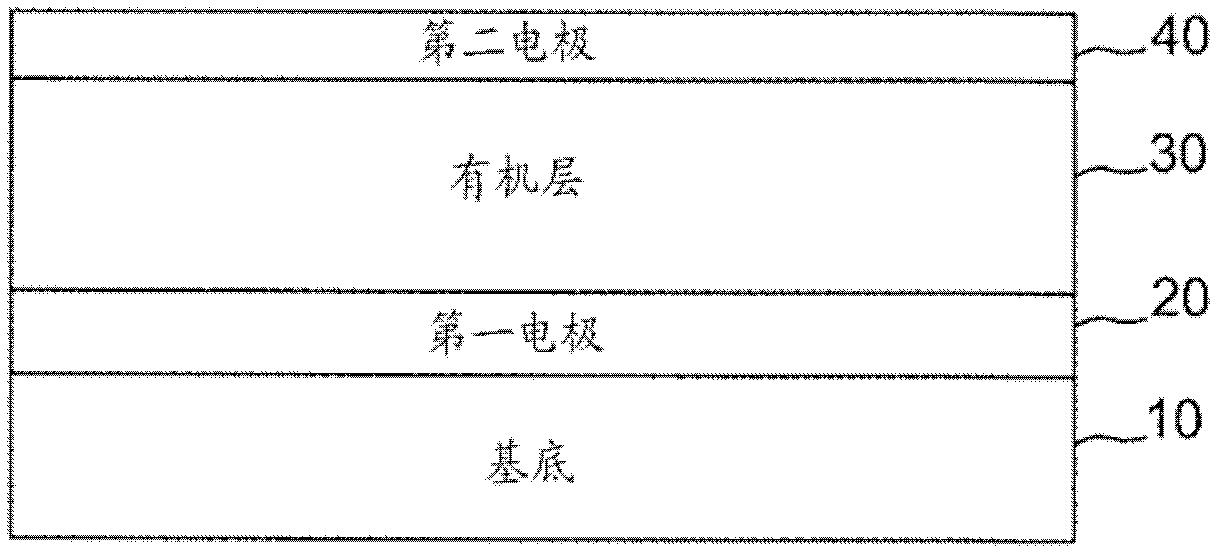

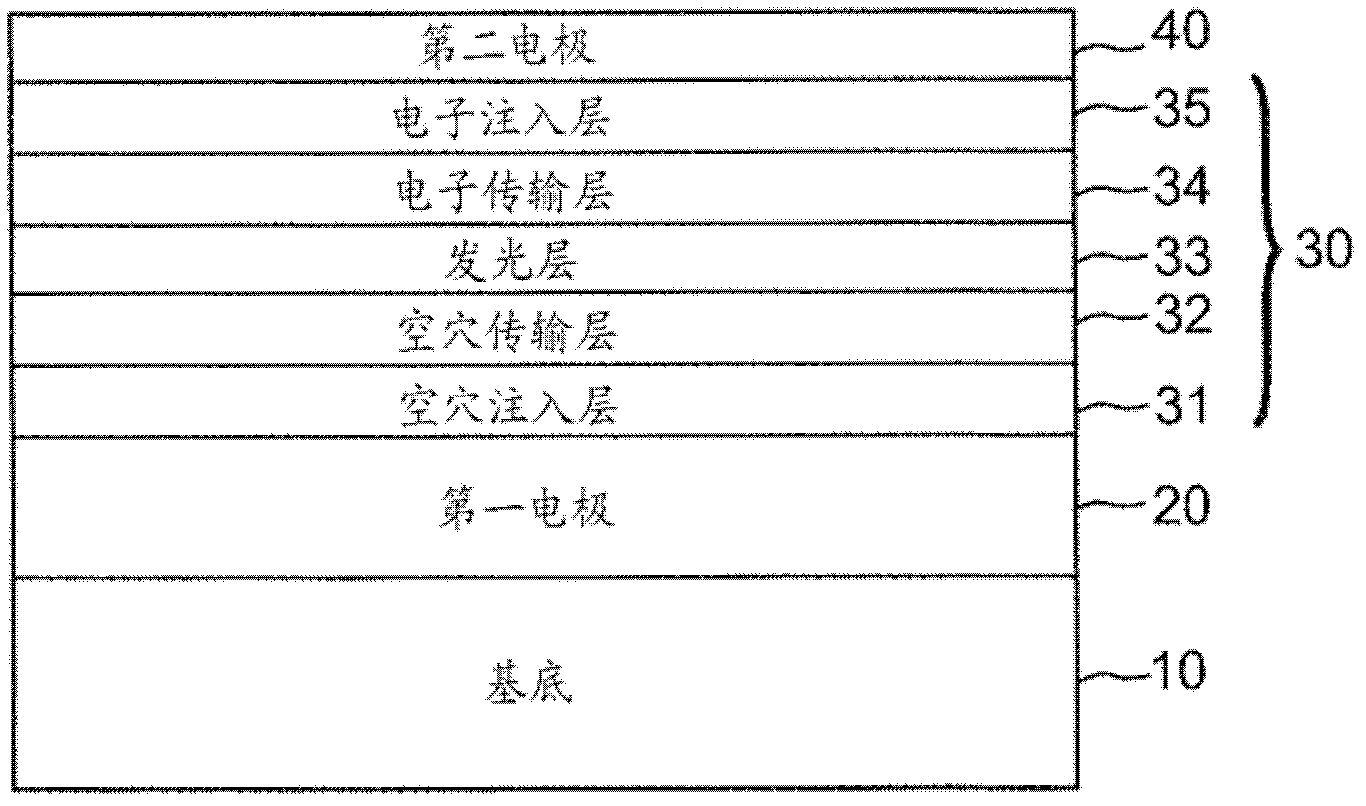

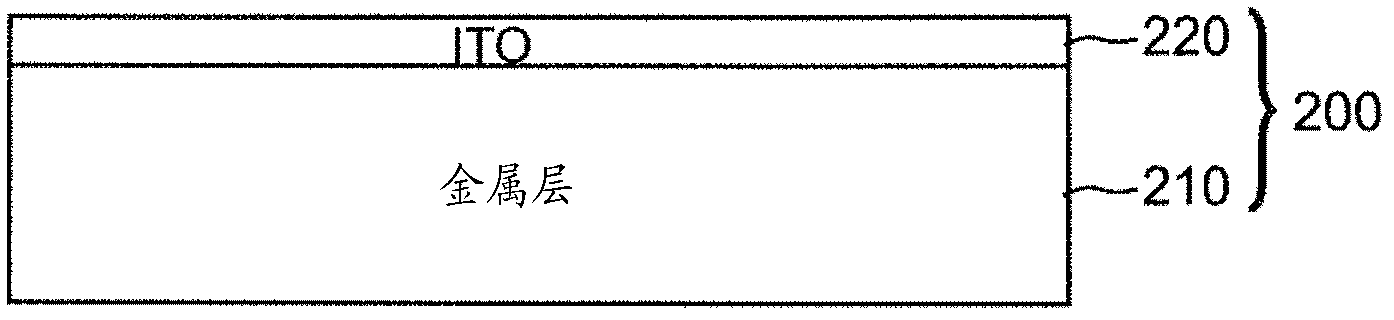

Electrode including magnetic material and organic light emitting device including the electrode

InactiveCN102842684AImprove light emission efficiencyGood injection propertiesElectroluminescent light sourcesSolid-state devicesCharge injectionOrganic light emitting device

An electrode, which includes a magnetic material to improve the flow of charges, and an organic light emitting device using the electrode. The electrode for the organic light emitting device has an excellent charge injection property, so that it is possible to improve the efficiency of light emission of the organic light emitting device.

Owner:SAMSUNG DISPLAY CO LTD

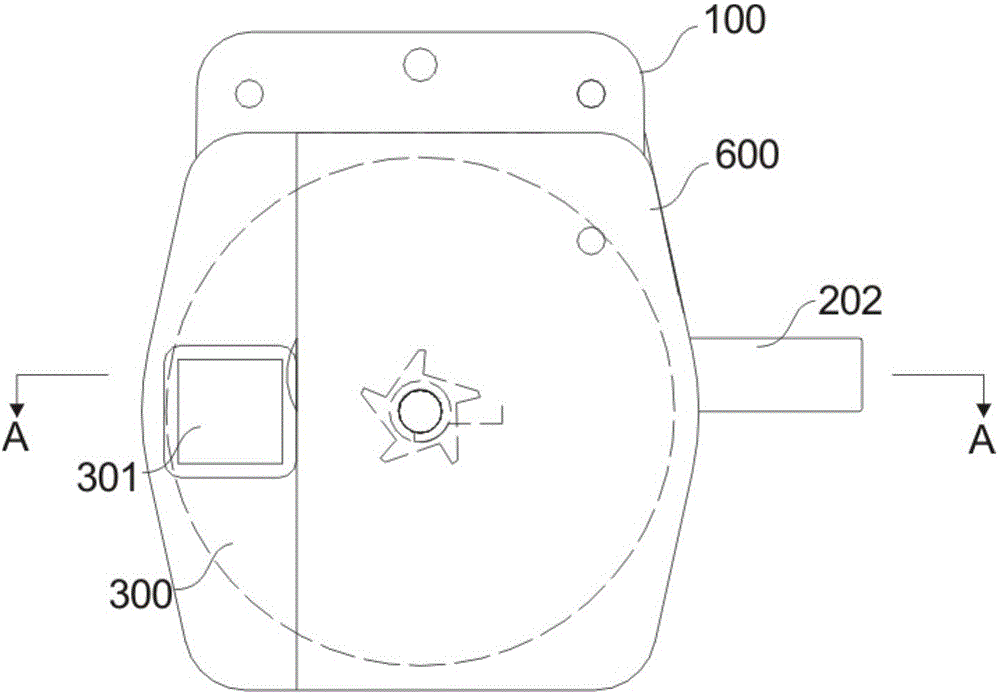

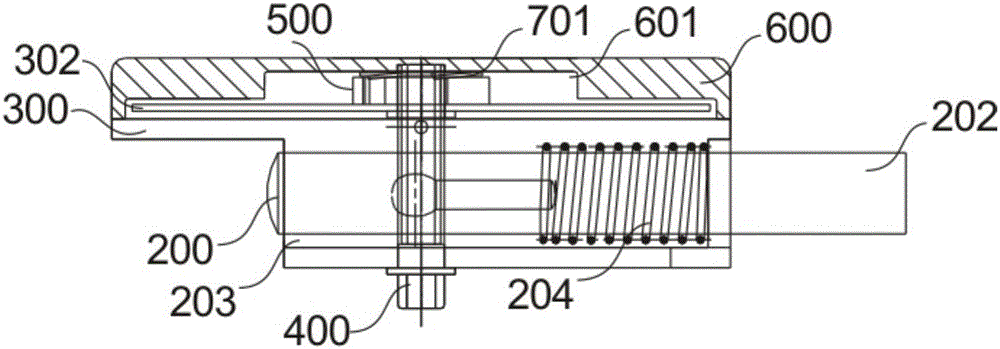

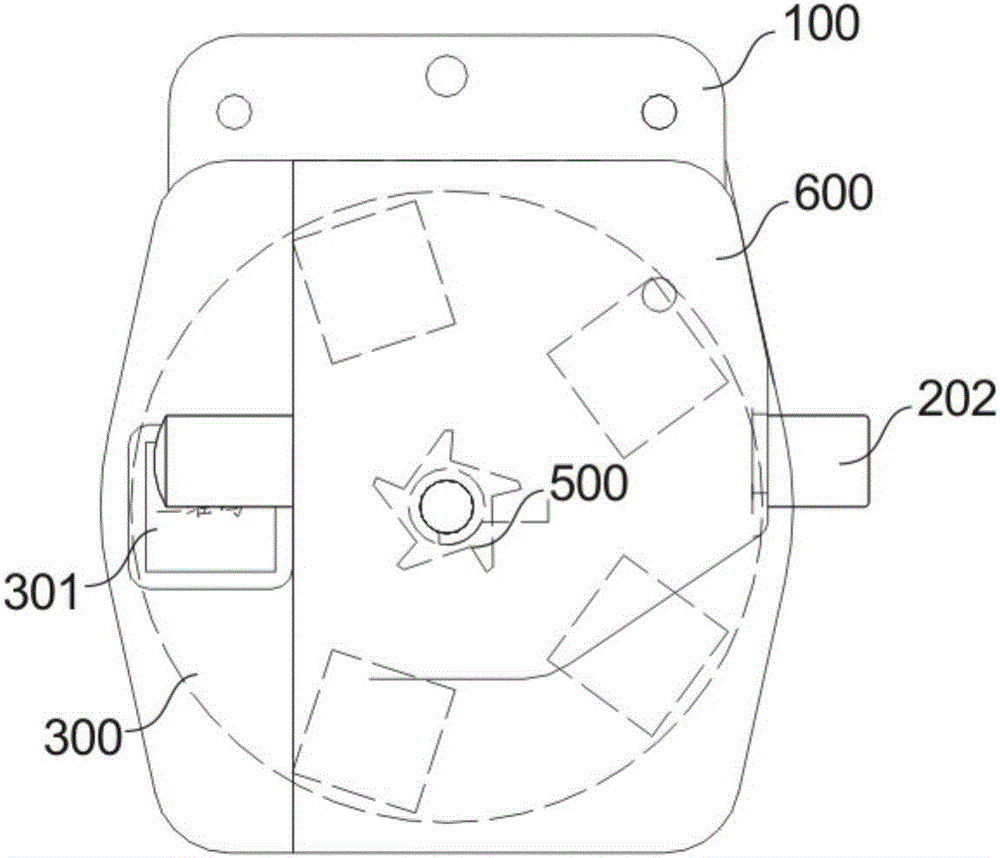

Mechanical type dynamic two-dimensional code lock for public bike

PendingCN106780920AAvoid reuseSimple structureBuilding locksApparatus for meter-controlled dispensingSoftware engineering

Owner:DAOMEI TECH SHANGHAI CO LTD

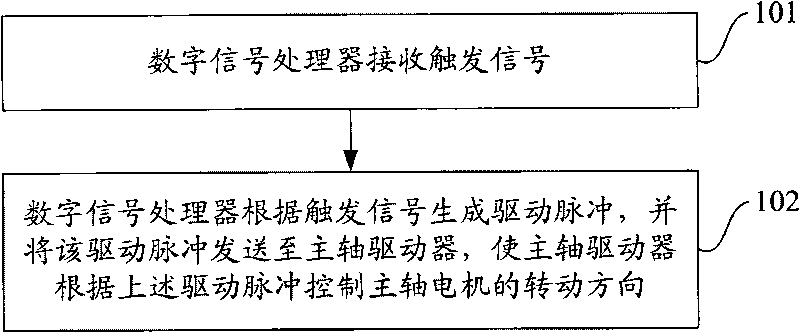

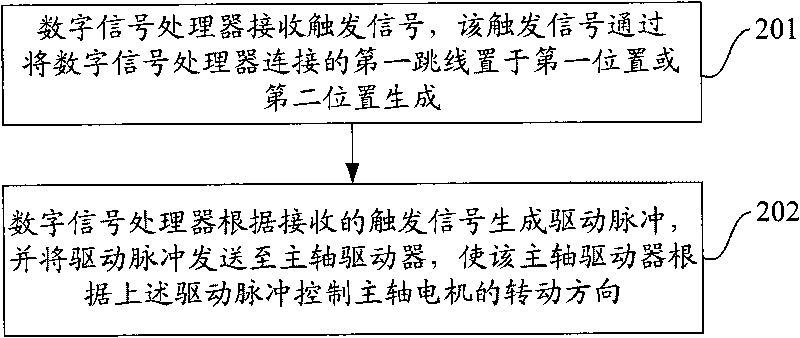

Disc rotating direction control method and device and disc

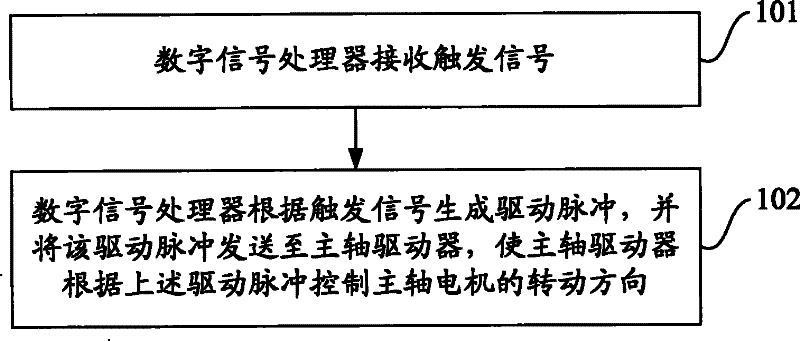

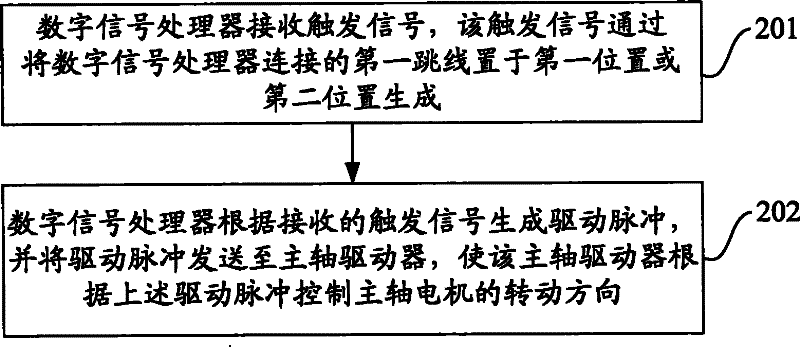

InactiveCN101727940AControl the direction of rotationMemory adressing/allocation/relocationRecord information storageResonanceElectric machine

The embodiment of the invention discloses disc rotating direction control method and device and a disc. The disc rotating direction control method comprises the steps of: receiving a trigger signal; generating a driving pulse according to the trigger signal; and sending the driving pulse to a spindle driver so that a spindle driver can control the rotating direction of a spindle motor according to the driving pulse, wherein the spindle motor is used for driving discs to rotate. The embodiment of the invention can control the rotating direction of discs, effectively lower the disc resonance and reduce the disc vibration, thereby realizing the purpose of disc protection.

Owner:HUAWEI DIGITAL TECH (CHENGDU) CO LTD

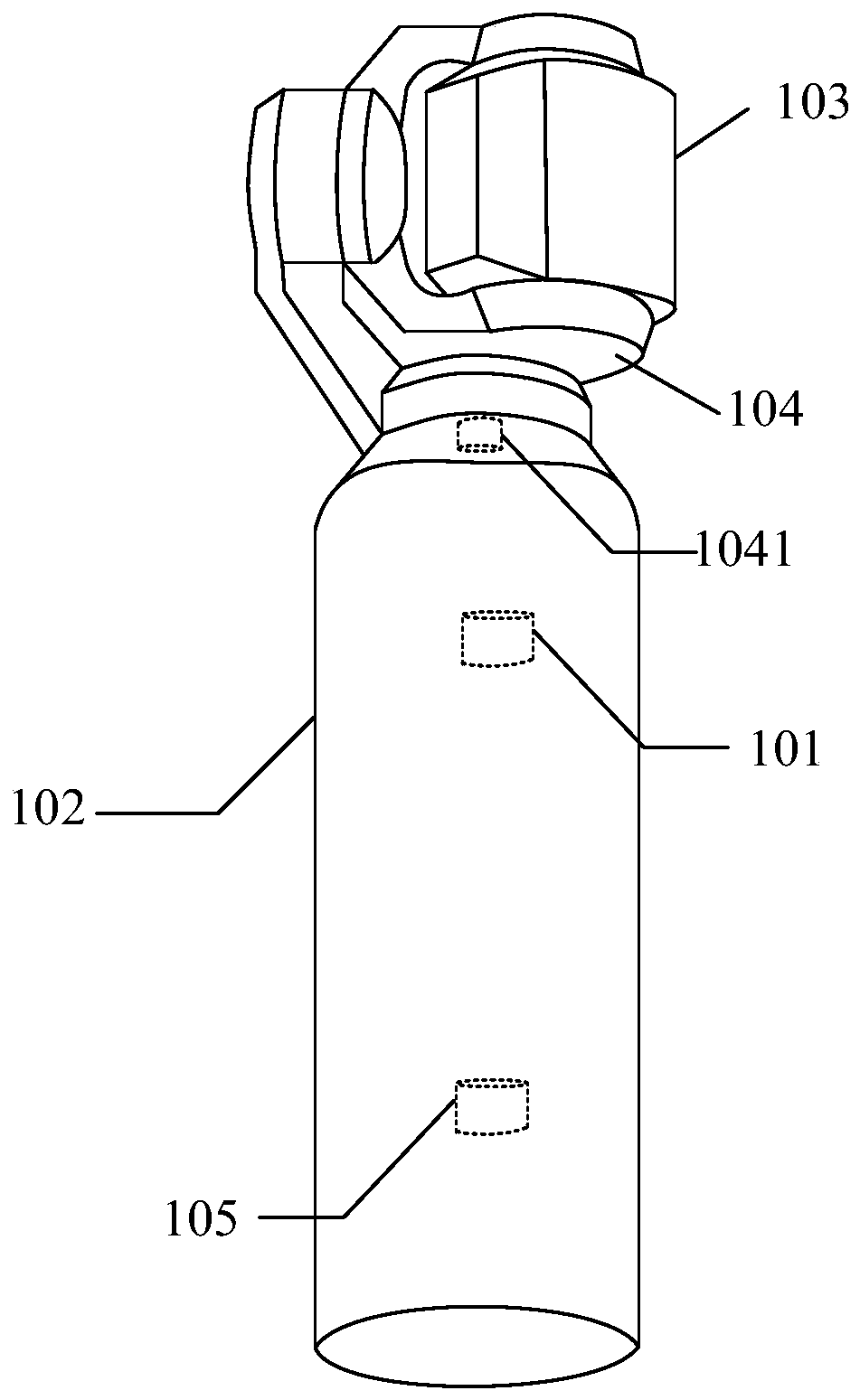

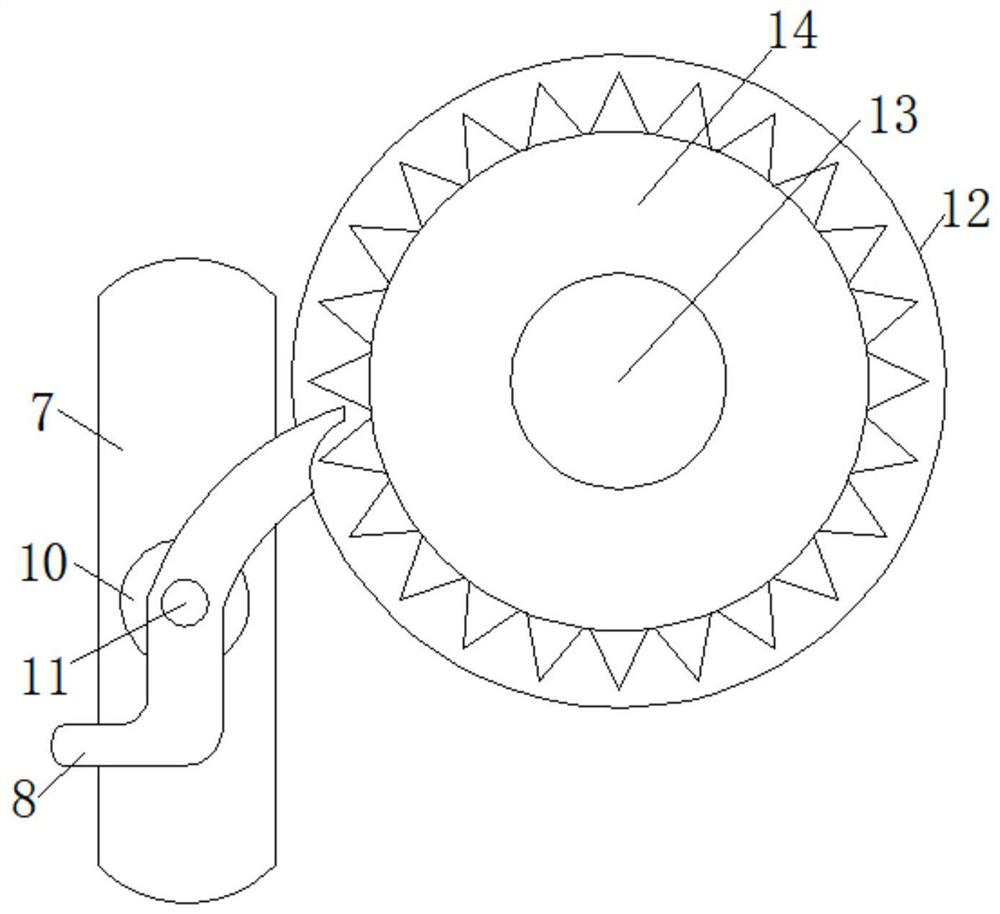

Volume-variable air spring auxiliary air chamber

InactiveCN108730397AModerate stiffnessImprove wear resistanceSpringsGas based dampersAir springEffective volume

The invention discloses a volume-variable air spring auxiliary air chamber, and relates to the technical field of automobile air spring auxiliary air chambers. The volume-variable air spring auxiliaryair chamber mainly comprises a first-stage air chamber body, a second-stage air chamber and a third-stage air chamber body and further comprises a connecting pipeline connected with a main air chamber body, a top cover, a separation plate, a ratchet wheel, a rotary disc, a ratchet wheel shaft and the like. According to the auxiliary air chamber, changing of the volume of the auxiliary air chambercan be achieved by controlling rotation of the rotary disc, and a driving mechanism drives the ratchet wheel shaft to rotate. The ratchet wheel on the ratchet wheel shaft rotates through the ratchetwheel shaft to interact with a pawl on the rotary disc, and then the rotary disc is driven to do circling motion. When a hole in the rotary disc is coaxial with a hole in a separation plate, the effective volume of the auxiliary air chamber changes, the rigidity of an air spring system is finally changed to meet various running working conditions of a vehicle, and the aim of improving the comprehensive performance of an air suspension system is achieved.

Owner:HAINAN UNIVERSITY

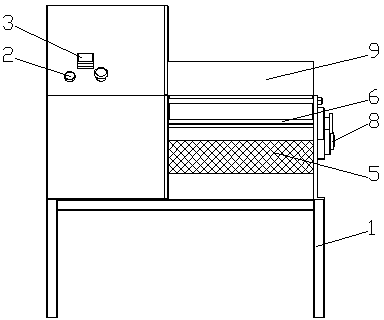

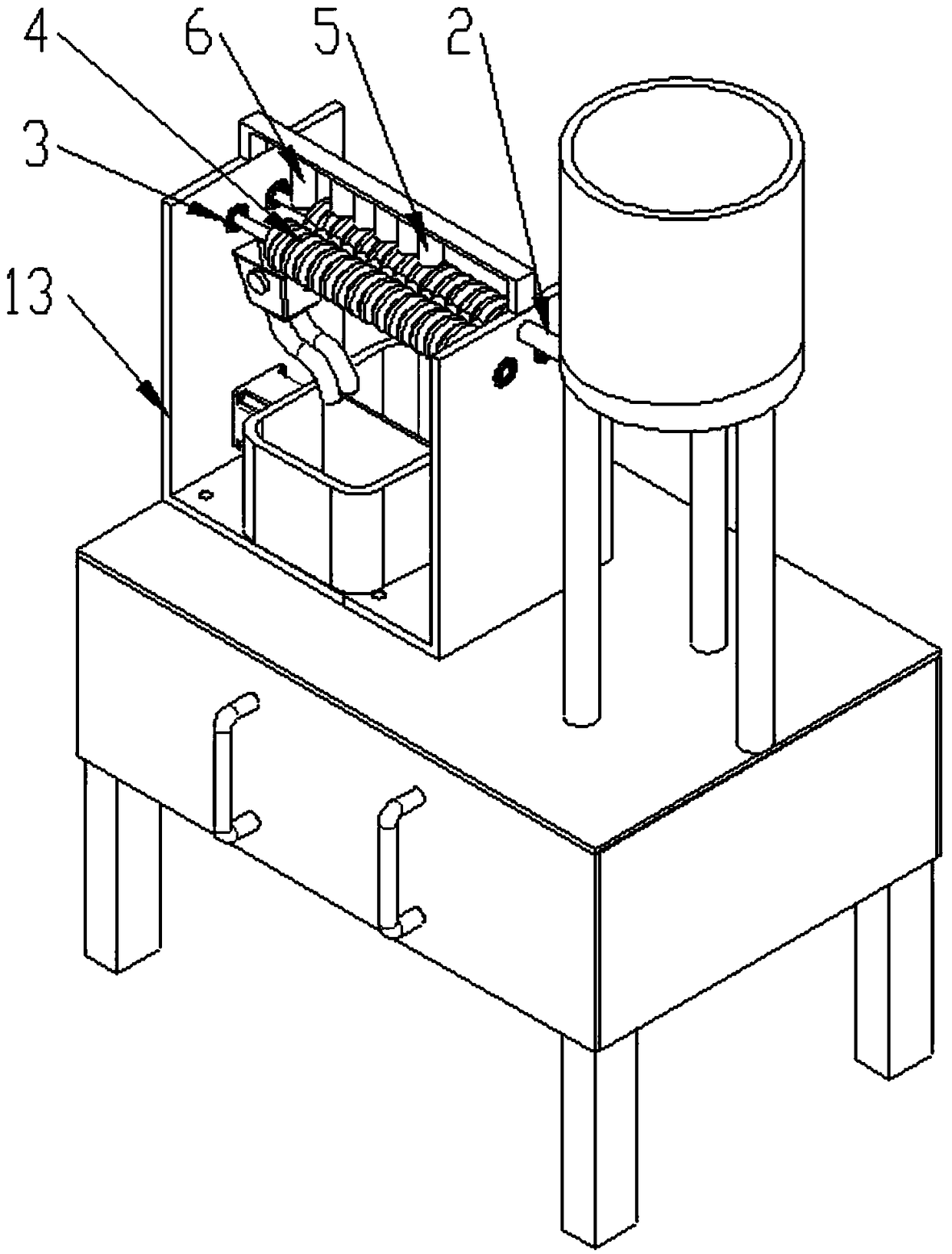

Rapidly screening machine

InactiveCN103639109ASimple structureEasy to useSievingScreeningScreening effectAgricultural engineering

The invention discloses a rapidly screening machine, and relates to a screening machine. The rapidly screening machine is characterized in that an electric motor, a speed reducer, a switch button, screen stencil tension shafts and a trough are arranged on a machine frame; a main shaft and a screen stencil scraping cage are arranged in the trough; the screen stencil scraping cage is fixed on the main shaft; a screen stencil is arranged at the bottom of the trough; the two screen stencil tension shafts are used for tensioning the screen stencil; the electric motor drives the main shaft and the screen stencil scraping cage to rotate by the speed reducer. The rapidly screening machine has a simple structure, and is convenient to use, high in production efficiency, good in screening effect and particularly suitable for screening in peach slices, and has a high popularization value.

Owner:重庆市合川区互帮机械电器加工厂

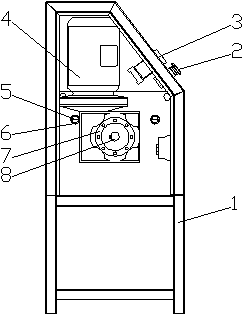

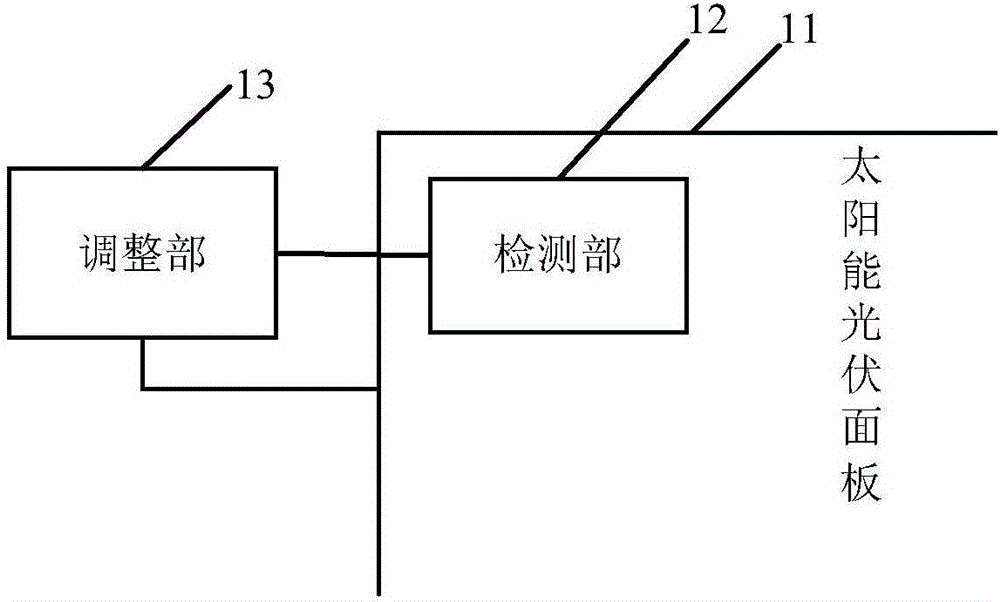

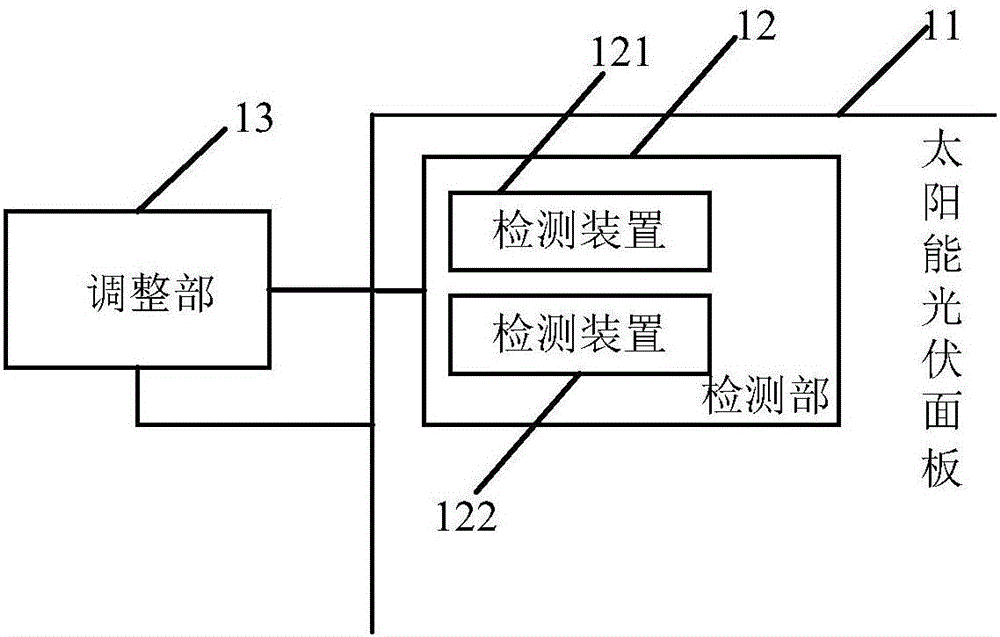

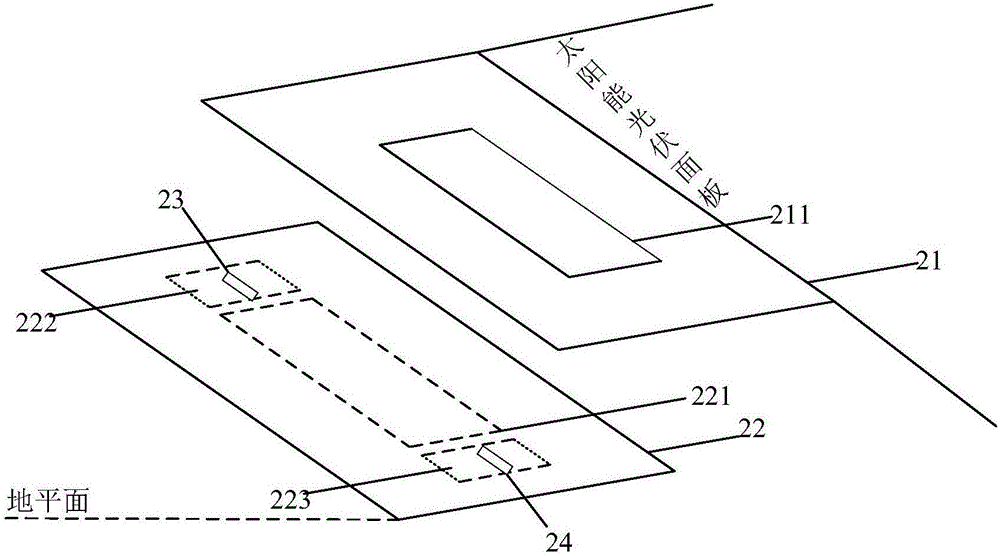

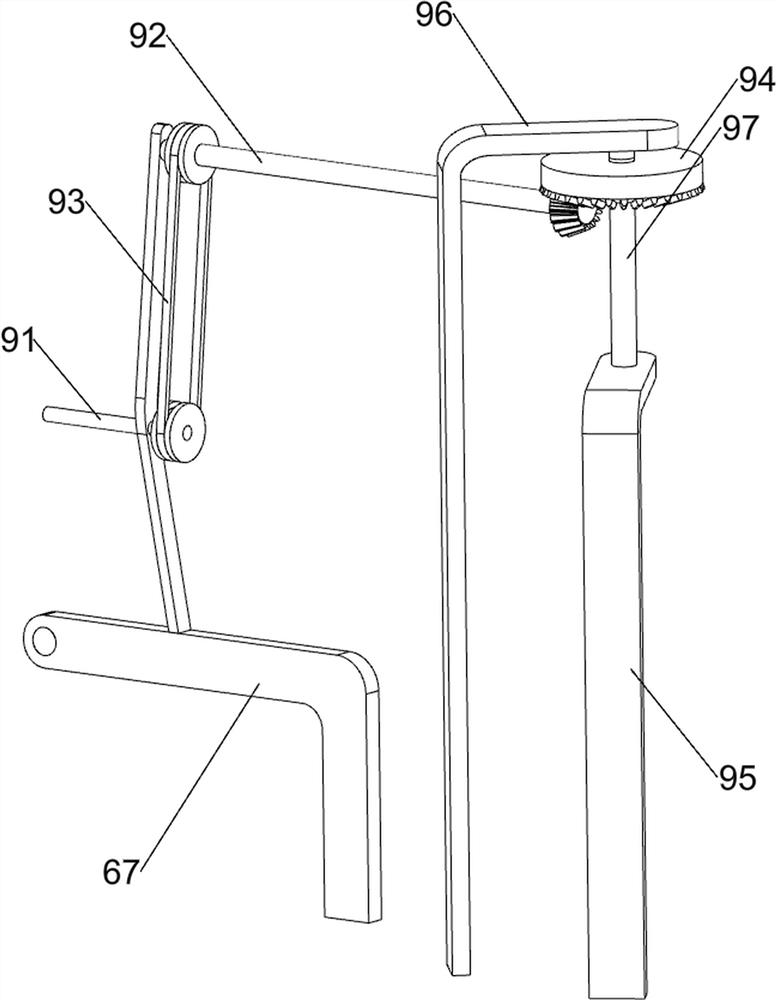

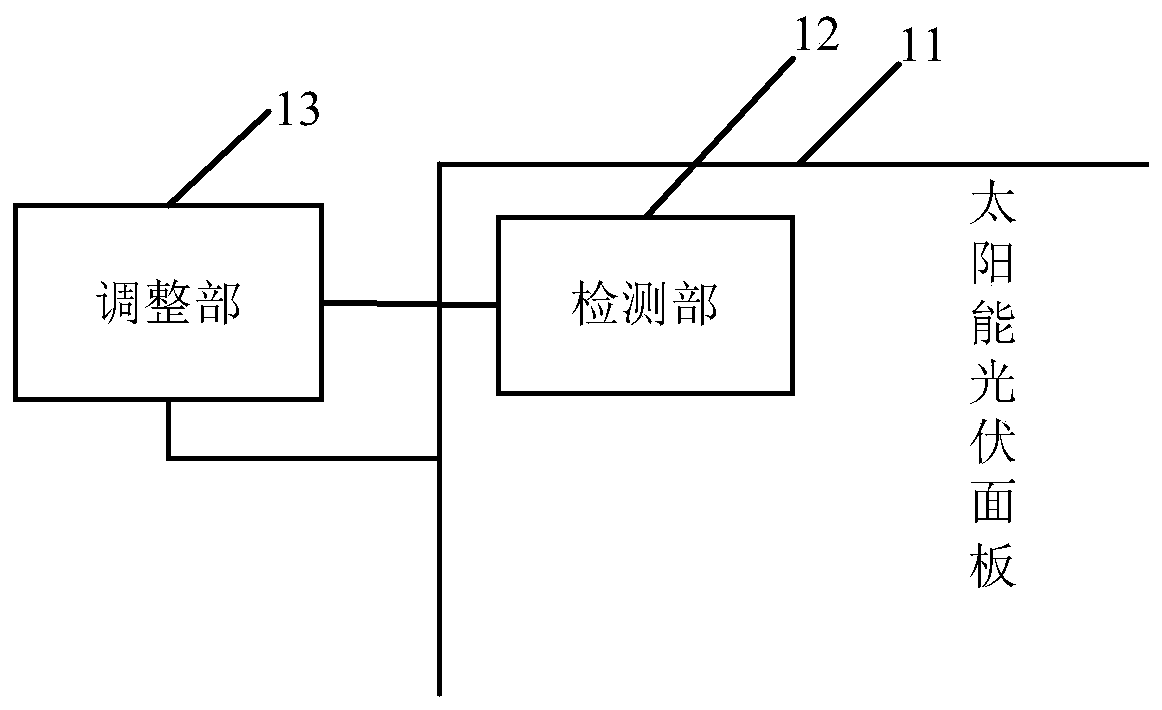

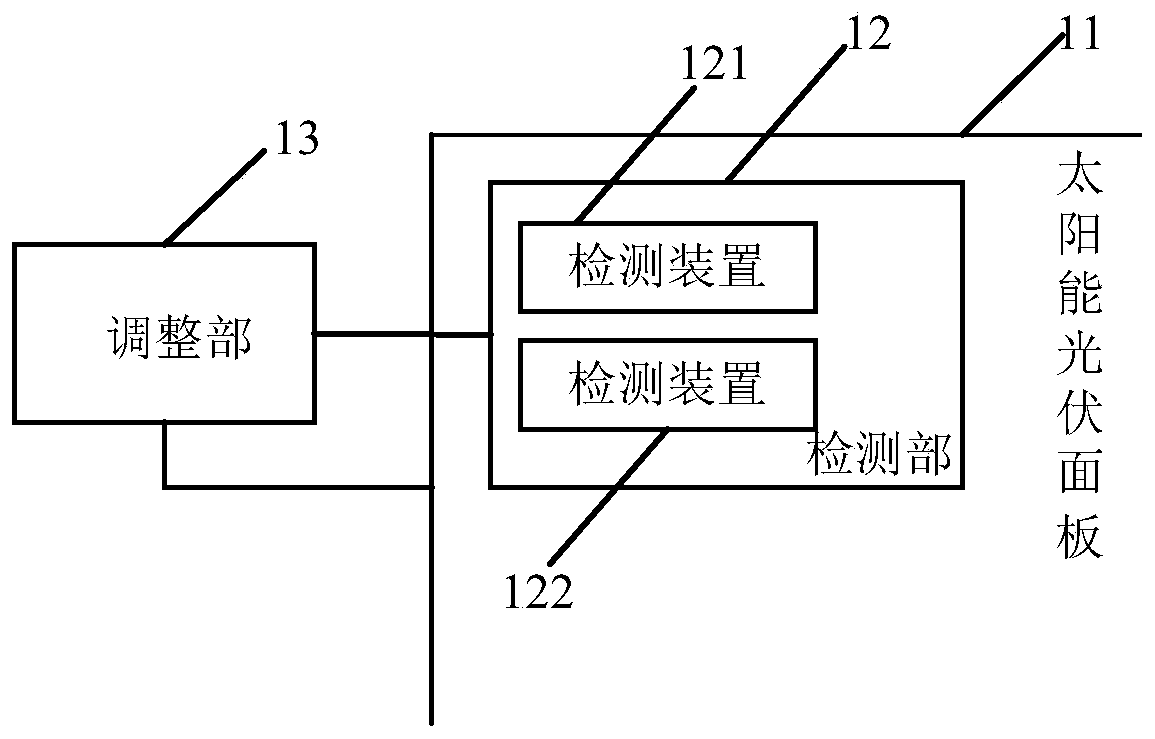

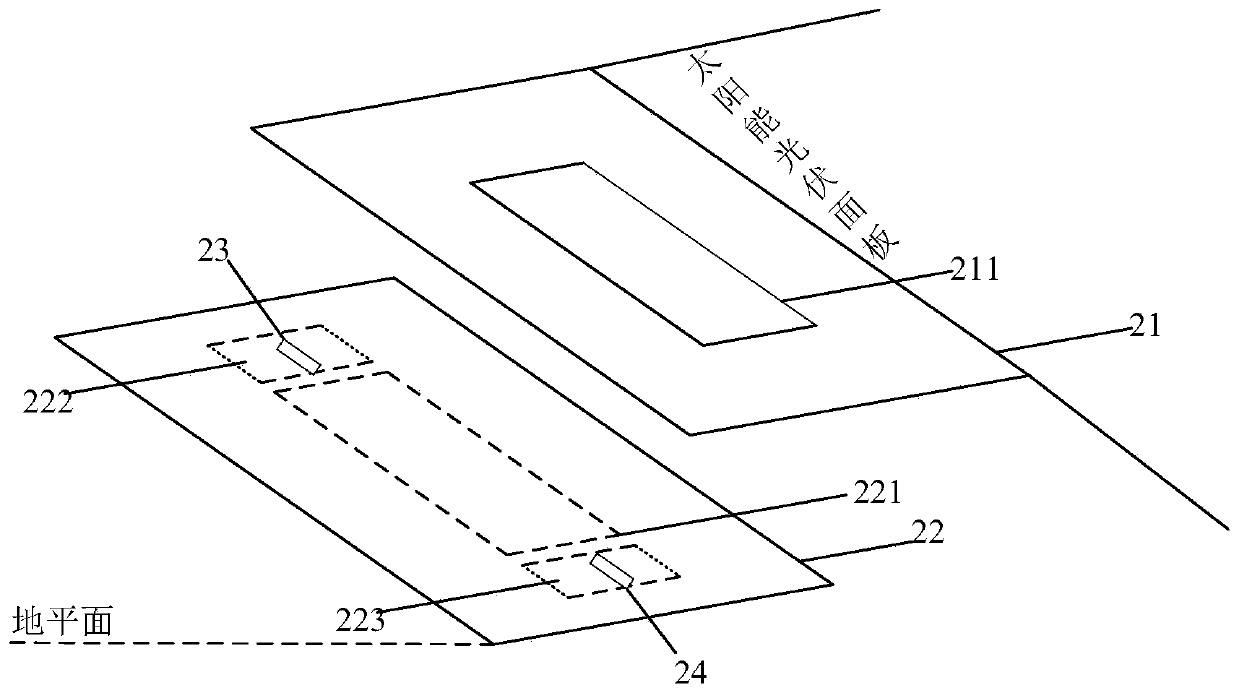

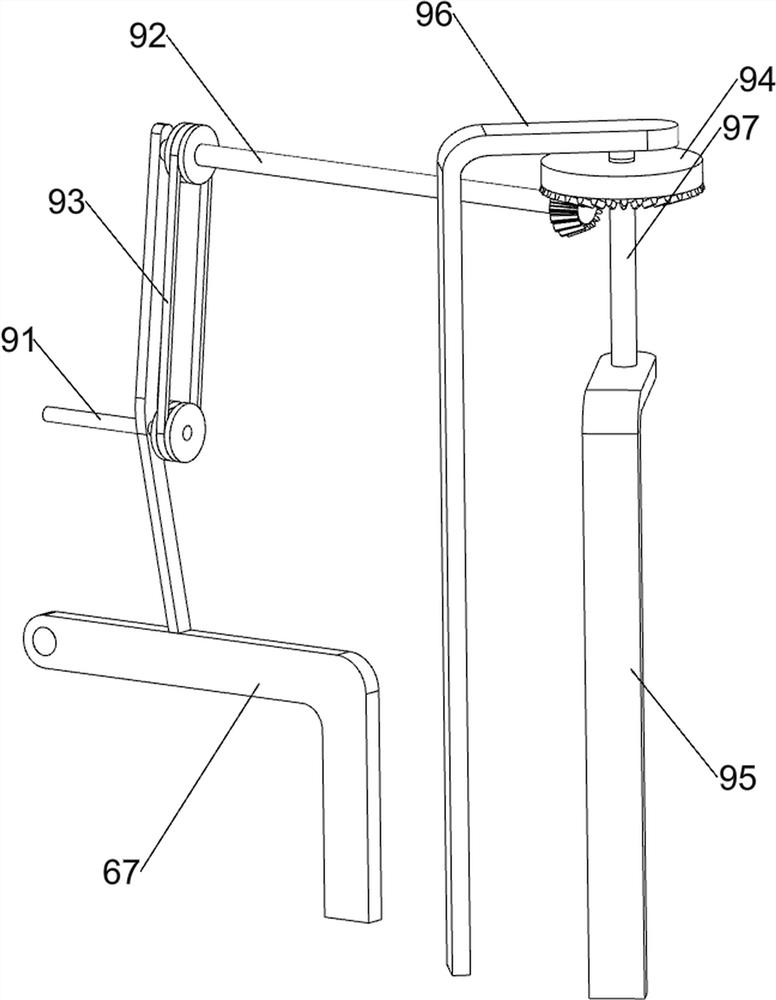

Solar device and control method thereof

ActiveCN106444856AMaximize the use of sunlightIncrease profitControl using feedbackLight energyEngineering

The invention relates to the field of luminous energy radiation, and discloses a solar device and a control method thereof. The solar device comprises a solar photovoltaic panel, a detection part and an adjusting part. The detection part is arranged on the solar photovoltaic panel and parallel to the solar photovoltaic panel. The adjusting part is connected with the solar photovoltaic panel in a linkage way. The adjusting part is electrically connected with the detection part. The detection part detects whether the facing direction of the solar photovoltaic panel and the irradiation direction of sunlight to the solar photovoltaic panel are opposite at the moment. If the detection result is no, the adjusting part adjusts the facing direction of the solar photovoltaic panel according to triggering of the detection part until the facing direction of the solar photovoltaic panel and the irradiation direction of sunlight to the solar photovoltaic panel are opposite at the moment. The invention also discloses a control method of the solar device. Whether the facing direction of the solar photovoltaic panel and the irradiation direction of sunlight to the solar photovoltaic panel are opposite at the moment is monitored in real time, and the facing direction of the solar photovoltaic panel is automatically adjusted according to the monitoring result so as to enhance the utilization rate of sunlight.

Owner:XIAN YIPU COMM TECH

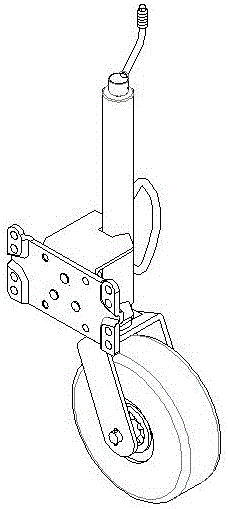

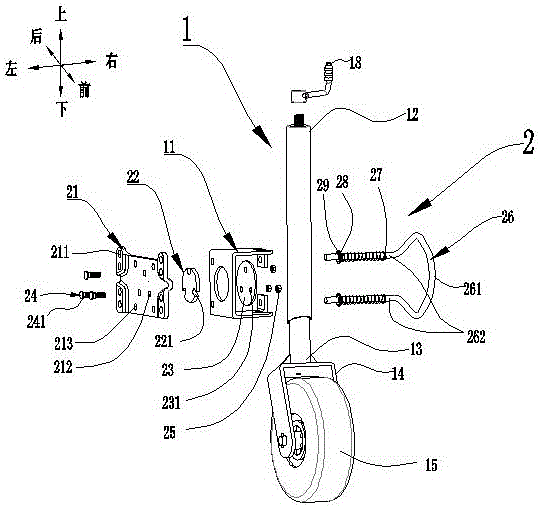

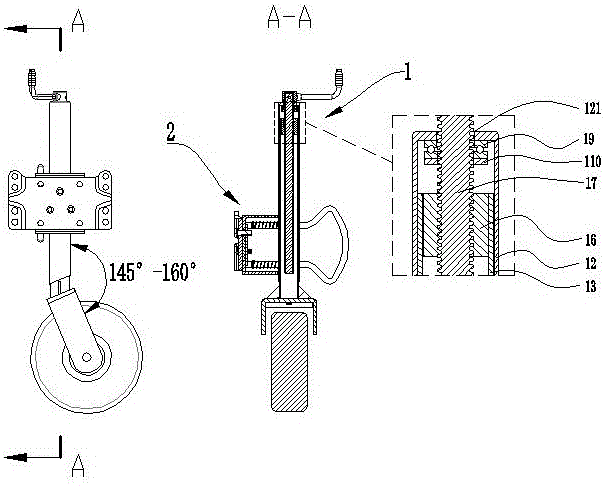

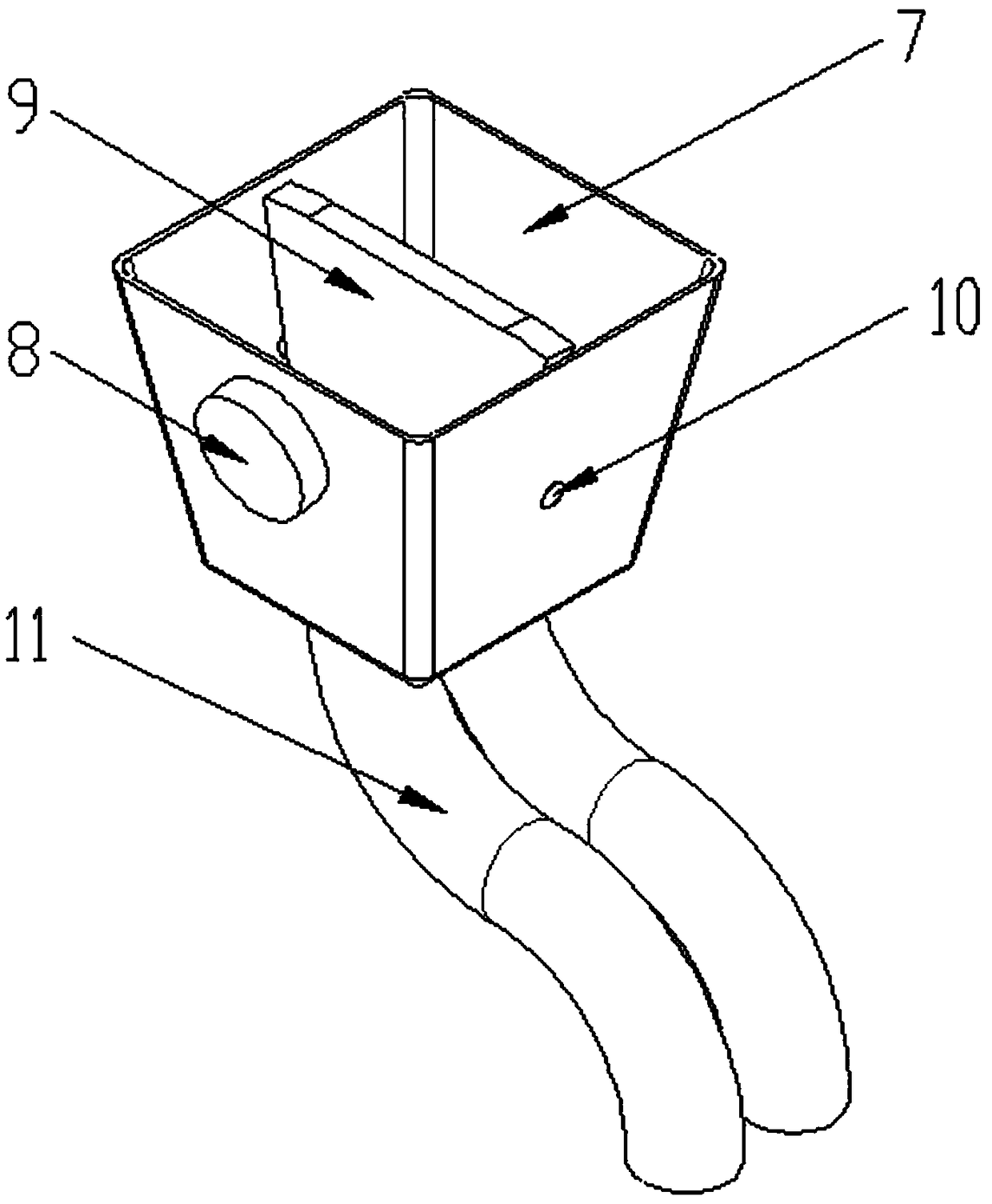

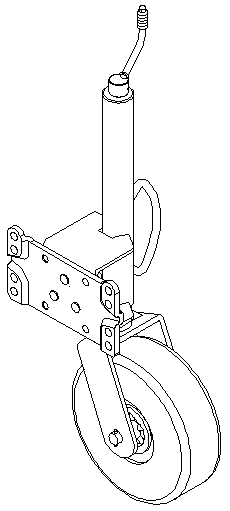

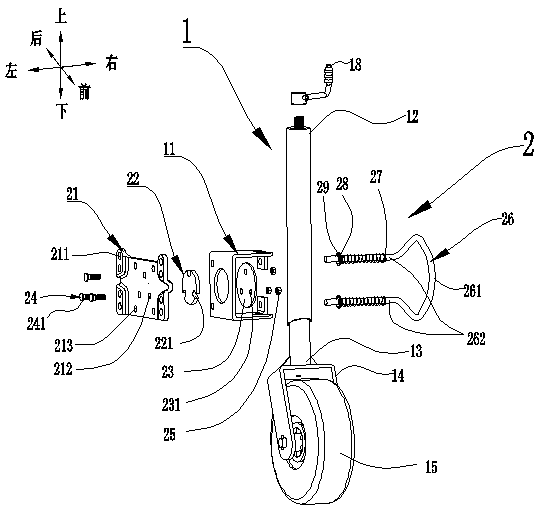

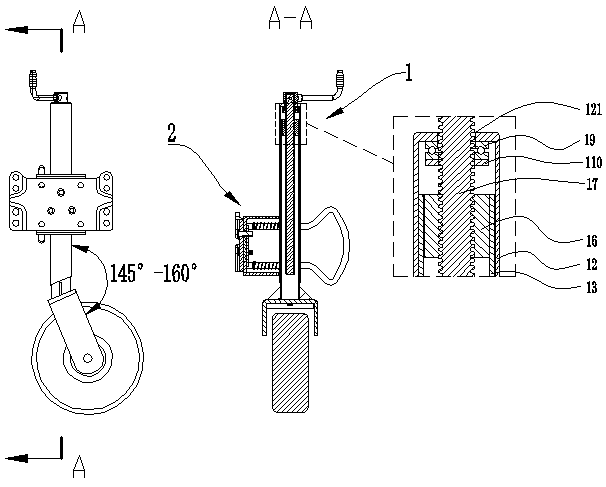

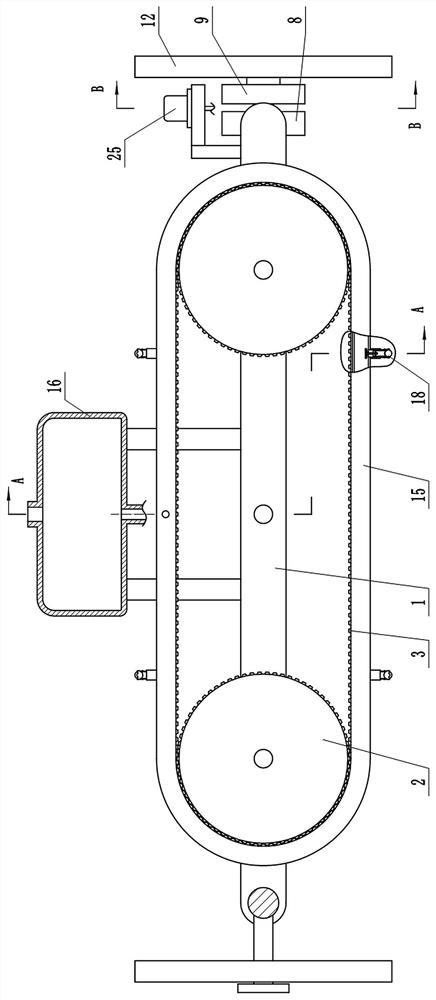

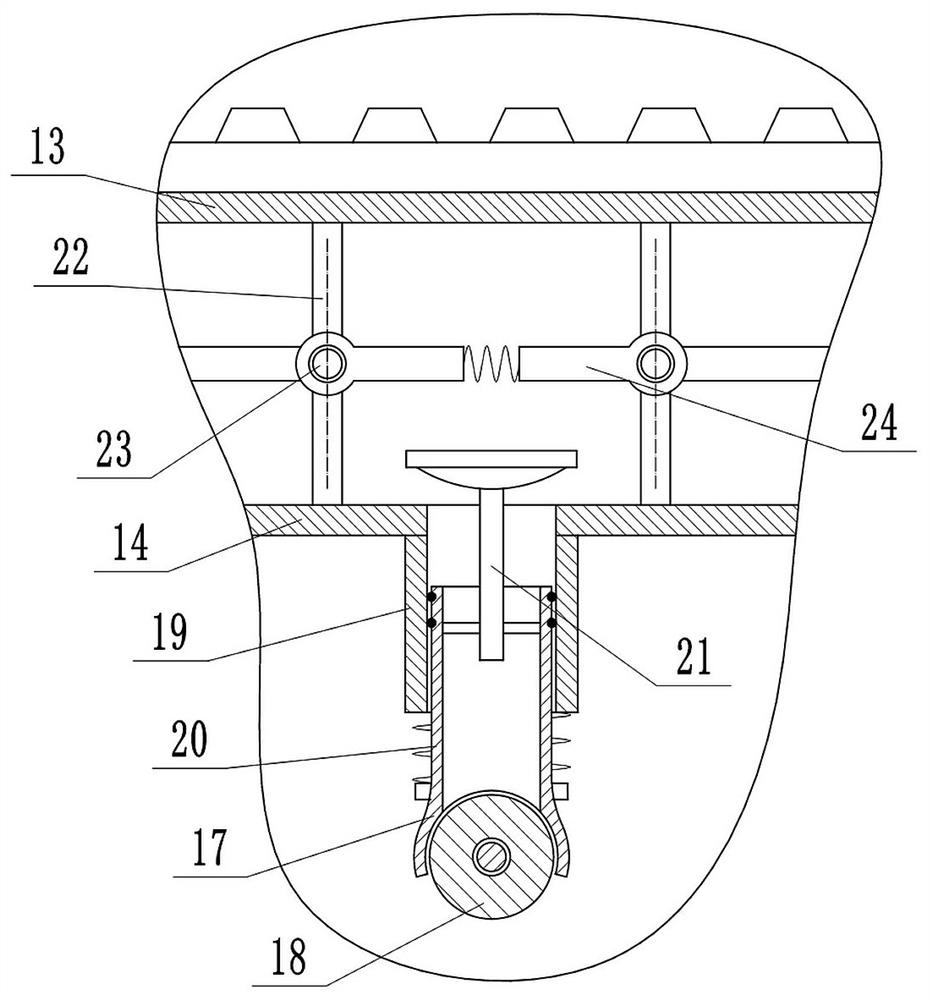

Travel trailer guide wheel device

ActiveCN106335478ASimple structureEasy to processVehicle fittings for lifting and manoeuvringVehicle with living accommodationEngineeringMechanical engineering

The invention relates to a travel trailer guide wheel device, comprising a guide wheel telescopic device and a guide wheel collecting and placing device. The travel trailer guide wheel device is characterized in that one lateral surface of the guide wheel collecting and placing device is fixedly connected to the corresponding position of a travel trailer, the middle part of the guide wheel telescopic device is movably connected with the guide wheel collecting and placing device, the guide wheel telescopic device can rotate relative to the overall guide wheel collecting and placing device by tensioning a pull rod of the guide wheel collecting and placing device, the guide wheel telescopic device can be locked at a horizontal or vertical position by loosening the pull rod, an overall guide wheel can stretch and contract up and down by rotating a handle of the guide wheel telescopic device, and the guide wheel can turn by continuously rotating the handle when the guide wheel is in reliable contact with the ground. The travel trailer guide wheel device is simple in structure, convenient to machine and install and low in cost, can allow the travel trailer to move in the specified direction before parking, and has a broad application space.

Owner:WEIHAI GOLDEN TRAVEL & LEISURE PROD CO LTD

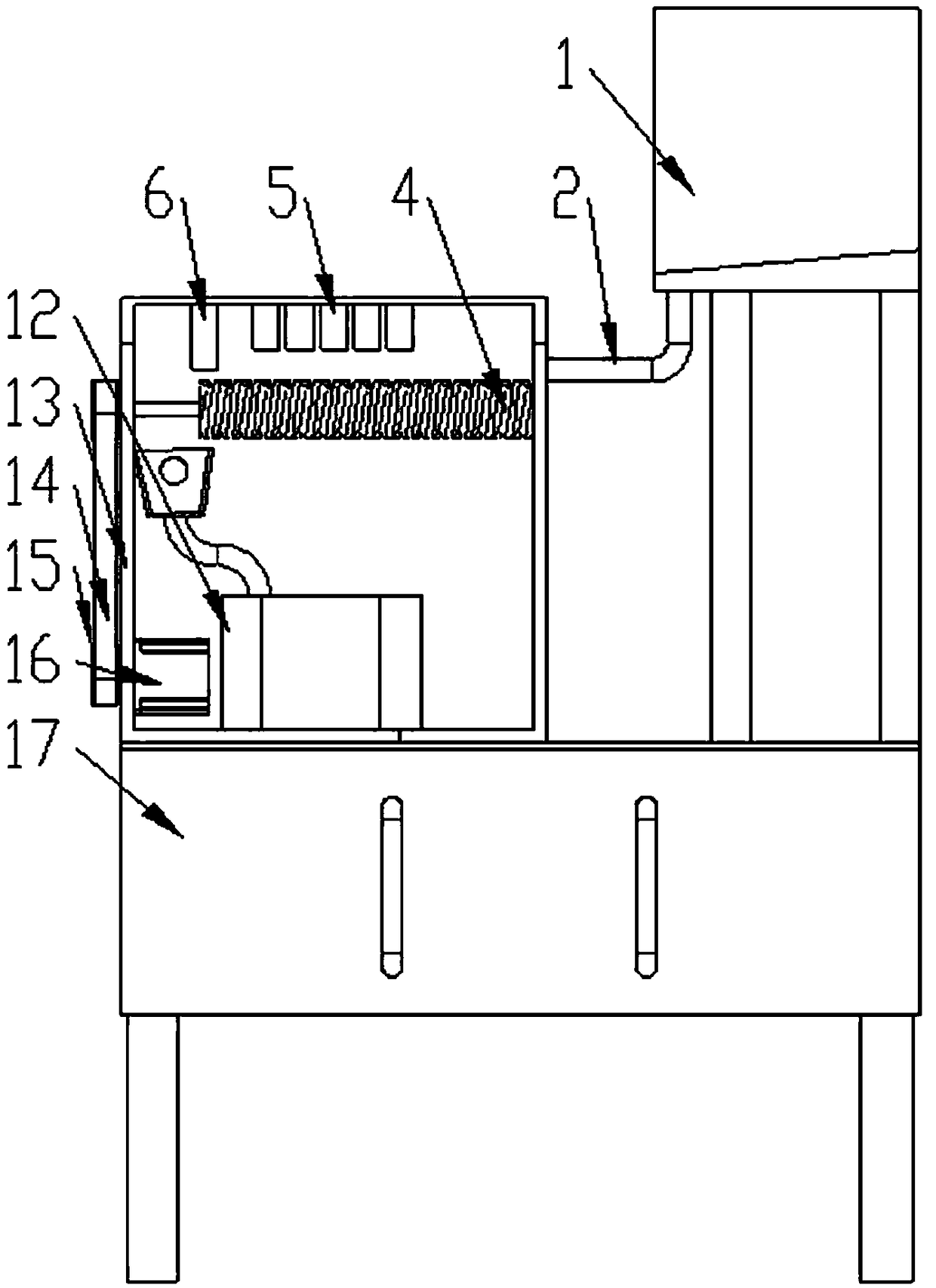

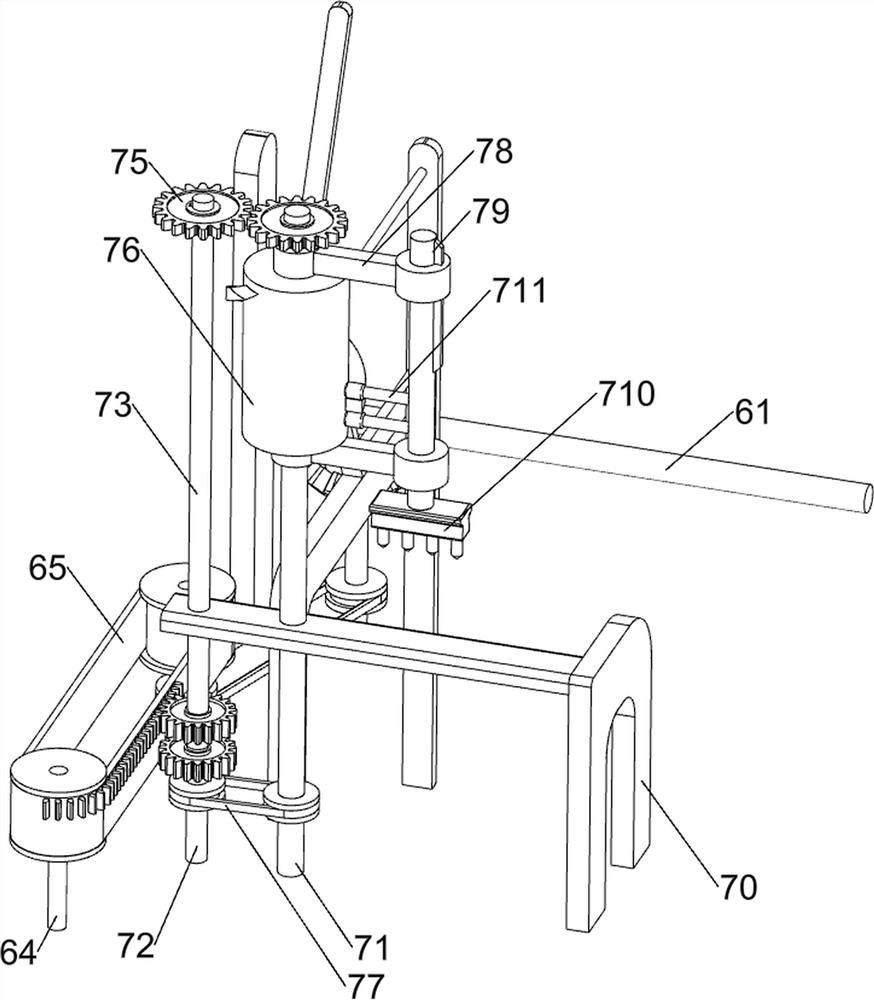

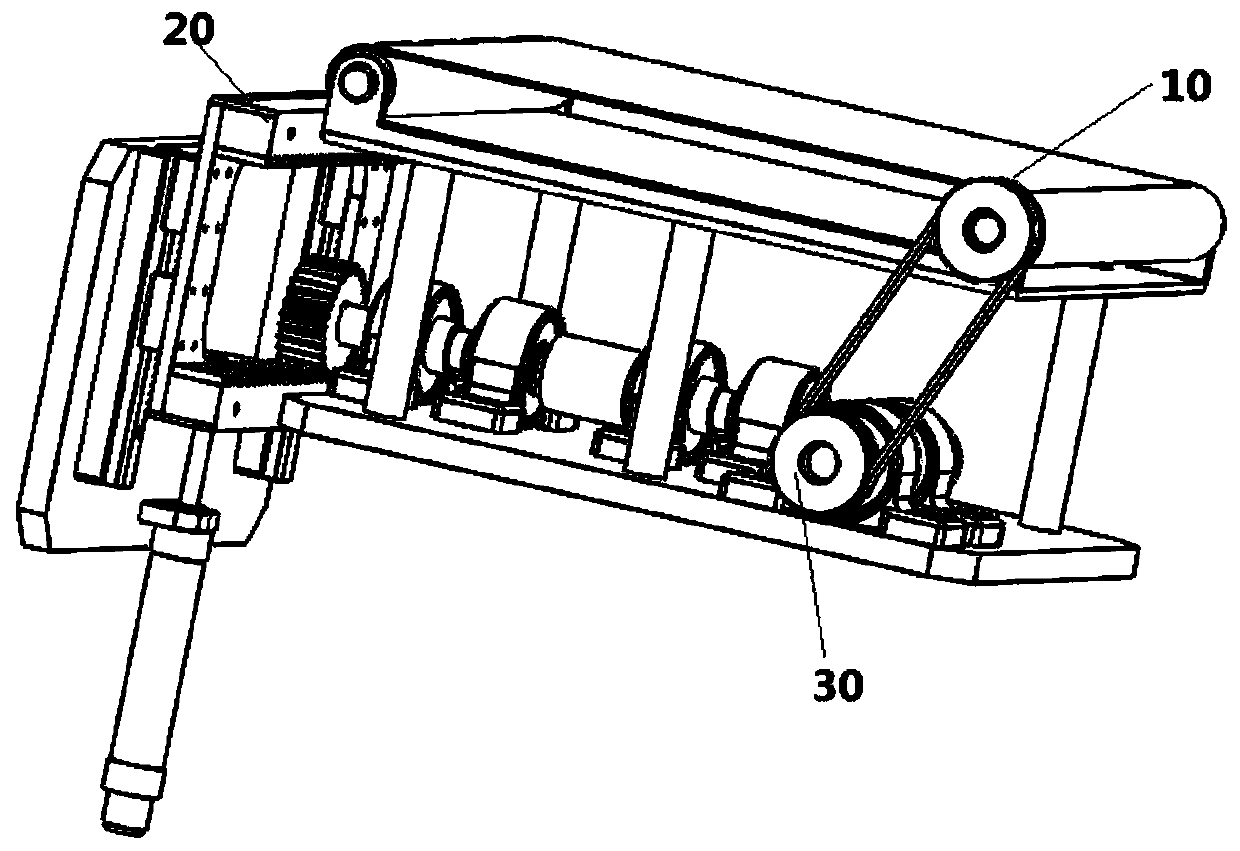

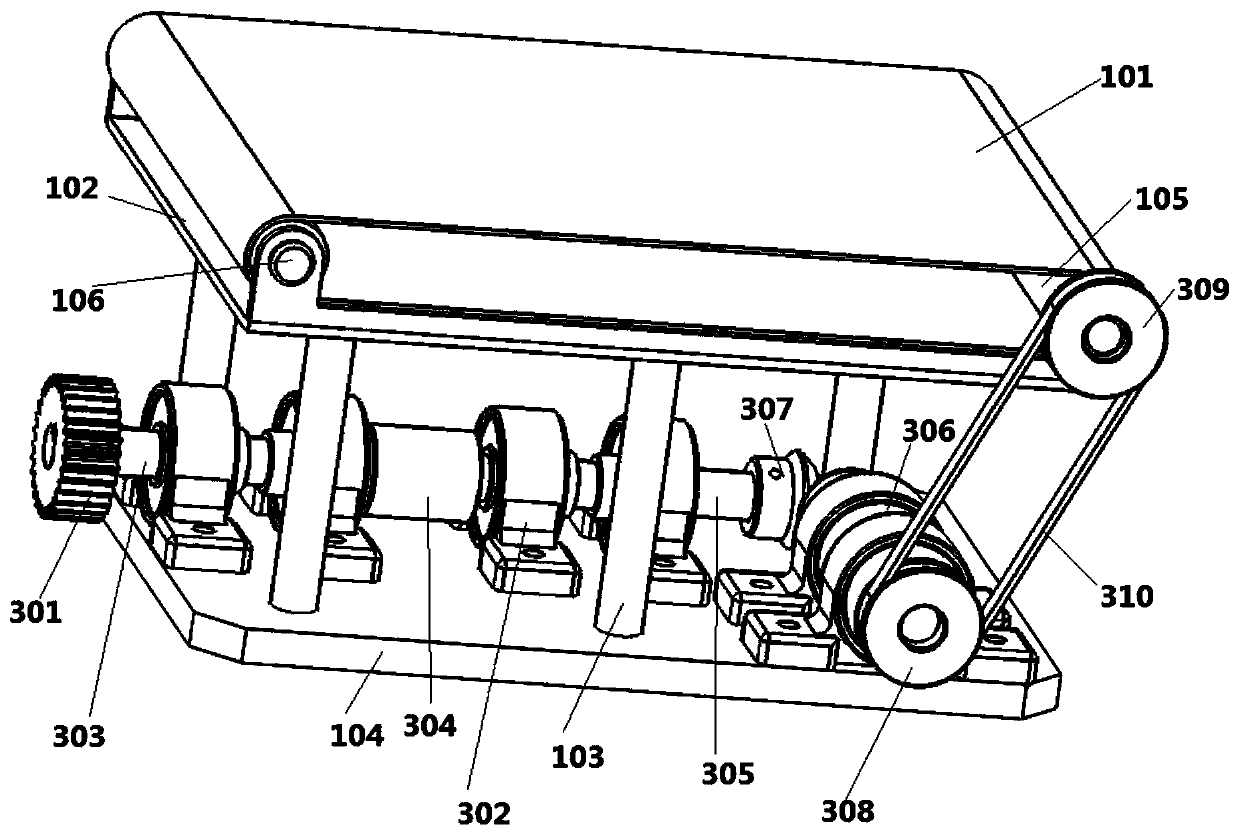

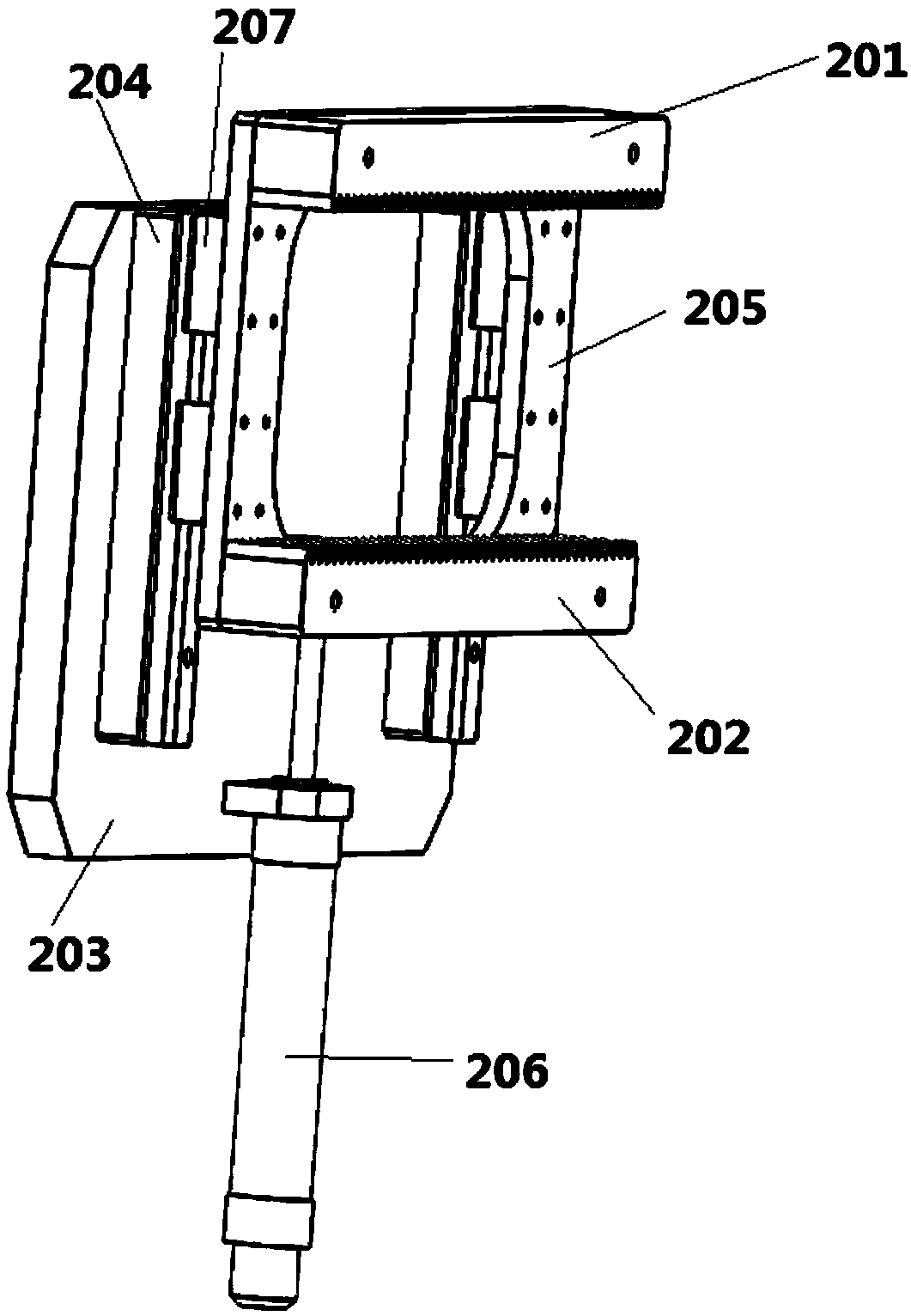

Environment-friendly and energy-saving type metal plate welding equipment

ActiveCN112317989ARealize the function of intermittently fixing sheet metalControl the direction of rotationWelding/cutting auxillary devicesAuxillary welding devicesGear wheelType metal

The invention relates to welding equipment, in particular to environment-friendly and energy-saving type metal plate welding equipment. The provided environment-friendly and energy-saving type metal plate welding equipment is high in welding efficiency, a workpiece does not need to be clamped by auxiliary equipment, and welding quality is high. The environment-friendly and energy-saving type metalplate welding equipment provided by the invention comprises a bottom plate used for installing the whole equipment, a first supporting frame, a servo motor, a placing mechanism, a clamping mechanism,a conveying mechanism and a welding mechanism. The first supporting frame is arranged on one side of the top of the bottom plate. The servo motor is arranged at the top of the first supporting frame.The placing mechanism is arranged on one side of the top of the bottom plate. The clamping mechanism is arranged in the placing mechanism. The conveying mechanism is arranged on one side of the top of the bottom plate. The welding mechanism is arranged in the middle of the top of the bottom plate. A toothed belt wheel assembly is matched with second gears, the toothed belt wheel assembly is meshed with the second gears on the upper portion and the lower portion respectively, therefore the rotating direction of a fourth rotating shaft can be controlled, and then a welding gun can be driven tomove up and down.

Owner:佛山市顺德区瑞利凯金属制品有限公司

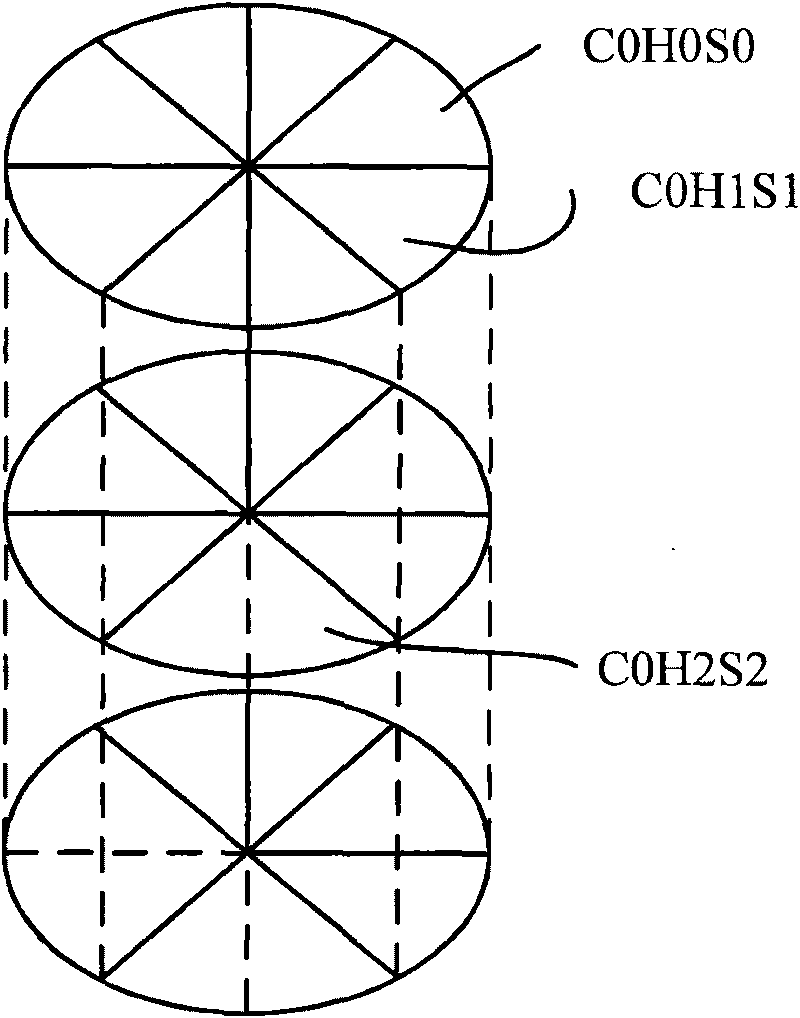

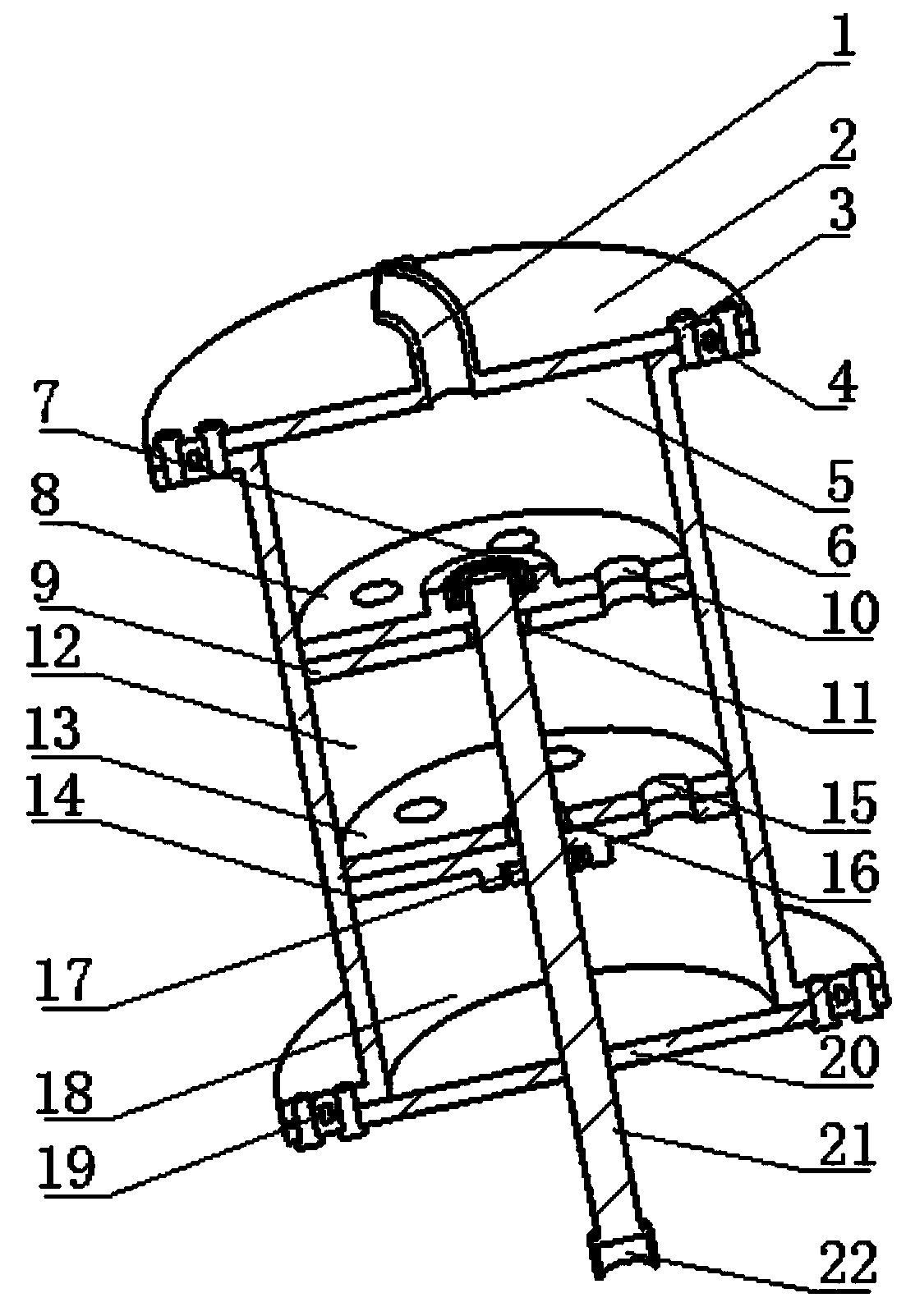

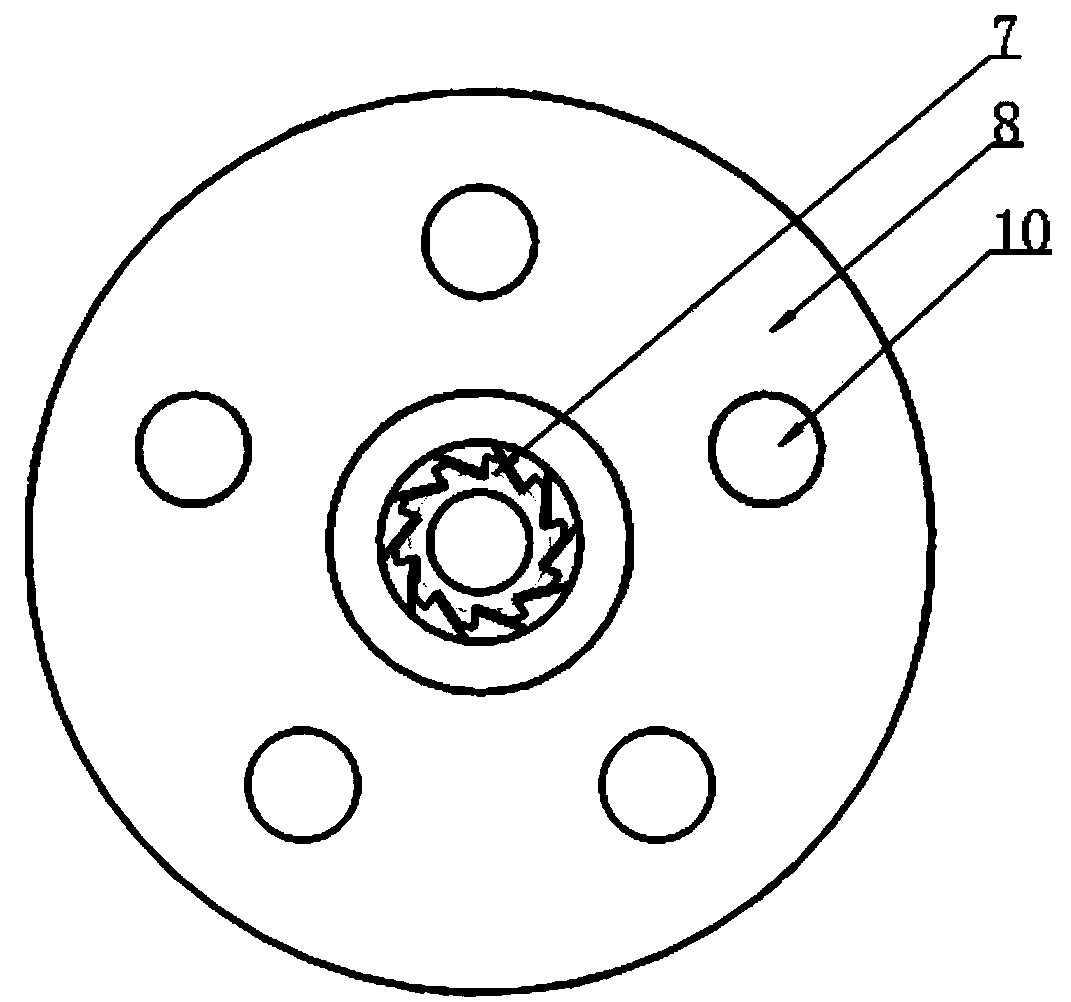

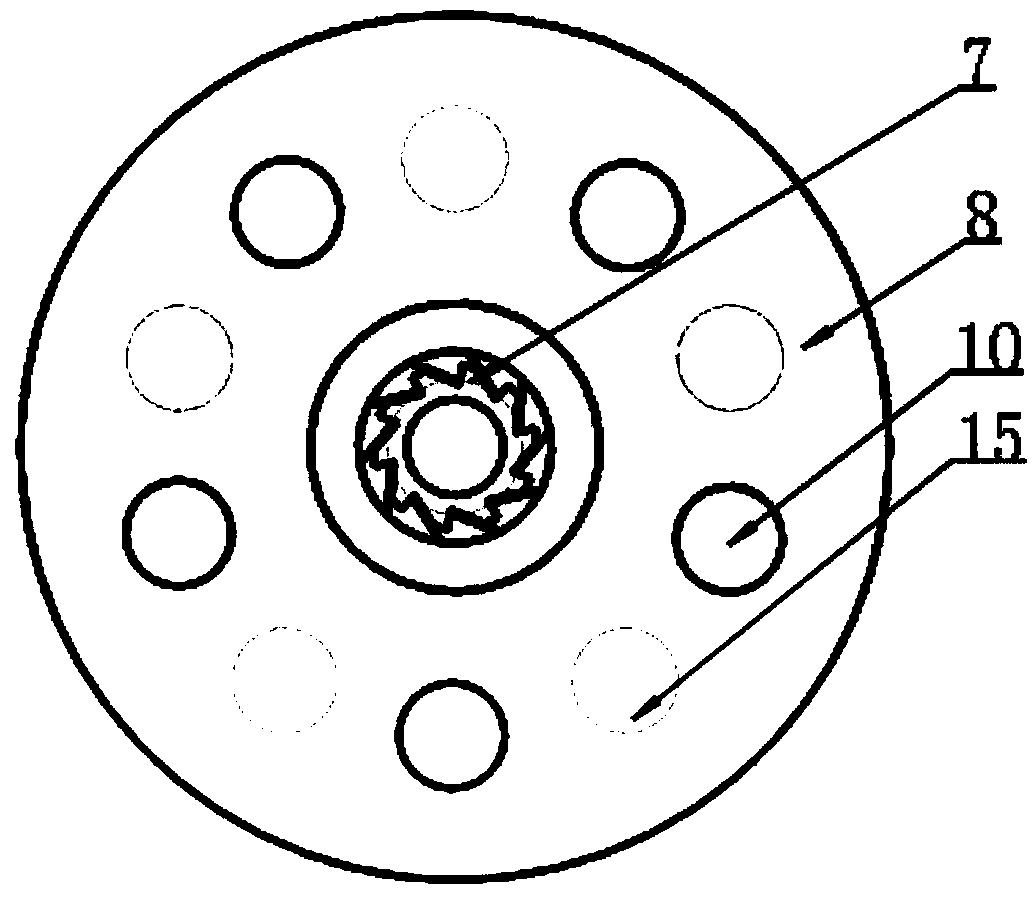

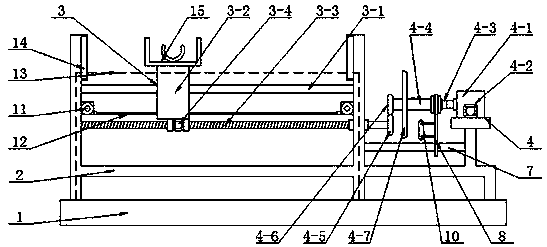

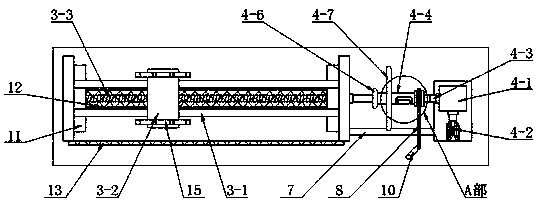

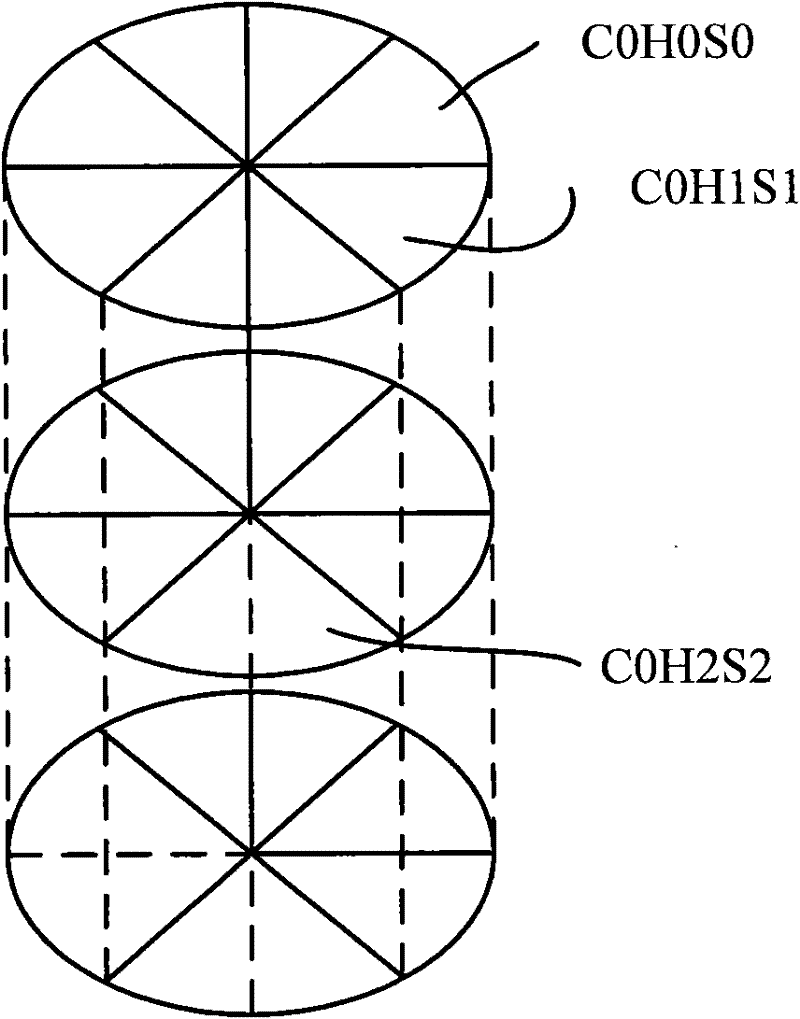

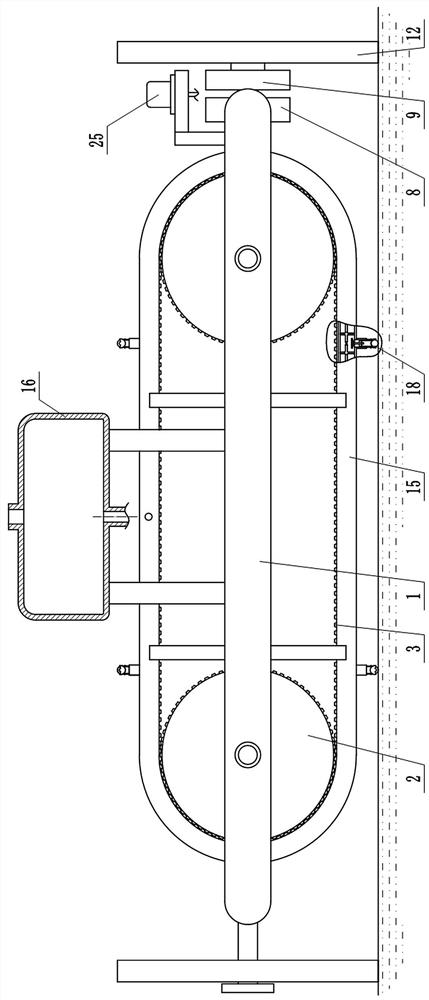

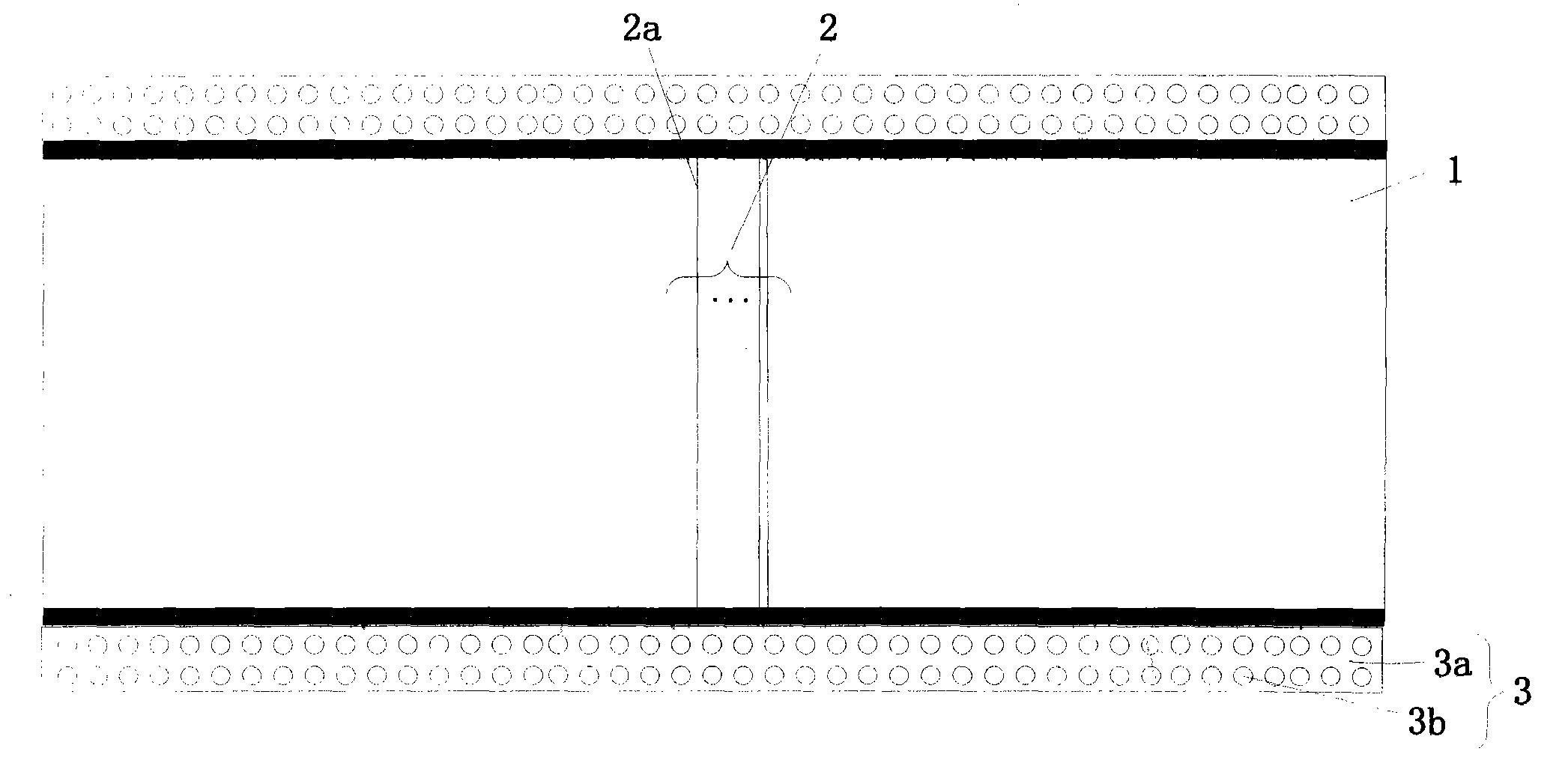

Method for detecting surface defects of steel ball based on double-thread expansion method

InactiveCN108896573AReduce severe wear and tearImprove fullyMaterial analysis by optical meansHelical lineSteel ball

The invention relates to a method for detecting surface defects of a steel ball based on a double-thread expansion method. The method comprises a transmission mechanism, an expansion mechanism, a sorting mechanism and a detection system, wherein the feeding mechanism is connected with inlet ends of lead screws through a feeding pipeline, two ends of the lead screws are fixed on bearings, the leadscrews are driven to synchronously rotate by a stepping motor through a synchronous belt, threads with relatively large screw pitches are formed in the lead screws, the steel ball falls into a space between the threads of the two lead screws to form four contact surfaces with thread forms, the lead screws rotate to drive the steel ball to do a variable axis rotary motion, an expansion surface of the steel ball is changed according to the track of a helical line, five high-speed cameras are distributed above the lead screws and can be used for alternately capturing a to-be-detected surface of the expanded steel ball; and the tails of the lead screws are step-shaped, the detected steel ball falls into a receiving hopper through the step-shape tails, and an electromagnet is arranged in the front-back direction of the receiving hoper and is used for controlling a baffle to rotate around the shaft so that the steel balls fall into a storage box through a discharging pipe. According to the system described by the invention, the defects of the steel ball in a certain diameter range can be detected, and the system has relatively high detection efficiency.

Owner:SHANDONG UNIV OF SCI & TECH

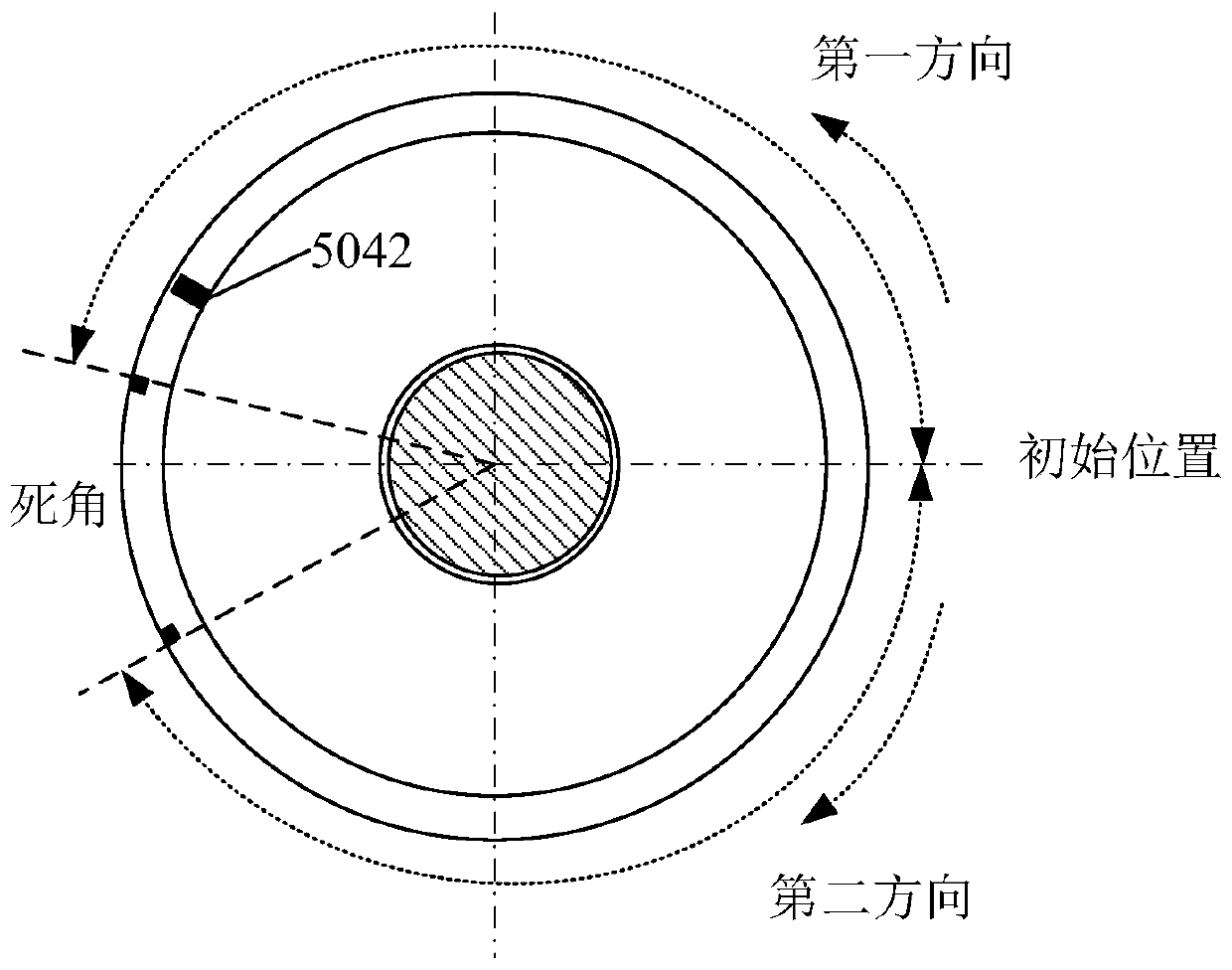

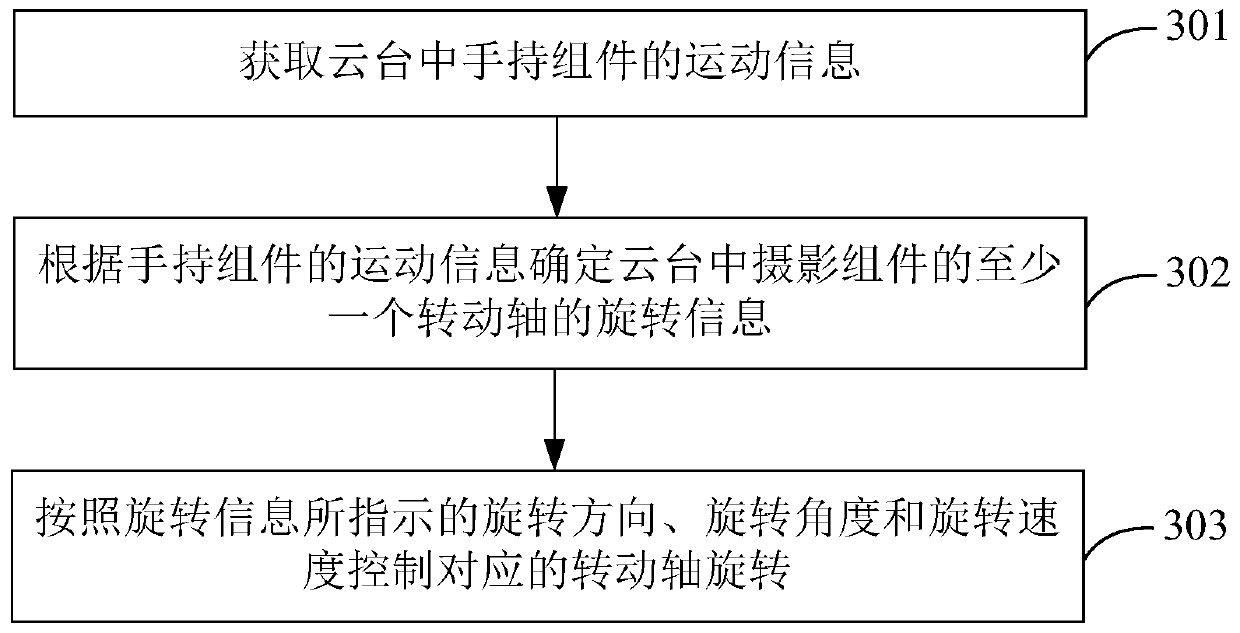

Pan-tilt, pan-tilt control method, pan-tilt control device and computer storage medium

ActiveCN111142580AGuaranteed stabilityQuality assuranceTelevision system detailsColor television detailsControl theoryMechanical engineering

The embodiment of the invention provides a pan-tilt, a pan-tilt control method, a pan-tilt control device and a computer storage medium. The pan-tilt comprises a processor, a handheld assembly, a camera assembly and a shaft assembly, the camera assembly can rotate relative to the handheld assembly through the shaft assembly; the maximum angle of the camera assembly rotating around a preset rotating shaft in the first direction from the initial position is a first angle, the maximum angle of the camera assembly rotating around the preset rotating shaft in the second direction from the initial position is a second angle, the first angle is not equal to the second angle, and at least one rotating shaft comprises the preset rotating shaft. When a user holds the pan-tilt by a hand, the rotationangle of the camera assembly is ensured to be larger, the processor controls the rotation direction, the rotation angle and the rotation angular speed of the rotation shaft more accurately, and the better shooting quality is kept.

Owner:SHANGHAI MOSHON TECH CO LTD

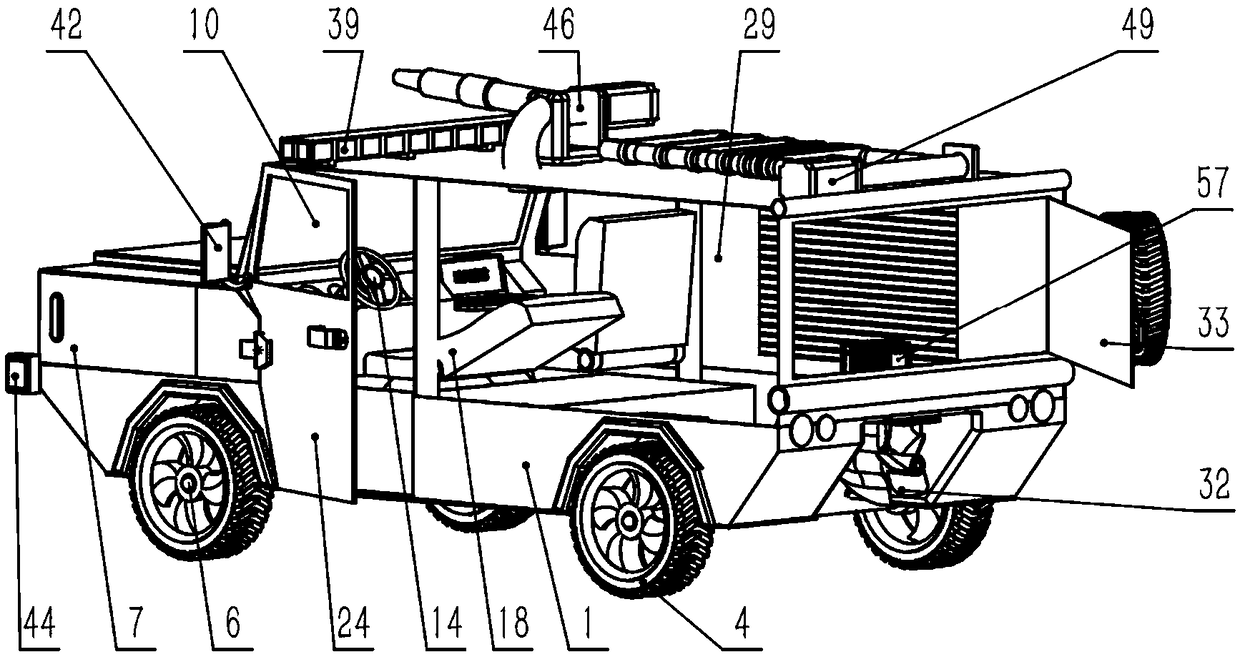

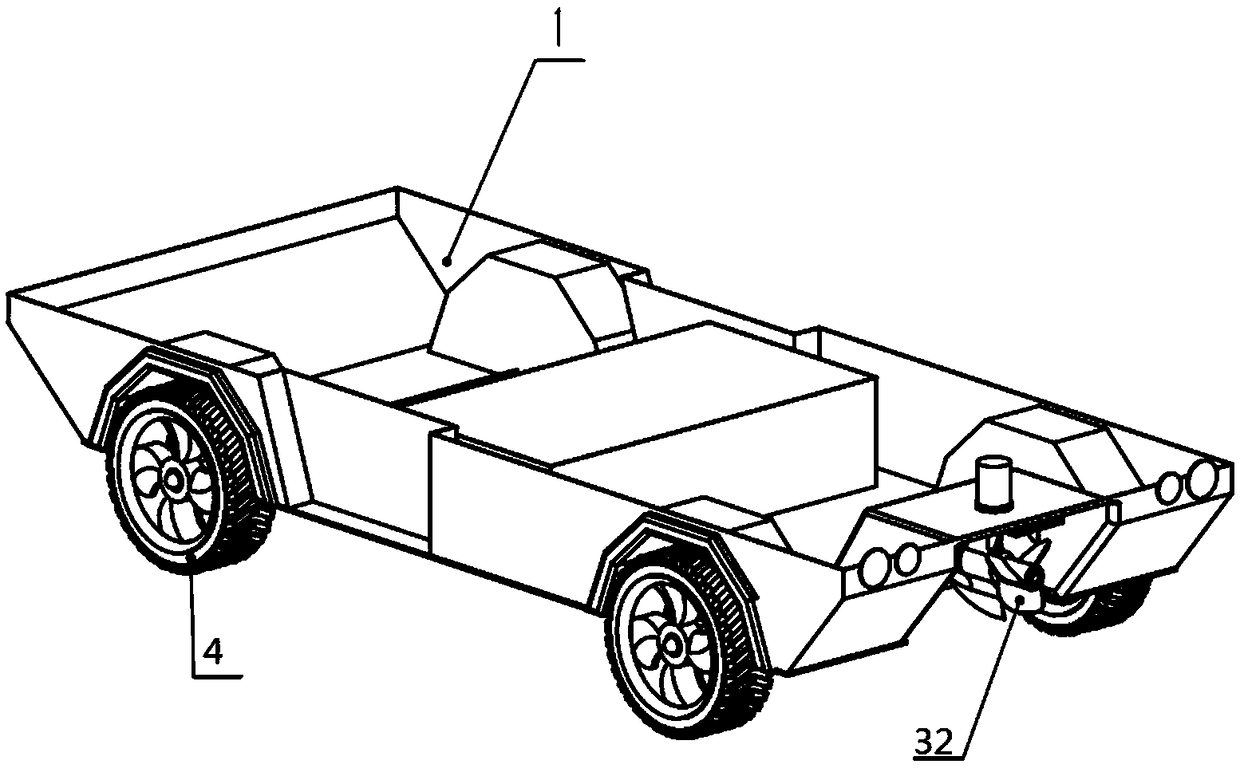

Amphibious fire truck

InactiveCN109017179AScientific and reasonable designEasy to useAmphibious vehiclesFire rescueHull structureAutomotive engineering

The invention discloses an amphibious fire truck, comprising a chassis, a propeller, a propeller driving mechanism, an amphibious cab, an electric motor, a wheel, a vehicle transmission shaft and an electric control device arranged on the chassis; The chassis is a ship hull structure and is made of a ship steel plate; The electric control device is respectively connected with the amphibious cab, the propeller driving mechanism and the motor; The propeller driving mechanism is used for driving the propeller to rotate when the fire truck is located in the water so as to provide thrust for the fire truck and drive the fire truck to travel in the water; The electric motor is used for driving the wheels to move through the vehicle transmission shaft when the fire truck is located on the land, thereby driving the fire truck to travel on the land. The amphibious fire truck of the invention is scientifically and reasonably designed, the chassis is made of marine steel plate, can realize the amphibious function of the amphibious truck, adapts to various working conditions, has good popularization and use value, and has strong practicability.

Owner:浙江睦田消防科技开发有限公司

A guide wheel device for a towed caravan

ActiveCN106335478BSimple structureEasy to processVehicle fittings for lifting and manoeuvringVehicle with living accommodationMechanical engineeringEngineering

Owner:威海黑系畅游智能科技有限公司

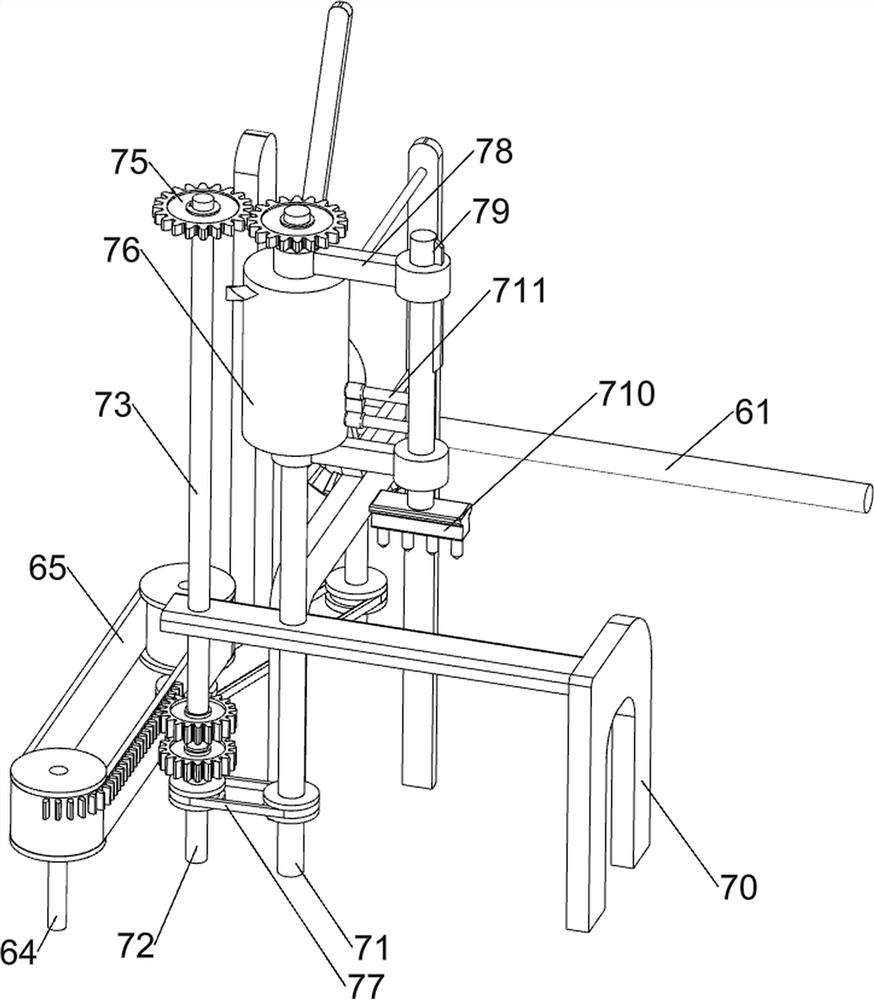

Vehicle spraying device with spraying amount convenient to control

ActiveCN110449298AControl spray volumeControl the direction of rotationSpraying apparatusEngineeringSpur gear

The invention discloses a vehicle spraying device with the spraying amount convenient to control, and relates to the technical field of automobile maintenance equipment. A first guiding rod is fixedlyarranged on a support, and a sliding block is slidably arranged on the first guiding rod; a mounting frame is fixedly arranged on the sliding block, and a screw nut is fixedly arranged on the lower surface of the sliding block; a screw rod is arranged in the screw nut in a threaded manner, and a gearbox is fixedly arranged on the support; a transmission rod is fixedly arranged on the output shaftof the gear box; a guiding sleeve is movably arranged on the transmission rod in a sleeving manner, and a spur gear is fixedly arranged at the left end of the guiding sleeve; a transmission gear is fixedly arranged at the right end of the screw rod, the spur gear is engaged with the transmission gear, and a ring gear is fixedly arranged on the guiding sleeve; and by controlling the traveling speed of a spray gun, the spraying amount per unit area is controlled, the vehicle spraying device can be cooperatively used with equipment such as an existing spray gun, and the equipment updating cost is low.

Owner:江苏长虹机械设计院有限公司

Disc rotating direction control method and device and disc

InactiveCN101727940BControl the direction of rotationMemory adressing/allocation/relocationRecord information storageResonanceElectric machine

The embodiment of the invention discloses disc rotating direction control method and device and a disc. The disc rotating direction control method comprises the steps of: receiving a trigger signal; generating a driving pulse according to the trigger signal; and sending the driving pulse to a spindle driver so that a spindle driver can control the rotating direction of a spindle motor according to the driving pulse, wherein the spindle motor is used for driving discs to rotate. The embodiment of the invention can control the rotating direction of discs, effectively lower the disc resonance and reduce the disc vibration, thereby realizing the purpose of disc protection.

Owner:HUAWEI DIGITAL TECH (CHENGDU) CO LTD

Indoor decoration wire harness drawing device

ActiveCN112746722AControl the direction of rotationControl speedDecorative surface effectsBuilding constructionsEngineeringBevel gear

The invention provides an indoor decoration wire harness drawing device. The problems that in the prior art, when a wall face and the ground are decorated, the distances between drawn oblique lines are not uniform, and the later watching effect is affected are effectively solved. According to the technical scheme, the indoor decoration wire harness drawing device comprises a rack, wherein belt wheels are arranged on the rack, a synchronous belt is arranged between the two belt wheels on the belt wheels, and a rolling brush is arranged on the synchronous belt; and a planetary gear mechanism is arranged on the rear side of the rack, a first bevel gear is arranged on the left side of a sun wheel, a second bevel gear is arranged on the belt wheel on the right side, a cylinder is arranged at the right end of a gear ring, a first friction wheel is arranged at the right end of the cylinder, a second friction wheel is arranged on the right side of the first friction wheel, a small friction wheel is arranged between a first friction disc and a second friction disc, and a wheel is connected to the right end of the second friction wheel. The indoor decoration wire harness drawing device is ingenious in structure, standard oblique lines or grid lines required by a user can be drawn according to a certain rule, drawing can be carried out according to a pre-designed route, the distances between the lines are distributed uniformly in the drawing process, operation is convenient, and adaptability is high.

Owner:YELLOW RIVER CONSERVANCY TECHN INST

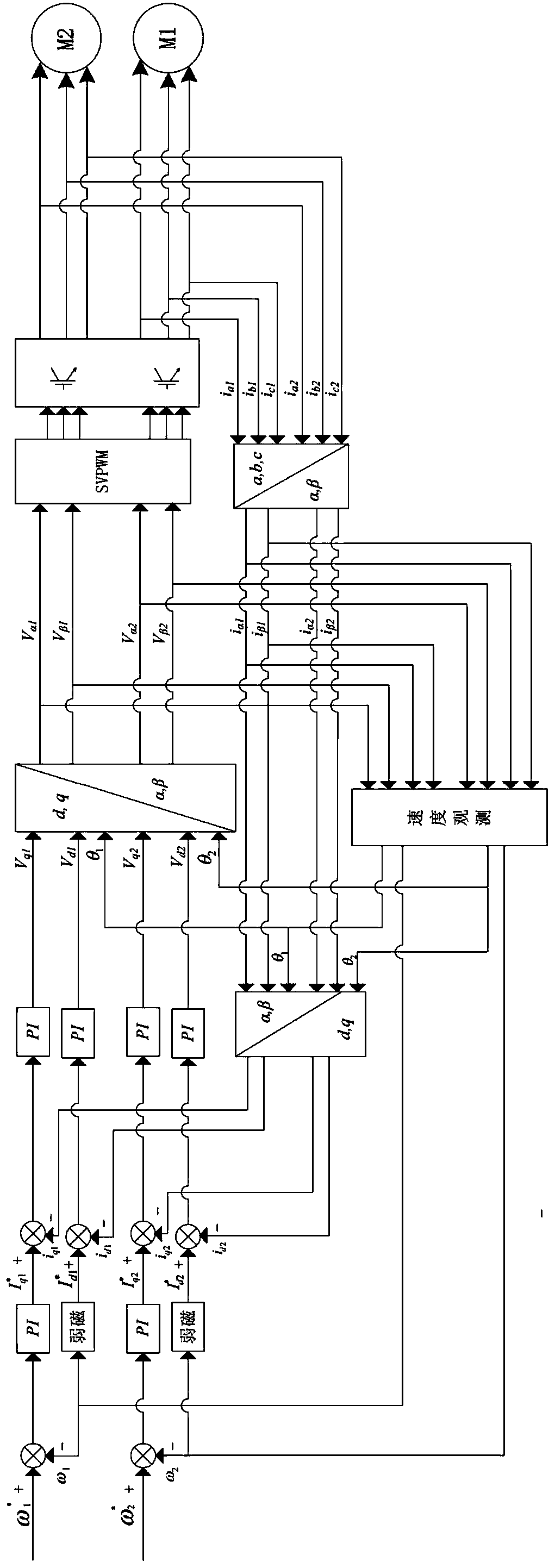

Synchronous vector control method for two motor linkage systems

InactiveCN103532460AModulate the direction of rotationControl the direction of rotationElectronic commutation motor controlVector control systemsControl vectorControl engineering

The invention relates to a synchronous vector control method for two motor linkage systems. The method comprises the following steps: synchronously acquiring signals of two motors to convert coordinates; synchronously sampling external signals, and synchronously converting from a three-phase static coordinate system to a two-phase static coordinate system; observing the speed; converting from the two-phase static coordinate system to a two-phase rotating coordinate system; synchronously regulating PI; synchronously converting from the two-phase rotating coordinate system to the two-phase static coordinate system; synchronously implementing the modulation output of SVPWM. The synchronous vector control method has the following benefits: the sampling and the data processing are synchronously implemented for all signals of the two motors; the vector control of movement states of the two motors is implemented only through one algorithm without the coordination of other controllers; the synchronous vector control method can control parameters such as rotating directions, operation speeds and moment output states of the motors.

Owner:DAYU ELECTRIC

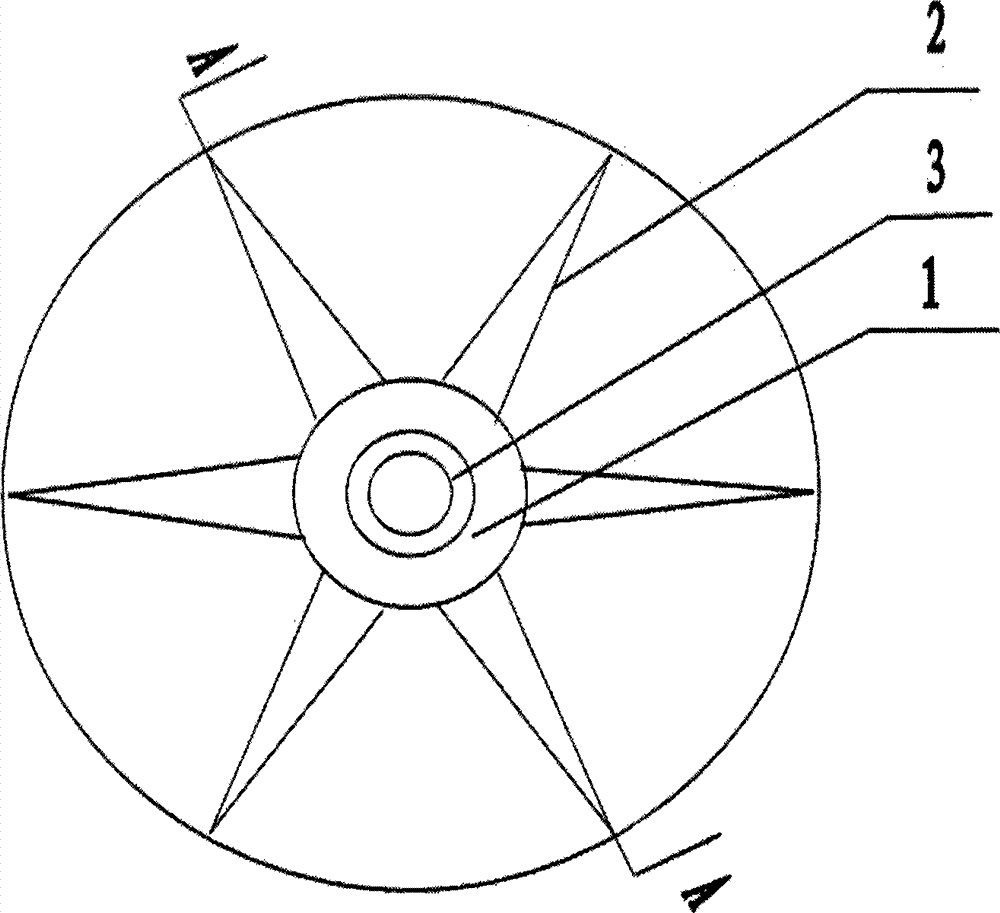

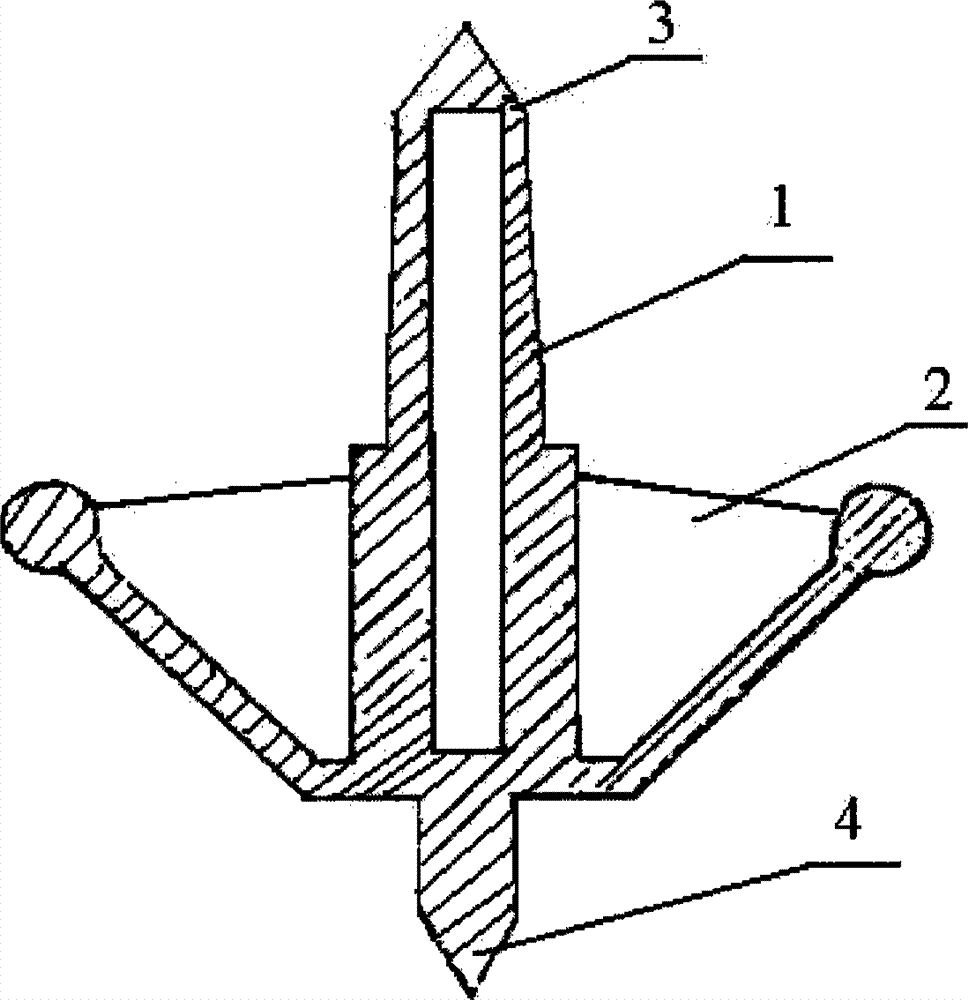

Gyroscope

The invention provides a gyroscope, which comprises a gyroscope handle, wing sheets and a gyroscope pedicle; the wing sheets are uniformly arranged around the gyroscope handle and radially extend. The gyroscope has the beneficial effects that based on the structure, when the gyroscope is used, a gyroscope cap pedicle can be held to rotate the gyroscope pedicle on the ground, and on the contrary, the gyroscope cap pedicle can be held to rotate the gyroscope pedicle on the ground; in addition, when the gyroscope rotates by an external force, a gamer can blow the wing sheets of the gyroscope by a blowing device such as an inflator, so the gyroscope can continuously rotate and the rotation direction of the gyroscope can be controlled.

Owner:LISHUI UNIV

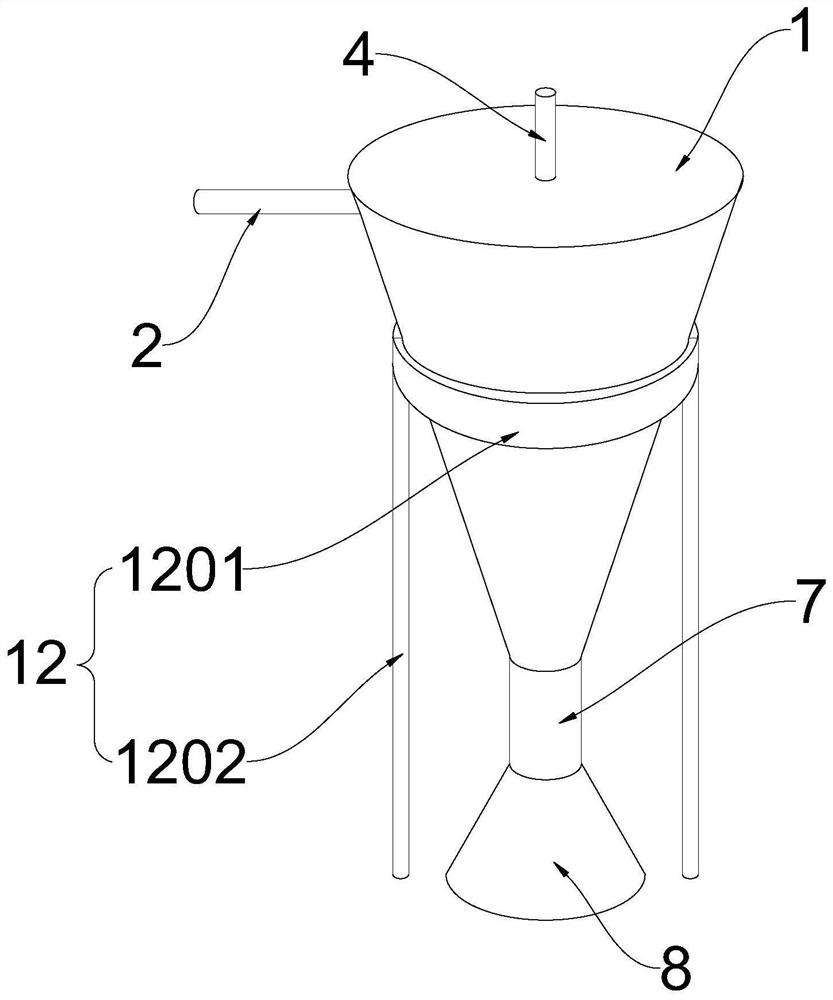

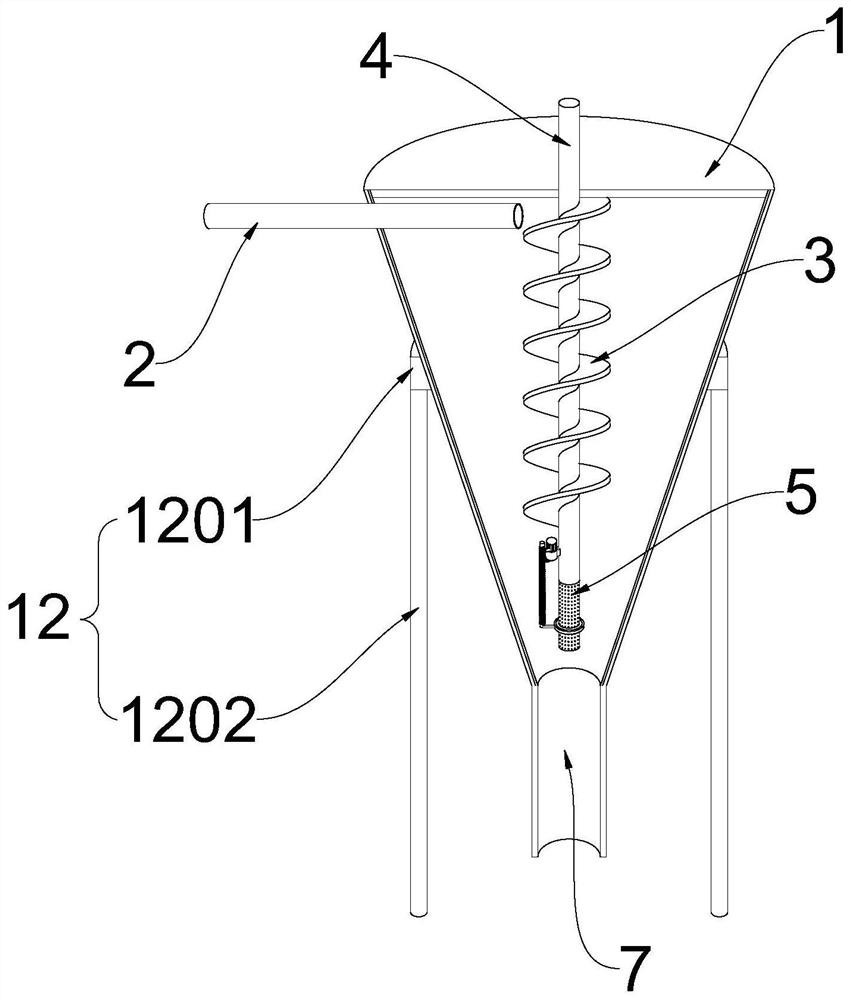

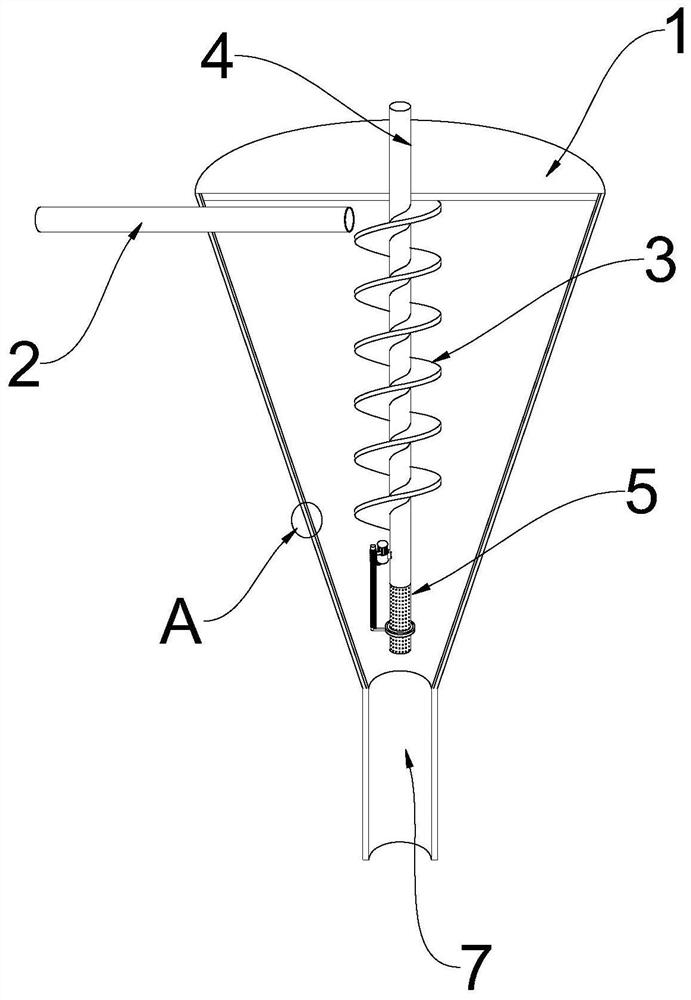

Cyclone dust collector

InactiveCN114433367APrevent intrusionAvoid enteringReversed direction vortexThermodynamicsHelical blade

The invention relates to the technical field of dust collectors, in particular to a cyclone dust collector which is characterized in that an air inlet pipe is mounted at the top of a conical body; a spiral blade is installed in a cavity of the conical body and installed on an exhaust pipe, the axis of the exhaust pipe coincides with the axis of the conical body, and a filter pipe is installed at the air inlet end of the exhaust pipe. A dust removal pipe is mounted at the top of the conical body; the conical body is installed on the supporting frame. The problem that the gas flow rate of a cyclone dust collector in the prior art needs to be strictly controlled is solved. The spiral blade is mounted in the conical body of the cyclone dust collector, on one hand, dust-containing airflow can be divided into two strands of airflow by the spiral blade, axial airflow can be uniformly and slowly changed into tangential airflow, and the dust collection efficiency is remarkably improved; on the other hand, the spiral blade can control the airflow rotating direction, and therefore the dust-containing airflow is prevented from directly entering the exhaust pipe.

Owner:苏州安建环保科技有限公司

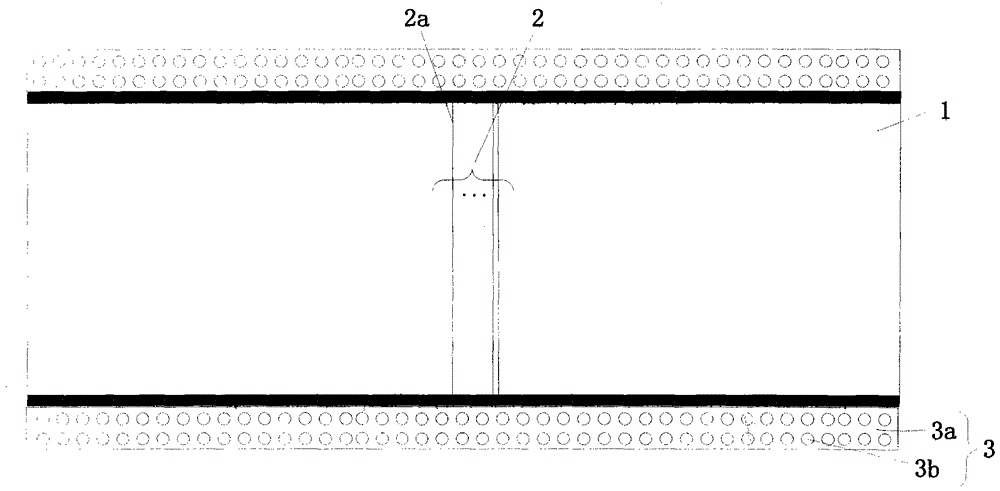

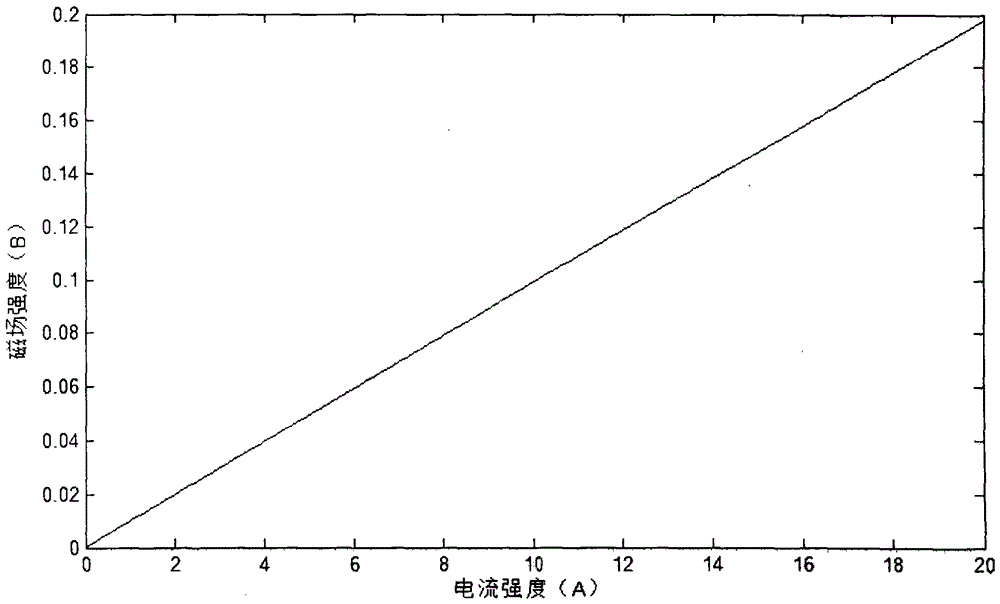

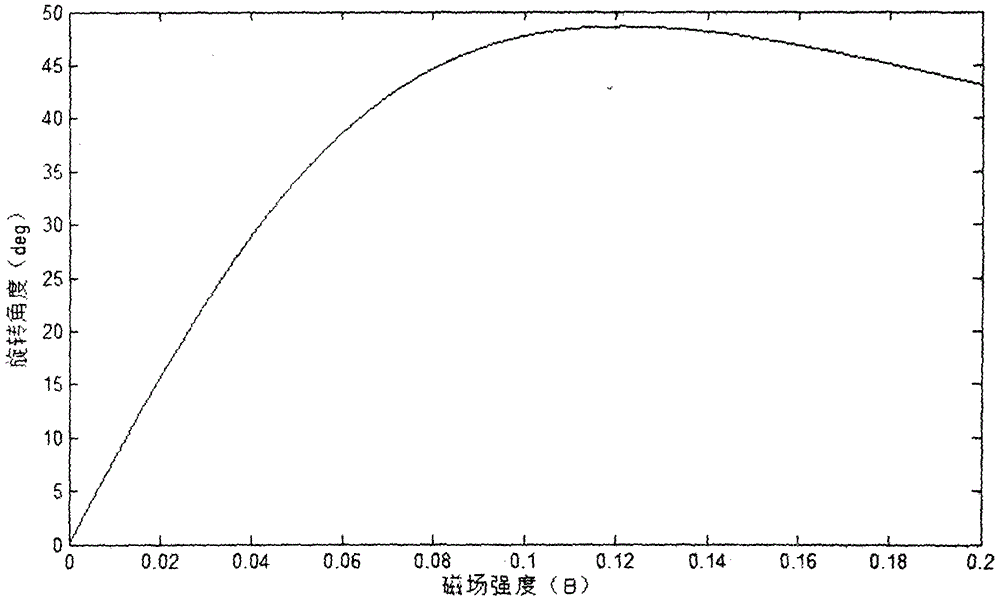

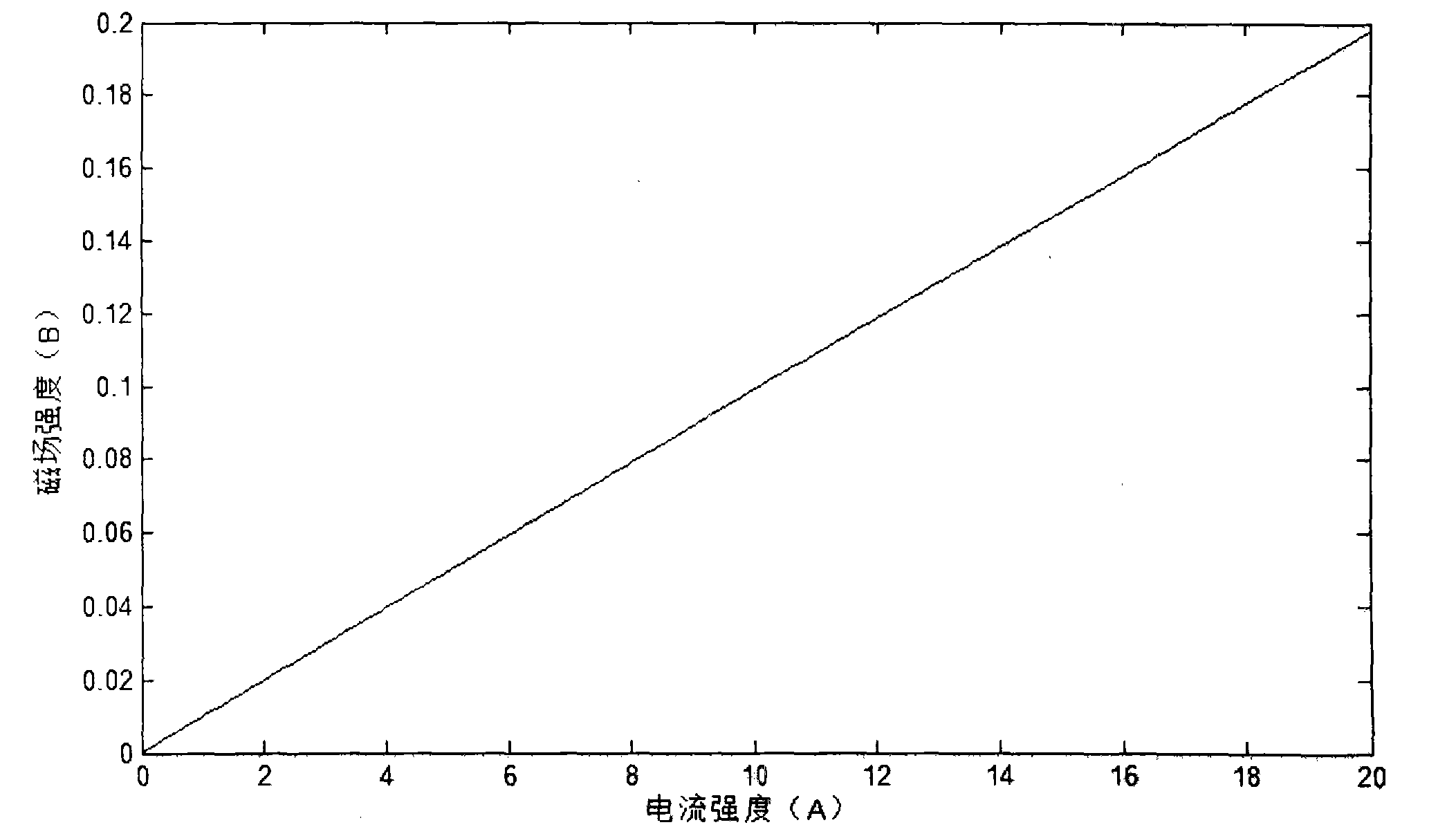

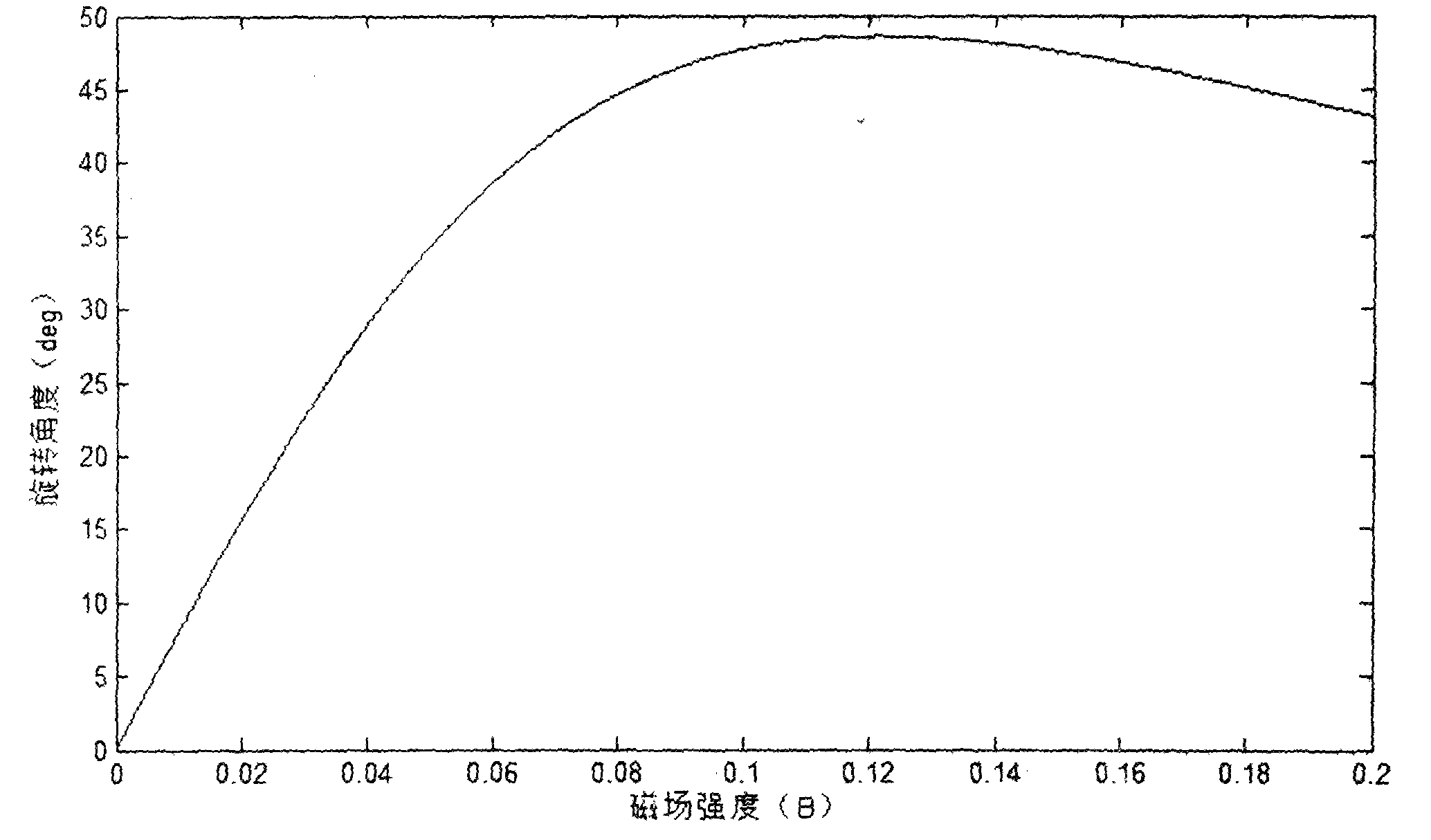

Graphene-based magnetically tunable Faraday rotators

InactiveCN103985938BCompact structureReduce volumeWaveguide type devicesMicrowave frequency rangePower flow

The invention relates to a graphene-based magnetic adjustable Faraday rotator. The structure is composed of three portions, i.e., a circular waveguide applied to a microwave frequency range, a multilayer graphene module vertical to a microwave signal propagation direction in the circular waveguide, and a solenoid module sleeving the circular waveguide for providing magnetic field offset. The multilayer graphene module is composed of multiple single-layer graphene sheets in parallel arrangement inside the module. The solenoid module can control the strength of an externally added bias static magnetic field through controlling the size of currents. When electromagnetic waves in a TE11 mode, transmitted inside the circular waveguide, are transmitted through the graphene module under a condition with the magnetic offset, angle deflection is generated. By using the rotator, a rotation angle can be accurately adjusted within a certain scope. Besides, the Faraday type rotator also has the advantages of simple and compact structure, quite small size, easy integration, simple control, and convenient use.

Owner:CHINA JILIANG UNIV

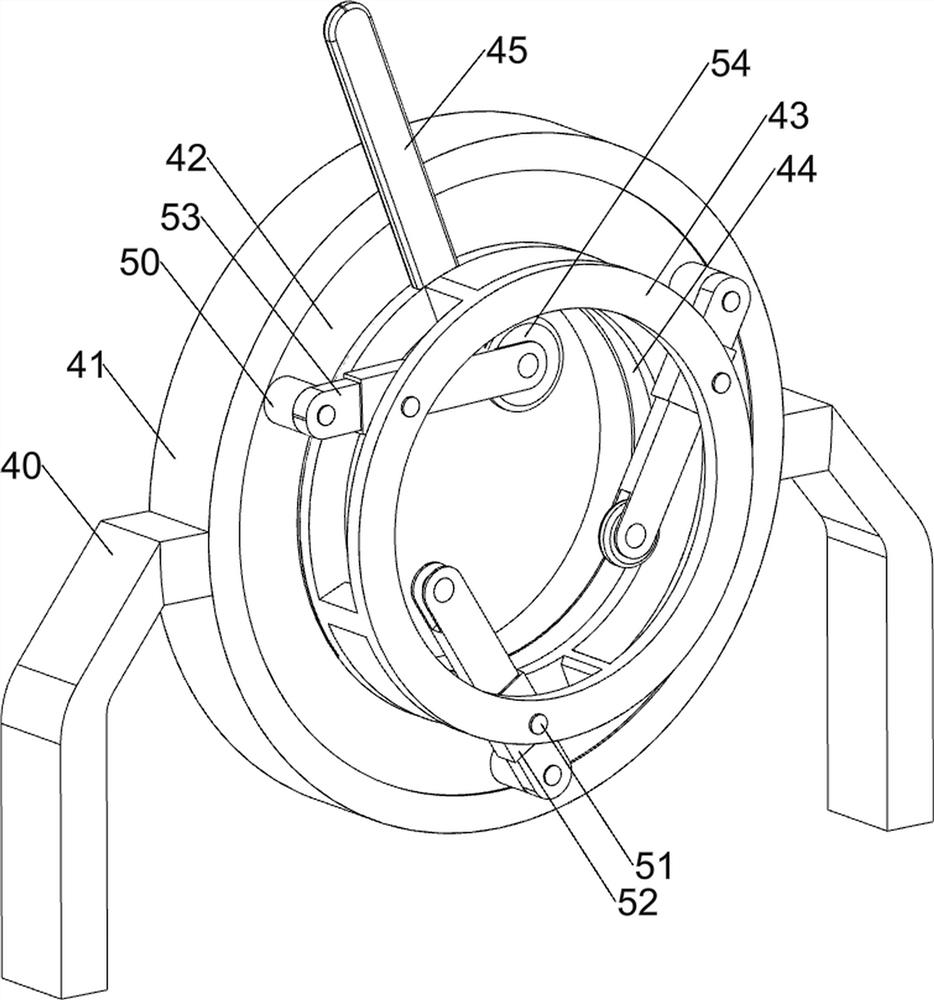

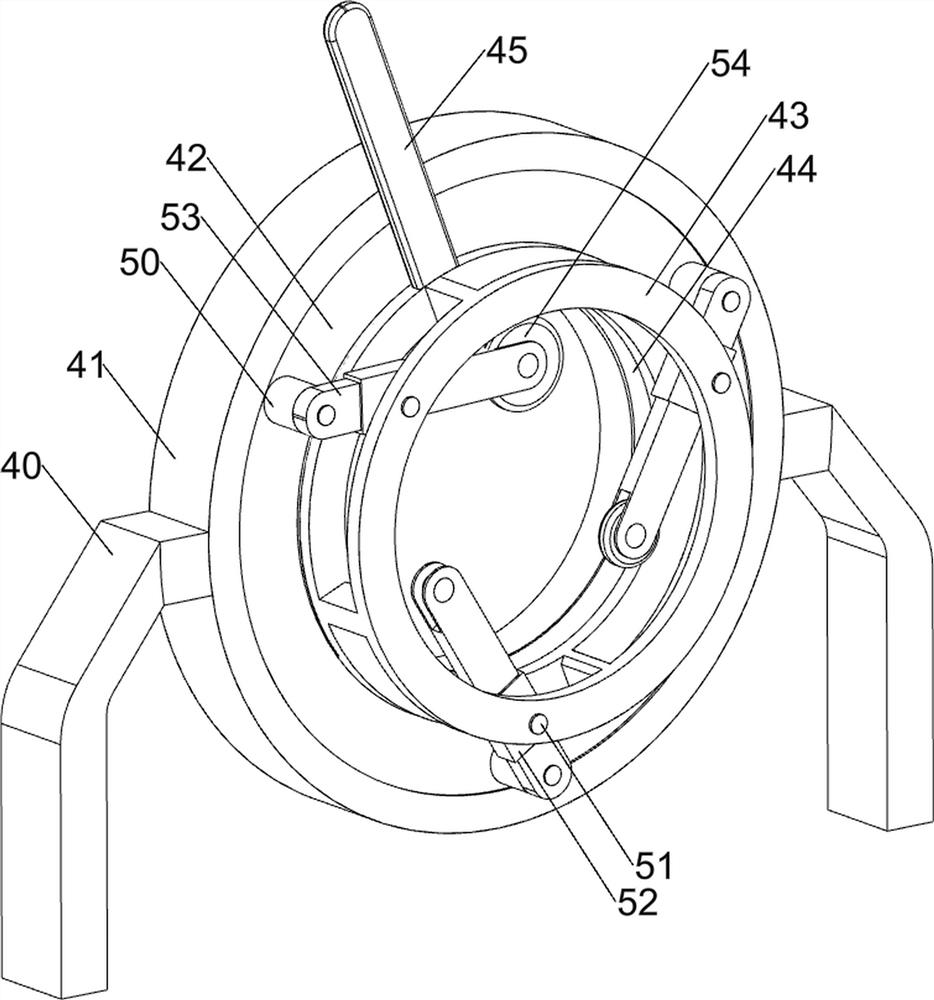

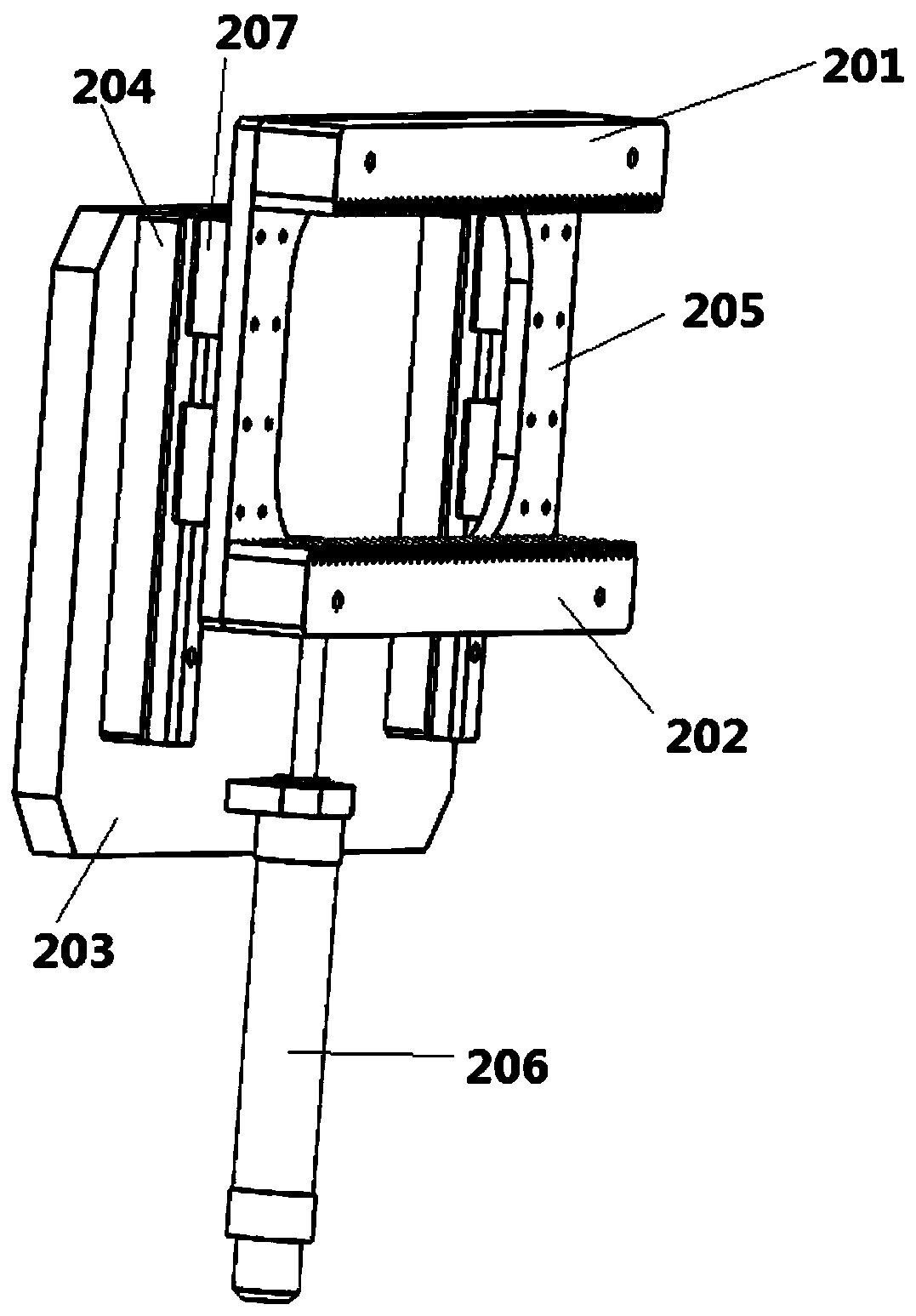

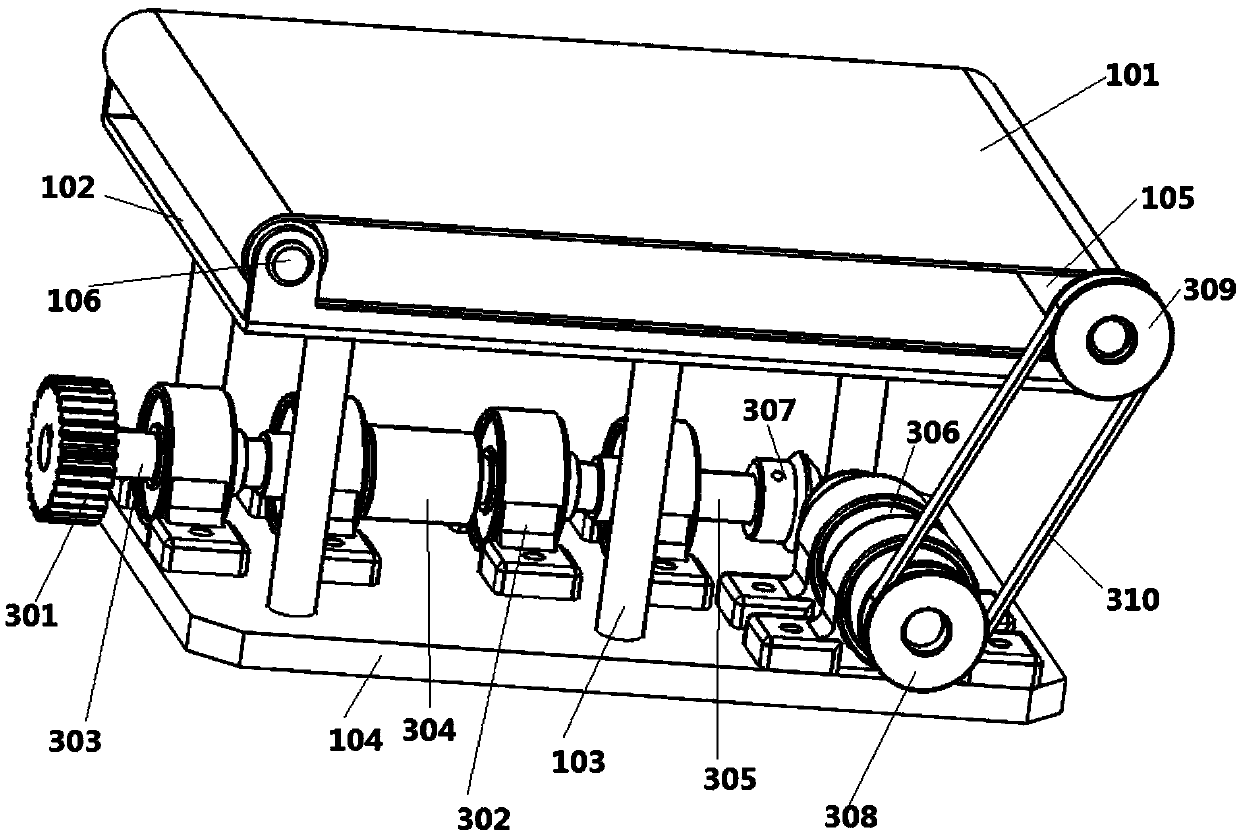

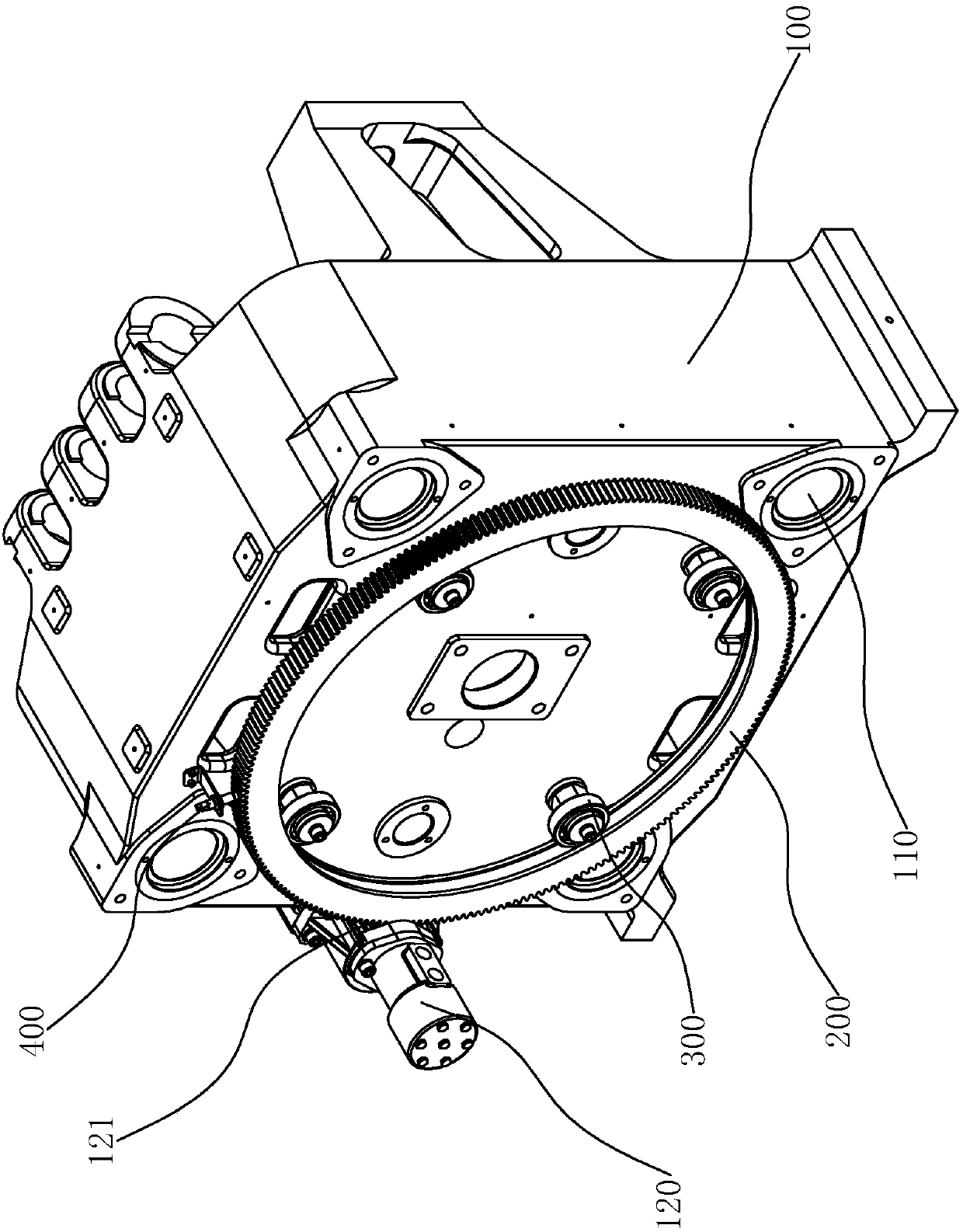

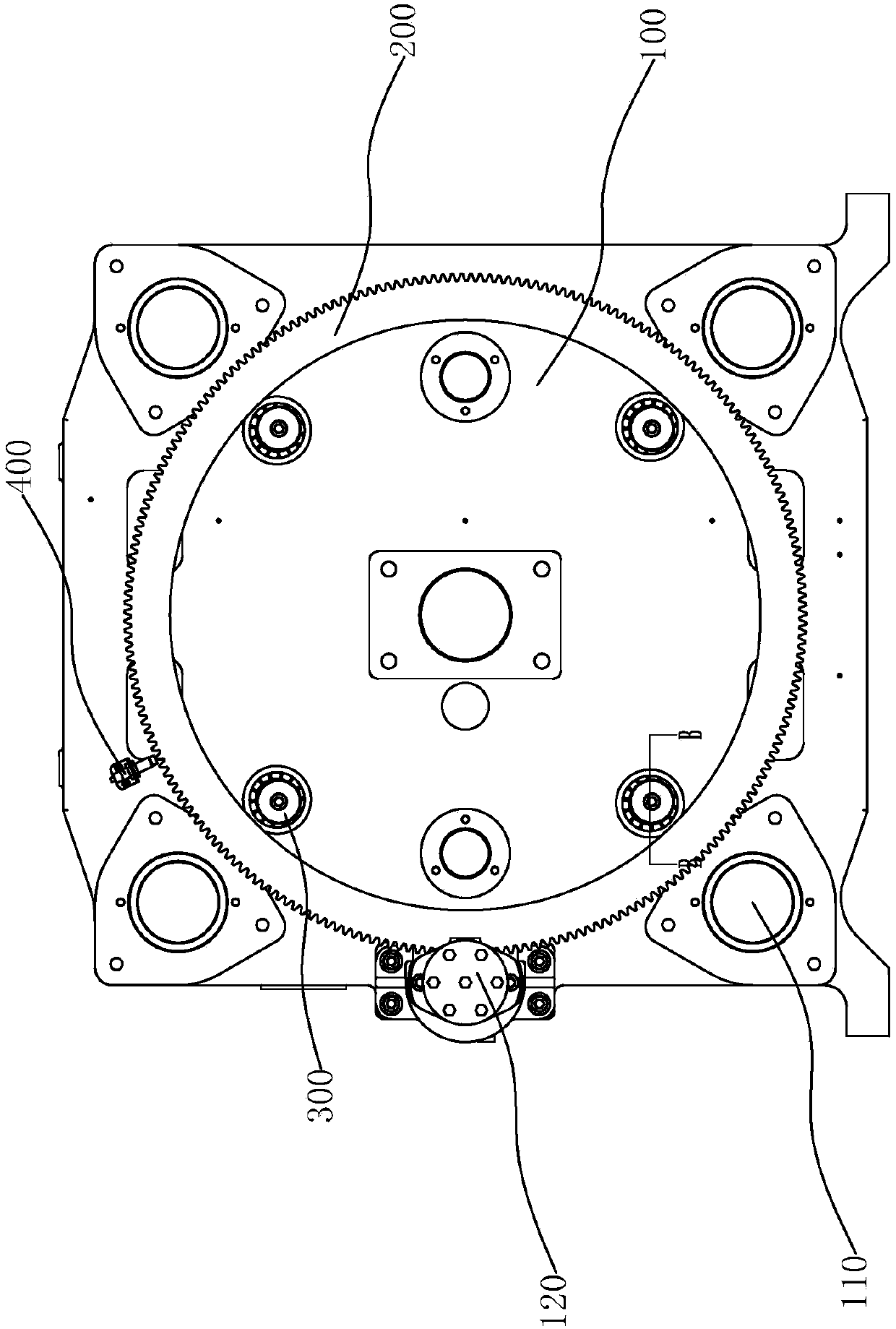

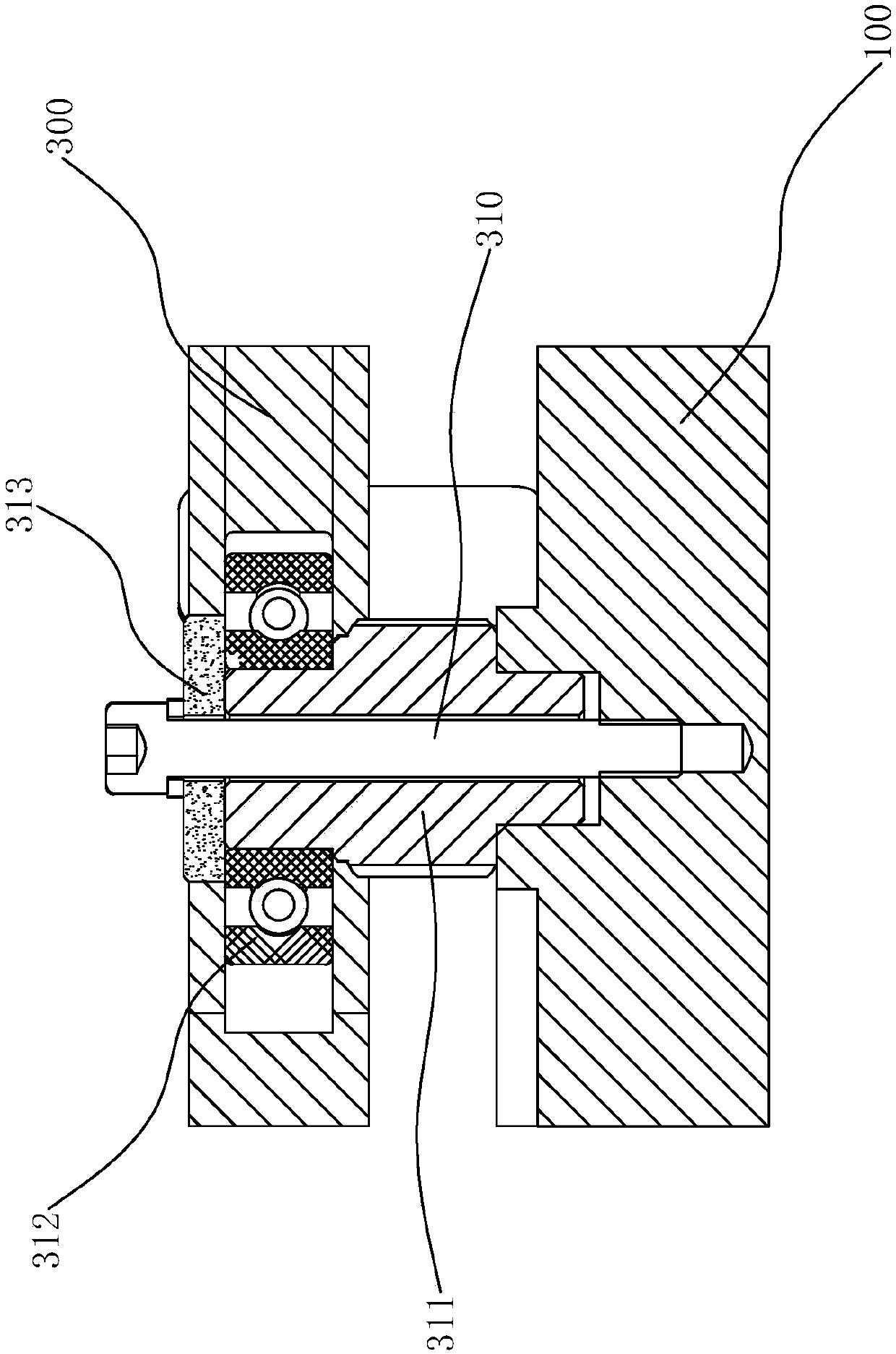

Hub concentric clamping mechanism

PendingCN114178879AAchieve clampingControl the direction of rotationPositioning apparatusMetal-working holdersEngineeringStructural engineering

The invention discloses a hub concentric clamping mechanism, and relates to the field of hub machining, the hub concentric clamping mechanism comprises a cam lifting plate located on the upper portion and a cam rear plate arranged on the lower side of the cam lifting plate, a cam front plate is arranged on the lower side of the cam rear plate, and at least three sets of claw hooks are arranged on the lower side of the cam front plate; the multiple sets of claw hooks are arranged in an equal-angle radial mode with the center of the cam front plate as the center, transmission structures are arranged on the cam rear plate and the cam front plate, and the transmission structures are used for achieving synchronous movement of the multiple sets of claw hooks in the direction away from or close to the center of the cam front plate. When the claw hooks move towards the center of the cam front plate, the hub can be clamped at the moment, and due to the fact that each set of claw hooks synchronously advance, the time for each set of claw hooks to reach the inner ring face of the hub is the same, the hub can be positioned and clamped at a time, follow-up adjustment is not needed, and the machining efficiency of the hub is greatly improved.

Owner:江苏一凡智能装备有限公司

Solar energy device and control method thereof

The invention relates to the field of luminous energy radiation, and discloses a solar device and a control method thereof. The solar device comprises a solar photovoltaic panel, a detection part and an adjusting part. The detection part is arranged on the solar photovoltaic panel and parallel to the solar photovoltaic panel. The adjusting part is connected with the solar photovoltaic panel in a linkage way. The adjusting part is electrically connected with the detection part. The detection part detects whether the facing direction of the solar photovoltaic panel and the irradiation direction of sunlight to the solar photovoltaic panel are opposite at the moment. If the detection result is no, the adjusting part adjusts the facing direction of the solar photovoltaic panel according to triggering of the detection part until the facing direction of the solar photovoltaic panel and the irradiation direction of sunlight to the solar photovoltaic panel are opposite at the moment. The invention also discloses a control method of the solar device. Whether the facing direction of the solar photovoltaic panel and the irradiation direction of sunlight to the solar photovoltaic panel are opposite at the moment is monitored in real time, and the facing direction of the solar photovoltaic panel is automatically adjusted according to the monitoring result so as to enhance the utilization rate of sunlight.

Owner:XIAN YIPU COMM TECH

A sheet metal welding equipment

ActiveCN112317989BRealize the function of intermittently fixing sheet metalControl the direction of rotationWelding/cutting auxillary devicesAuxillary welding devicesGear wheelEngineering

The invention relates to a welding device, in particular to a sheet metal welding device. Provided is a sheet metal welding device with high welding efficiency, no need for auxiliary equipment to clamp workpieces, and high welding quality. The present invention provides such a sheet metal welding equipment, comprising: a bottom plate, the bottom plate is used to install the whole equipment; a first support frame, the first support frame is provided on one side of the top of the bottom plate; There is a servo motor; a placement mechanism, a placement mechanism is provided on one side of the top of the bottom plate; a clamping mechanism, a clamping mechanism is provided in the placement mechanism; a transmission mechanism, a transmission mechanism is provided on one side of the top of the bottom plate; a welding mechanism is provided in the middle of the top of the bottom plate There is a welding mechanism. With the cooperation between the toothed belt wheel assembly and the second gear, the toothed belt wheel assembly meshes with the upper and lower second gears respectively, so that the rotation direction of the fourth rotating shaft can be controlled, and the welding torch can be driven to move up and down.

Owner:佛山市顺德区瑞利凯金属制品有限公司

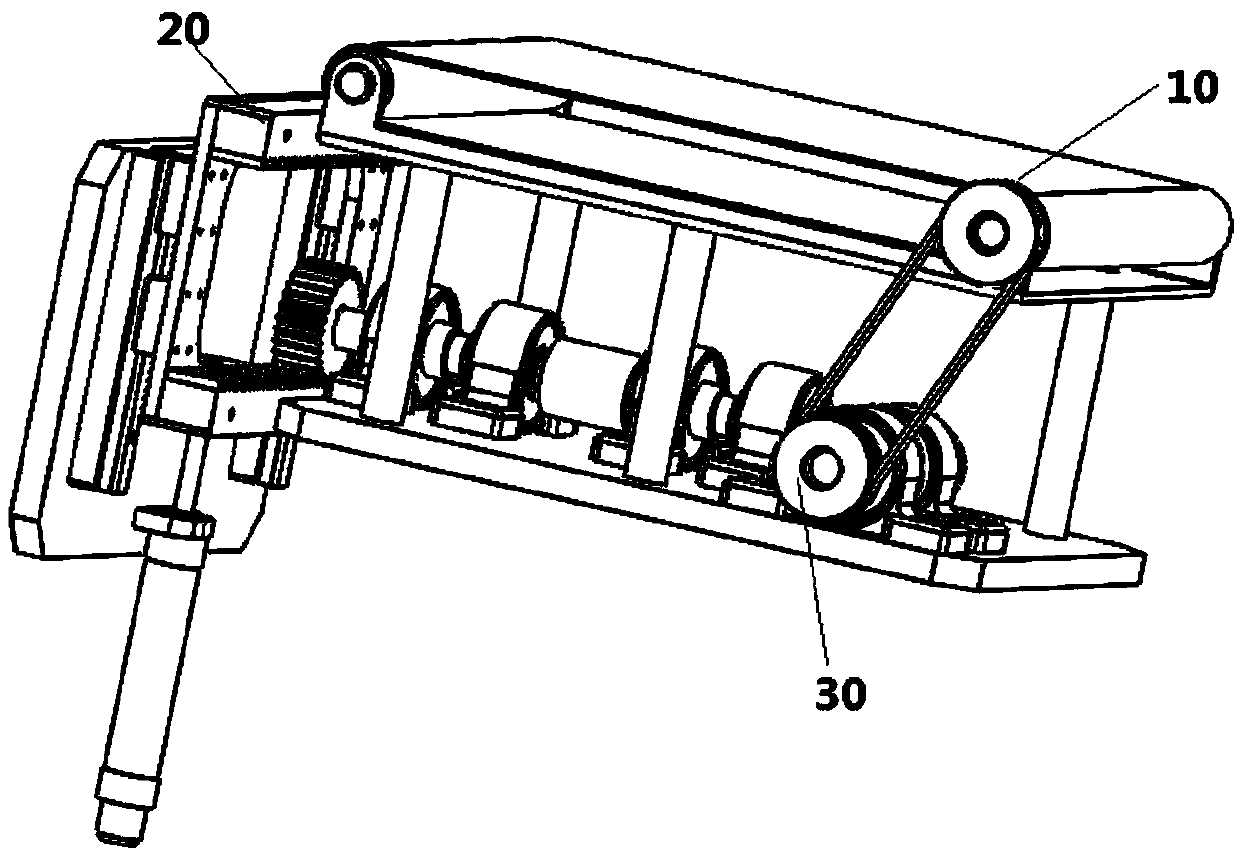

A rack-driven crawler trolley

The invention discloses a rack drive type crawler bogie. The rack drive type crawler bogie comprises a bogie main body, a rack support and a transmission device, wherein the bogie main body is provided with a crawler used for carrying and conveying cargoes; the transportation direction of the crawler is perpendicular to the advancing direction of the bogie; the rack support is arranged on the sideedge of the bogie main body; the side, facing the bogie main body, of the rack support is provided with an upper rack and a lower rack which can be ascended and descended vertically; and the transmission device is arranged under the crawler and comprises a gear engaged with an upper gear and a lower gear, a synchronous pulley set which is in transmission connection with the crawler, and a transmission assembly for transmitting rotation of the gear to the synchronous pulley set. The rack drive type crawler bogie has the beneficial effects that through relative movement of the bogie and the racks, the crawler is driven to move through a gear-rack engagement mechanism in cooperation with the relevant transmission device, and the cargoes on the crawler of the bogie are dropped from a conveying line.

Owner:合肥东天晓慧科技有限公司

Rack drive type crawler bogie

The invention discloses a rack drive type crawler bogie. The rack drive type crawler bogie comprises a bogie main body, a rack support and a transmission device, wherein the bogie main body is provided with a crawler used for carrying and conveying cargoes; the transportation direction of the crawler is perpendicular to the advancing direction of the bogie; the rack support is arranged on the sideedge of the bogie main body; the side, facing the bogie main body, of the rack support is provided with an upper rack and a lower rack which can be ascended and descended vertically; and the transmission device is arranged under the crawler and comprises a gear engaged with an upper gear and a lower gear, a synchronous pulley set which is in transmission connection with the crawler, and a transmission assembly for transmitting rotation of the gear to the synchronous pulley set. The rack drive type crawler bogie has the beneficial effects that through relative movement of the bogie and the racks, the crawler is driven to move through a gear-rack engagement mechanism in cooperation with the relevant transmission device, and the cargoes on the crawler of the bogie are dropped from a conveying line.

Owner:合肥东天晓慧科技有限公司

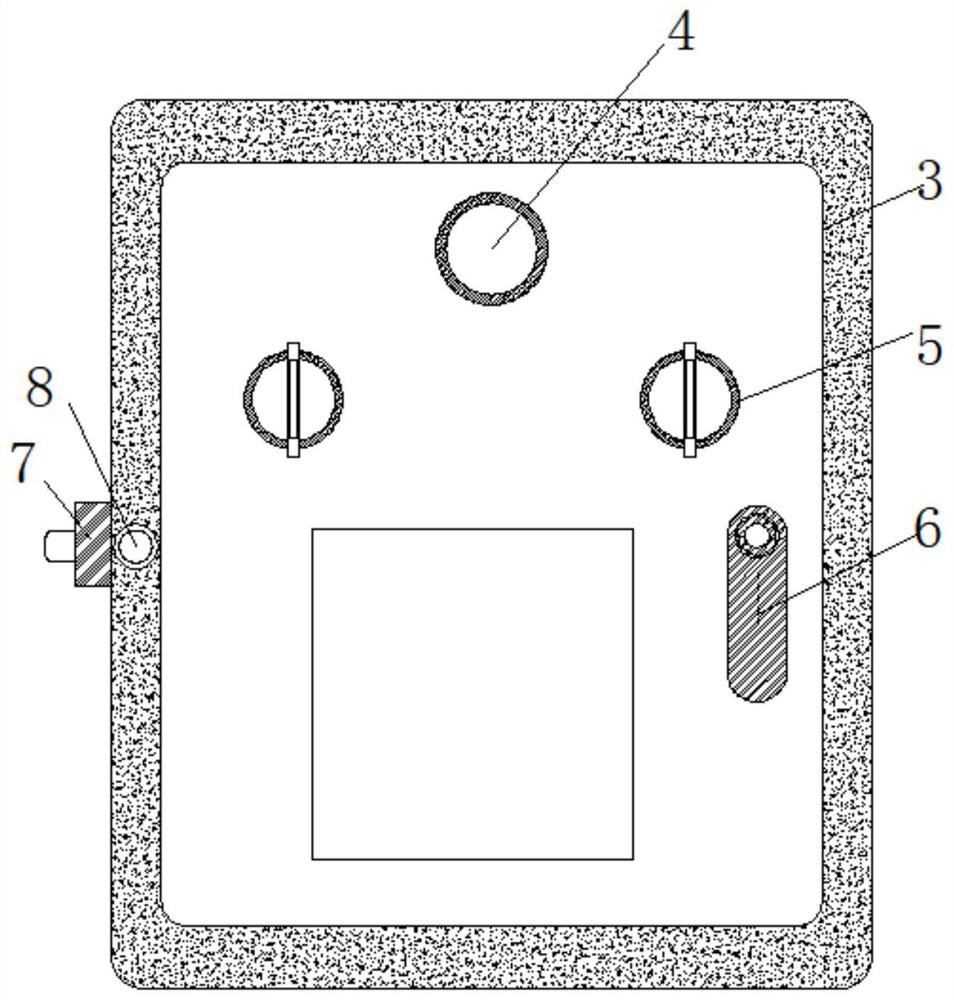

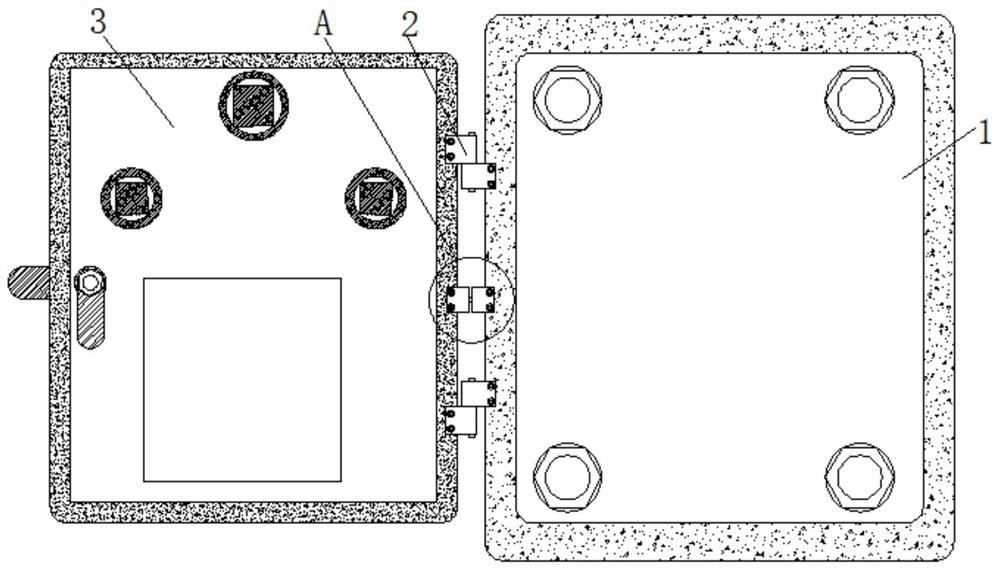

Distribution box door opening and closing mechanism based on alternating-current distribution device

ActiveCN112018629AControl the direction of rotationSubstation/switching arrangement detailsCurrent distributionGear wheel

The invention relates to the technical field of alternating-current power distribution devices, and discloses a power distribution box door opening and closing mechanism based on an alternating-current power distribution device. The mechanism comprises a box body; the left side of the box body is fixedly connected with a connecting block. According to the distribution box door opening and closingmechanism based on the alternating-current distribution device, when a gear rotates counterclockwise, at the moment, a clamping block moves downwards under the powerful action of teeth on the clampingblock, the gear can rotate anticlockwise; when the gear rotates clockwise, the clamping block can generate resistance to the teeth, so that the teeth cannot rotate, the gear cannot rotate clockwise;and therefore, the effect of controlling the rotating direction of the gear is achieved. When wind power acts on an opened box door, the box door can rotate anticlockwise through the wind power, a clamping rod can drive the gear to rotate clockwise, the box door cannot be closed through the wind power due to the fact that the gear cannot rotate clockwise, and therefore the effect that closing of the box door cannot be affected by the wind power when the box door is opened and closed at any angle is achieved.

Owner:广东浩城电气有限公司

Mould adjusting device

Owner:王芳

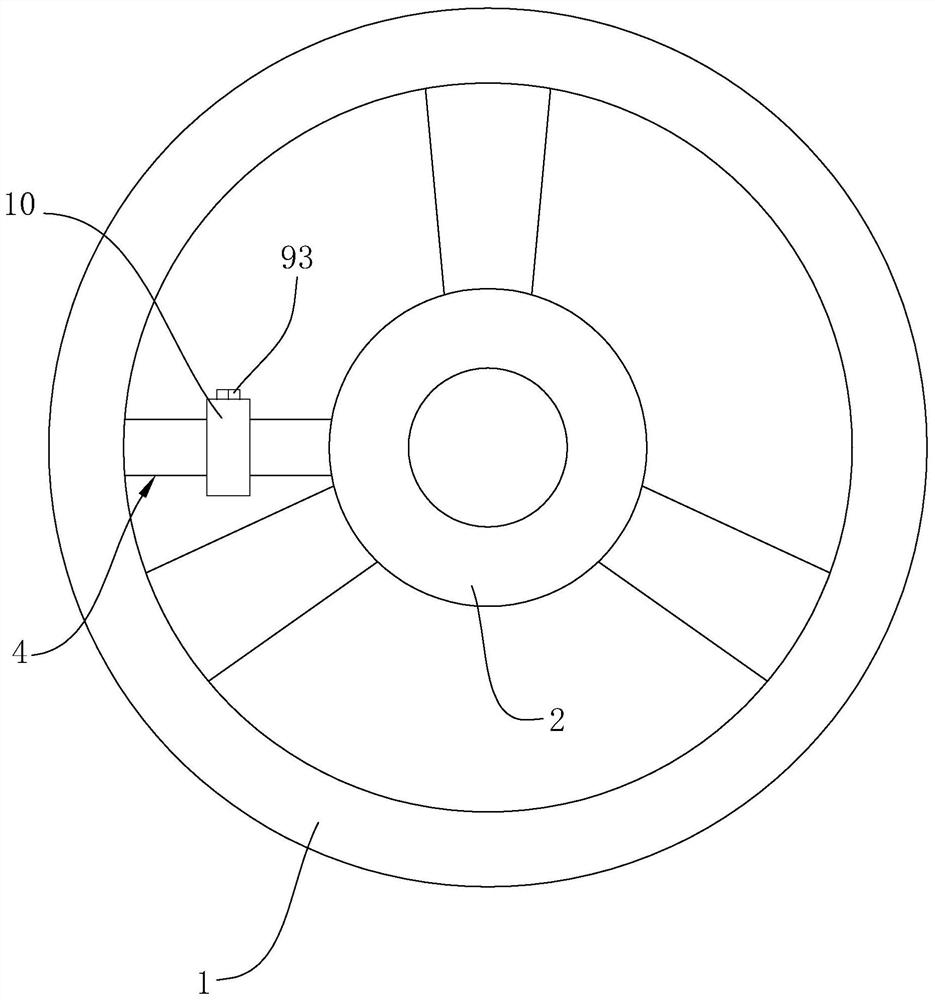

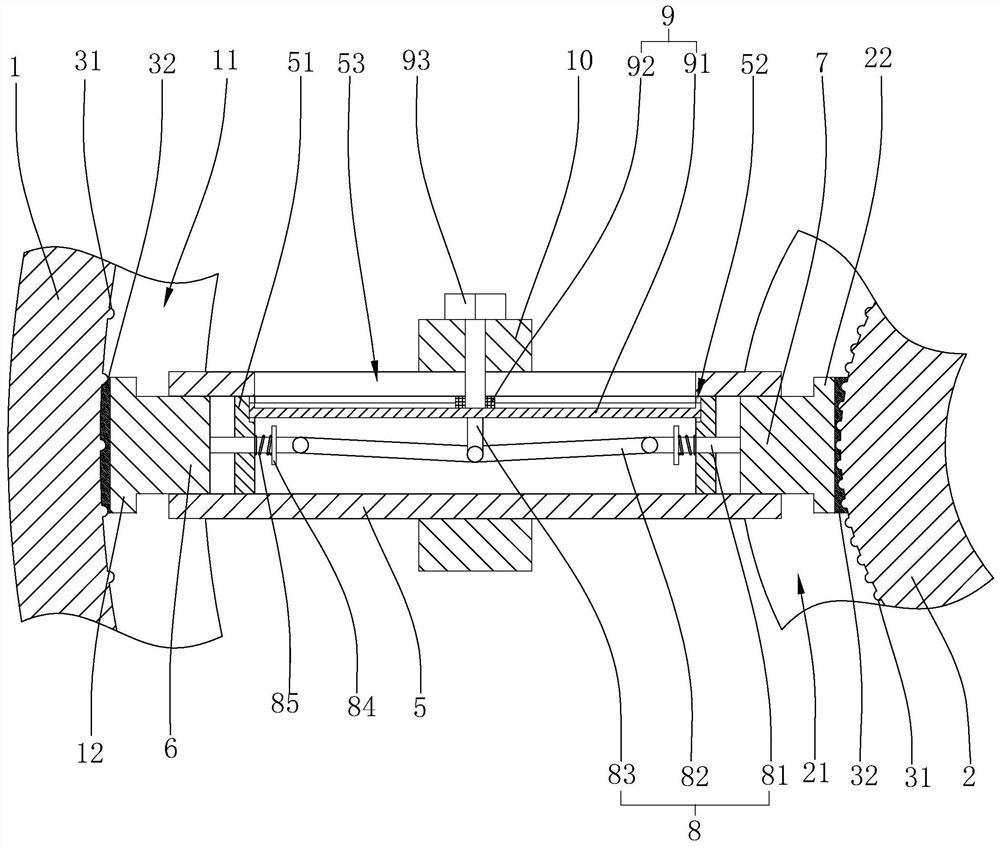

A kind of electric vehicle wheel hub assembly structure

ActiveCN112590454BEasy to adjustReduce eccentric forceWheel-ballasting weightsClassical mechanicsElectric cars

The invention relates to an assembly structure of an electric vehicle wheel hub, comprising a coaxial outer hub 1 and an inner hub 2, spokes are fixed at intervals in the circumferential direction between the outer hub 1 and the inner hub 2, and at the same time, there is a coaxial opening on the inner side of the outer hub 1. The outer slideway 11 is coaxially provided with an inner slideway 21 on the outer side of the inner hub 2, and a slider one 12 is embedded in the outer slideway 11, and a slider two 22 is embedded in the inner slideway 21. A connecting rod assembly 4 is installed between 12 and the second slider 22, the length of the connecting rod assembly 4 can be adjusted in the radial direction of the wheel hub, and a counterweight ring 10 is sleeved on the connecting rod assembly 4, and the counterweight ring 10 is along the The length direction of the connecting rod assembly 4 is slid or fixed, wherein the first slider 12 and the second slider 22 can adopt a block structure, wherein the weight ring can be adjusted around the center of the wheel hub and moved radially, so as to facilitate adjustment and reduce eccentricity force, saving time and manpower.

Owner:XUZHOU XIAOQIANG WHEEL TECH CO LTD

Graphene-based magnetic adjustable Faraday rotator

InactiveCN103985938ACompact structureReduce volumeWaveguide type devicesMicrowave frequency rangeSingle layer graphene

The invention relates to a graphene-based magnetic adjustable Faraday rotator. The structure is composed of three portions, i.e., a circular waveguide applied to a microwave frequency range, a multilayer graphene module vertical to a microwave signal propagation direction in the circular waveguide, and a solenoid module sleeving the circular waveguide for providing magnetic field offset. The multilayer graphene module is composed of multiple single-layer graphene sheets in parallel arrangement inside the module. The solenoid module can control the strength of an externally added bias static magnetic field through controlling the size of currents. When electromagnetic waves in a TE11 mode, transmitted inside the circular waveguide, are transmitted through the graphene module under a condition with the magnetic offset, angle deflection is generated. By using the rotator, a rotation angle can be accurately adjusted within a certain scope. Besides, the Faraday type rotator also has the advantages of simple and compact structure, quite small size, easy integration, simple control, and convenient use.

Owner:CHINA JILIANG UNIV

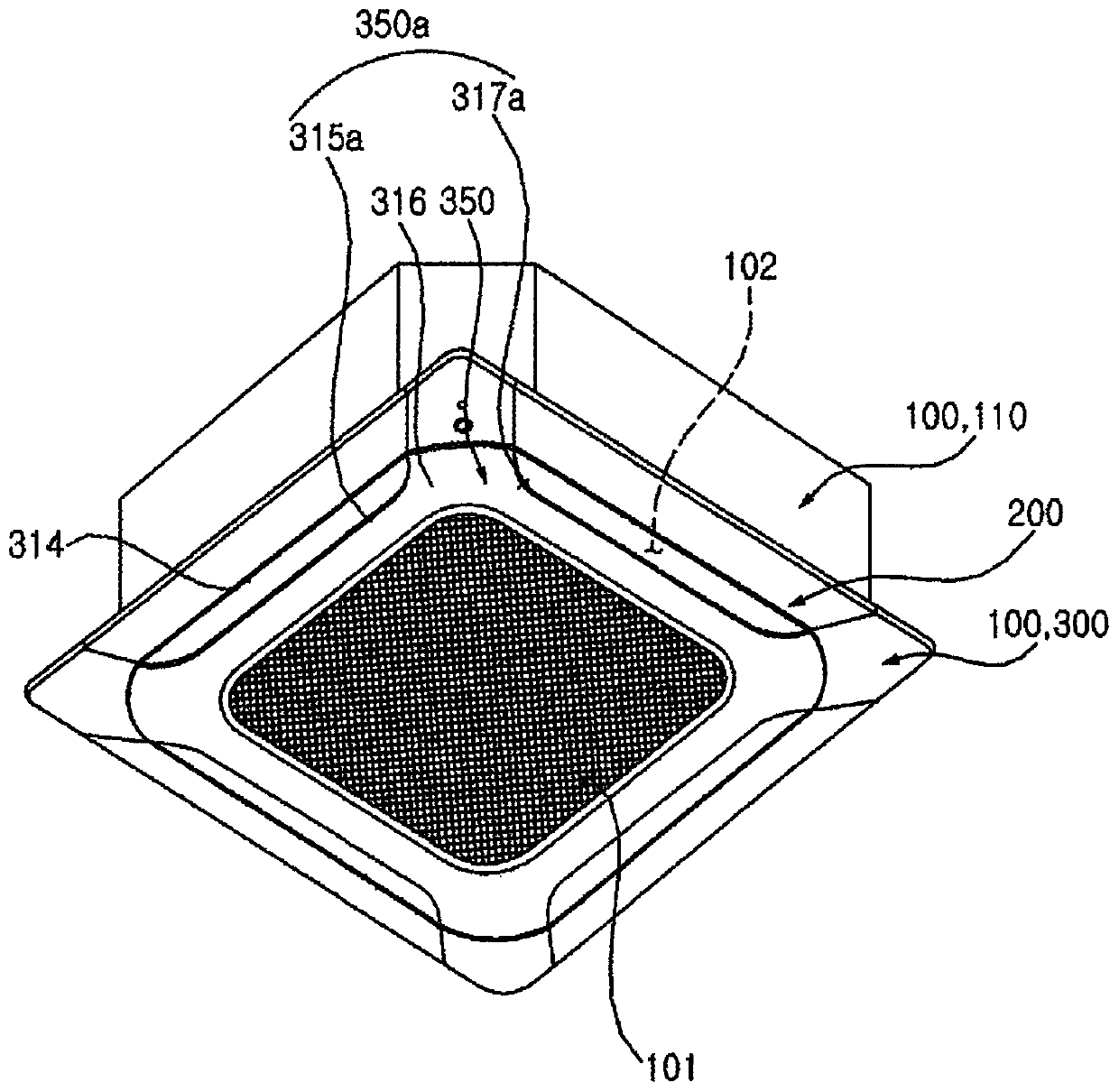

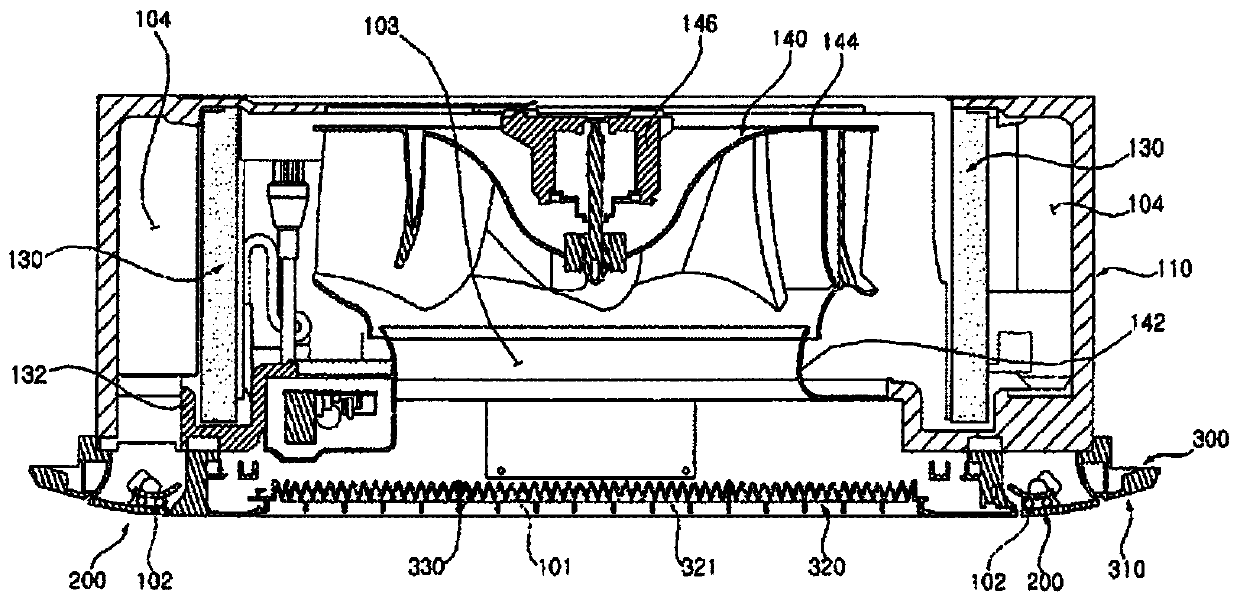

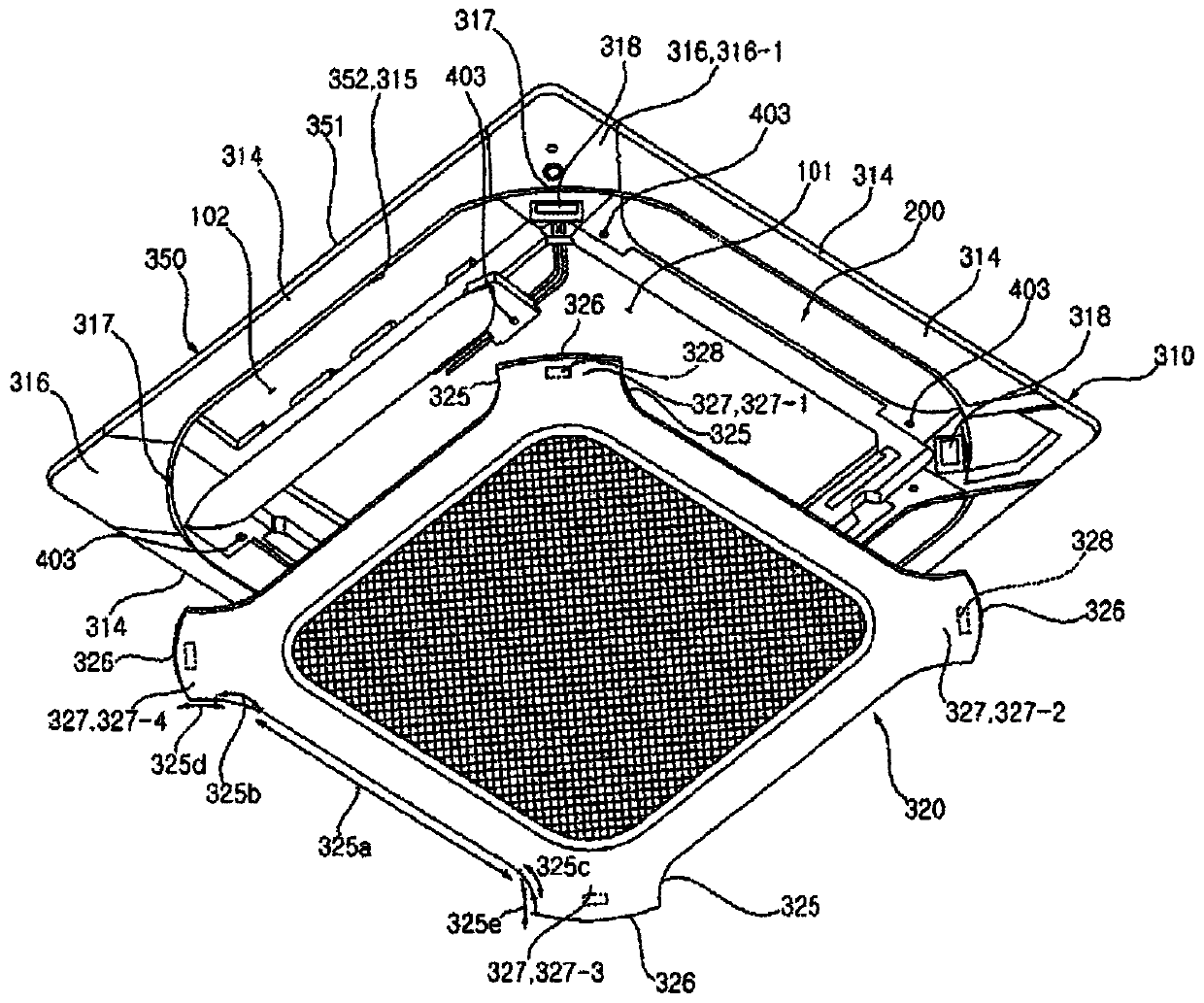

Ceiling type indoor unit of air conditioner

ActiveCN111373208AControl the direction of rotationDead zone minimizationDucting arrangementsMechanical apparatusControl theoryMechanical engineering

Owner:LG ELECTRONICS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com