Surface flaw detection device

A defect detection and defect technology, which is applied in the direction of measuring devices, optical test defects/defects, image data processing, etc., can solve the problems of affecting detection efficiency, low degree of automation, inconvenient use, etc., and achieve the effect of improving detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

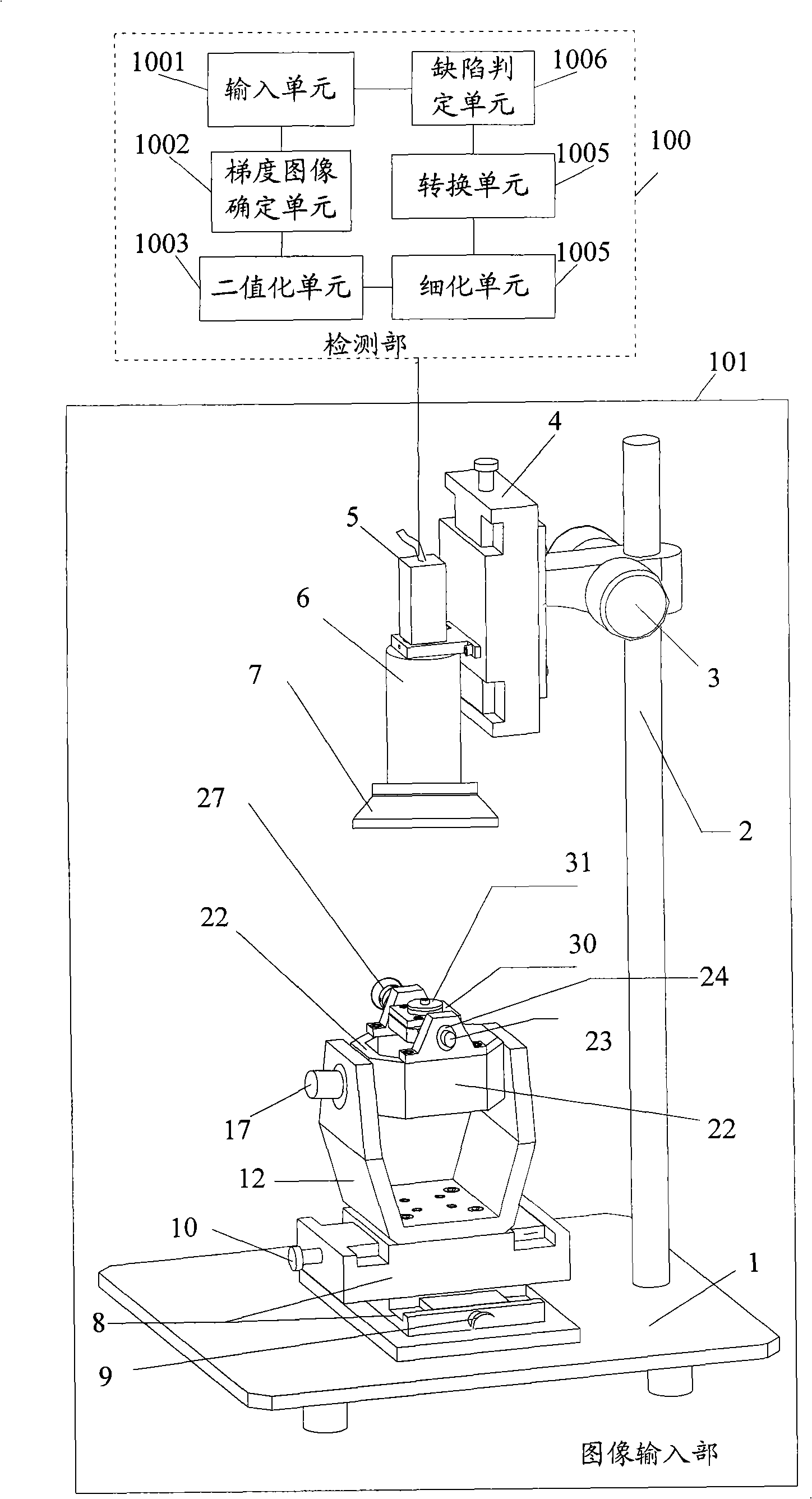

[0034] figure 1 It is a schematic structural diagram of the surface defect detection device provided in this embodiment. As shown in the figure, the device is composed of an image input unit 11 and a detection unit 10 .

[0035] Wherein the image input unit 101 includes:

[0036] Support table 1, support member 2, focusing mechanism 3 and 4, optical objective lens 6, imaging device 5 connected to the top of optical objective lens 6, detection mechanism 801 connected with said imaging device 5, latitude and longitude adjustment table 8, installed in the latitude and longitude The rolling mechanism (rolling support 12, rolling shaft 13 and rolling motor 17) and pitching mechanism (comprising pitching support 22, pitching shaft 23 and pitching motor 27) on the adjustment table 8, and the pitching shaft 23 on the stage 30 . in:

[0037] The support member 2 is fixed on the support platform 1 for supporting the optical objective lens 6;

[0038] The optical objective lens 6 is ...

Embodiment 2

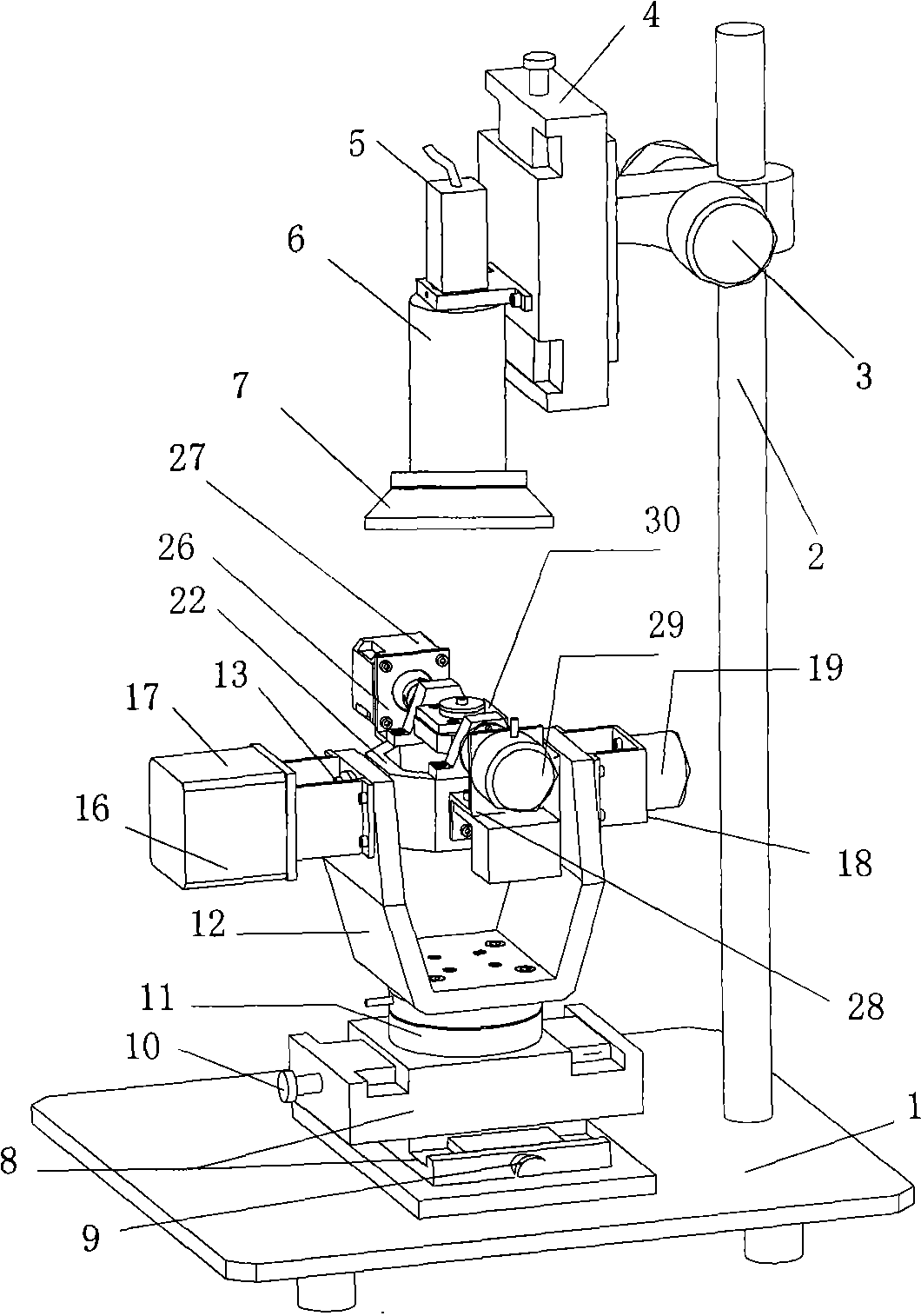

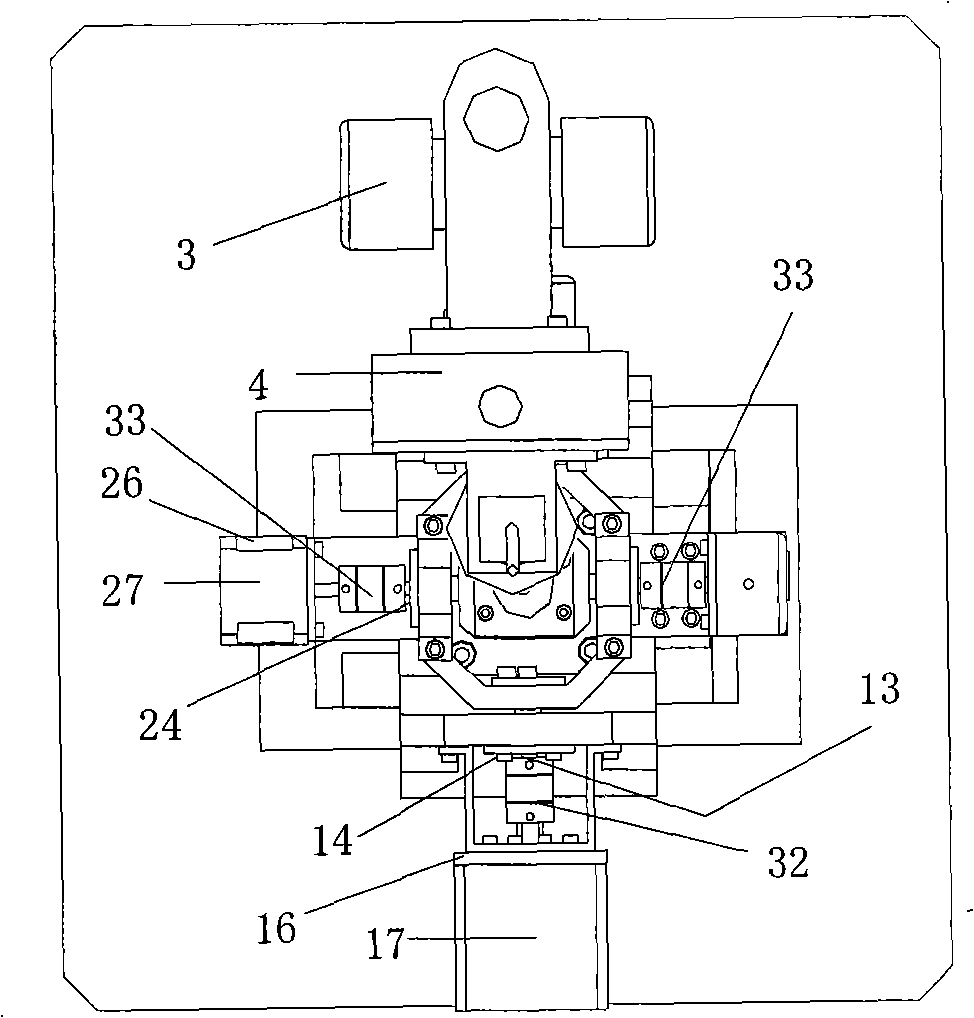

[0080] figure 2 It is another schematic perspective view of the structure of the image input unit in the surface defect detection device provided in this embodiment, image 3 is corresponding figure 2 A schematic diagram of the top view state of the image input unit, Figure 4 and Figure 5 yes figure 2 The corresponding side view of the image input section.

[0081] The structure and embodiment of the surface defect detection device of this embodiment figure 1 The structures shown are roughly the same, the difference is that the image input part of this embodiment is different from that of Embodiment 1, the main difference is that the image input part in this embodiment also includes an encoder feedback system, which is the same as Together, the motor drive system forms the closed-loop control circuit. The encoder feedback system includes a pan encoder 19, a pitch encoder 29 and a control circuit (not shown in the figure).

[0082] More specifically, in this embodim...

Embodiment 3

[0091] Figure 6 It is a schematic structural diagram of the surface defect detection device of this embodiment. As shown in the figure, the difference between this embodiment and Embodiment 1 is that the detection unit 60 of the device may also include:

[0092] The defect level determination unit 601 is configured to determine the defect level of the defect according to the area and / or shape of the defect determined by the defect determination unit 1006, so as to facilitate subsequent corresponding processing according to the defect level.

[0093] In the process of industrial inspection, after the defect is detected, the defect can also be divided, and the defect can be dealt with accordingly according to the division. (the shape of the defect edge of the closed loop), and / or, determine whether the defect is a point defect, a line defect, or a surface defect, so as to perform corresponding processing according to the defect level.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com