Method for detecting surface defects of steel ball based on double-thread expansion method

A technology of defect detection and expansion method, which is applied in the direction of measuring devices, material analysis through optical means, instruments, etc., can solve the problems of poor effect in the edge area of steel balls, high application and maintenance costs, and affect the production of steel balls, etc., to achieve reduction The effect of labor cost, high degree of deployment automation, reduction of control difficulty and manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The principles and features of the present invention will be described below with reference to the accompanying drawings. The examples cited are only used to explain the present invention, and are not used to limit the scope of the present invention.

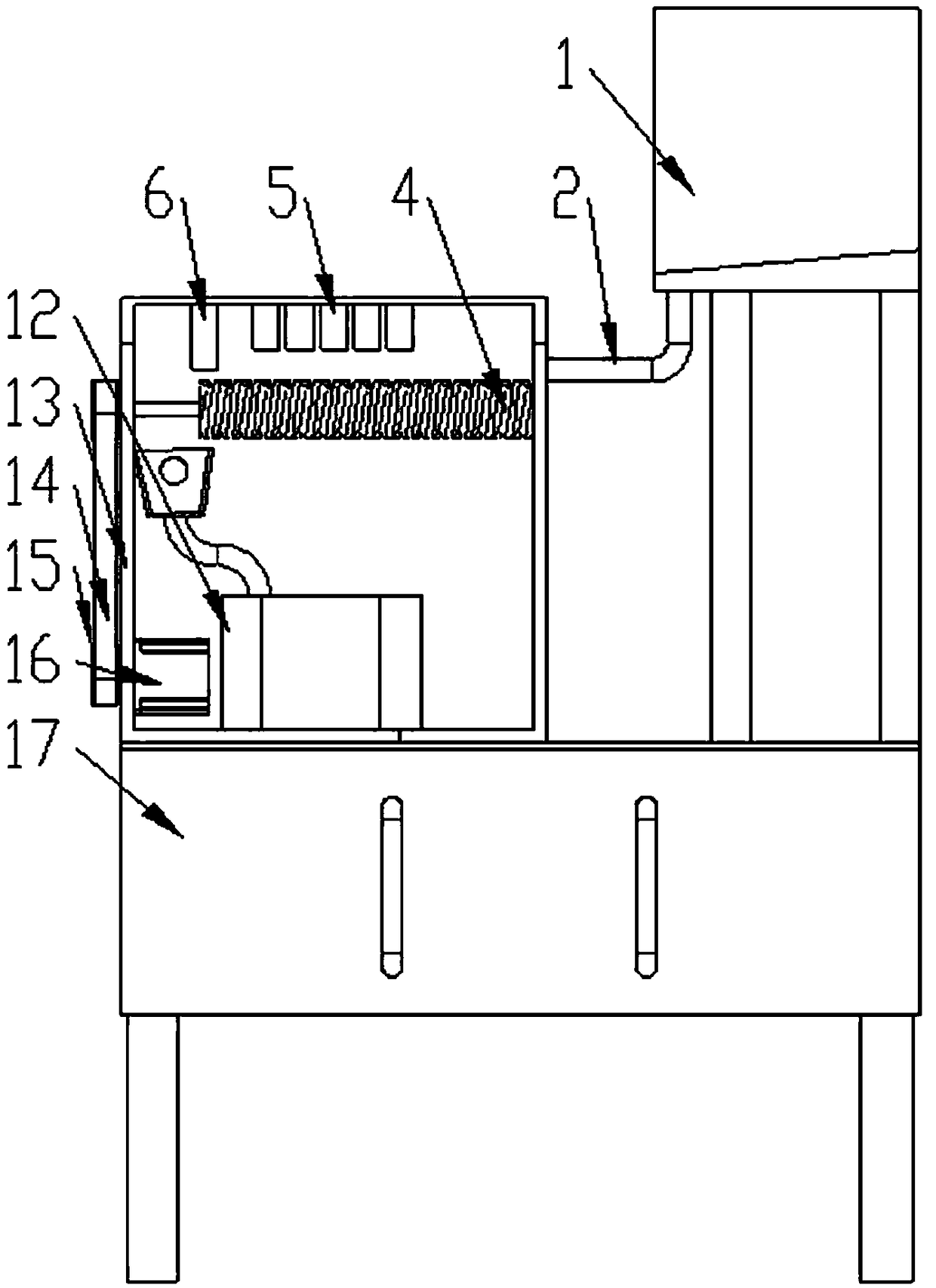

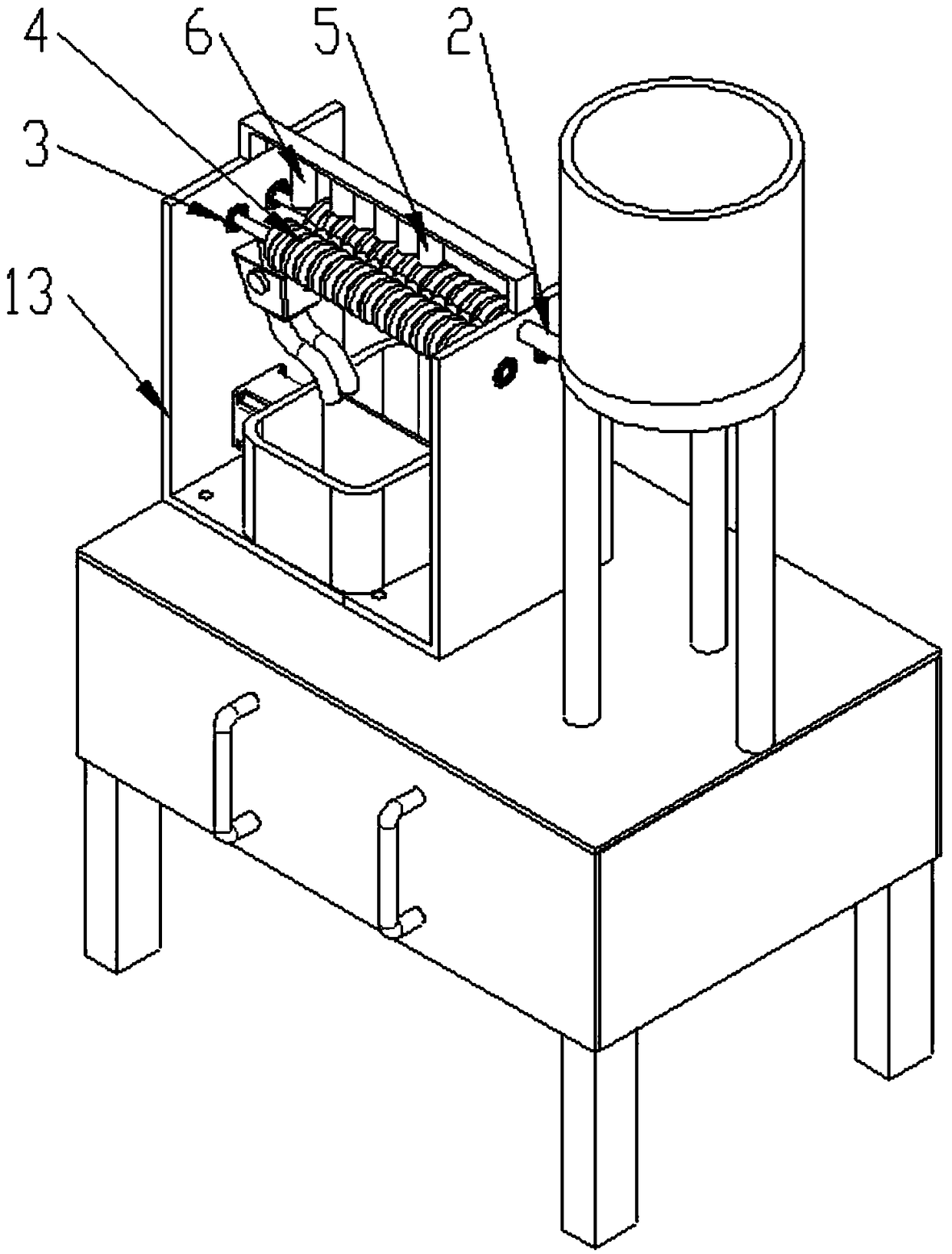

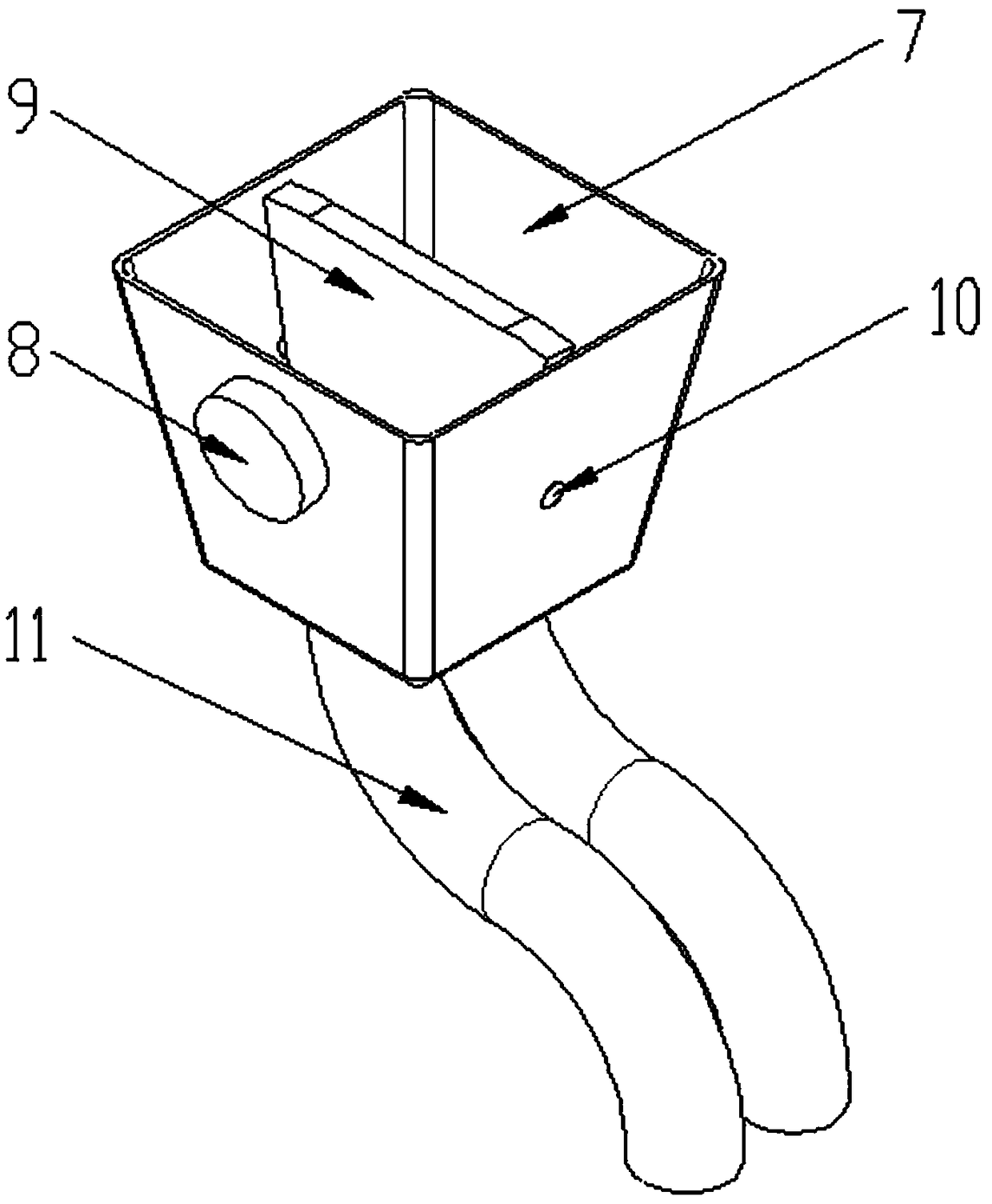

[0030] Such as figure 1 As shown, a steel ball surface defect detection system based on the double-thread development method is the front view of the patent of the invention. The top of the bracket is the feeding mechanism 1, and the bottom surface of the feeding mechanism 1 is inclined. The material channel 2 falls on the thread between the two lead screws 4. The rotation direction of the two lead screws 4 is the same, and they are on the same horizontal plane. They have the same angular velocity during rotation. In the transmission mechanism, the stepping motor 16 is fixed on the L plate. On 13, the output shaft transmits the torque to the timing pulley 15 through the timing belt 14, and the timing pulley 15 then transmits ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com