An offshore platform pile pin insertion control system and control method thereof

A control system and offshore platform technology, applied in the field of construction machinery, can solve problems such as drag reduction, achieve the effect of reducing severe wear and avoiding friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

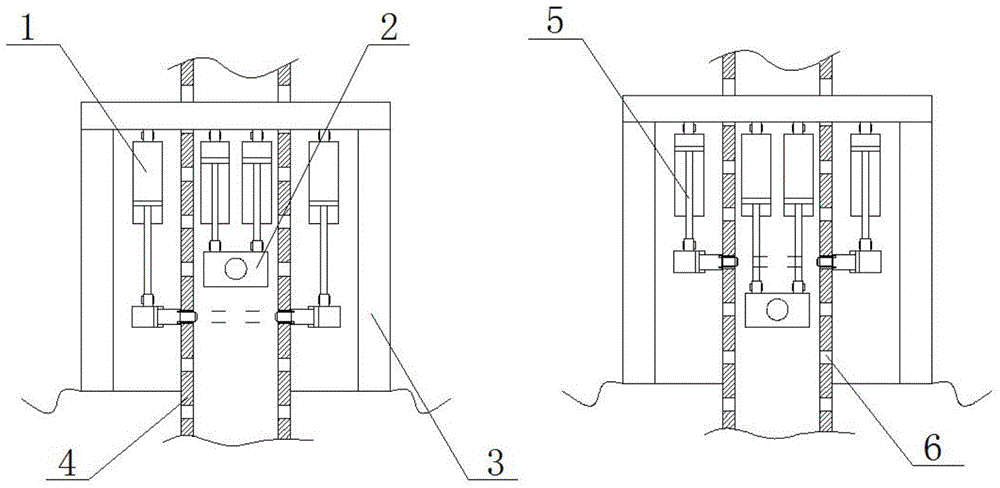

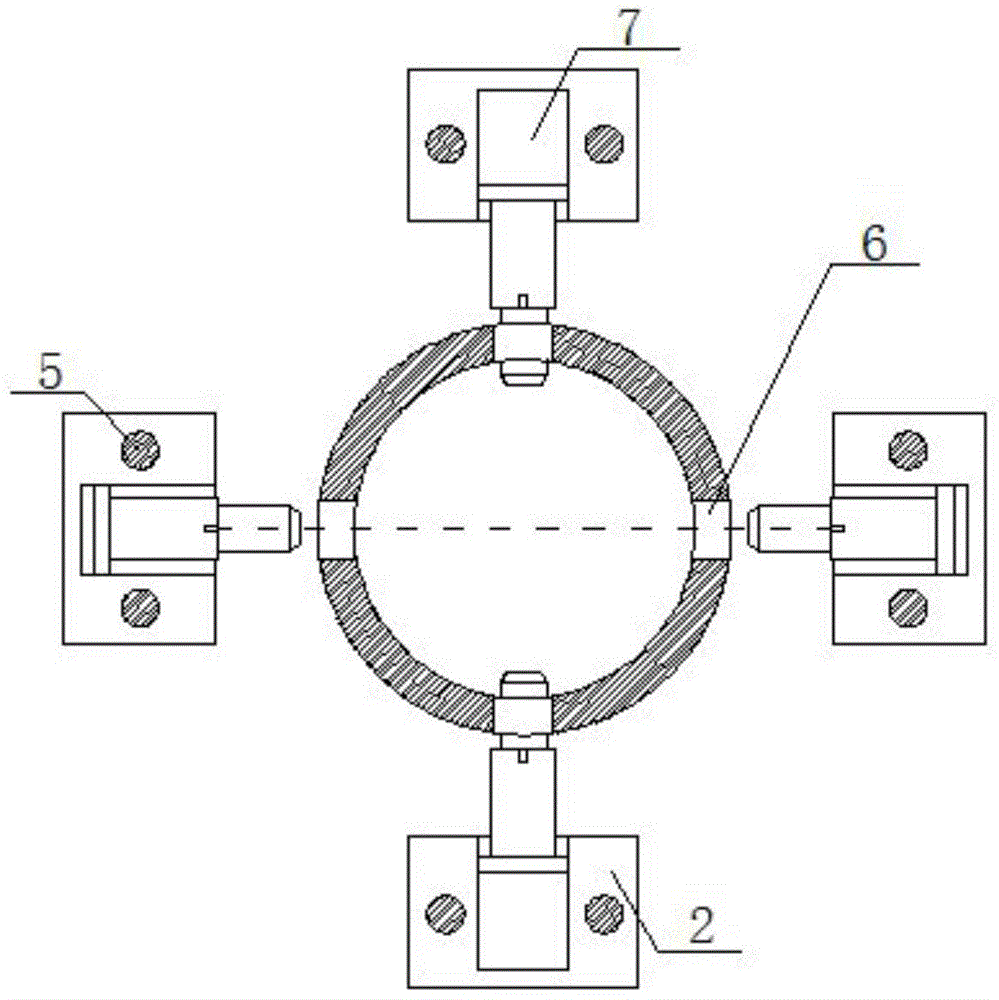

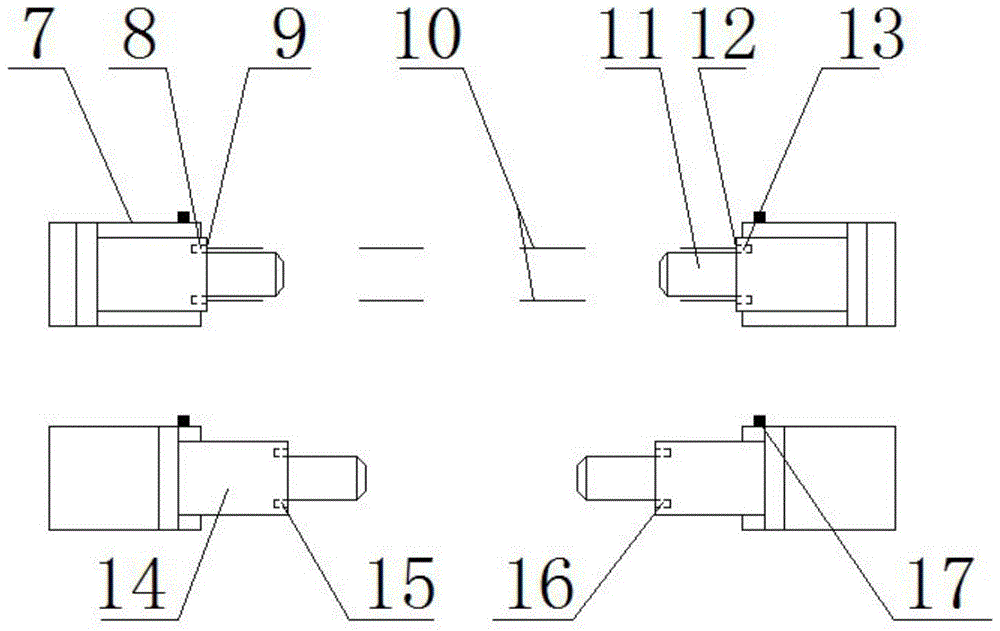

[0028] Such as Figure 1 to Figure 3 As shown, the present invention provides an offshore platform pile pin insertion control system, including: pile legs 4, pile support brackets 3, a plurality of positioning pin holes 6 are distributed on the pile legs 4, and the control system also includes lateral anti-collision The bolt unit 2, the horizontal anti-collision bolt unit 2 is connected with the pile fixing bracket 3, the horizontal anti-collision bolt unit 2 at least includes the pile fixing pin 11, which is used to cooperate with the positioning pin hole 6 of the pile leg 4; the laser detection device is used for Detect the position of the pile-fixing pin 11 relative to the positioning pin hole 6. When the pile-fixing pin 11 starts to be inserted, the laser detection device detects that the horizontal position of the pile-fixing pin 11 coincides with the positioning pin hole 6. 11 is inserted into the positioning pin hole 6; when the pile-fixing pin 11 is unloaded, the horiz...

Embodiment 2

[0030] Such as Figure 1 to Figure 3 As shown, the present invention provides an offshore platform pile-fixing pin insertion control system, which includes a pile-fixing bracket 3, pile legs 4, and a lifting system. The lifting system includes a vertical lifting hydraulic cylinder 1 and a lifting plunger 5, and two sets of horizontal The anti-collision latch unit 2, each group of transverse anti-collision latch units includes two oppositely arranged transverse anti-collision latch units, which are respectively the first group of transverse anti-collision latch units and the second group of transverse anti-collision latch units. The pile leg 4 moves up and down in the pile-fixing bracket 3, and the longitudinal lifting hydraulic cylinder is suspended in the pile-fixing bracket 3. The horizontal anti-collision bolt unit 2 is connected with the vertical lifting hydraulic cylinder 1 through the lifting plunger 5, and each vertical lifting hydraulic cylinder 1 drives a horizontal a...

Embodiment 3

[0037] Such as Figure 1 to Figure 3 As shown, the present invention provides a method for controlling the insertion and removal of pile-fixing pins on offshore platforms, which includes the following steps: setting a plurality of positioning pin holes 6 on pile legs 4; when the pile-fixing pins 11 are inserted, the laser detects the The pile fixing pin 11 coincides with the horizontal position of the positioning pin hole 6, and the pile fixing pin 11 is inserted into the positioning pin hole 6; when the pile fixing pin 11 is unloaded, adjust the position of the pile fixing pin 11 When the laser detects that the horizontal position of the pile fixing pin 11 coincides with the positioning pin hole 6, the pile fixing pin 11 is pulled out of the positioning pin hole 6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com