A high-speed train brake pad with optimized friction particle combination and installation method

A technology of brake pads and friction particles, applied in the direction of friction linings, brake types, brake components, etc., can solve the problem of reducing train operation efficiency and economic benefits, harming the physical and mental health of passengers and residents along the way, reducing vibration and noise and Problems such as poor stress distribution can ensure braking reliability and safety, reduce production and operating costs, and reduce wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

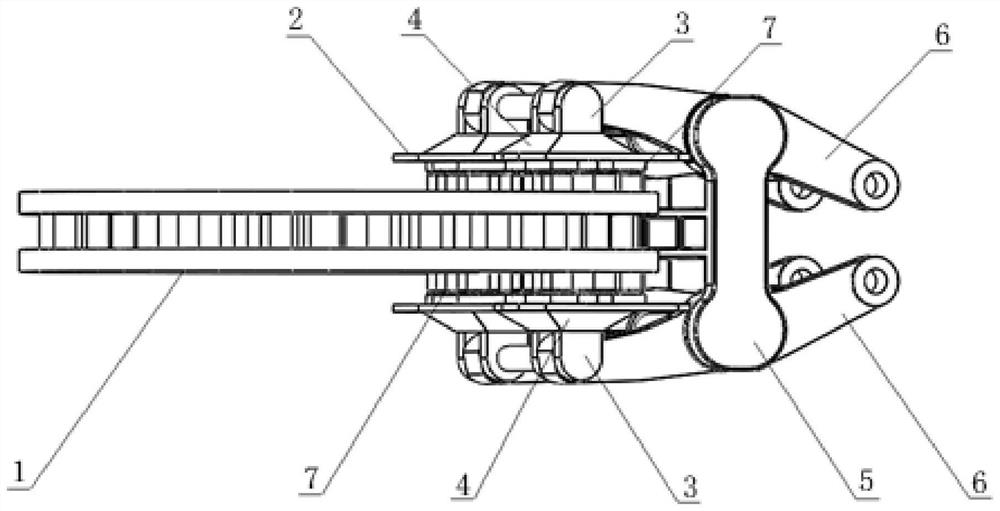

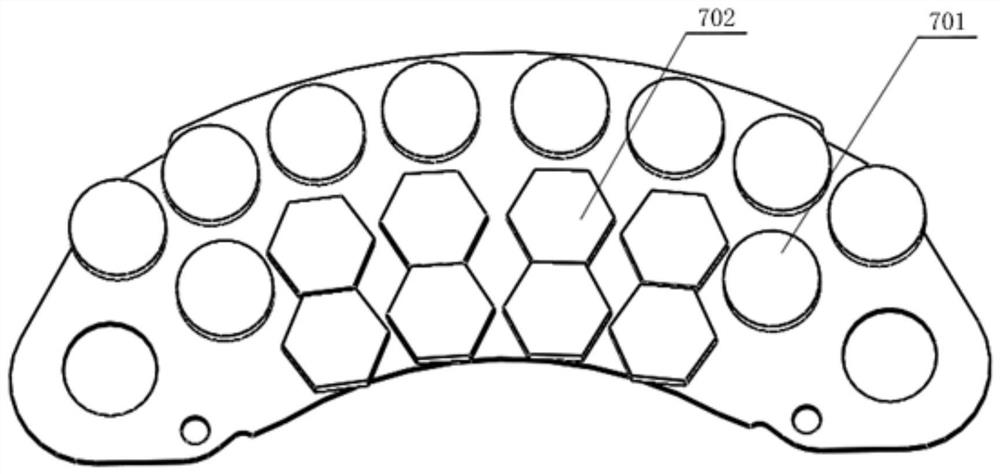

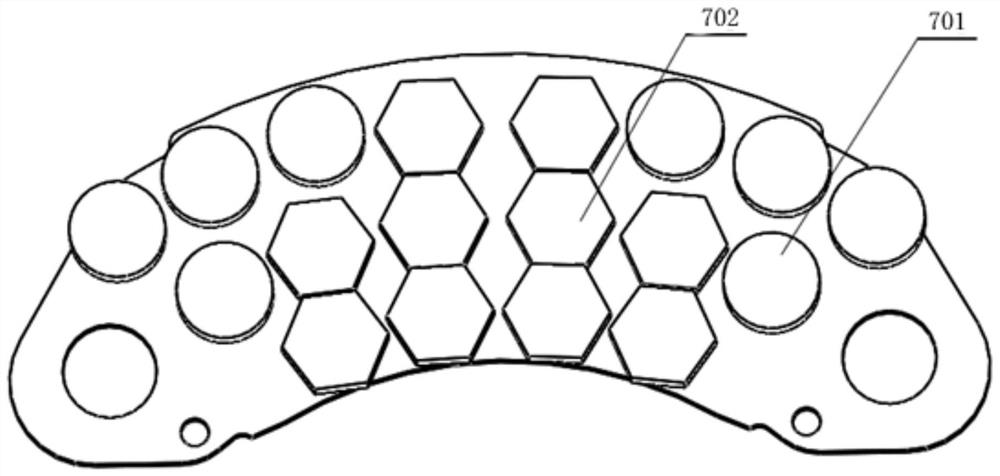

[0051] A high-speed train brake pad with optimized friction particle combination and installation method, comprising a brake disc 1, a brake pad structure and a loading device, the loading device is connected to the brake pad structure, and the brake pad structure is connected to the brake pad structure The brake disc 1 cooperates, and the brake pad structure includes a brake pad back plate 2, and several friction particles 7 are arranged on the brake pad back plate 2, and the several friction particles 7 have two types and above shape. In this embodiment, the structure of the brake pad back plate 2 is left-right symmetrical, and its shape is arc-like, and it is stamped and formed by steel material.

[0052] The friction particles 7 include polygonal friction particles 702 and circular friction particles 701 . In this embodiment, the polygonal friction particles 702 are regular hexagonal friction particles.

[0053] Studies have shown that hexagonal friction particles are ob...

Embodiment 2

[0064] The technical solution of this embodiment is basically the same as that of Embodiment 1, the difference is that:

[0065] Such as figure 2 As shown, in this embodiment, the number of friction particles 7 is eighteen, ten of which are circular friction particles 701 , and the remaining eight are regular hexagonal friction particles 702 . The ten circular friction particles 701 are arranged on the outer layer and the cut-in end of the brake pad back plate 2 with relatively large relative speed and impact; the eight regular hexagonal friction particles 702 are arranged on the brake pad with relatively small speed and impact Brake pad back plate 2 inner layer and middle part. Due to the large number of passengers in the city, excessive braking noise will seriously affect the passenger experience. Therefore, high-speed trains operating in cities put forward higher requirements for vibration and noise reduction of the braking system. In addition, when the high-speed train ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com