A flexible combined oil well pump plunger

An oil pump and plunger technology, which is applied in the field of petroleum machinery exploitation, can solve the problems of high machining precision, high leakage, and increase the downward resistance of the plunger, so as to prolong the effective sealing period, reduce severe wear and prolong the The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

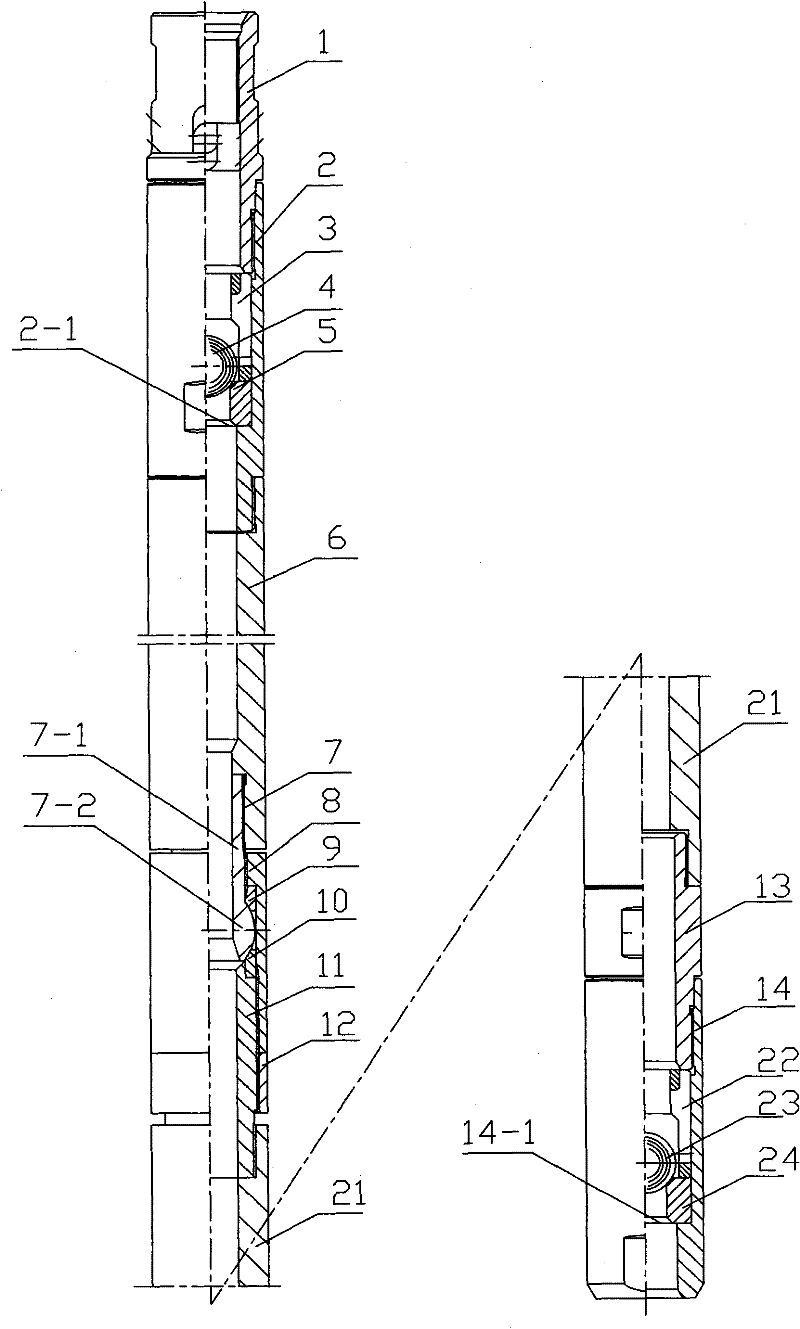

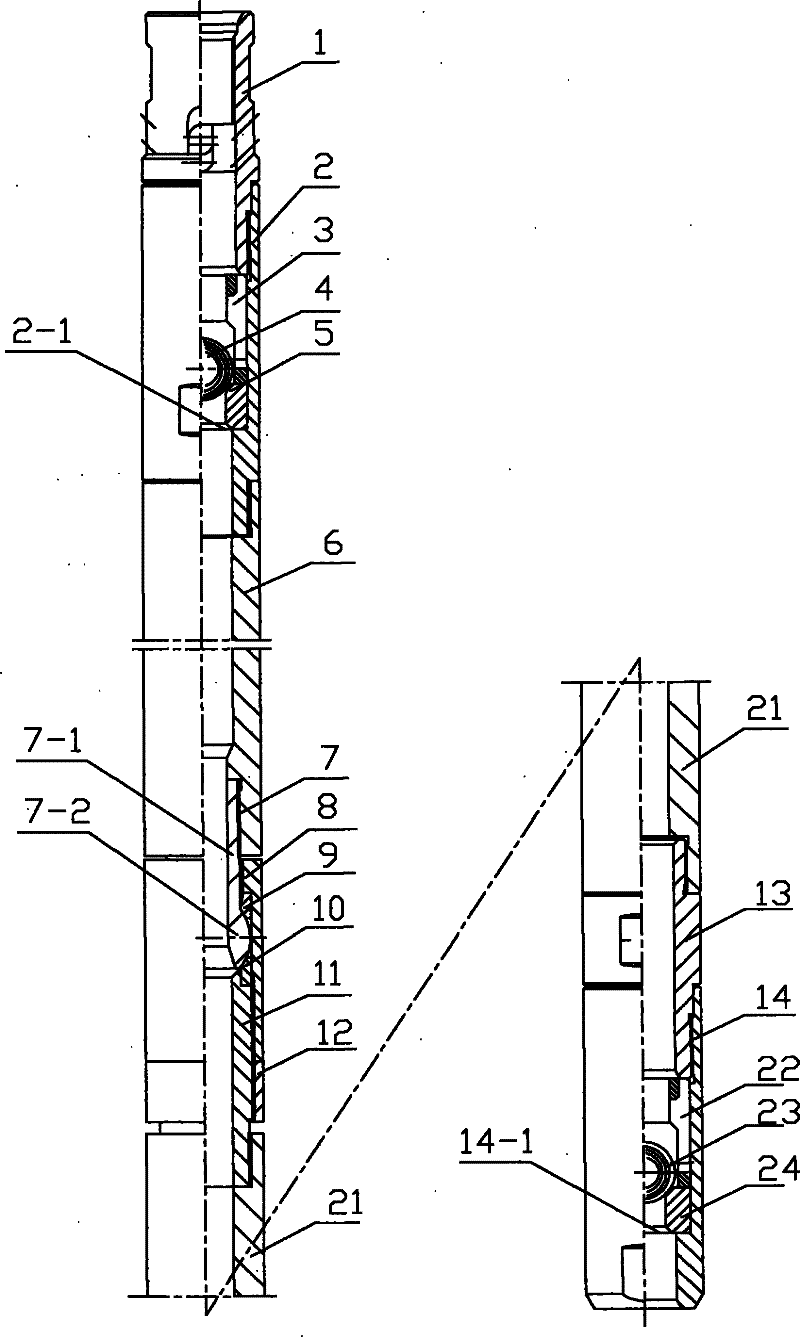

[0025] Such as figure 1 As shown, there are two rigidly combined oil well pump plungers, including an upstream traveling valve, an upper plunger body 6, a flexible connector, a lower plunger body 18 and a lower traveling valve.

[0026] The upstream floating valve includes an upper joint 1, an upper valve housing 2, an upper valve cover 3, an upper valve ball 4 and an upper valve ball seat 5, the upper valve housing 2 is threadedly connected to the lower end of the upper joint 1, and the inner diameter of the upper valve housing 2 Fix the upper boss 2-1, install the upper valve ball seat 5, the upper valve ball 4 and the upper valve cover 3 sequentially above the upper boss 2-1, and the upper end of the upper valve cover 3 is pressed against the lower end of the upper joint 1 . The lower end of the upper valve casing 2 is threadedly connected to the upper plunger body 6 .

[0027] The flexible connector includes a ball connecting pipe 7 , a ball pressing cap 8 , a ball upper...

Embodiment 2

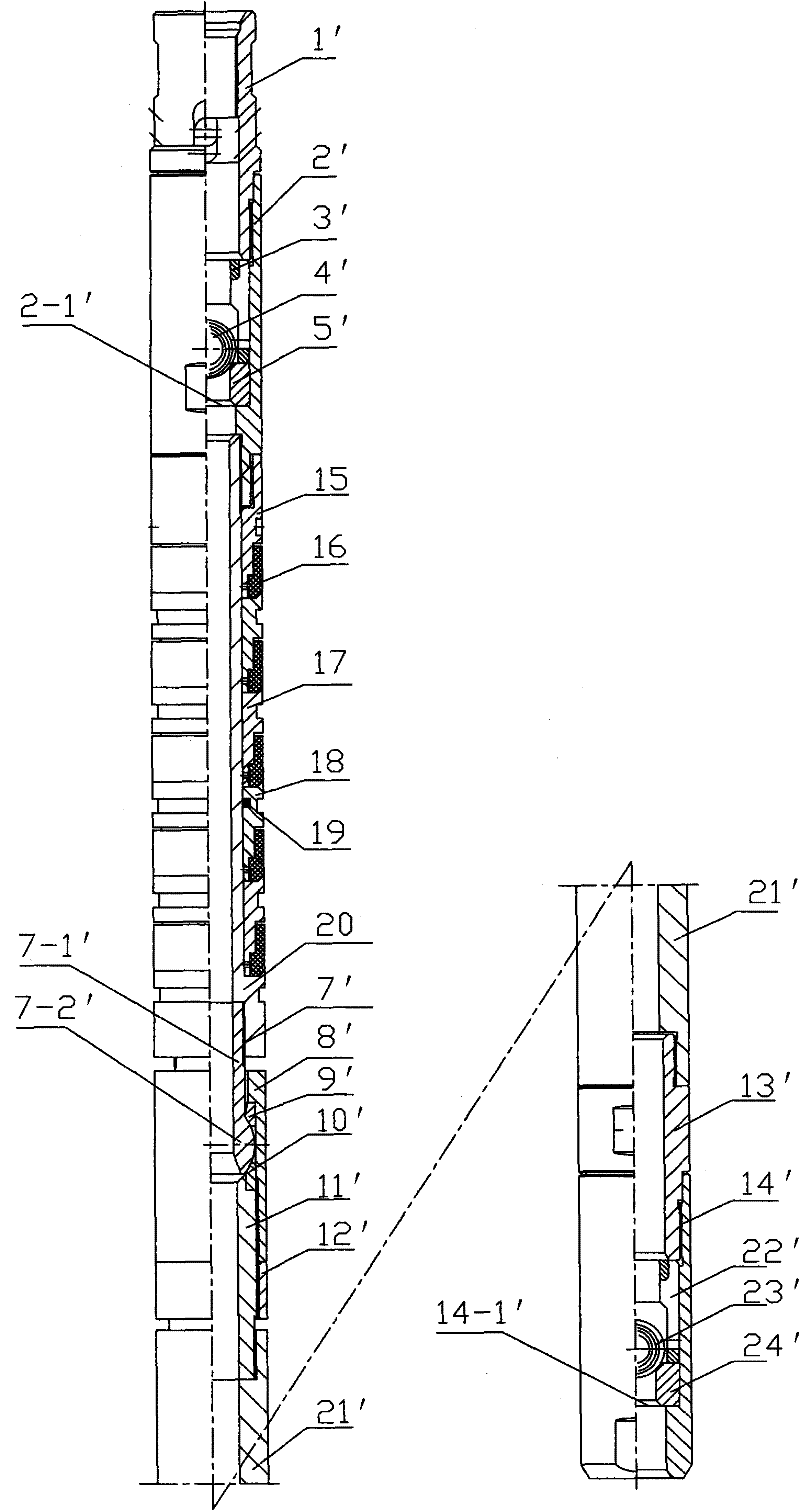

[0031] Such as figure 2 As shown, it is a rigid-flexible combined oil well pump plunger, including an upper floating valve, an upper soft sealing segment sealing body, a flexible connector, a lower plunger body 21' and a lower floating valve.

[0032] The upstream floating valve includes an upper joint 1', an upper valve housing 2', an upper valve cover 3', an upper valve ball 4' and an upper valve ball seat 5', and the upper valve housing 2' is threadedly connected to the lower end of the upper joint 1', The inner side of the upper valve shell 2' radially fixes the upper boss 2-1', and the upper part of the upper boss 2-1' is sequentially loaded into the upper valve ball seat 5', the upper valve ball 4' and the upper valve cover 3', and the upper The upper end of the valve cover 3' is pressed against the lower end of the upper joint 1'. The lower end of the upper valve casing 2 ′ is internally threaded to the central pipe 20 , and the lower end of the upper valve casing 2 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com