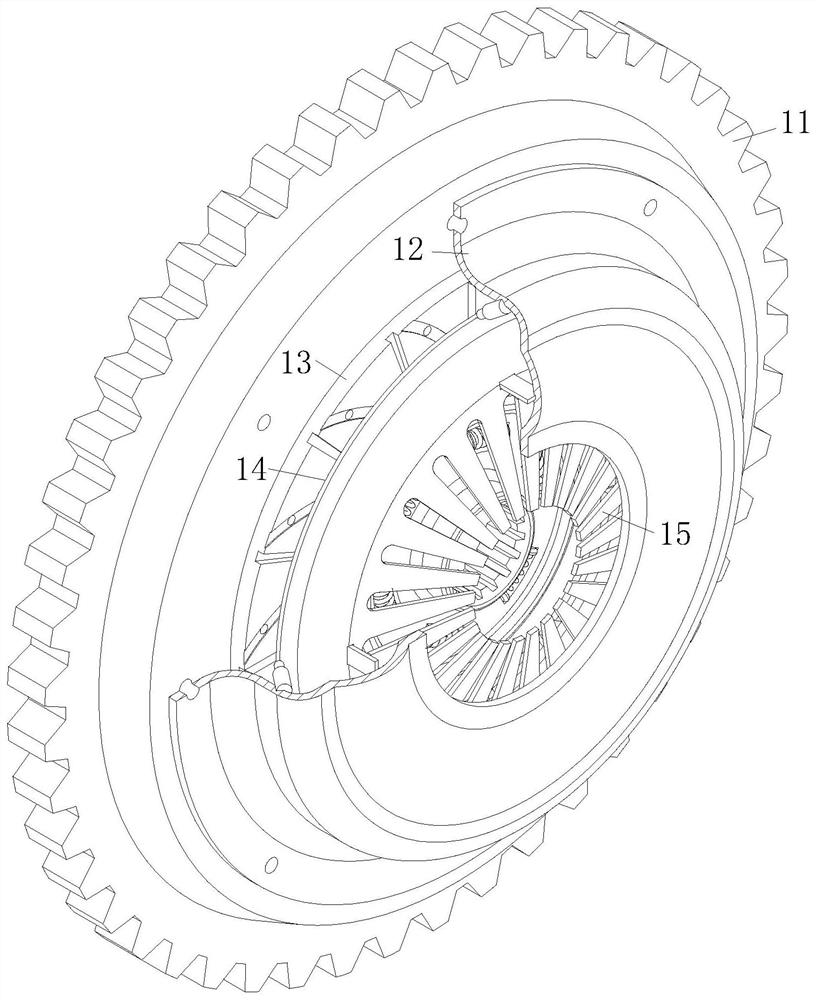

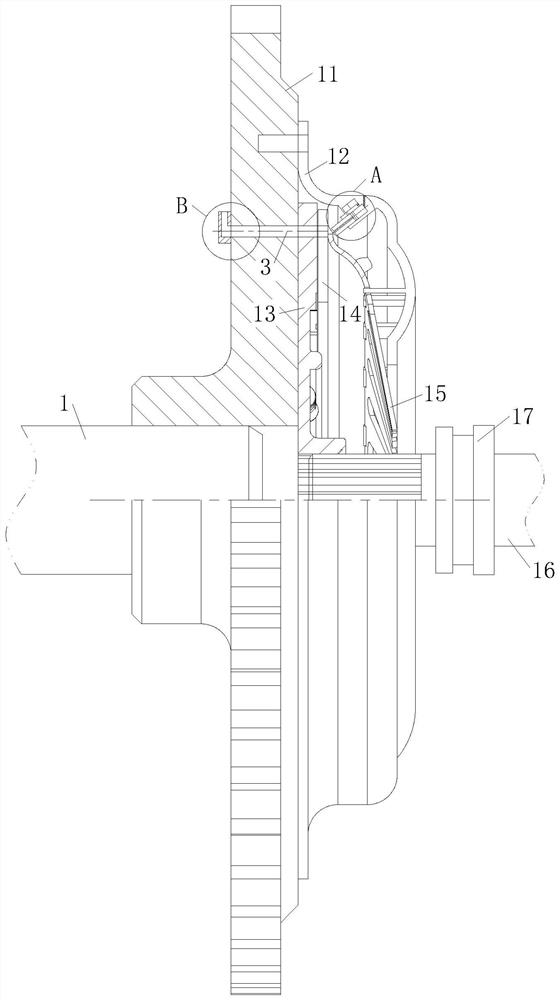

a clutch assembly

A clutch and clutch plate technology, applied in the field of clutches, can solve the problems of increasing clutch plate ablation, reducing clutch plate friction, shortening clutch service life, etc., to achieve the effects of increasing air exchange efficiency, reducing severe wear, and increasing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

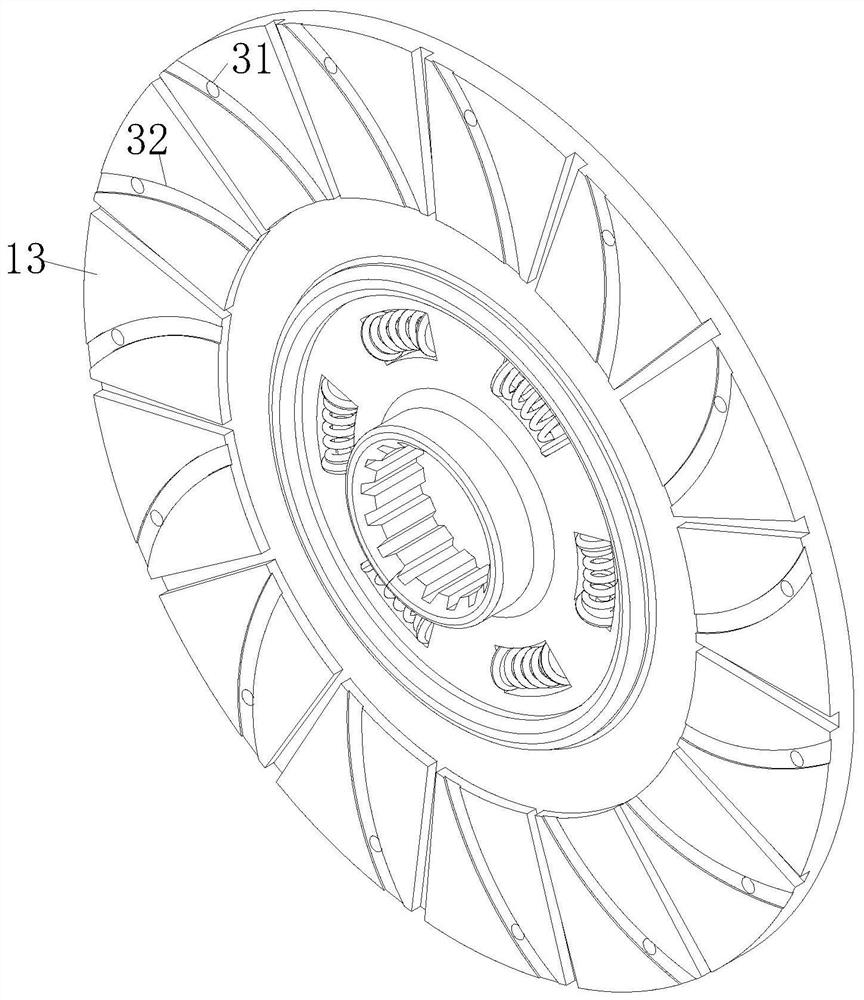

[0025] As an embodiment of the present invention, a set of No. 4 holes 3 for ventilation is provided on the flywheel 11; No. 5 holes 31 are provided on the clutch plate 13 corresponding to the No. 4 holes 3, through which air flows through No. 5 hole 31 and No. 4 hole 3 further increase the heat dissipation efficiency of clutch disc 13; through No. 4 hole 3 and No. 5 hole 31, the air ejected from No. 1 hole 22 is increased to enter the center of the contact part between clutch disc 13 and flywheel 11. Efficiency, so that the clutch plate 13 receives cooling airflow in multiple directions, increases the heat transfer efficiency between the clutch plate 13 and the airflow, further increases the heat dissipation speed of the clutch plate 13, reduces the ablation of the clutch plate 13 caused by high temperature, and then causes the torque of the clutch The transmission efficiency is reduced, and at the same time, the life of the clutch plate 13 is reduced.

[0026] As an embodime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com