Rapidly screening machine

A powder sieving machine, fast technology, applied in the direction of sieve, solid separation, grille, etc., can solve the problems of poor sieving effect, low production efficiency, poor effect, etc., to achieve good sieving effect, high production efficiency, use handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

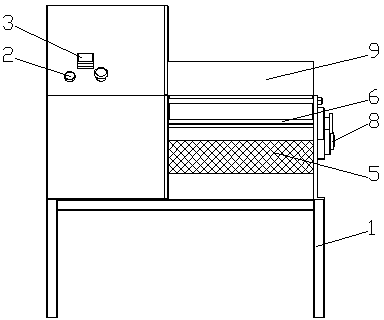

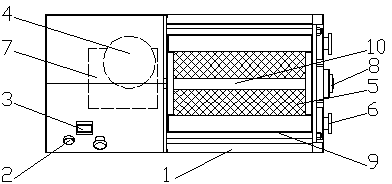

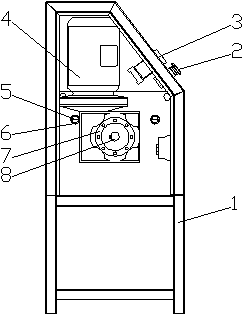

[0014] A fast powder sieving machine is characterized in that: a motor 4, a reducer 7, a switch button 2, a screen tensioning shaft 6, and a trough 9 are arranged on the frame 1, and a main shaft 8 and a sieve trough are arranged in the trough 9. The screen scraper cage 10, the screen scraper cage 10 is fixed on the main shaft 8, the screen 5 is arranged at the bottom of the trough 9, the screen 5 is tensioned by two screen tensioning shafts, and the motor 4 drives the main shaft through the reducer 7 8 and the screen scraper cage 10 rotate. The frame 1 is also provided with a controller 3 for controlling the rotation speed, rotation time, and rotation direction of the motor. The sieve 5 rolls are tensioned on the sieve tensioning shaft 6, and the controller 3 is a time relay.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com