Mould adjusting device

A technology of mold adjustment device and template adjustment, which is applied in the field of injection molding machines, can solve the problems of inconvenient disassembly and maintenance, poor gear stability, and low transmission precision, and achieve the effect of convenient mold adjustment, accurate mold adjustment, and rapid transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The following are specific embodiments of the present invention in conjunction with the accompanying drawings to further describe the technical solutions of the present invention, but the present invention is not limited to these embodiments.

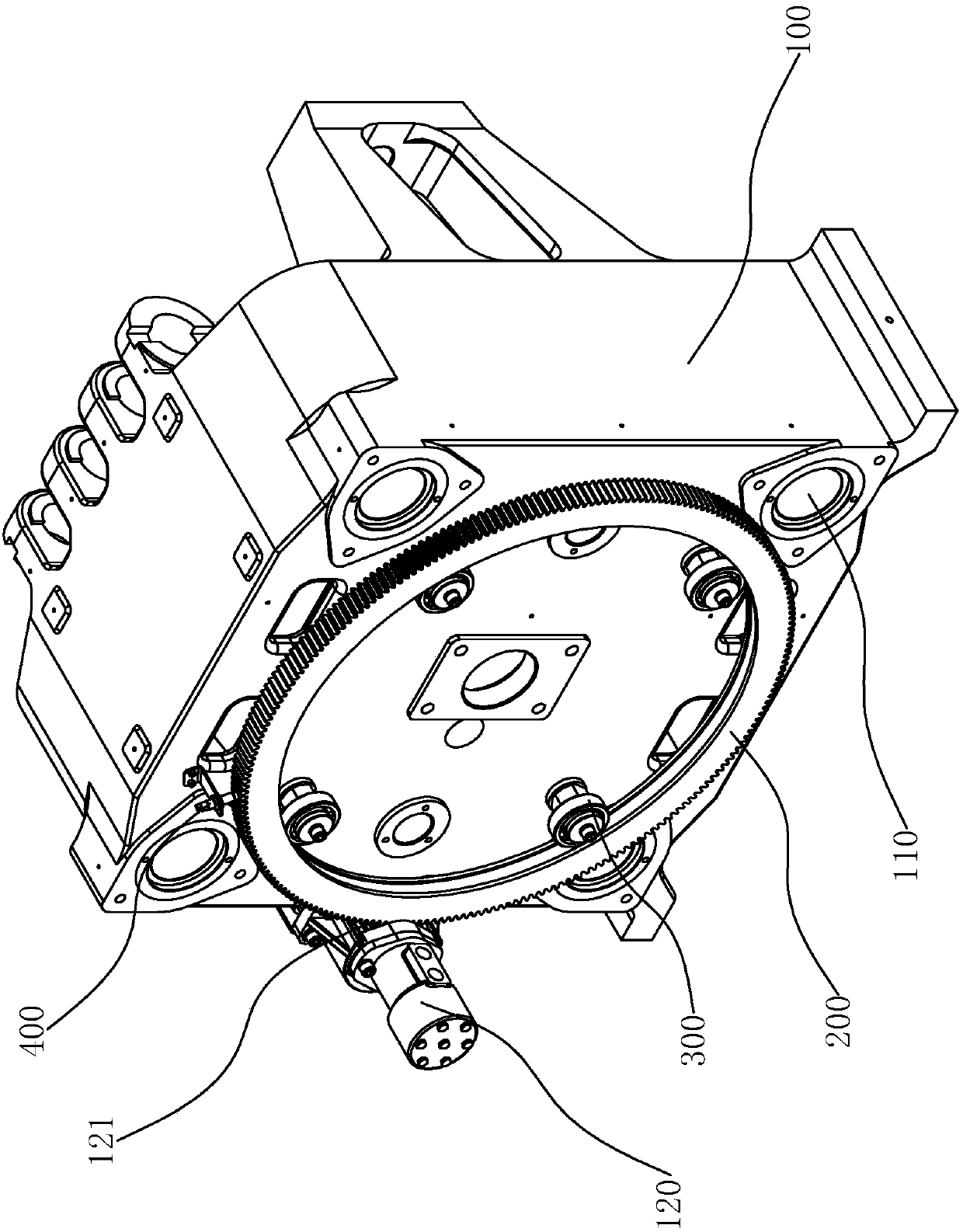

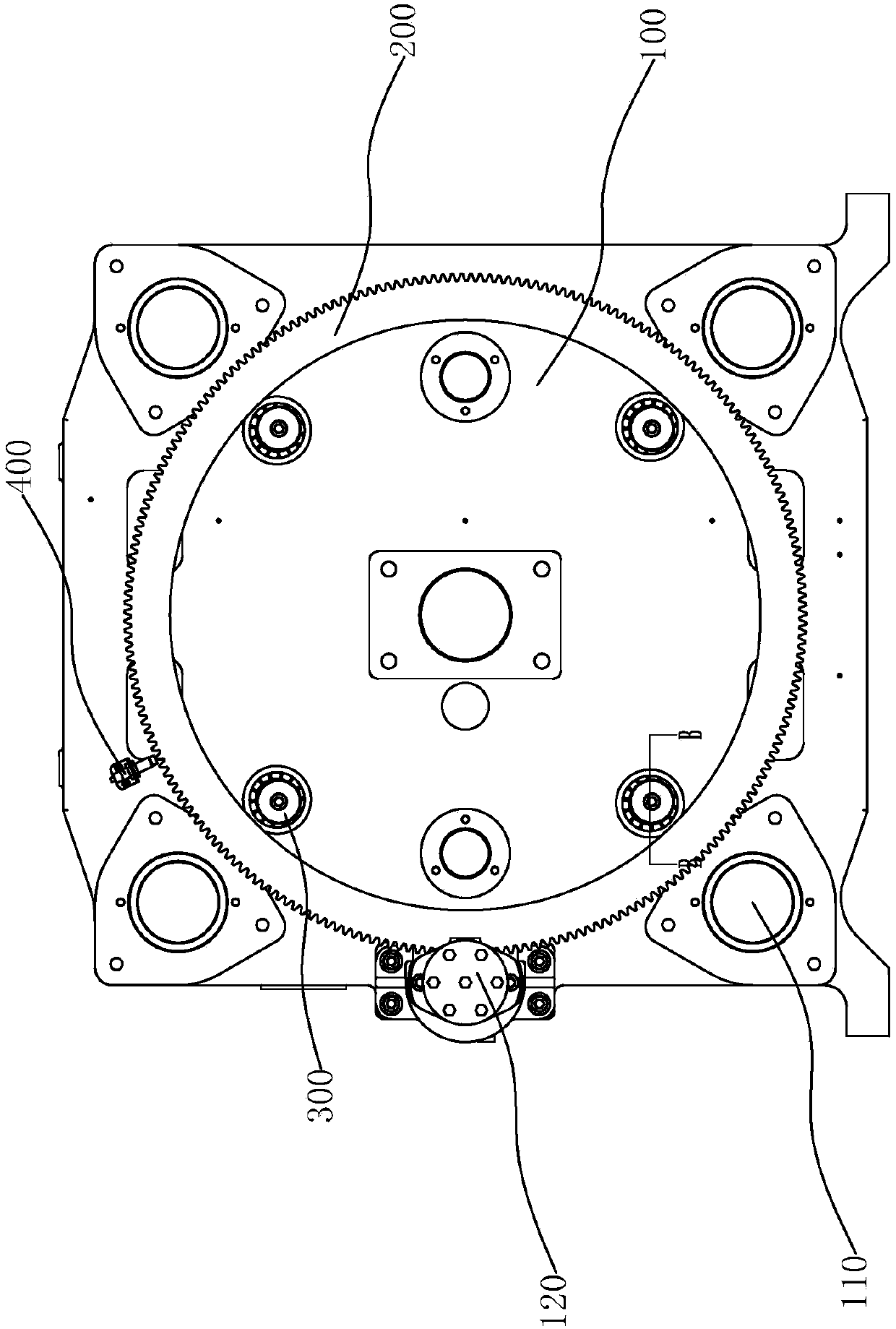

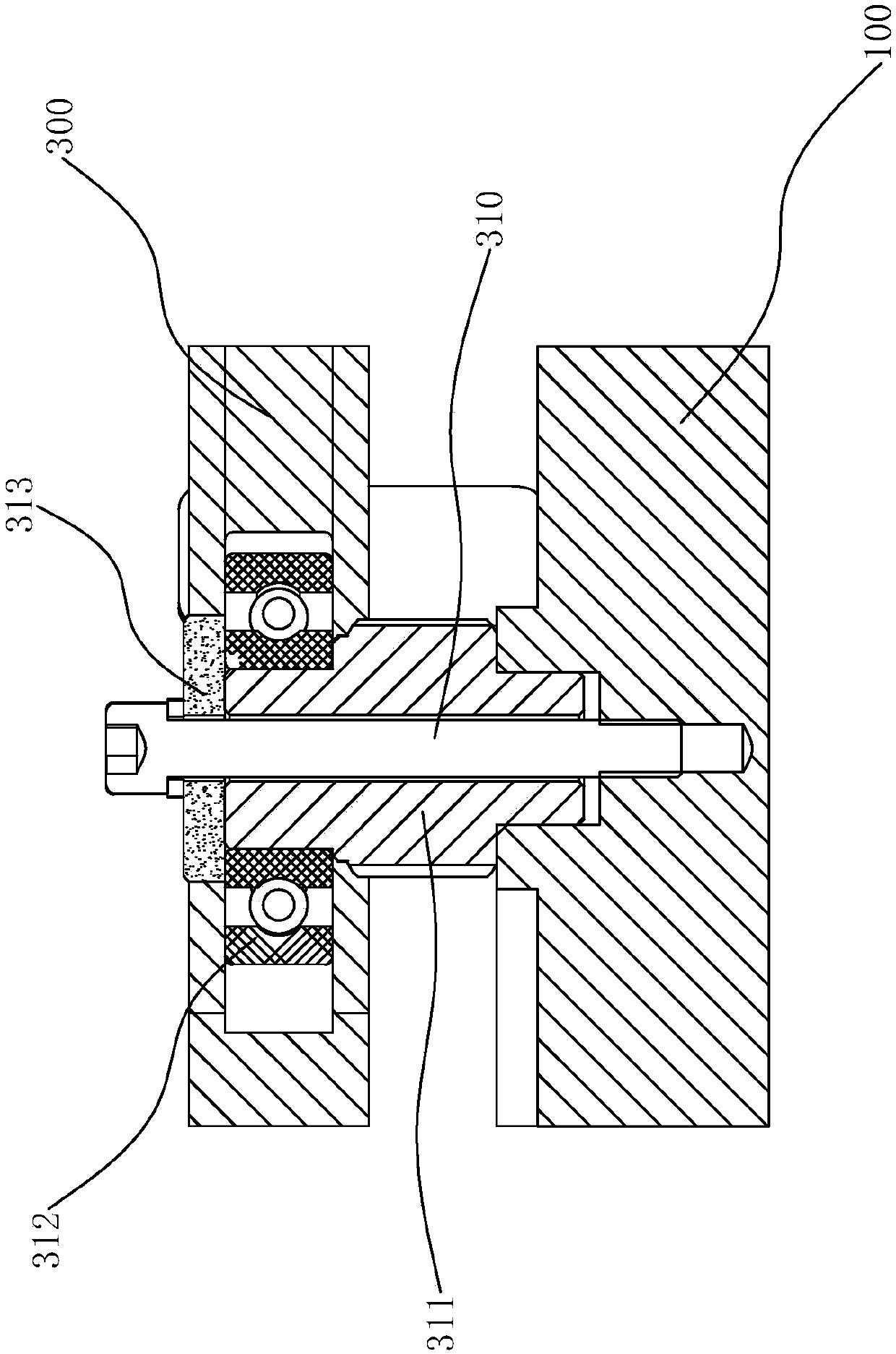

[0017] Such as figure 1 As shown, a mold adjusting device is arranged on the end face of the adjusting plate 100 of the injection molding machine. The four corners of the adjusting plate 100 are respectively provided with guide holes 110, and the four guide holes 110 are respectively provided with pull rods (not shown) , The adjusting plate 100 can move axially on the pull rod. The mold adjusting device includes a first gear 121 connected to the driving motor 120, a ring gear 200 arranged in the middle of the adjusting plate 100 and meshing with the first gear 121, and arranged in each A second gear (not shown) on a tie rod and meshingly connected with the ring gear 200. Four rollers 300 are evenly arranged on the adjusting template ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com