Patents

Literature

47results about How to "Reduce eccentric force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

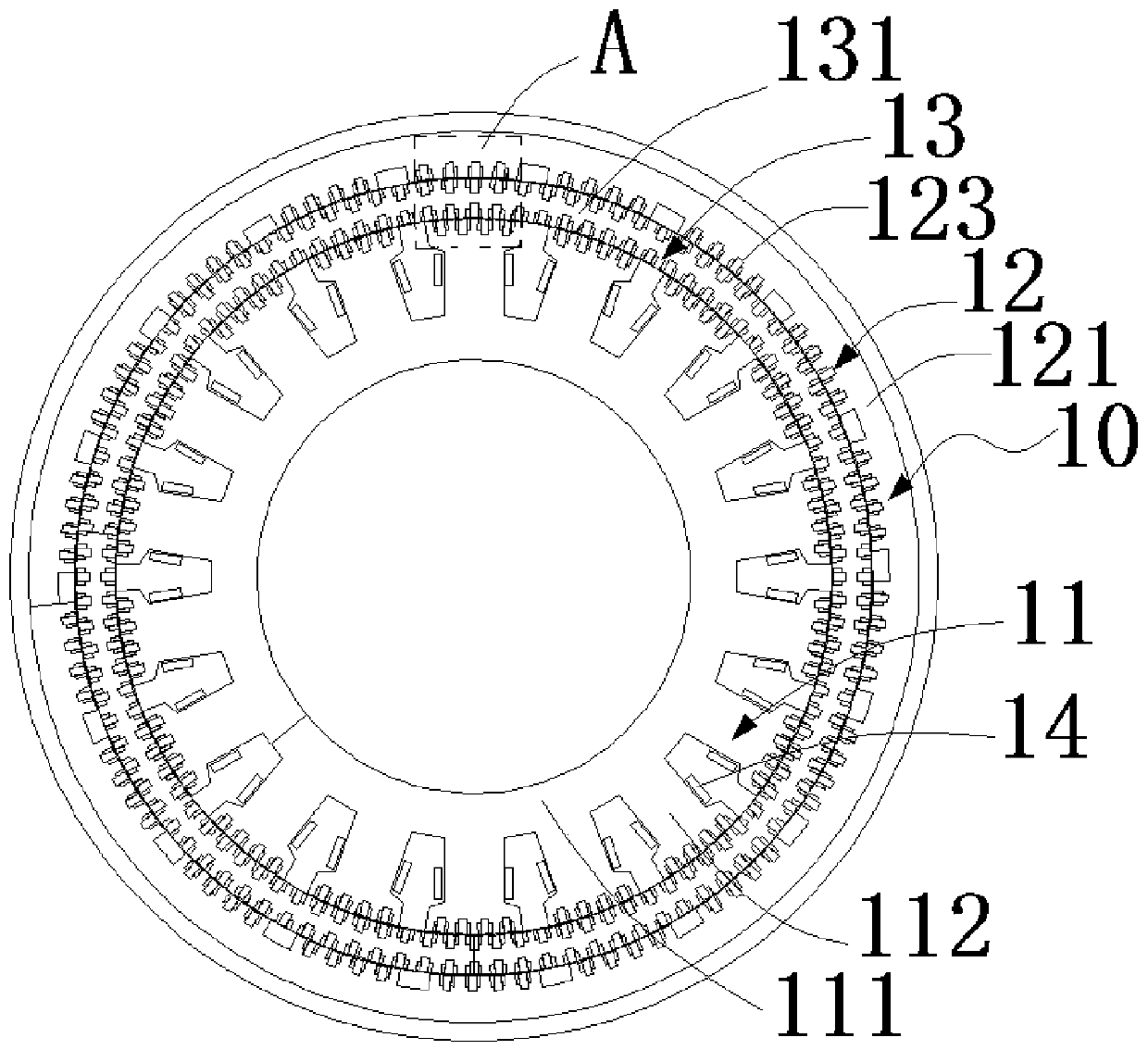

Aviation high-speed generator rotor structure

InactiveCN103532269AImprove efficiencyImprove reliabilityWindingsMagnetic circuit rotating partsAviationMagnetic poles

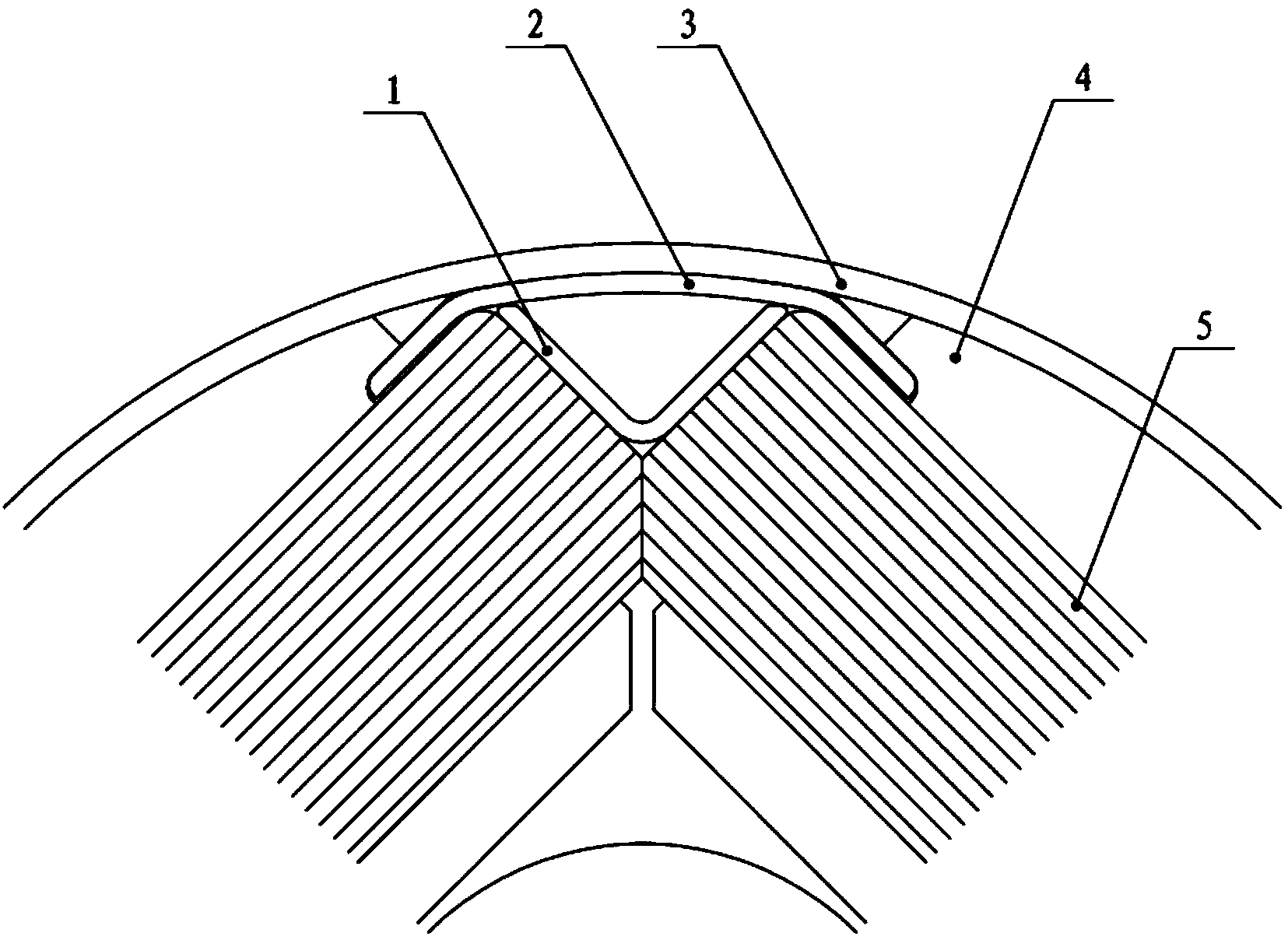

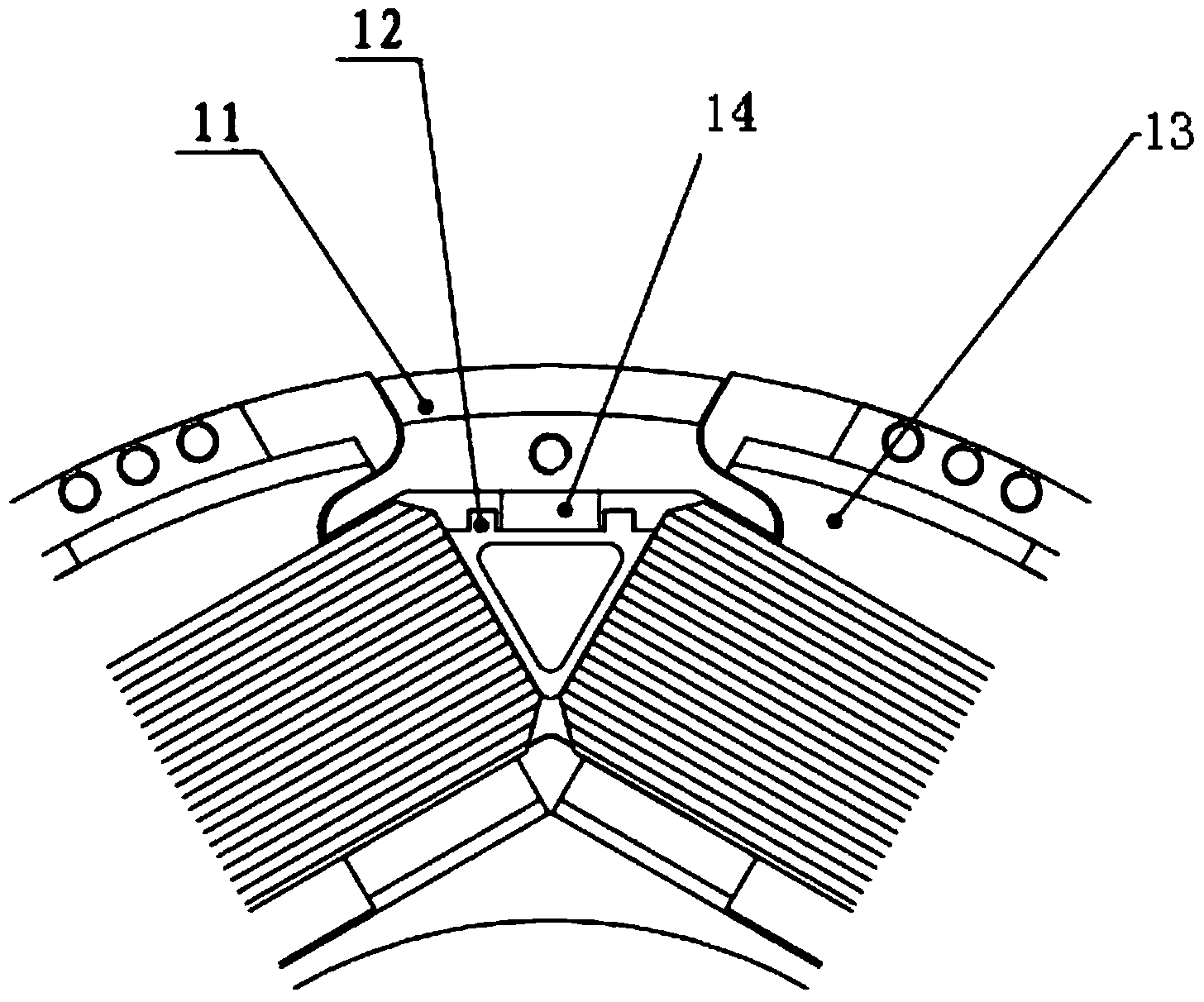

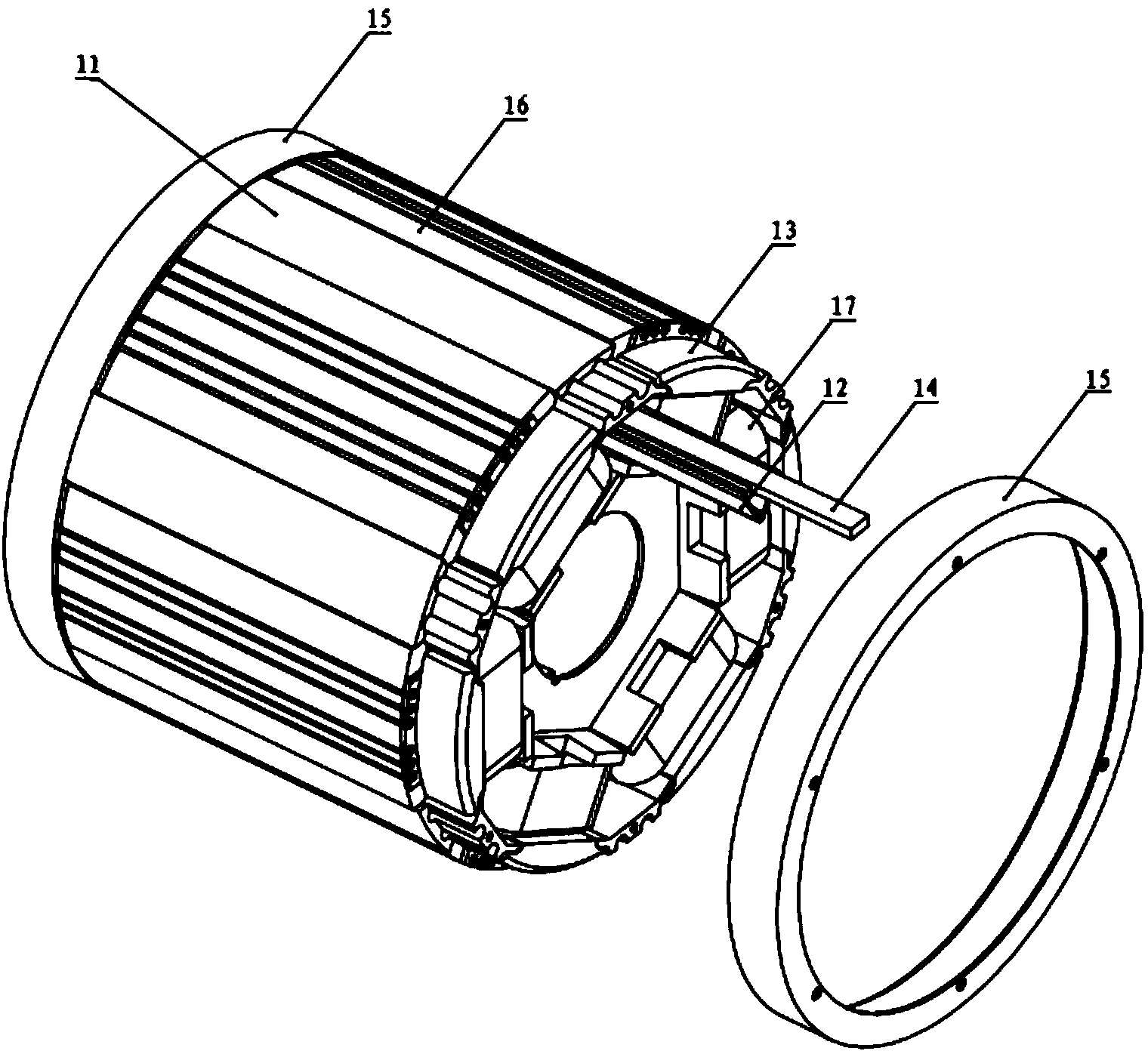

The invention relates to an aviation high-speed generator rotor structure, which comprises a plurality of V-shaped slot wedges, a wing-shaped slot wedge, a winding, two hoop rings and a magnetic pole iron core. The aviation high-speed generator rotor structure is characterized in that the V-shaped slot wedges are changed into triangular slot wedges, a wedge block is arranged on a triangular cross beam, and the upper surface of the wing-shaped slot wedge is aligned with an excircle of the magnetic pole iron core. The aviation high-speed generator rotor structure has the advantages that the magnetic pole iron core, an excitation winding, the slot wedges and the like in a main generator rotor form a whole, the work intensity problem of products at a high rotating speed is solved, in addition, because the wing-shaped slot wedge and the surface of a rotor iron core approximately form a whole circle, the problem of surface friction loss of the high-rotating-speed rotor is reduced, and the efficiency of a generator is improved. The excitation winding on the rotor is tightly pressed by the slot wedges, so the offset of the winding during the rotation at a high rotating speed is reduced, the eccentric force reduction caused by unbalance quantity due to high-rotating-speed rotation is reduced, the load is low during the bearing rotation, and the work reliability of the generator is improved.

Owner:SHAANXI AVIATION ELECTRICAL

High Frequency Fleece Needling Machine

ActiveCN105256467BIncrease acupuncture frequencyReduce vibrationNeedling machinesPunchingDrive shaft

Owner:SHANTOU SANHUI NONWOVEN MACHINERY FACTORY

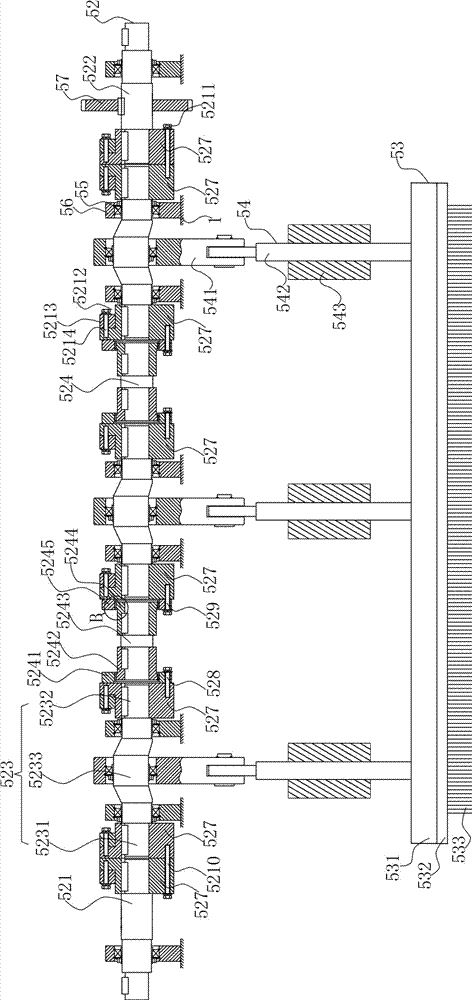

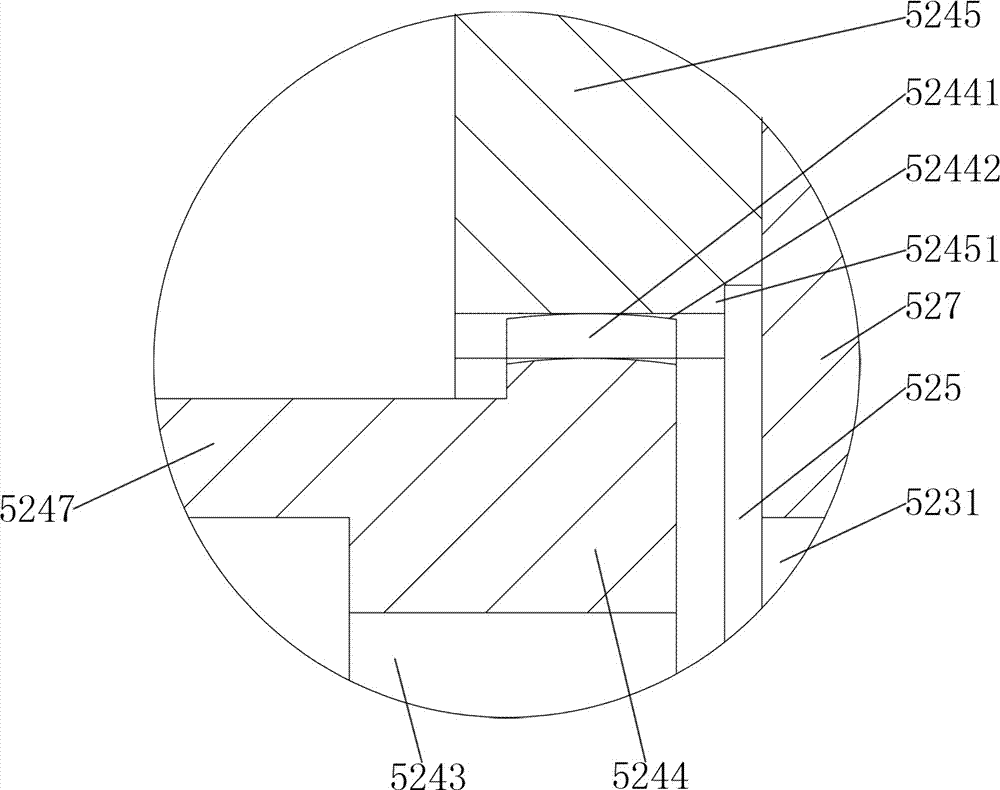

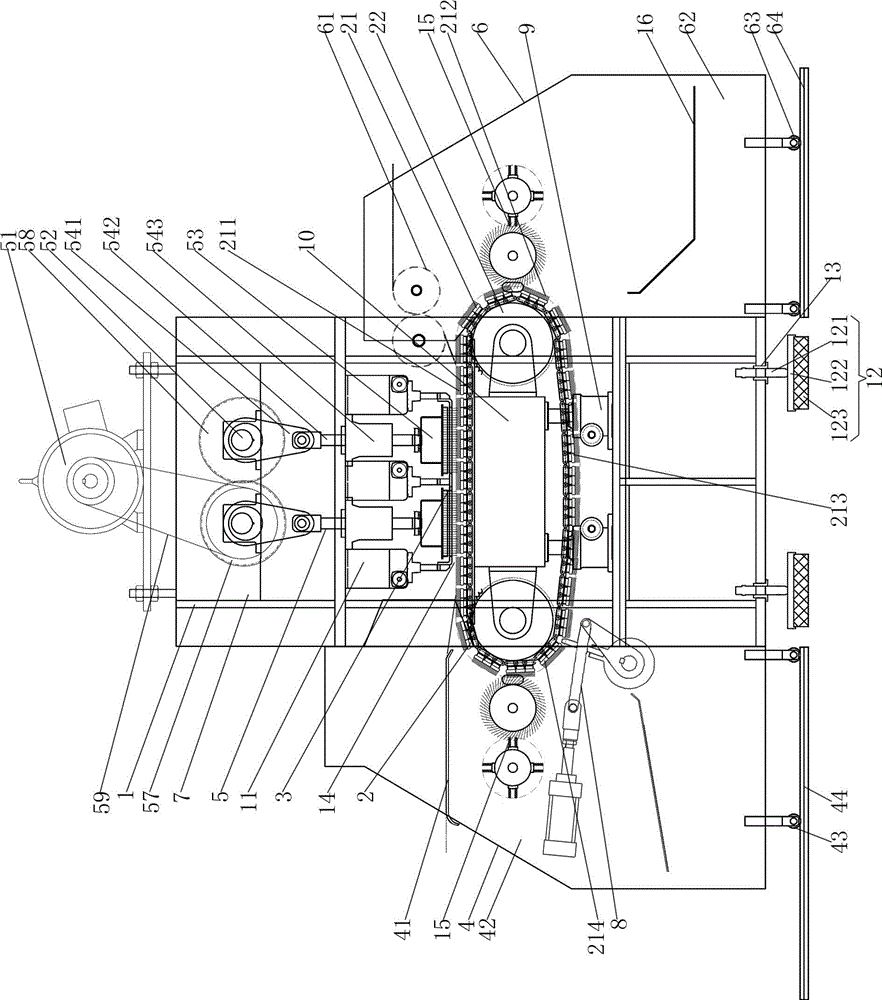

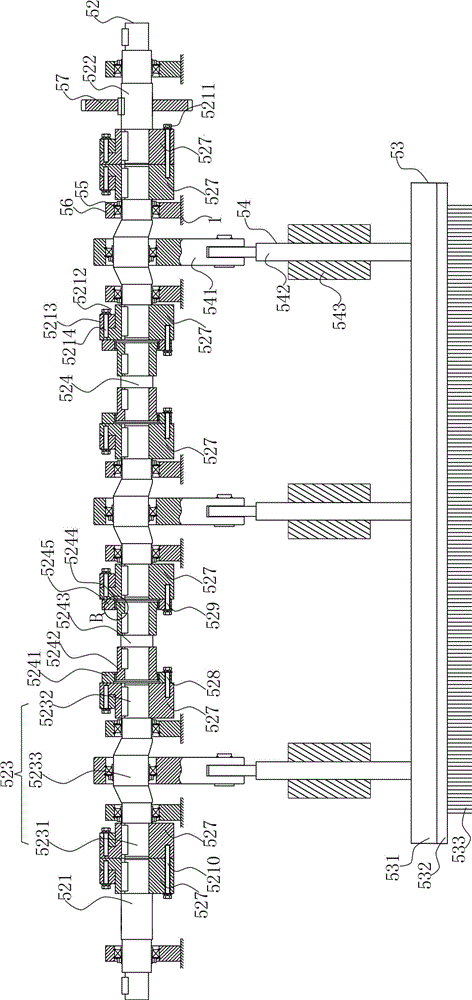

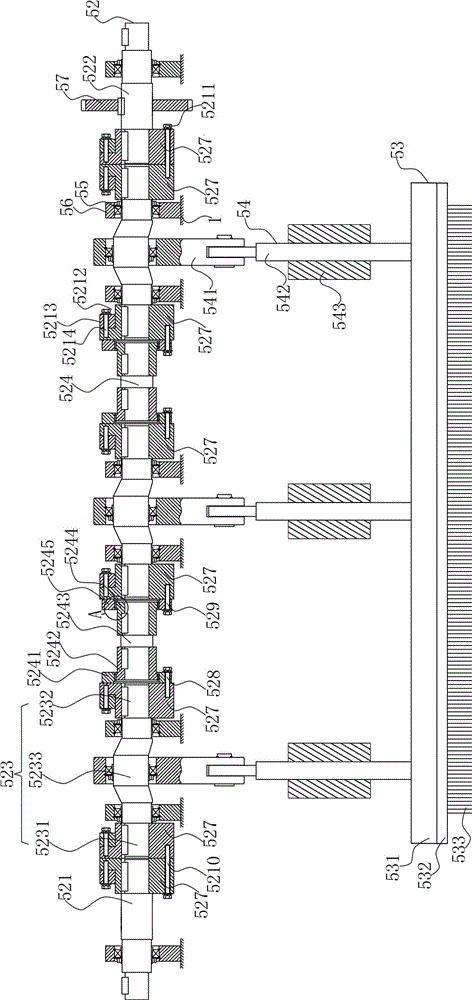

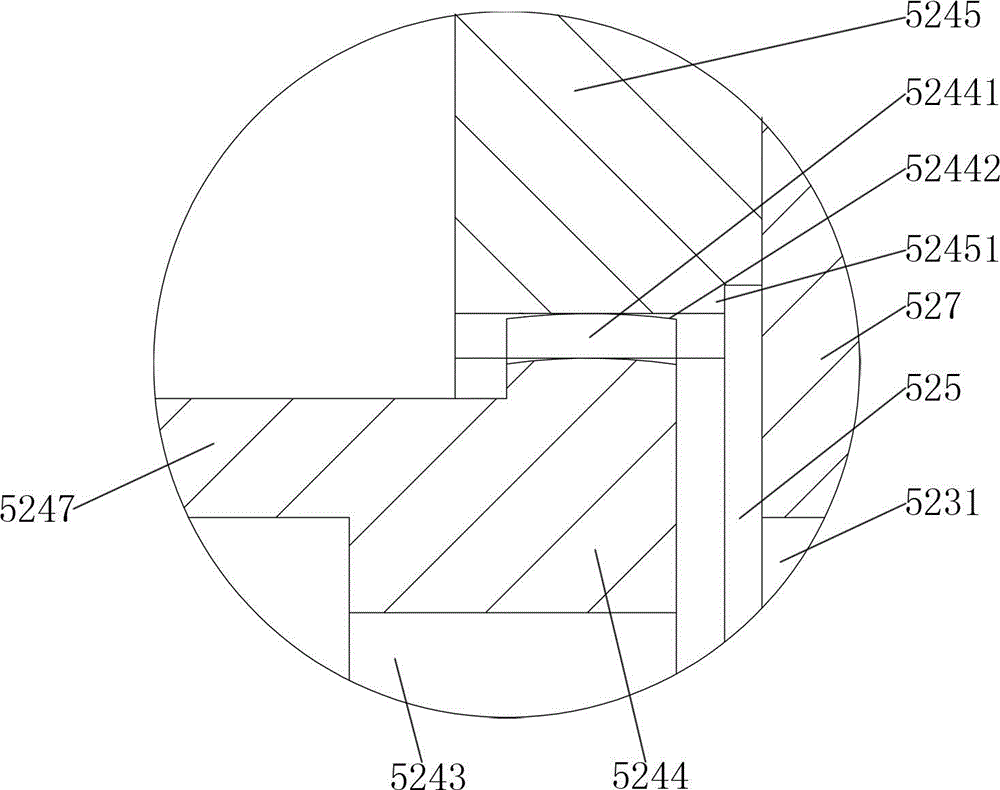

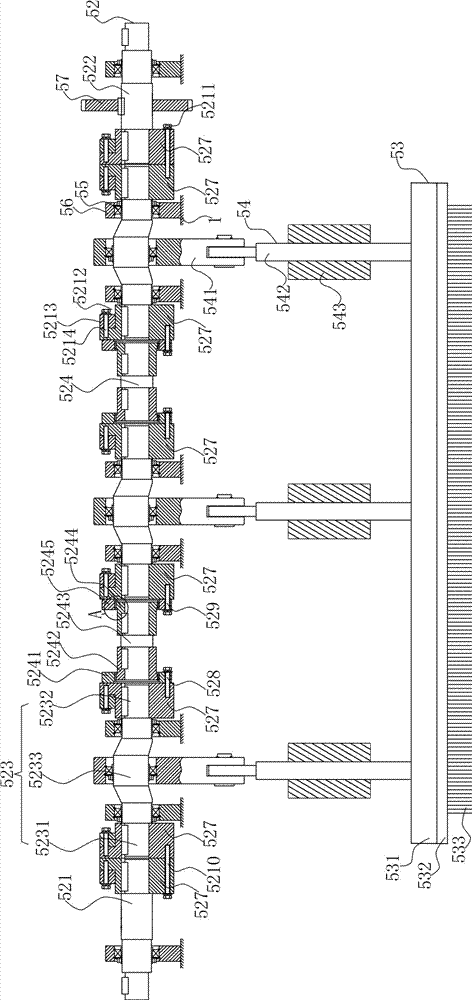

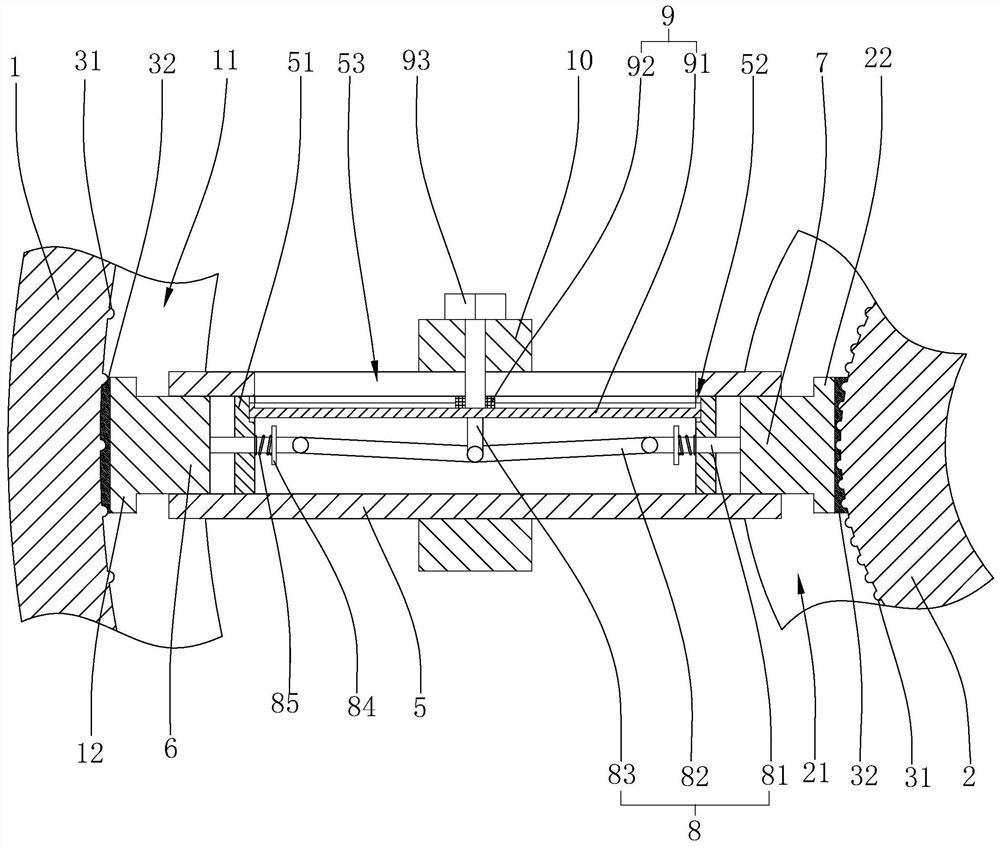

High-frequency raising needling machine

ActiveCN105256467AIncrease acupuncture frequencyReduce vibrationNeedling machinesRocker armEngineering

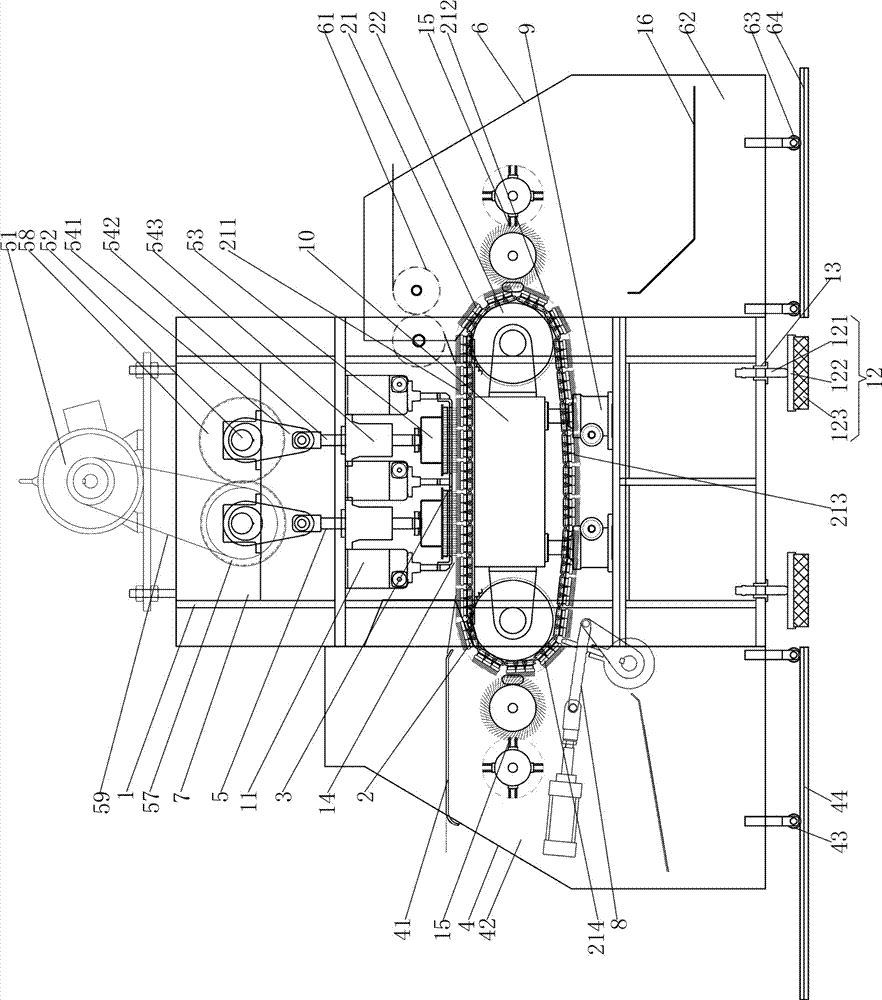

The invention discloses a high-frequency raising needling machine, comprising a machine frame, a feeding mechanism, a brush ring curtain, a net removing plate, a needling mechanism and a drawing mechanism, wherein the needling mechanism comprises a needling driving device, two transmission shaft components and two needle components; the two transmission shaft components are arranged abreast in a front-rear direction; the two needle components are arranged abreast in the front-rear direction; the two transmission shaft components are at the same rotating speed, but are in opposite rotating directions. The high-frequency raising needling machine is characterized in that each transmission shaft component comprises a left half shaft, a right half shaft, and a plurality of bent shafts which are sequentially connected between the left half shaft and the right half shaft; each bent shaft comprises two shaft heads and a boss which are all connected integrally; each boss is columnar; the center line of each boss is deviated from the axes of the corresponding shaft heads; one bent shaft corresponds to a lifting transmission mechanism; the lifting transmission mechanism comprises a swing arm, a push rod and a guiding sleeve; the upper end of the swing arm sleeves the boss of the corresponding bent shaft; the lower end of the swing arm is hinged to the upper end of the push rod; the lower end of the push rod is connected with the corresponding needle component. The high-frequency raising needling machine has the advantages that the needling frequency is high, the vibration provoking quantity is smaller, and the production efficiency and product quality are beneficially improved.

Owner:SHANTOU SANHUI NONWOVEN MACHINERY FACTORY

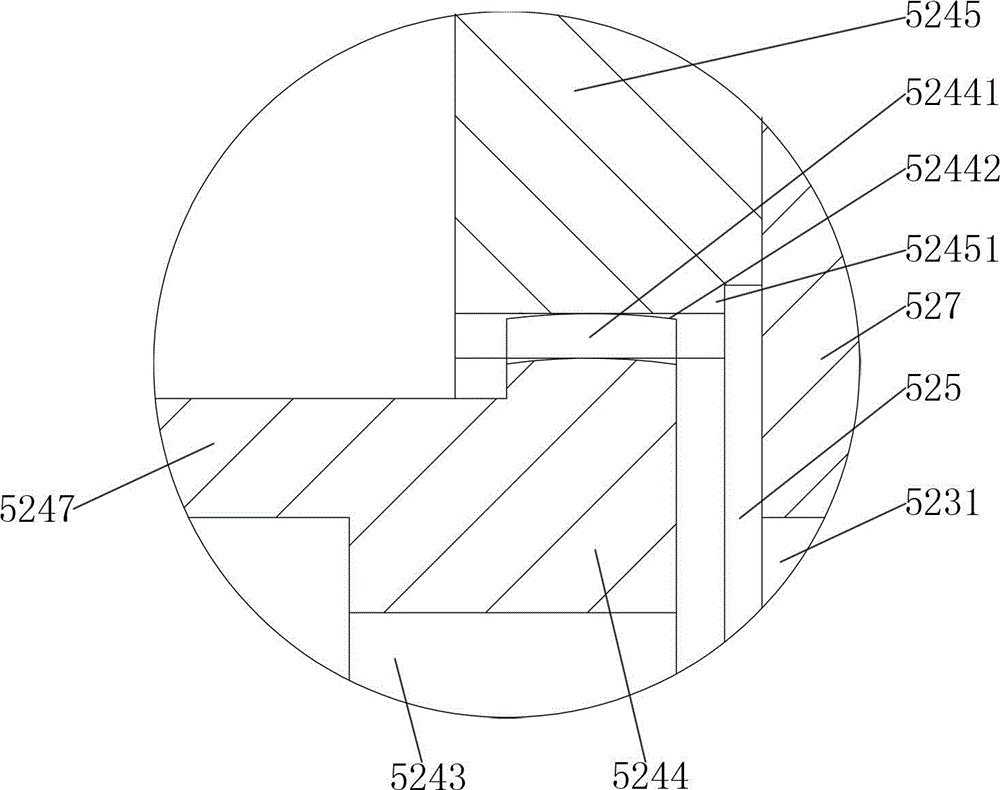

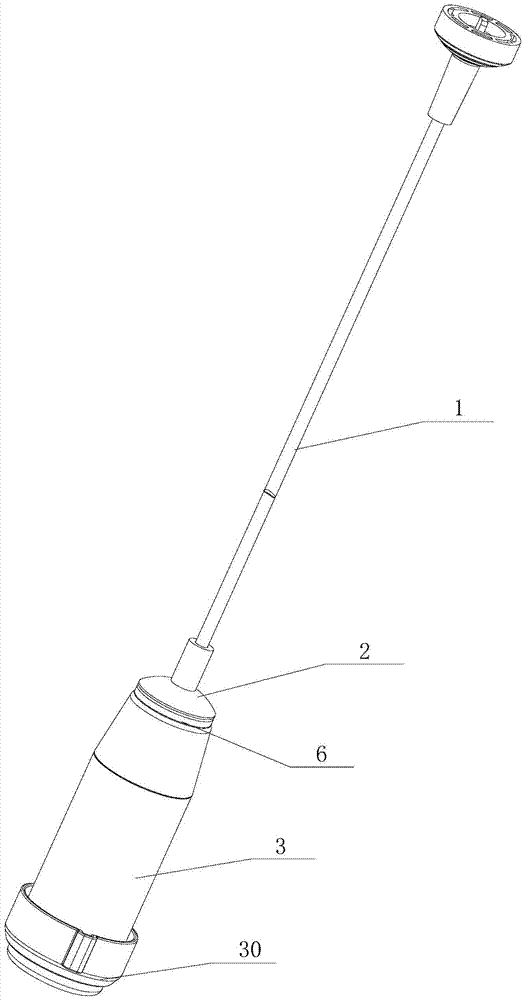

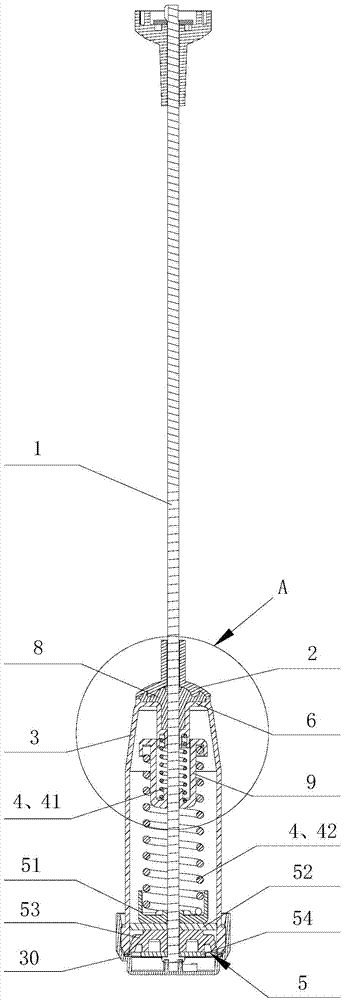

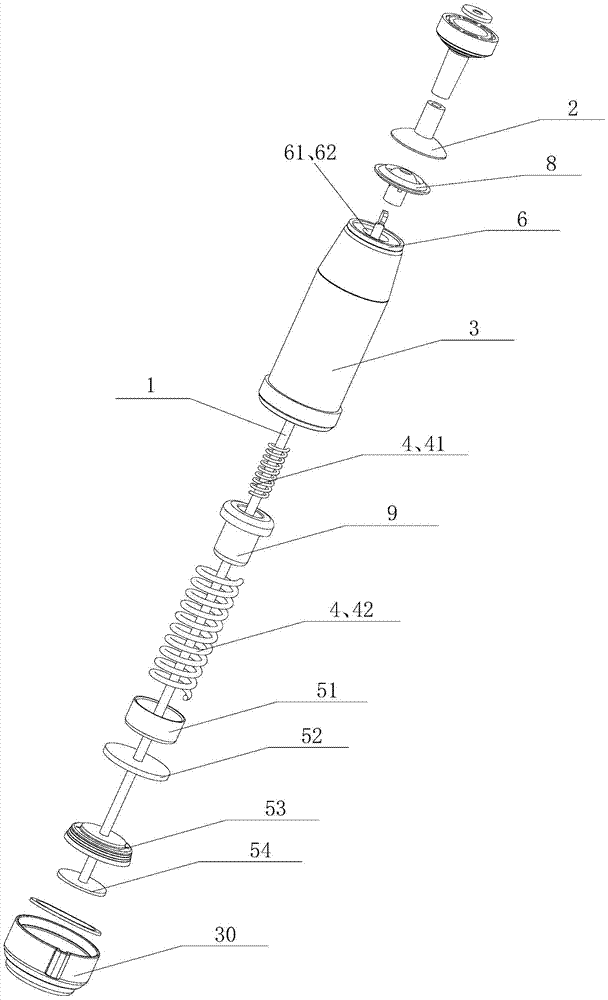

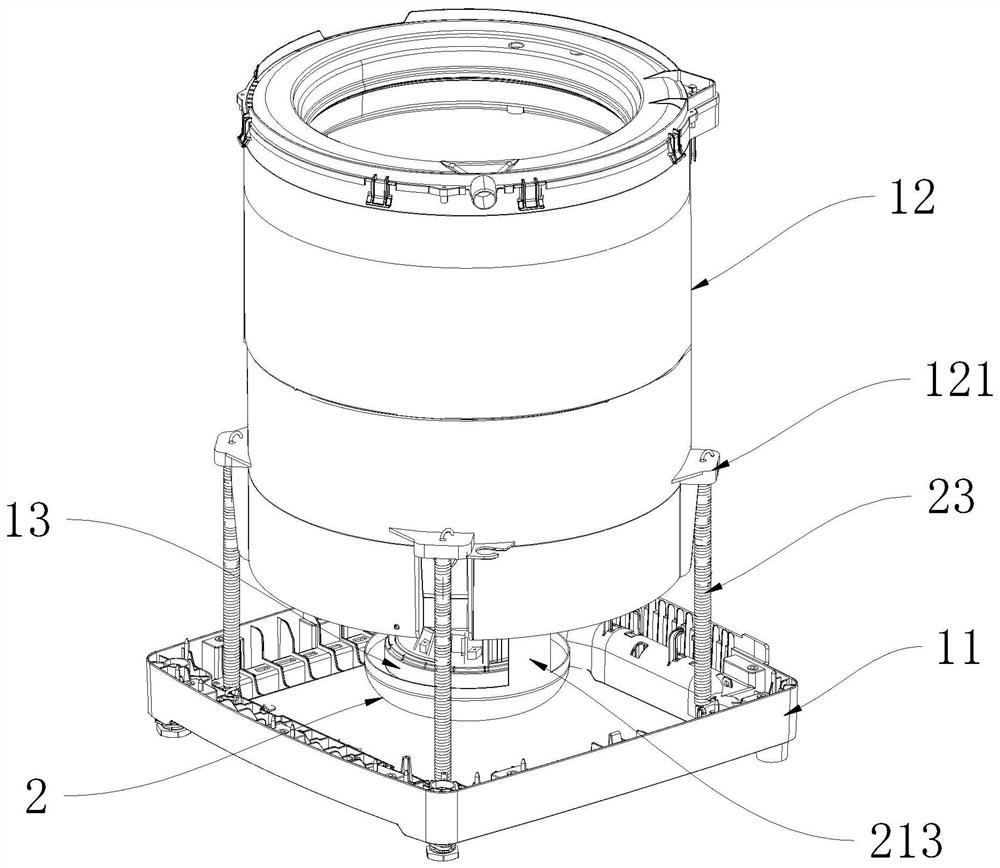

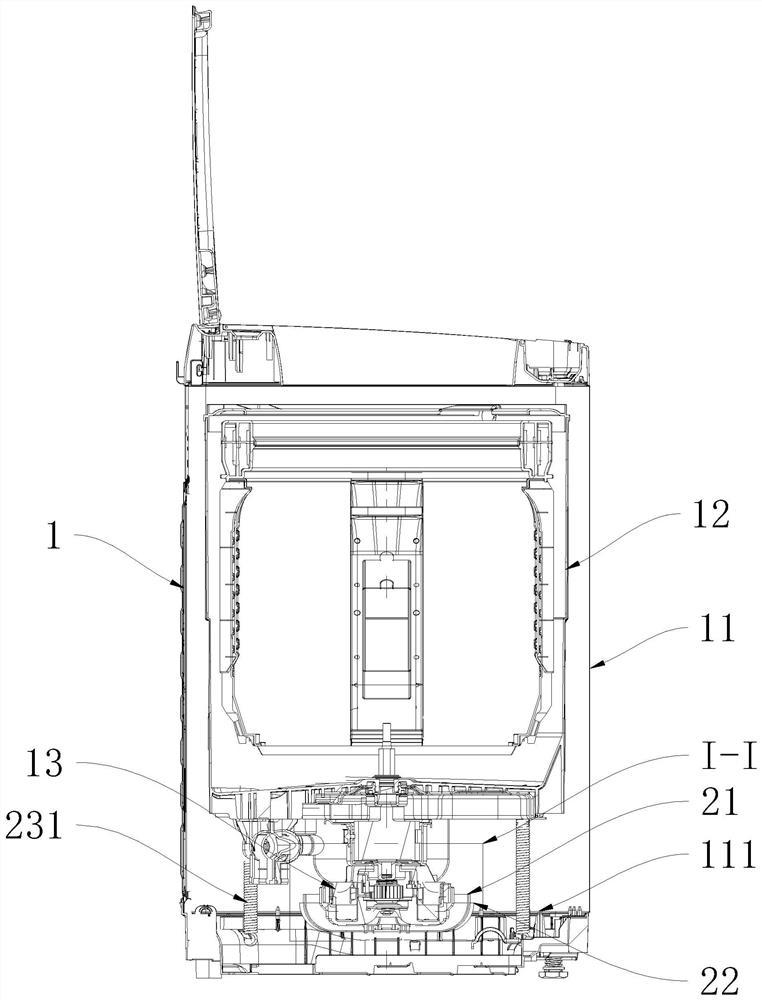

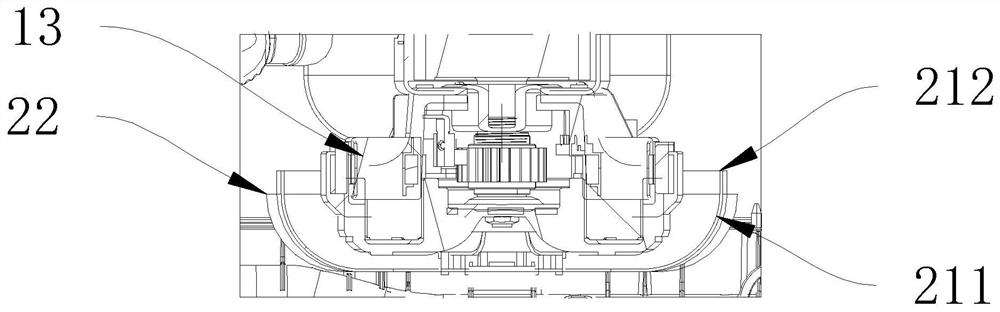

Variable-damping vibration-reduction device of washing machine and washing machine

ActiveCN106930046AMake up for the problem that uneven load is easy to press and cause loud noisePrevent up and down movementOther washing machinesTextiles and paperEngineeringMechanical engineering

The invention discloses a variable-damping vibration-reduction device of a washing machine and the washing machine. The variable-damping vibration-reduction device comprises a hanging rod, an upper support, a sleeve pipe and a pressure buffer mechanism arranged in the sleeve pipe. The upper end of the sleeve pipe is provided with a bracket. The hanging rod penetrates through the upper support and the bracket and stretches into the sleeve pipe to be connected to the pressure buffer mechanism. At least one set of damping sleeves is arranged between the upper support and the pressure buffer mechanism. Damping sleeves provide variable damping force to the hanging rod. When the washing machine starts to operate in a dehydration manner with excessive large uneven load, an outer drum applies eccentric force to the damping sleeves. The damping sleeves deform in a radial direction to extrude the hanging rod so that the damping force becomes larger. The machine continues to operate in a dehydrated manner and the partial load becomes smaller. The eccentric force of the outer drum applied to the damping sleeves is released. The damping sleeves restore and damping force becomes smaller. The variable-damping vibration-reduction device of the washing machine and the washing machine have the following beneficial effects: the elasticity coefficient of the hanging rod is stably and smoothly changed so that vibration-reduction performance is improved; working noise is reduced; and vibration-reduction effect is enhanced.

Owner:HEFEI HAIER WASHING MACHINE +1

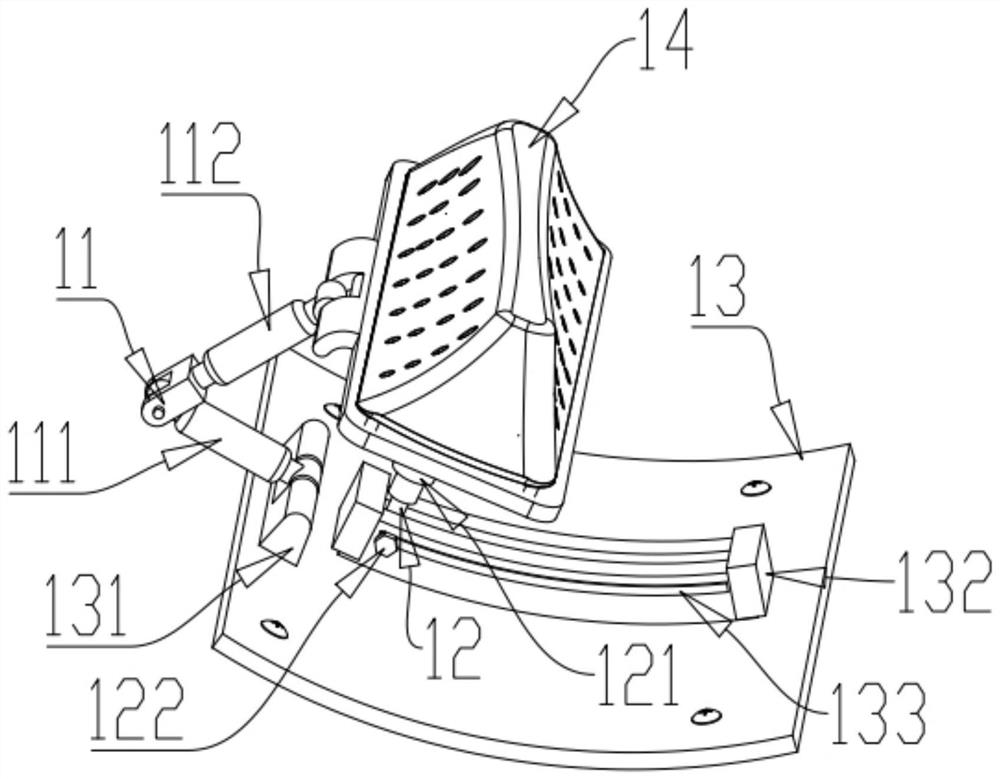

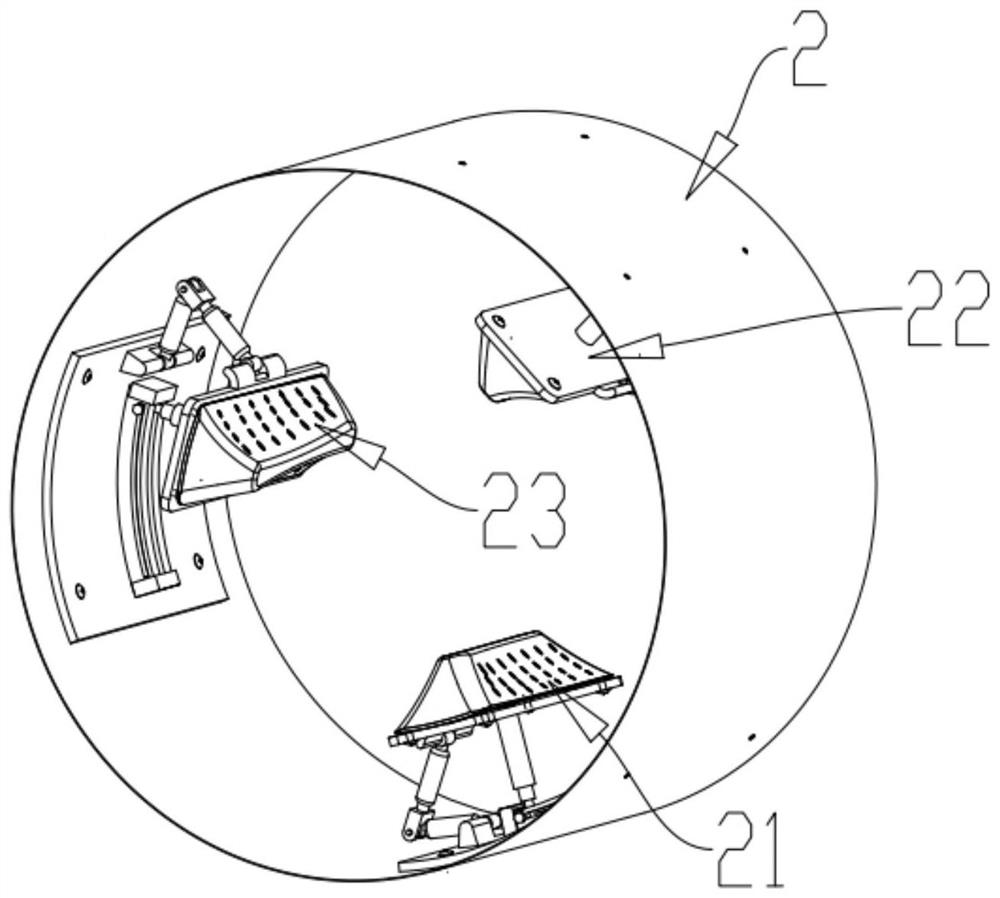

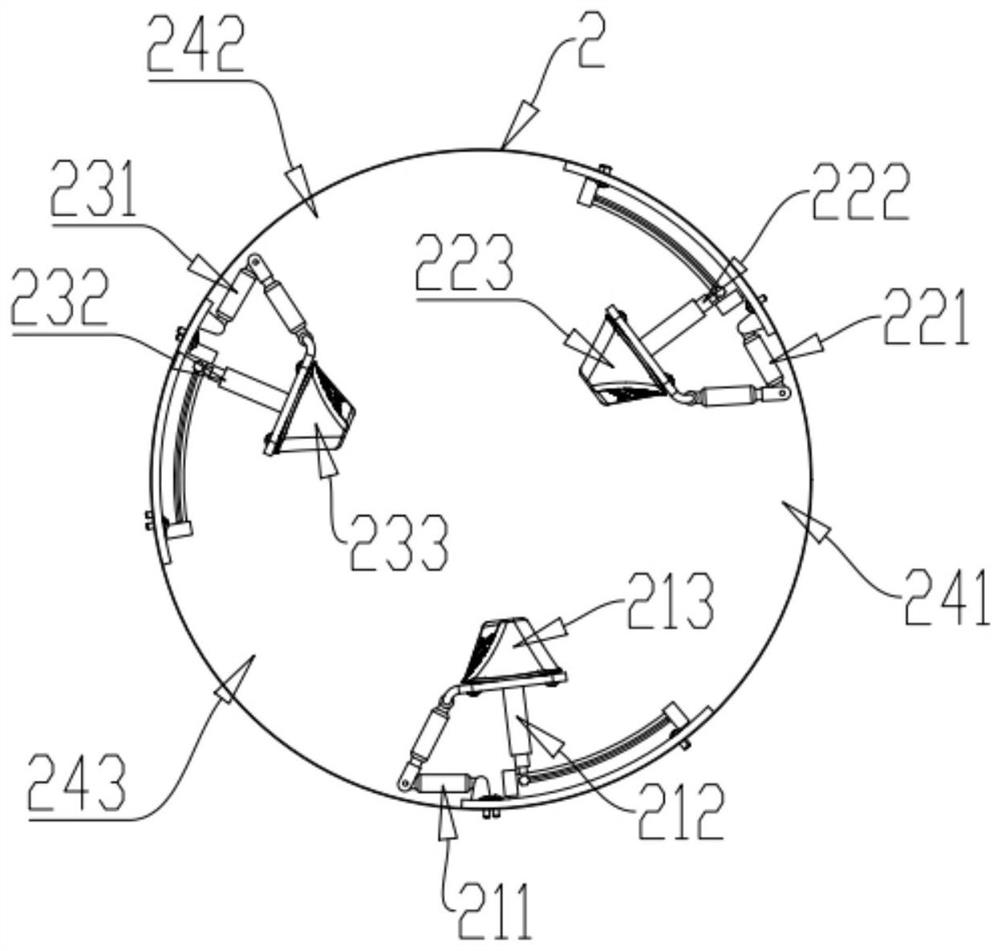

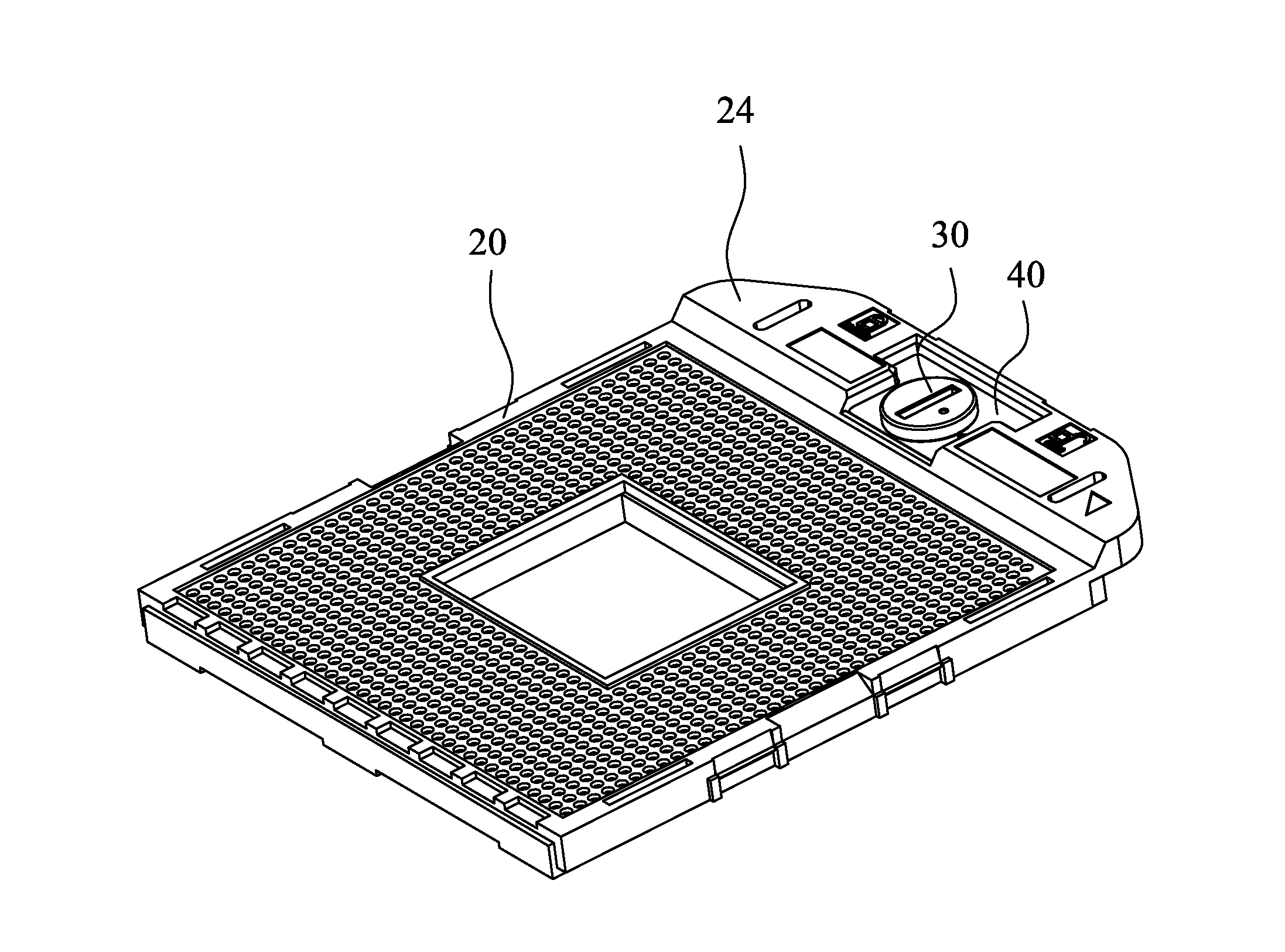

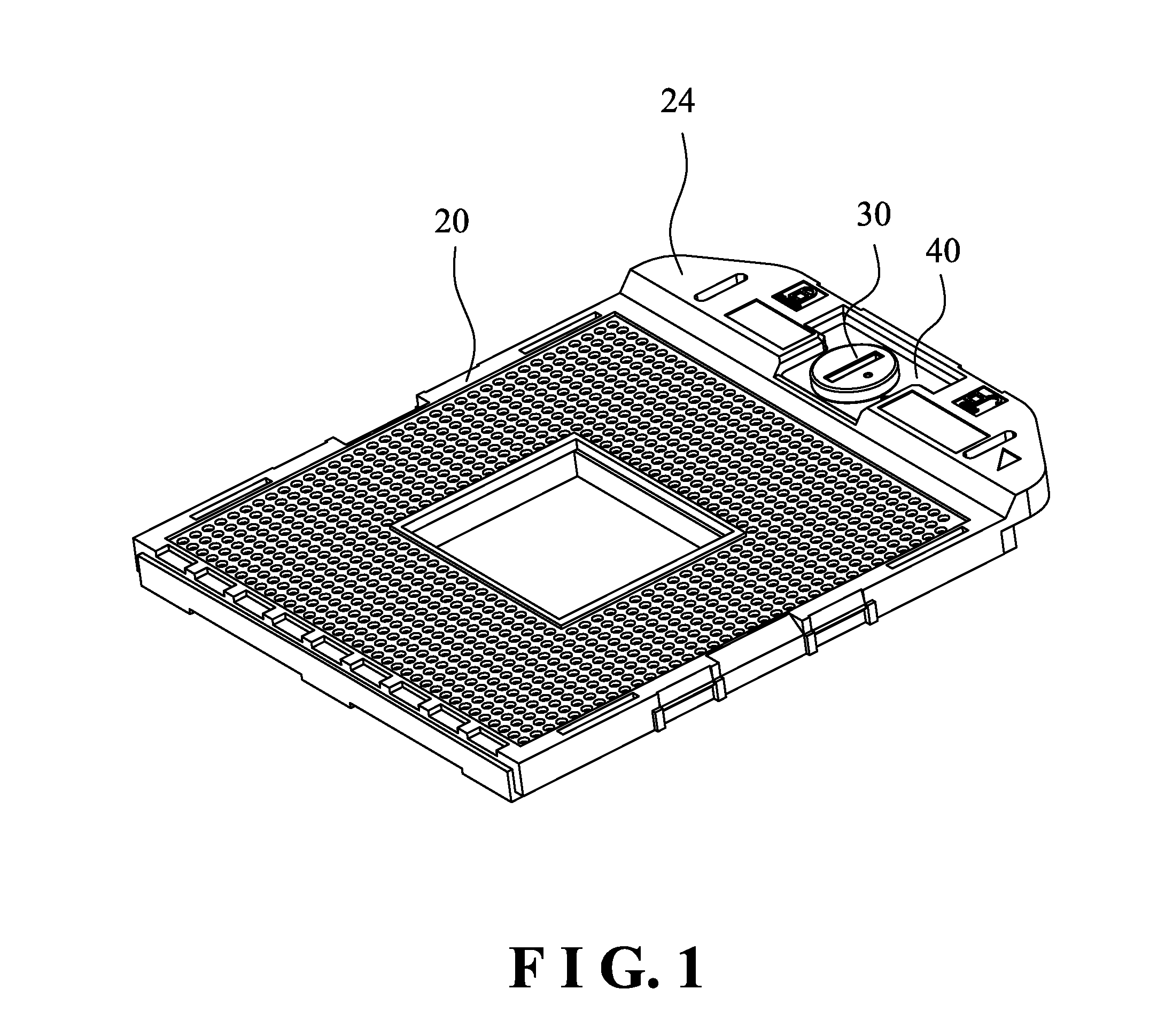

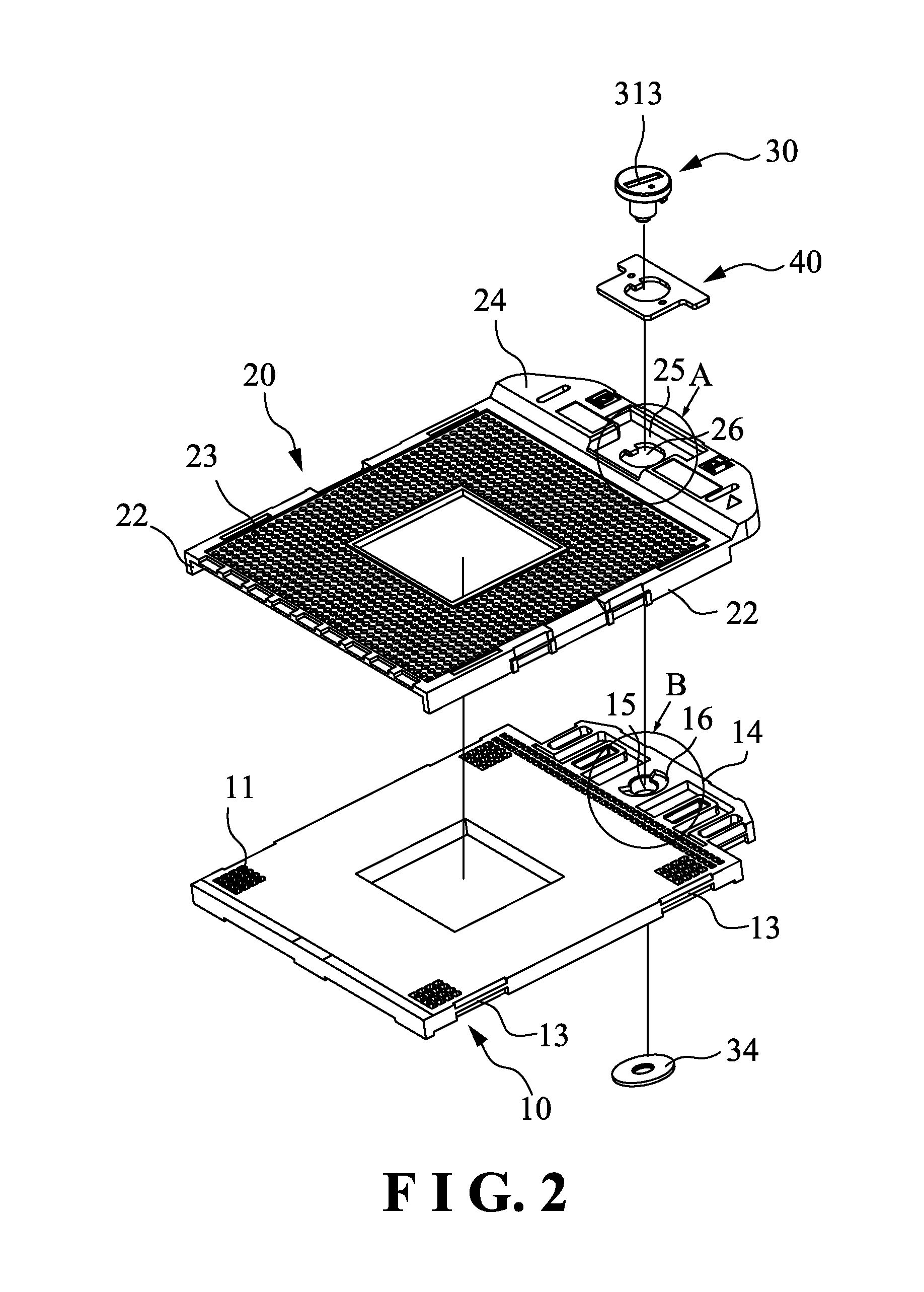

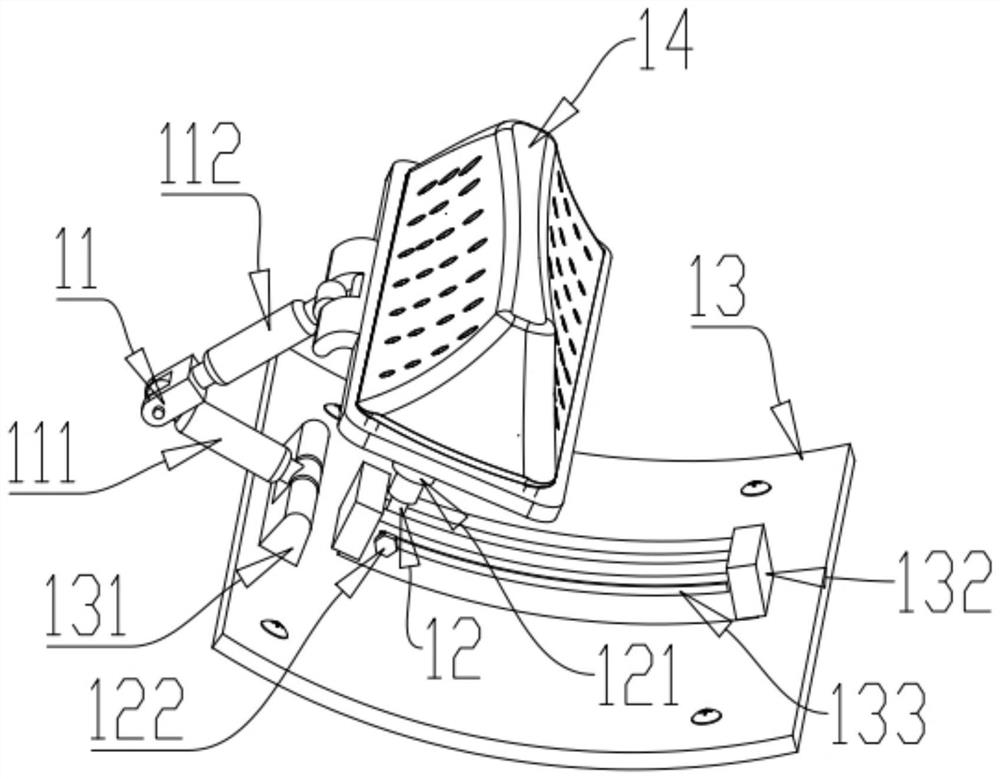

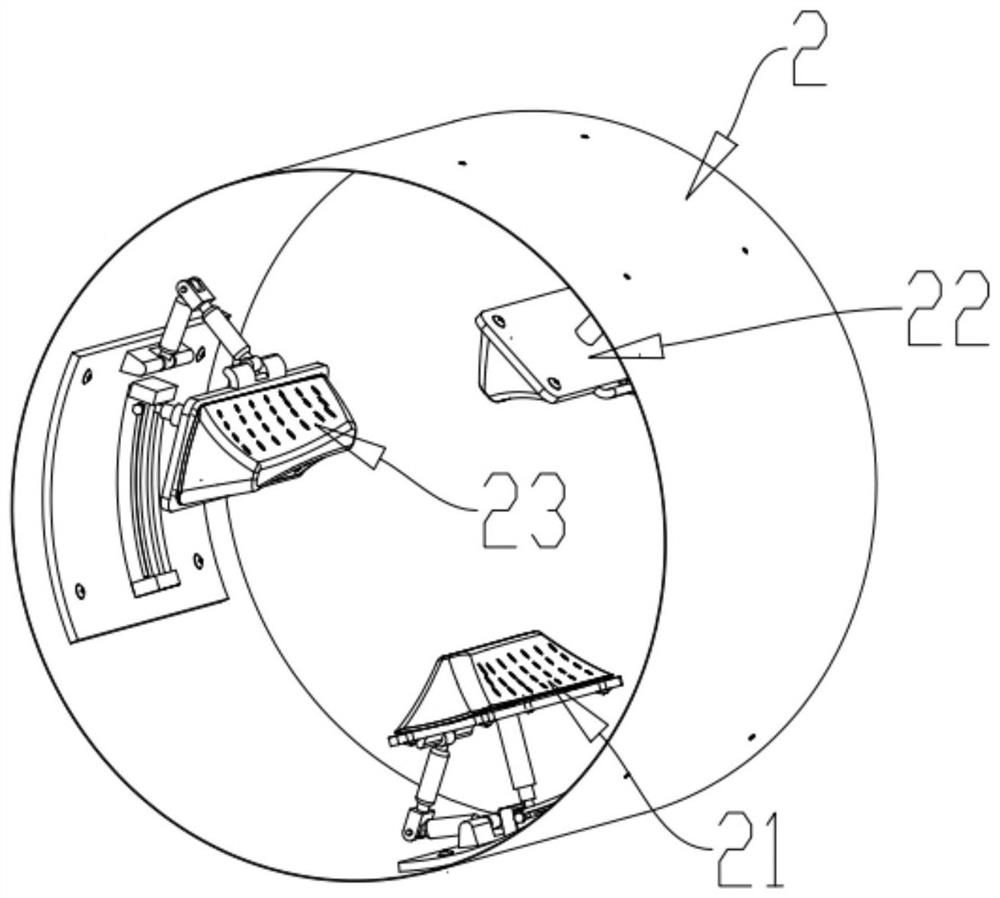

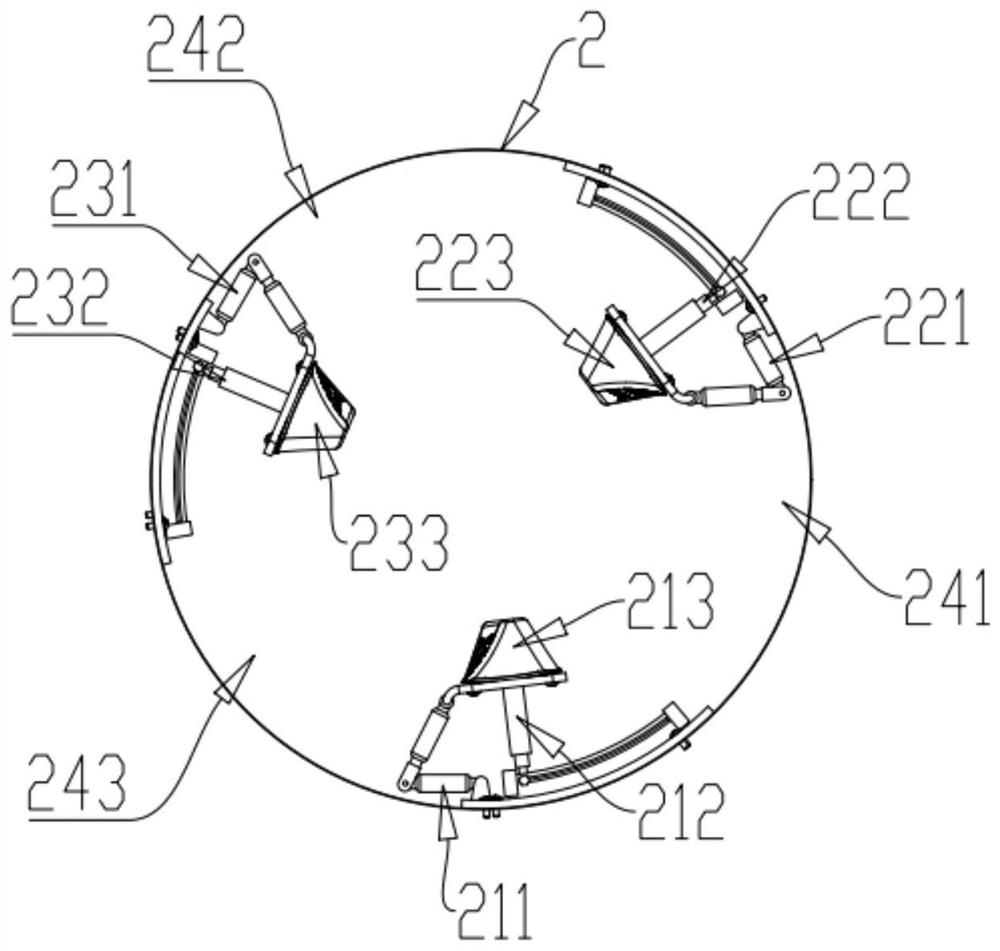

Lifting rib devices of washing machine, washing machine with lifting rib devices and control method

ActiveCN112899995AReduce eccentric forceStable dehydration processOther washing machinesControl devices for washing apparatusLaundry washing machineEngineering

The invention provides lifting rib devices of a washing machine, the washing machine with the lifting rib devices and a control method. Each lifting rib device comprises a base, a rotating assembly, a telescopic assembly and a lifting rib, wherein the bases are arranged on the inner wall of an inner barrel of the washing machine; under the action of the rotating assemblies and the telescopic assemblies, the lifting ribs rotate in the circumferential direction and move in the radial direction of the inner barrel; when the lifting rib devices are applied to the washing machine, the multiple lifting rib devices are arranged in the circumferential direction of the inner barrel of the washing machine; a clothes storage position is arranged between every two adjacent lifting rib devices; a weight detection device detects the weights of clothes at the clothes storage positions and transmits the weights to a washing machine controller, then the controller controls the rotating assemblies and the telescopic assemblies of the lifting rib devices to act, the clothes are scattered and moved into the adjacent clothes storage positions, and the weights of the clothes in the clothes storage positions are enabled to be similar, so that relatively large vibration caused by uneven distribution of the clothes in a dewatering process of the washing machine is avoided; and each device is simple in structure, high in automation degree and uniform in clothes distribution, and a dewatering program of the washing machine runs stably.

Owner:GREE ELECTRIC APPLIANCES INC

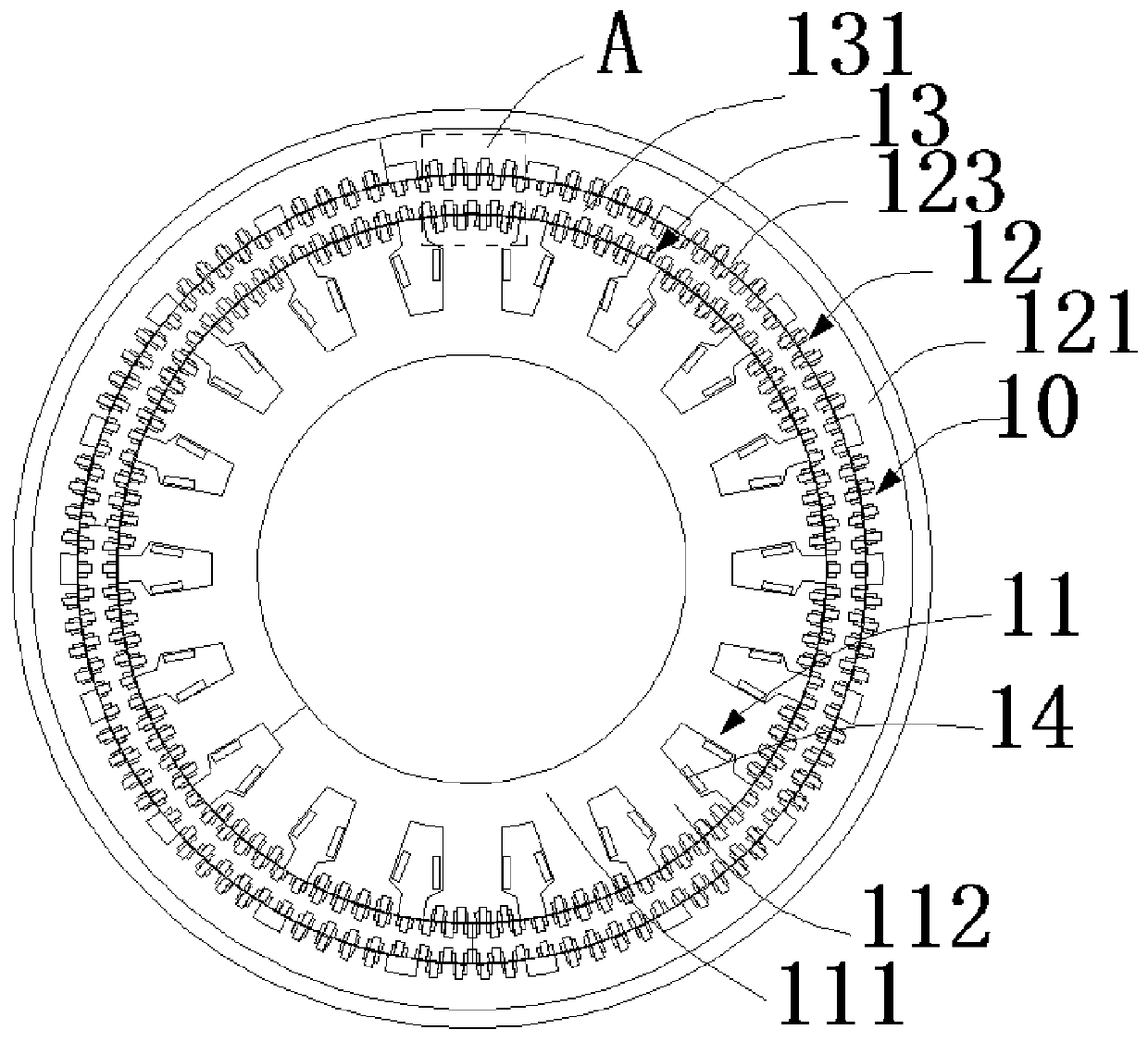

Motor and equipment comprising the same

InactiveCN111049341AOvercome limitationsIncrease maximum outputDynamo-electric machinesElectric machineControl theory

The invention provides a motor and equipment comprising the same. The motor comprises a stator assembly and a mover assembly. The stator assembly comprises a first stator and at least one second stator; the mover assembly comprises at least one mover; stators in the stator assembly and movers in the mover assembly are oppositely arranged at intervals, and air gaps exist between the adjacent stators and movers; each stator has the same number of pole pairs; and the first stator is provided with a first winding. According to the technical scheme, the multiple stators are arranged, magnetic fluxsaturation limitation of the single stator is overcome, maximum output of the motor can be improved, and a current protection degree is reduced.

Owner:NOVOMOTO LTD

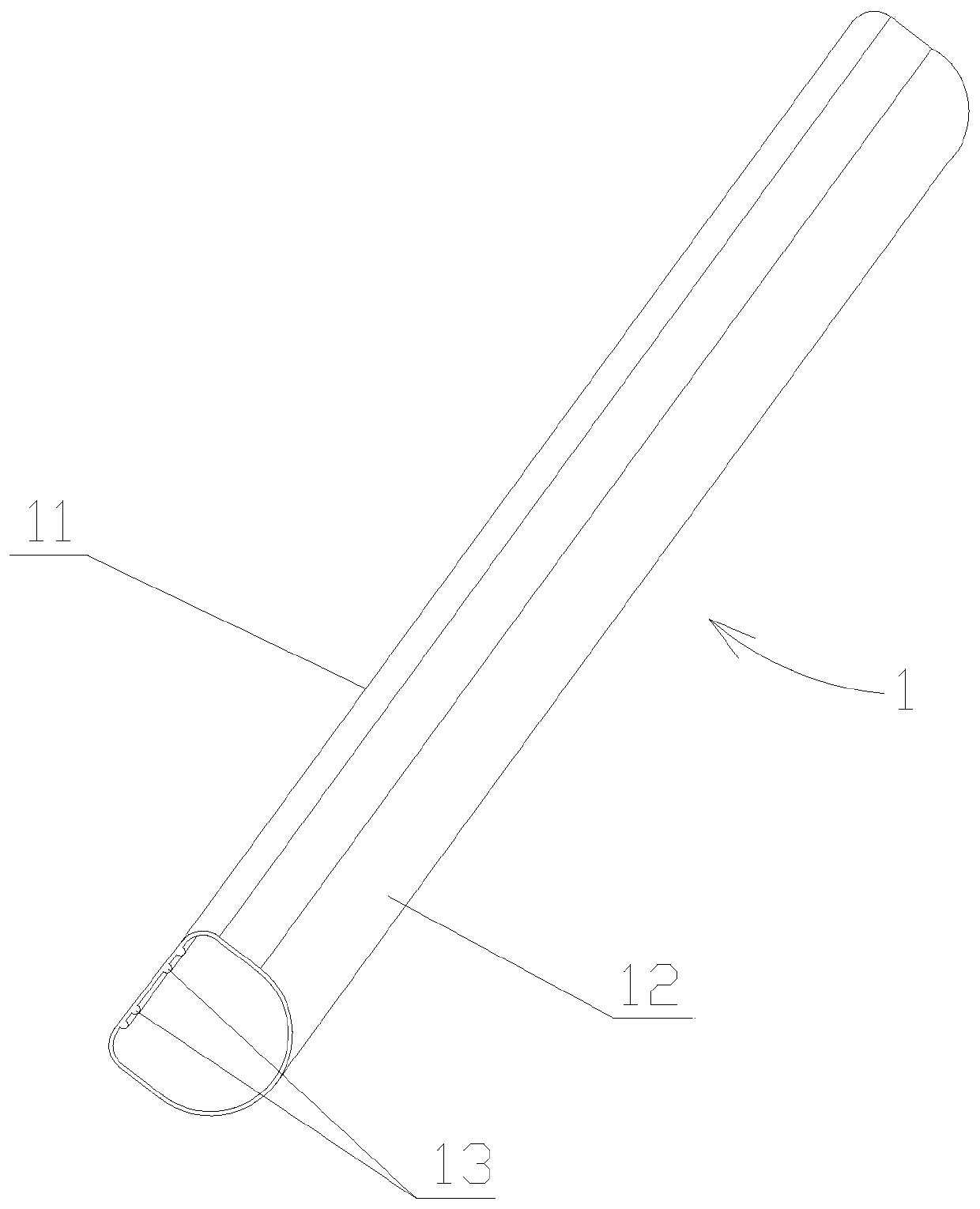

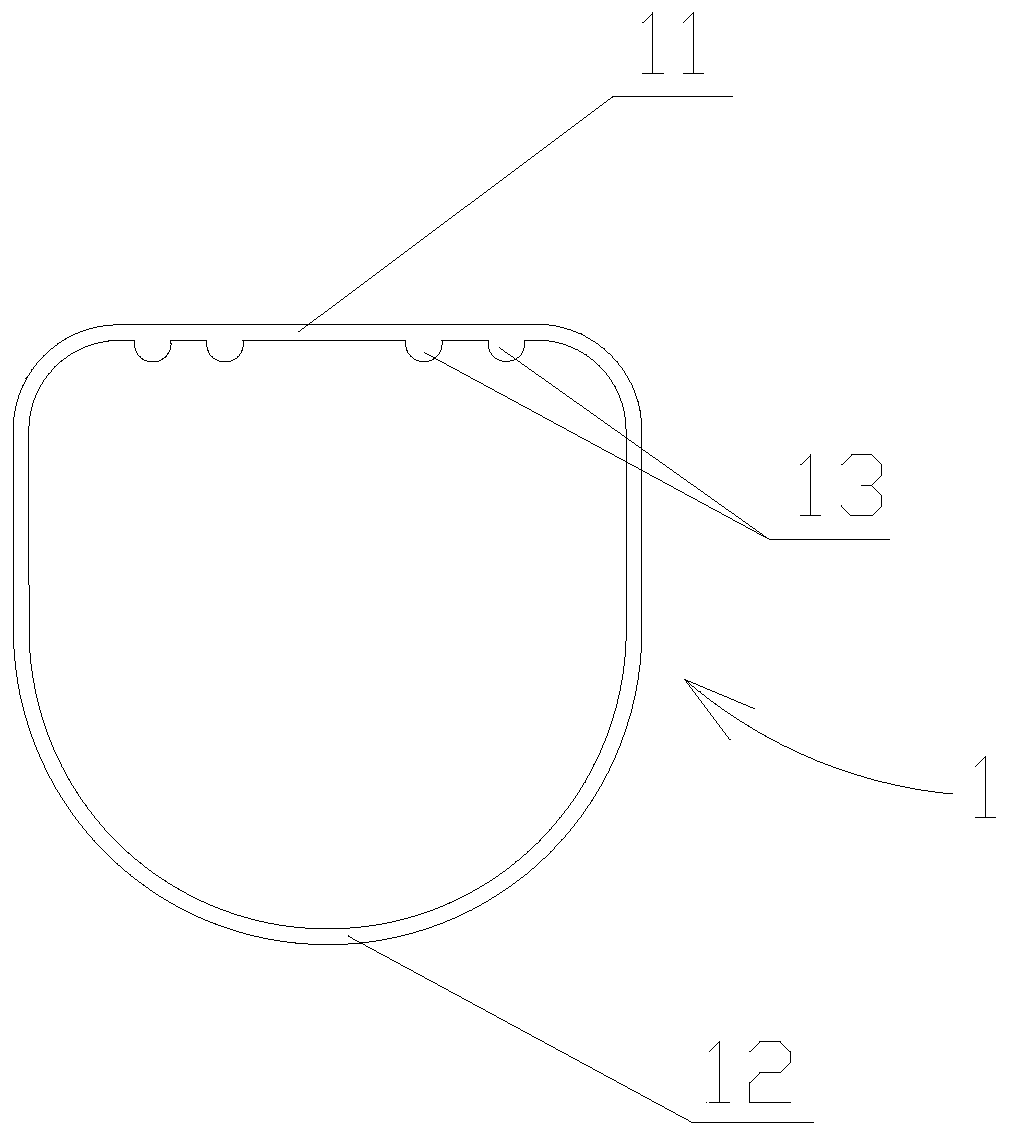

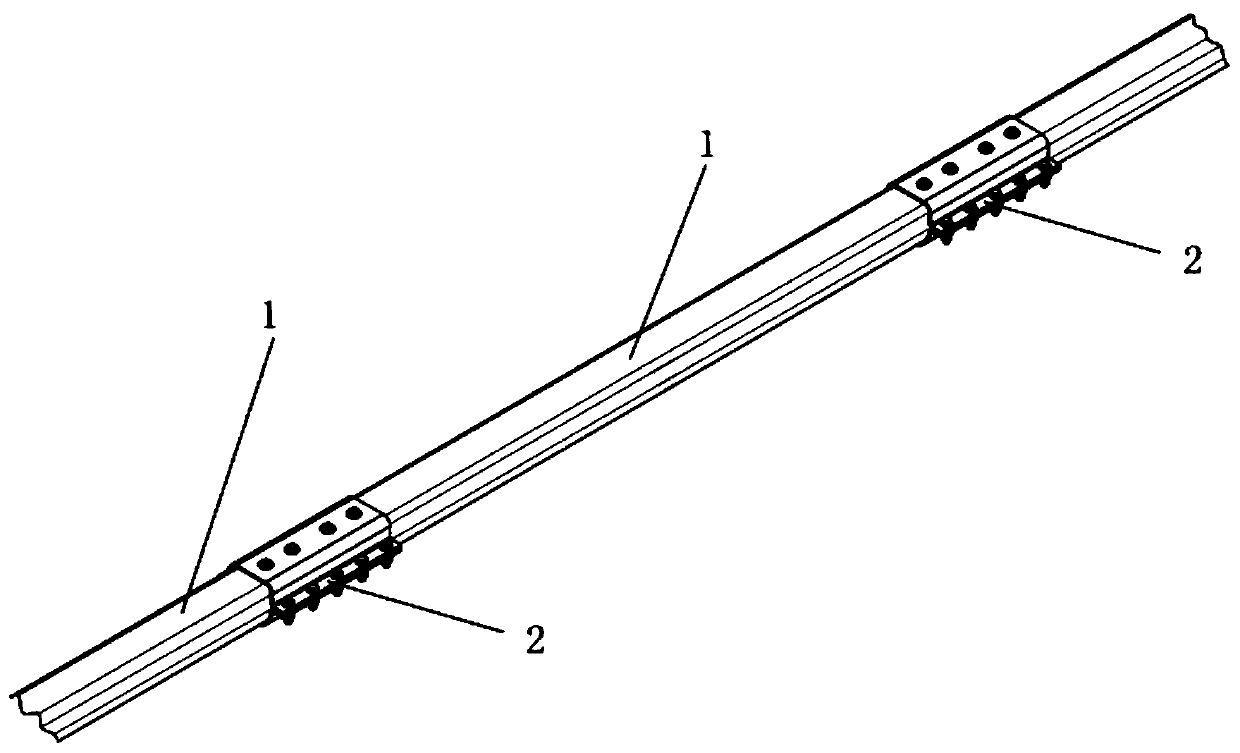

Main shaft of photovoltaic tracking support

InactiveCN110968116AThe moment of resistance of the transverse section is increasedLight in massControl using feedbackPipe fittingStructural engineering

The invention discloses a main shaft of a photovoltaic tracking support, which is made of a pipe fitting with a closed section, a mounting surface of one side of the main shaft for mounting a purlineis a plane, two sides of the main shaft are vertical to the mounting surface, one side of the main shaft opposite to the mounting surface is an arc surface, and two sides of the main shaft have the same width. Due to the special shape of the main shaft of the photovoltaic tracking support adopting the technical scheme, when the main shaft is applied to the photovoltaic tracking support, the crosssection of the main shaft resists moment, compared with square and round main shafts in the prior art, under the condition that the same thickness is guaranteed, the resistance moment is greatly improved, and the main shaft has good practical application value. The resistance moment of the cross section of the main shaft is improved, the weight is lighter, the cost of the main shaft is saved, andthe eccentric force of the panel assembly is reduced. After the main shaft is applied to the photovoltaic tracking bracket, besides the technical effects, the stress of the photovoltaic tracking bracket is more uniform, and the installation is more convenient and faster.

Owner:XIAMEN ANTAI NEW ENERGY TECH

Pile head stub rod connecting device used for foundation pile bearing capacity static test

The invention relates to an anchorage pile or tension pile head stub rod connecting device suitable for the foundation pile bearing capacity static test. The device comprises a conversion connector arranged on the pile head, a through hole allowing a pile head stub rod to penetrate is formed in the conversion connector, the portion, stretching to the upper side of the conversion connector, of the pile head stub rod forms a clamping part, a bolt hole used for being matched with a tension rod is formed in the conversion connector, and the device further comprises a clamp fixedly arranged on the clamping part. Tedious construction procedures of welding and the like of the pile head stub rod can be avoided, filed mounting and detaching are convenient, and the device is beneficial to improvement of the test result precision. Meanwhile, erecting and detaching efficiency of a foundation pile test platform is improved, and the safe stability of the test platform can be effectively ensured.

Owner:ANHUI INST OF BUILDING RES & DESIGN +1

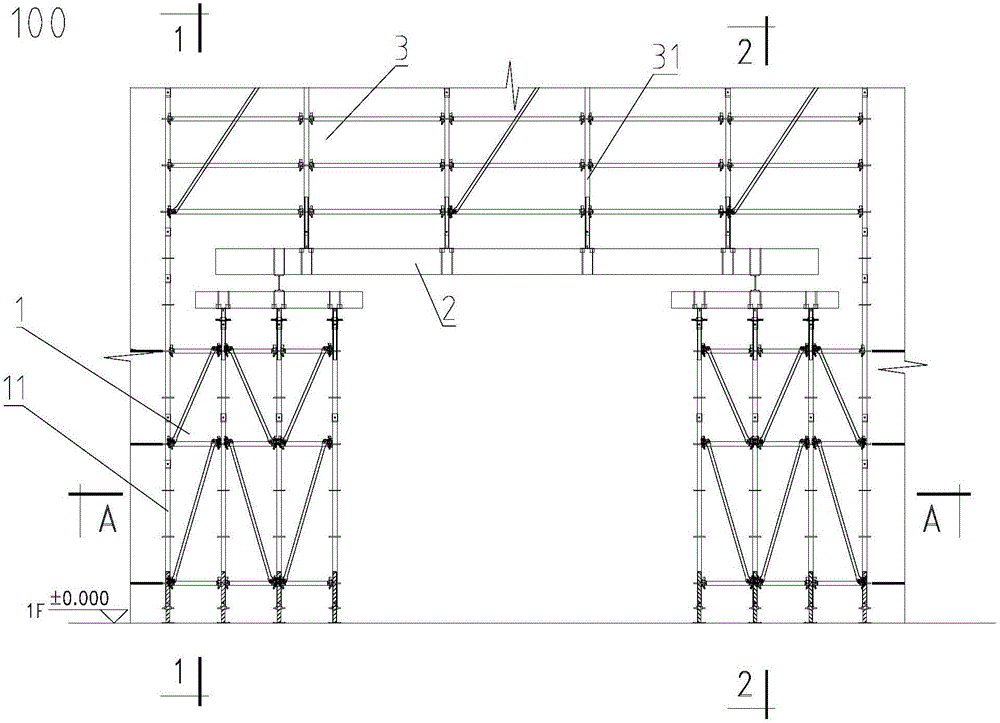

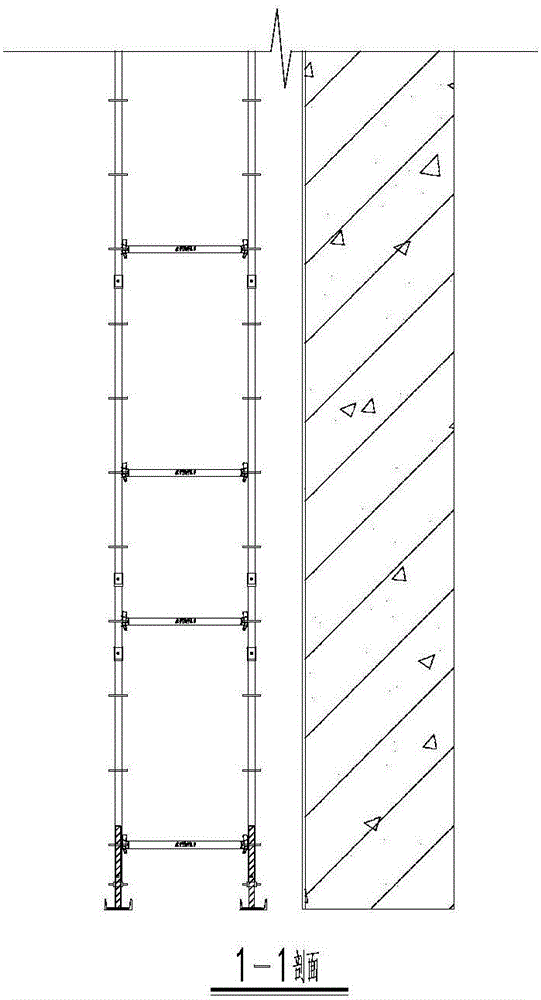

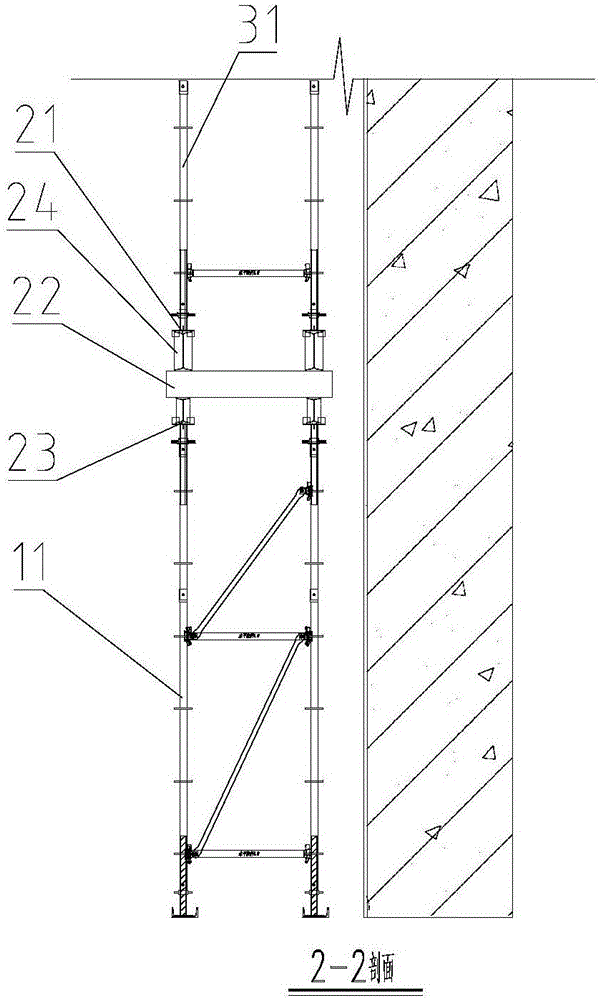

Ring lock scaffold opening portion bracket supporting system

ActiveCN106522531AImprove stabilityImprove securityForms/shuttering/falseworksBuilding scaffoldsSupporting systemEngineering

The invention provides a ring lock scaffold opening portion bracket supporting system and belongs to the technical field of scaffold construction. A refined formwork support, an upper formwork support and a novel supporting cross beam are fixedly connected into a whole, and thus the overall stability of the novel supporting system is improved. An upper vertical rod uniformly transfers loads to the novel supporting cross beam, so that excessively high eccentric torque is avoided, then a lower vertical rod of the refined formwork support is stressed perpendicularly, and the overall stability and safety of the novel supporting system are further improved. Besides, due to the fact that the novel supporting cross beam is fixedly connected with the refined formwork support and the upper formwork support, time consumption for erection of the formwork supports on site is effectively reduced; and meanwhile, the components can be integrally hoisted during disassembly, the project period is shortened to a certain extent, the work efficiency of assembly and disassembly is improved, and the system better meets the requirement of modern building construction for low risk, high efficiency and low cost.

Owner:NO 2 CONSTR GRP CO LTD OF SHANGHAI CONSTR GRP

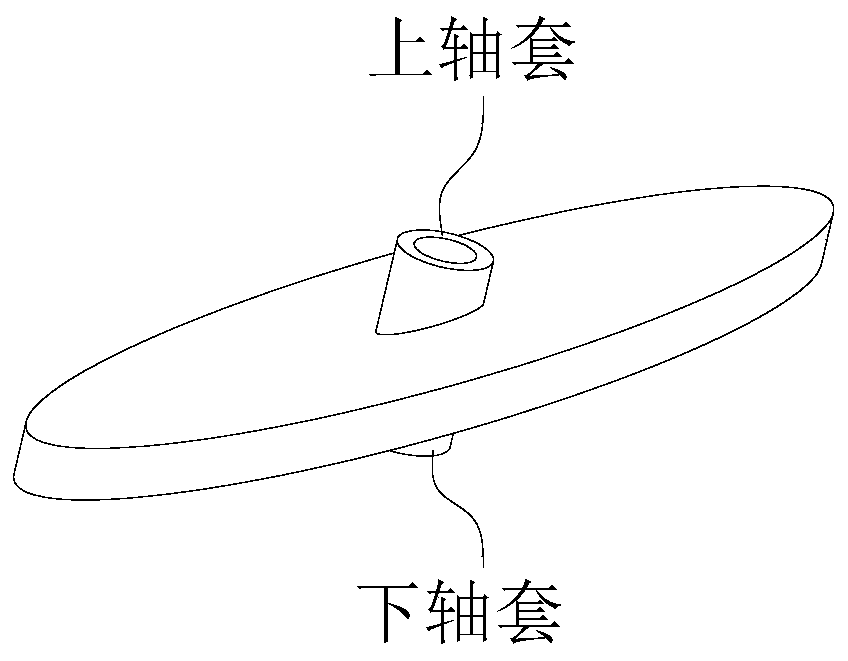

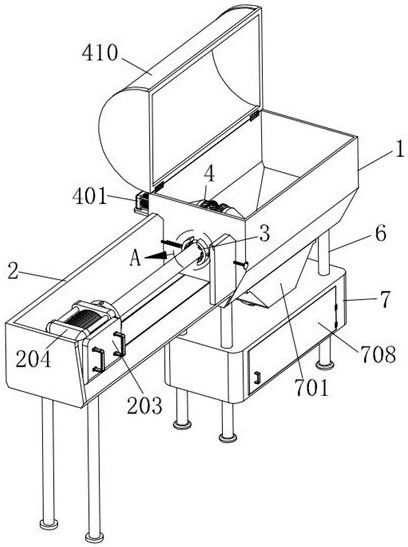

Machining machine for surface treatment after molding of air conditioner compressor accessories

ActiveCN110871386ANo shakingImprove uniformityGrinding drivesGrinding machinesElectric machineEngineering

The invention belongs to the technical field of air conditioner manufacturing, and particularly relates to a machining machine for surface treatment after molding of air conditioner compressor accessories. The machining machine comprises supporting legs and a workbench; the bottom surface of the workbench is provided with a rotating motor, the rotating motor is fixedly connected with a supportingblock, the supporting block is provided with a slot matched with a lower shaft sleeve of a swash plate, the workbench is provided with supporting frames, and the top of the supporting frames is provided with a mounting plate; a sleeve, a connecting shaft, a connecting block, a connecting rod, an adjusting rod and a limiting column are mounted on the mounting plate; the diameter of the limiting column is equal to the inner diameter of the lower shaft sleeve of the swash plate; a guide groove is formed in the workbench, and a steel ball is in rolling fit in the guide groove; a bearing plate is mounted on the steel ball, a limiting rod is mounted on the bearing plate, and magnet pieces are arranged on the outer part of the limiting rod in a sleeving manner; a limiting mechanism and a wire drawing mechanism are mounted on the inner side face of each supporting frame; and a grinding mechanism is mounted on the bottom surface of the mounting plate. When the swash plate is subjected to surface grinding and drawing adopting the machining machine, longitudinal shaking does not occur on the swash plate, and the uniformity of grinding and wire drawing on the surface of the swash plate is improved.

Owner:上海云飞工贸发展有限公司

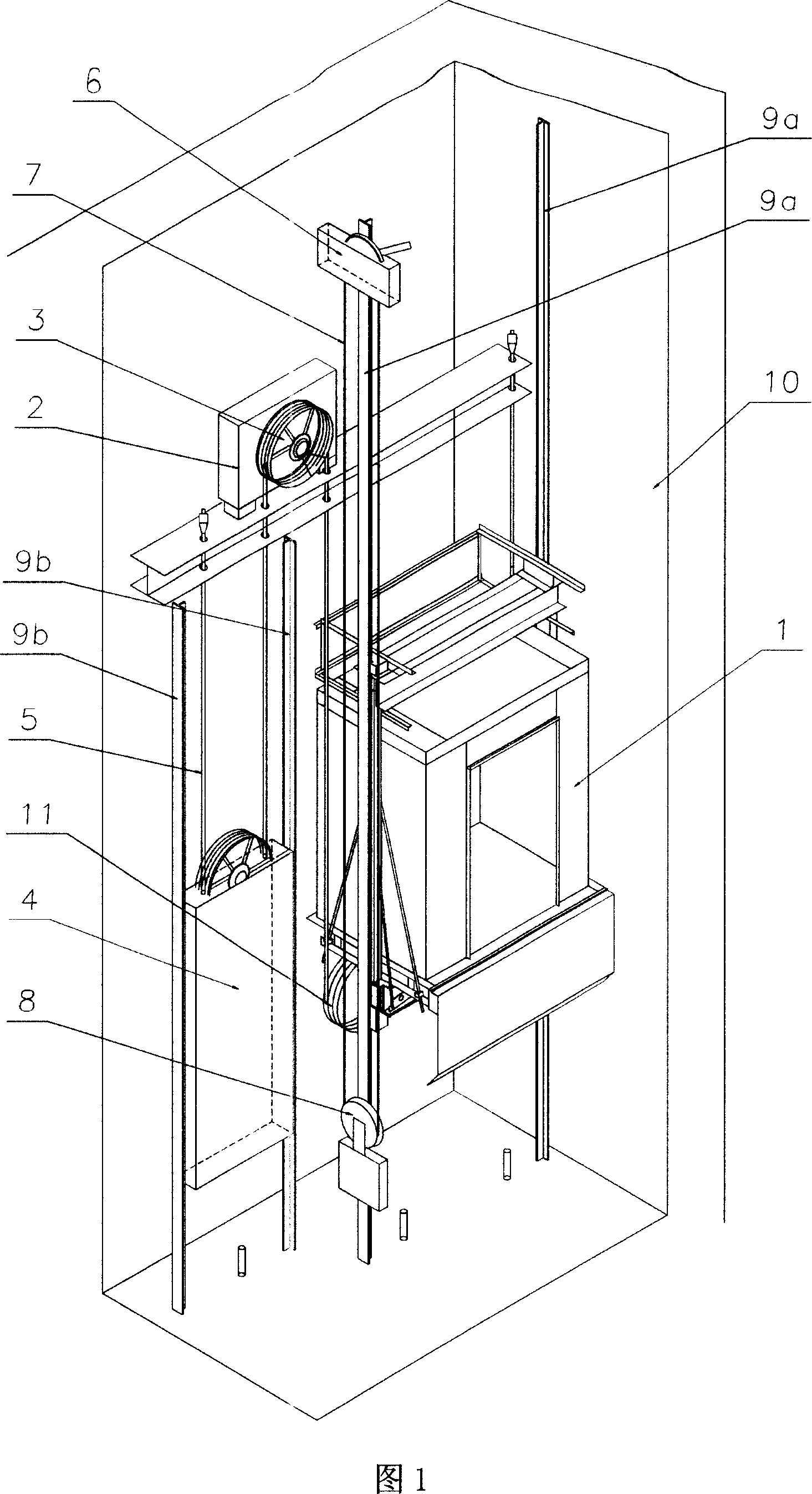

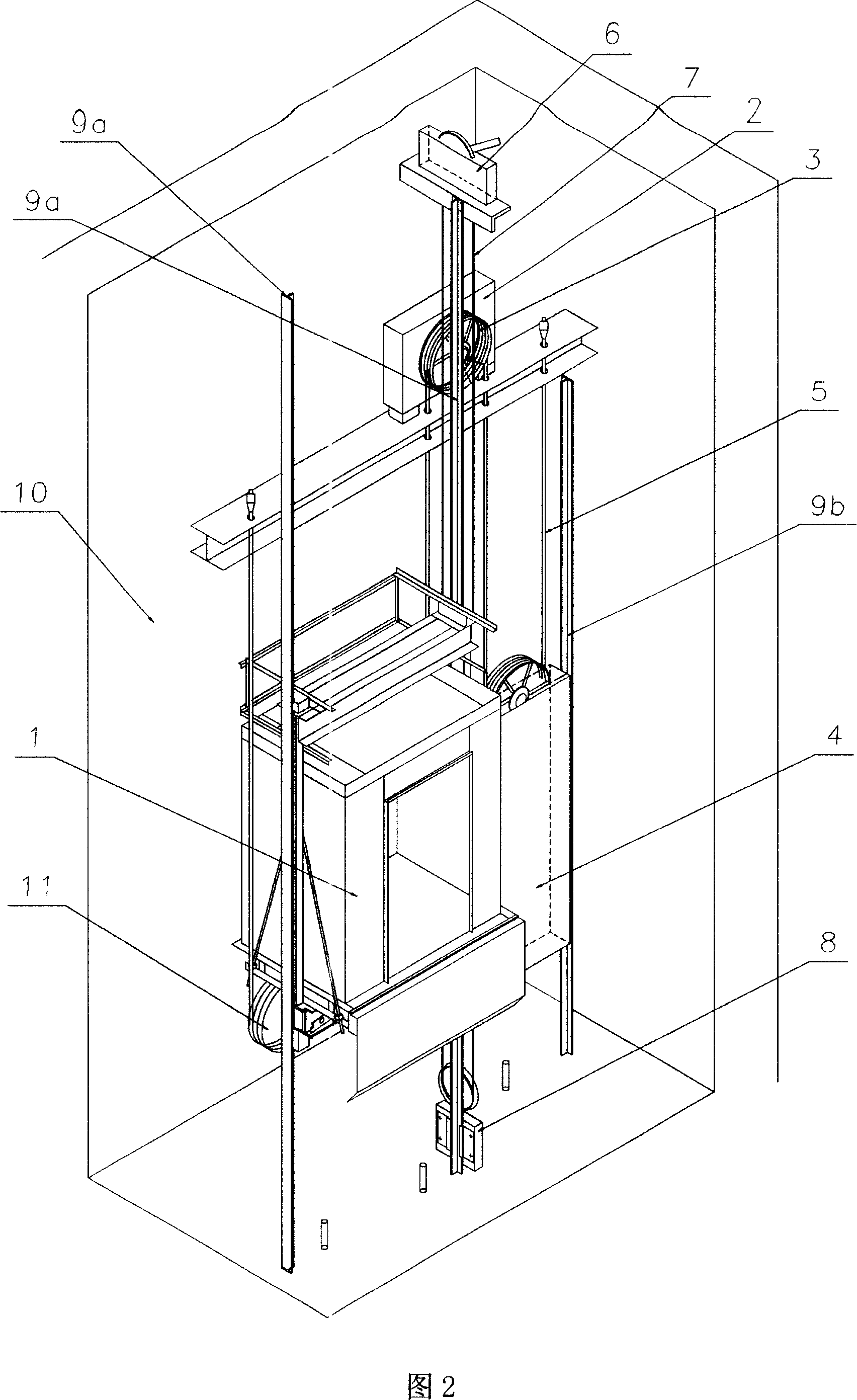

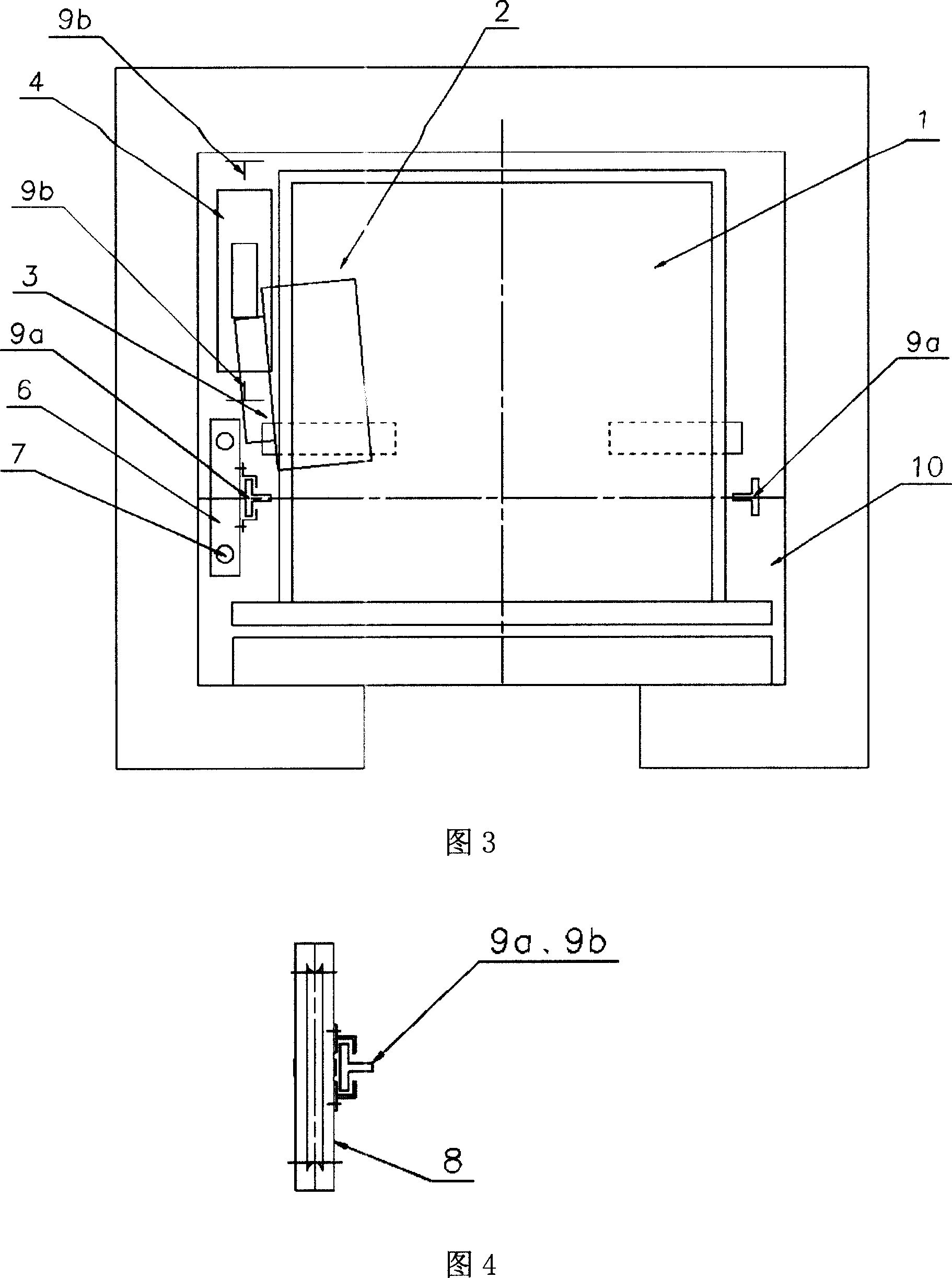

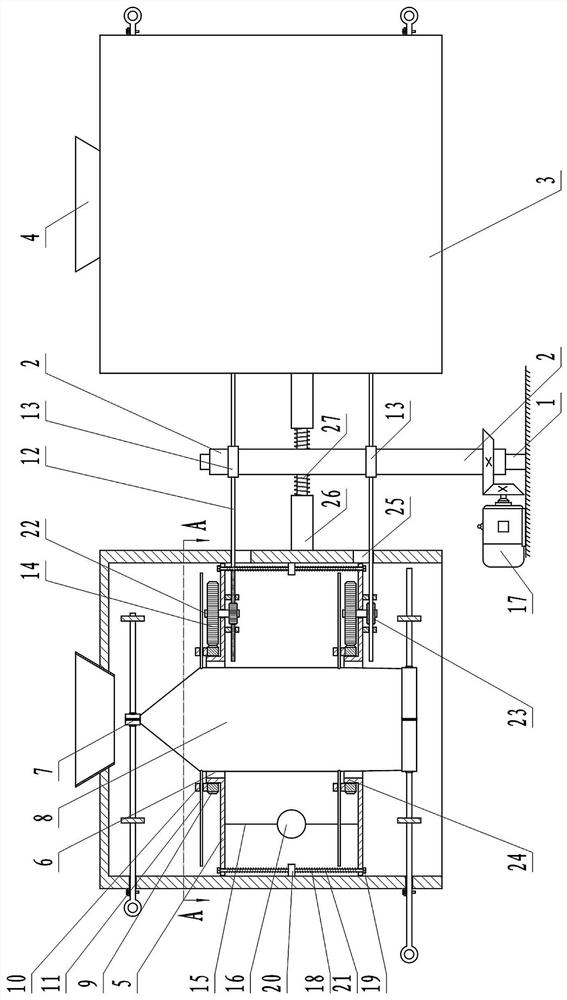

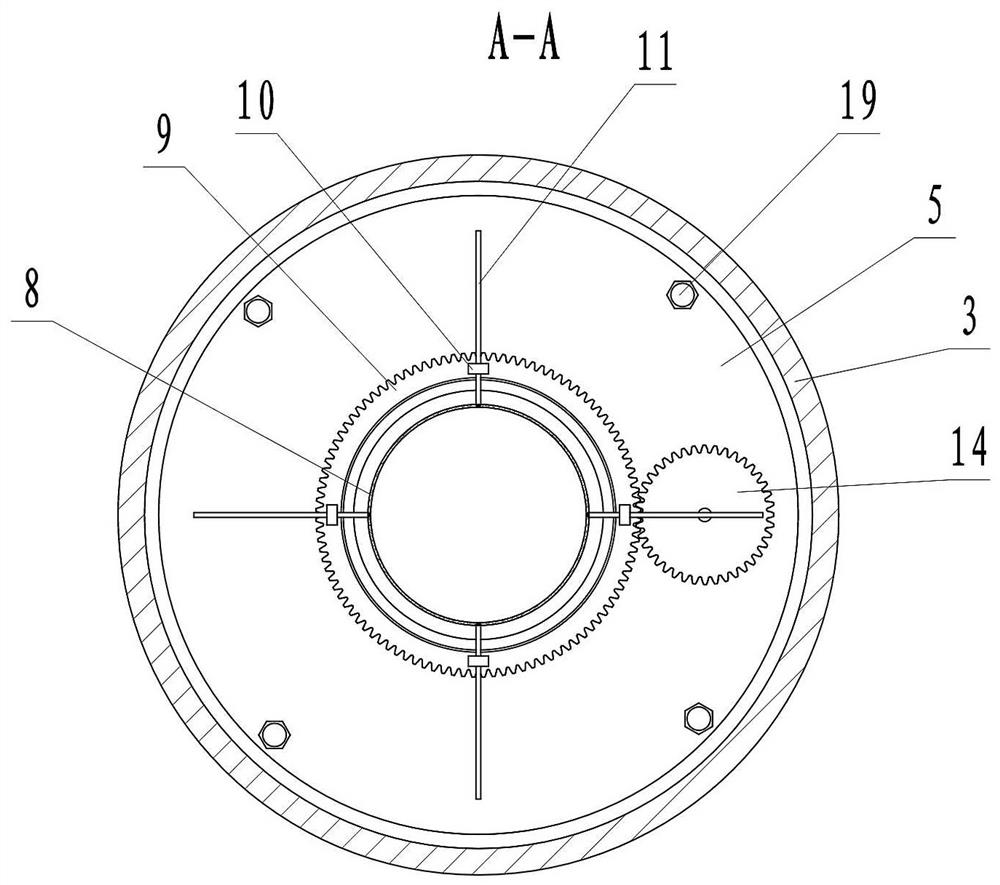

Elevator device

ActiveCN101143672AReduce eccentric forceOrientation structure is simpleElevatorsBuilding liftsEngineeringMechanical system

The invention discloses an elevator device, which includes a car, a drive device, a counterweight or cable tightening device, a cable connecting the car and the counterweight or cable tightening device, a speed limiter for monitoring the speed of the car, a limiter cable for transmitting the motion of the car, a limiter cable tightening device, a car guide rail and a counterweight guide rail for leading the car and a counterweight to move, and a lifting channel for containing the car, the drive device, the counterweight or cable tightening device and the cable, wherein, the limiter cable tightening device is arranged at the lower end of the lifting channel with the car or the counterweight guide rail as the a leading guide rail. The invention can make sure the eccentric force of a guide shoe and the guide rail, simplifies a guide structure of the limiter cable tightening device, reduces the cost, and meanwhile, results in more flexible structure deployment of the mechanical structure of the elevator and reduces the civil engineering dimension.

Owner:SHANGHAI MITSUBISHI ELEVATOR CO LTD

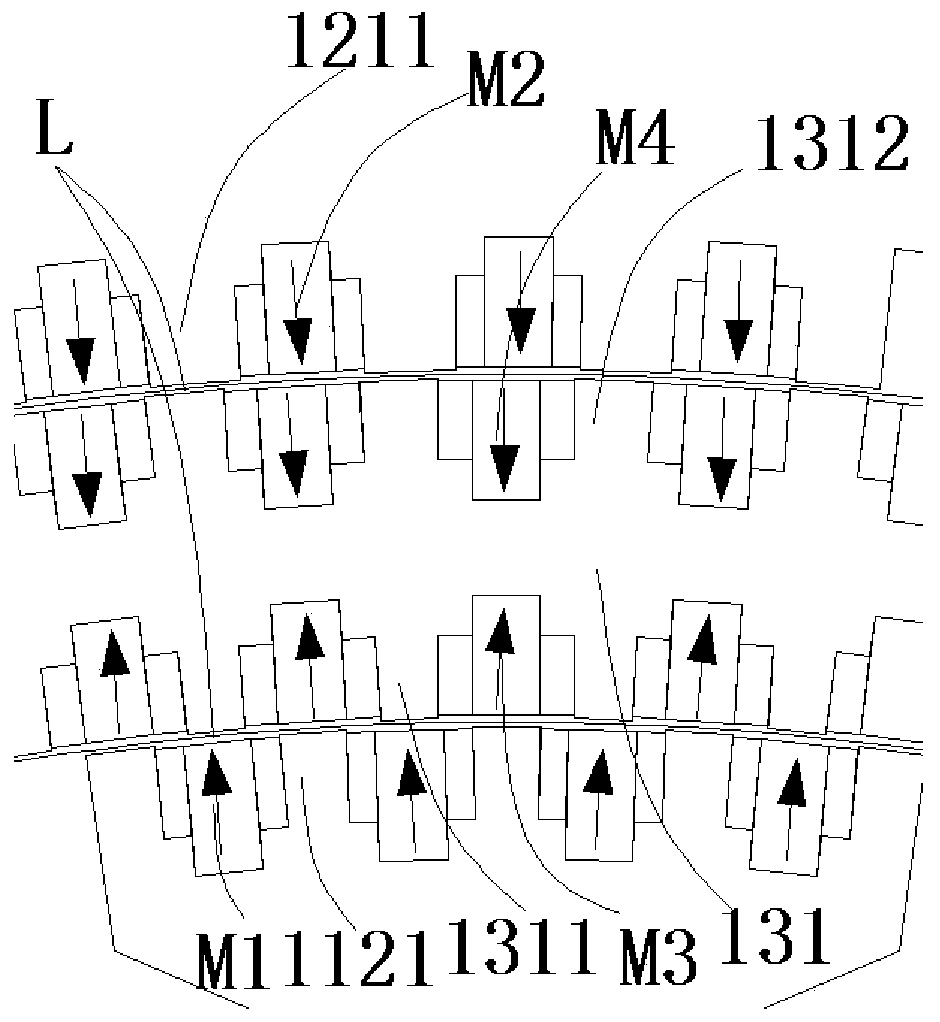

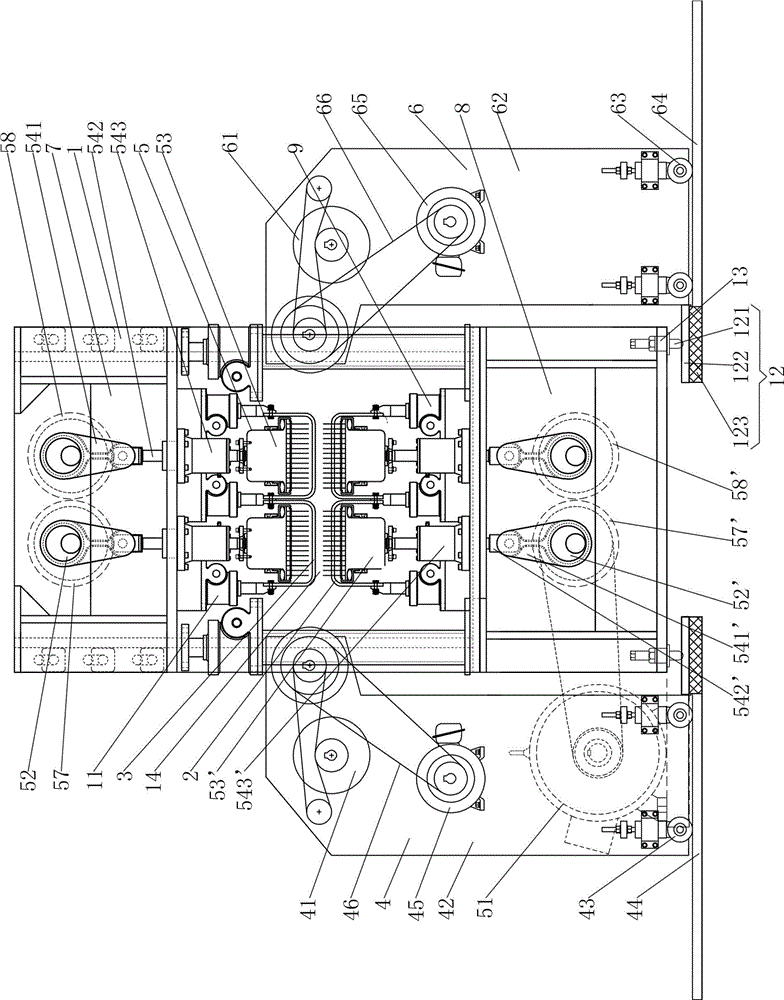

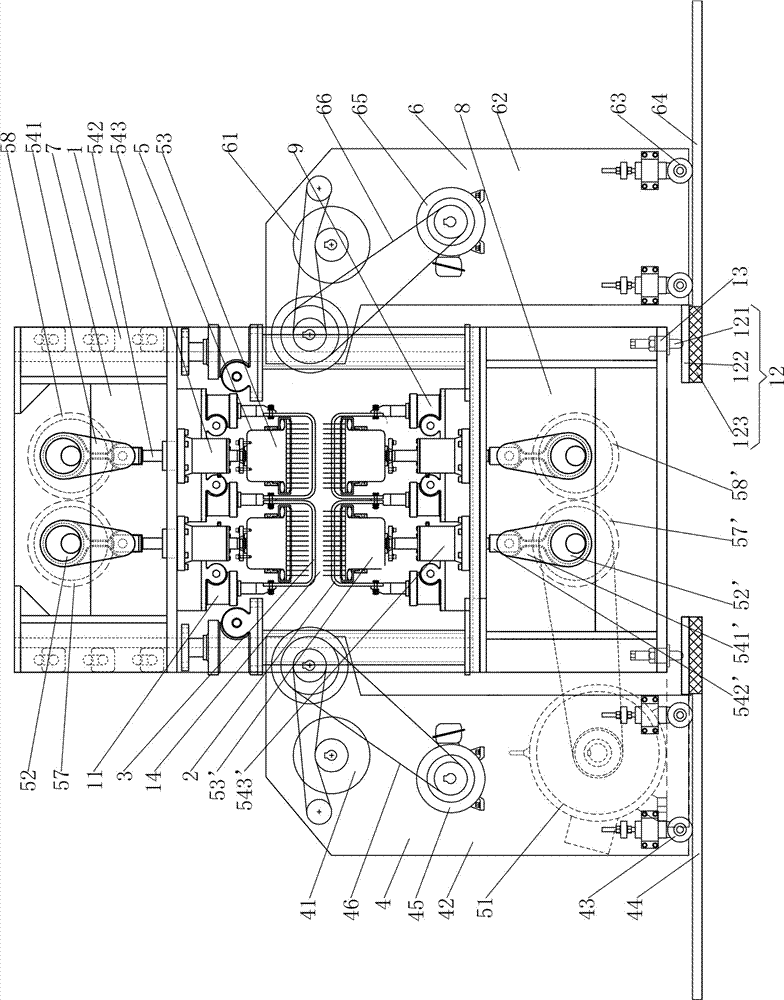

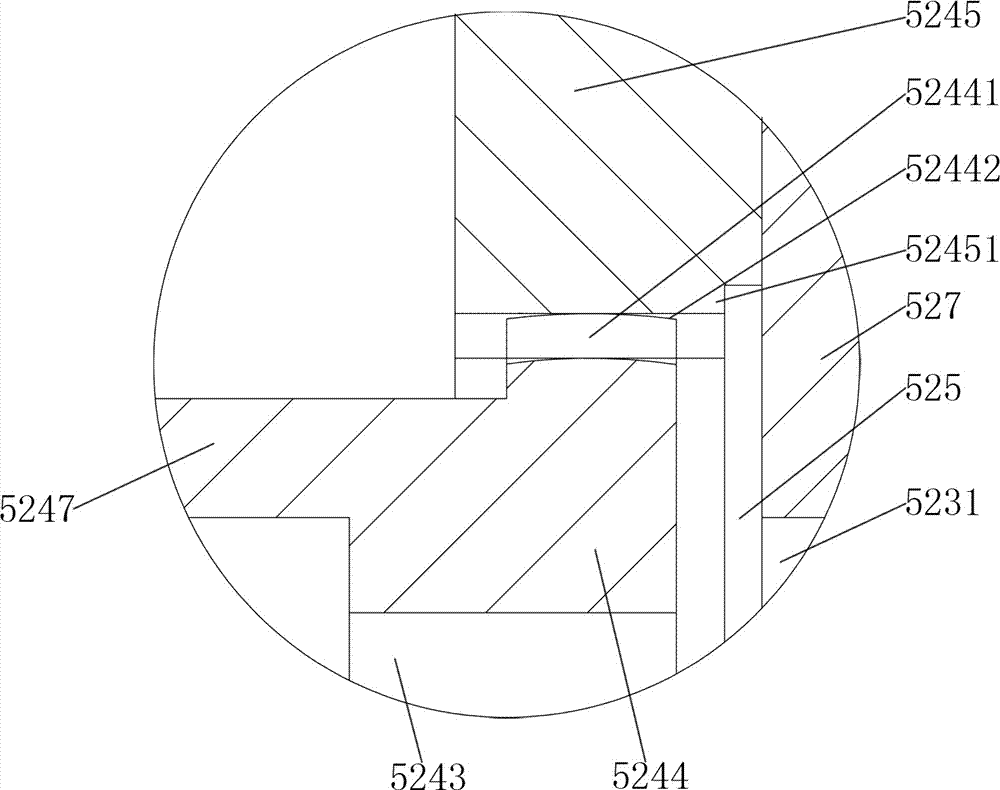

High-frequency apposition opposite-needling machine

ActiveCN105256466AIncrease acupuncture frequencyReduce vibrationNeedling machinesLeft halfApposition

The invention discloses a high-frequency apposition opposite-needling machine, comprising a machine frame, a net feeding mechanism, a lower net removing plate, an upper net removing plate, needling mechanisms and a drawing mechanism, wherein the upper needling mechanism comprises two upper transmission shaft components and two upper needle components; the lower needling mechanism comprises two lower transmission shaft components and two lower needle components. The high-frequency apposition opposite-needling machine is characterized in that each of the upper transmission shaft components and the lower transmission shaft components comprises a left half shaft, a right half shaft and a plurality of bent shafts; each bent shaft comprises two shaft heads and a boss which are all connected integrally; each boss is columnar; the center line of each boss is deviated from the axes of the corresponding shaft heads; one bent shaft from the upper transmission shaft components corresponds to one upper lifting transmission mechanism; the upper end of an upper swing arm of the upper lifting transmission mechanism is connected with the boss of the corresponding bent shaft in a sleeving manner; one bent shaft from the lower transmission shaft components corresponds one lower lifting transmission mechanism; the lower end of a lower swing arm of the lower lifting transmission mechanism is connected with the boss of the corresponding bent shaft in the sleeving manner. The high-frequency apposition opposite-needling machine has the advantages that the needling frequency is high, the vibration provoking quantity is smaller, and the production efficiency and product quality are beneficially improved.

Owner:SHANTOU SANHUI NONWOVEN MACHINERY FACTORY

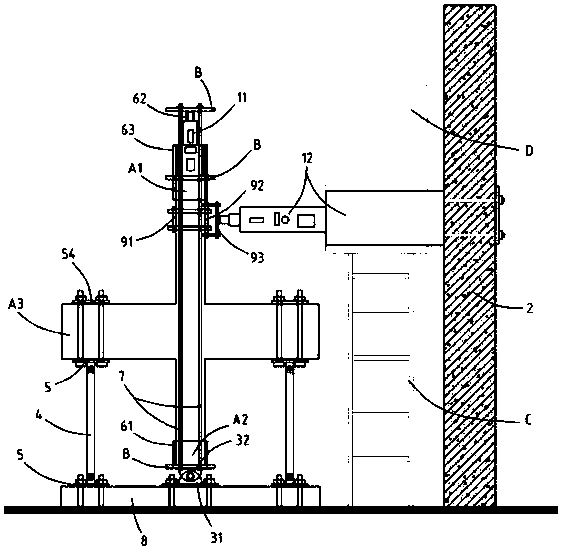

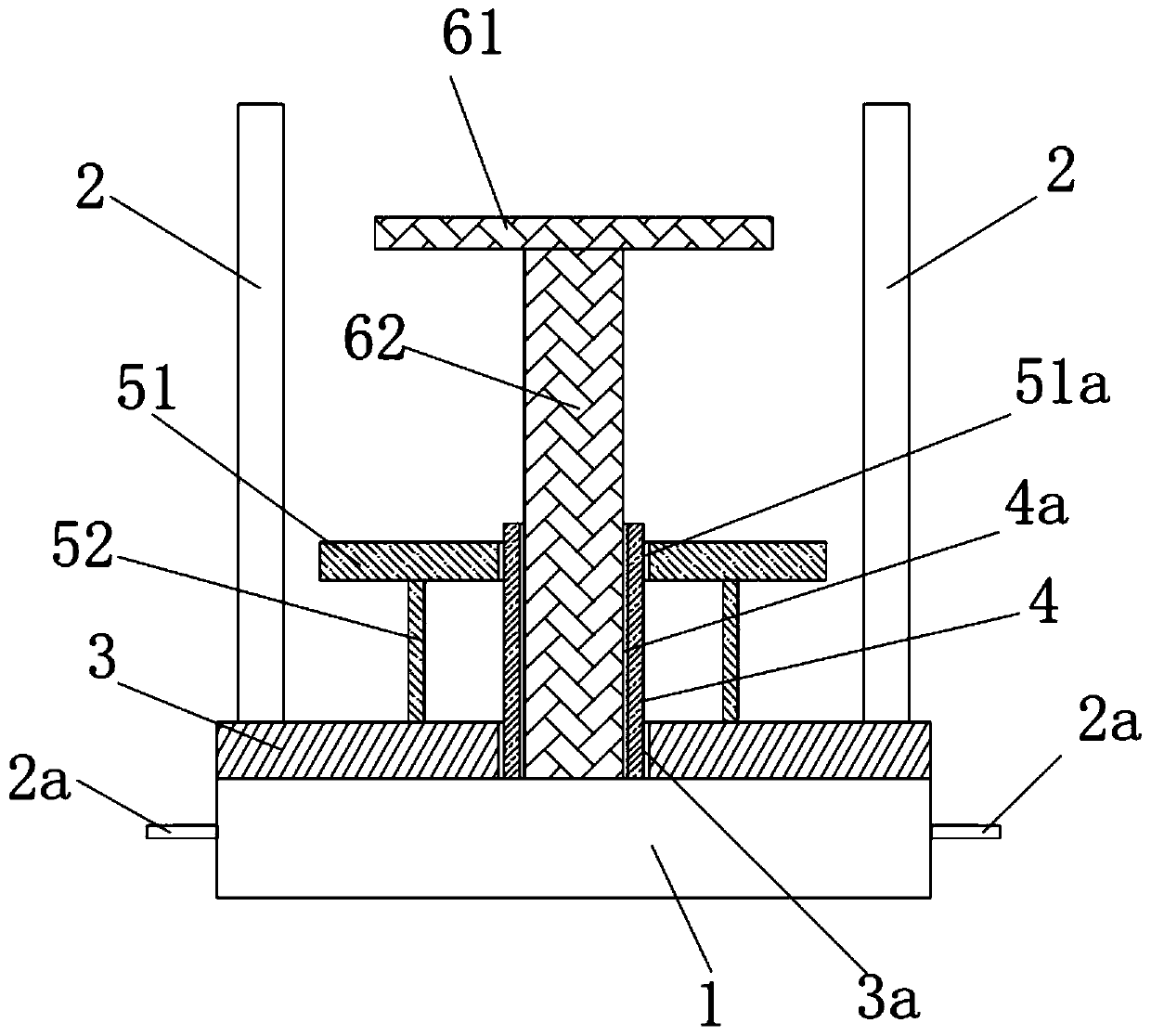

Test device for simulating horizontal earthquake effect bearing by cross-shaped beam-column joint

PendingCN109374246AStable axial pressure ratioEnsure safetyVibration testingHorizontal forceShaped beam

The invention, which belongs to the field of civil engineering, discloses a test device for simulating a horizontal earthquake effect bearing by a cross-shaped beam-column joint. The test device comprises a shaft stress loading device for applying pressures on a test piece column top, a reciprocating loading device for applying a horizontal force on the side of a column end, and a fixation frame for fixing the reciprocating loading device. The bottom of the test piece column is hinged to the ground by a hinging piece; connecting rods arranged vertically are arranged between the beam end and the ground; and the two ends of the connecting rods are hinged to the beam end and the ground respectively by hinge bases. In addition, the test device also includes a first sleeve sleeving the column bottom, a second sleeve in contact with a free end of the shaft pressure loading device, and a third sleeve coating the connection part between the column top and the shaft stress loading device; the third sleeve has a structure with two open ends, one open end coats the periphery of the column top, and the other open end coats the periphery of the shaft stress loading device; a separation board isarranged between the two open ends and is in contact with the test piece column top; and the three sleeves are connected into one by connecting pieces. With the test device, the stable axial stress ratio is realized; and the actual condition of bearing the horizontal earthquake effect by the beam-column joint is reflected truly.

Owner:HUNAN UNIV OF TECH

Electric connector

InactiveUS8419460B2Reduce eccentric forceGood stopping effectSecuring/insulating coupling contact membersCouplings bases/casesElectricityEngineering

An electric connector includes an insulation base, a cover which is slidably connected to the base and an eccentric driving cam which is connected to the insulation base and the cover. The insulation base has a first limit surface. The cover has a second limit surface. The eccentric driving cam includes a first stop surface and a second stop surface. The first stop surface is stopped by the first limit surface and the second stop surface is stopped by the second limit surface, providing a dual-stop effect.

Owner:SUYING ELECTRCNICS (DONG GUAN) CO LTD

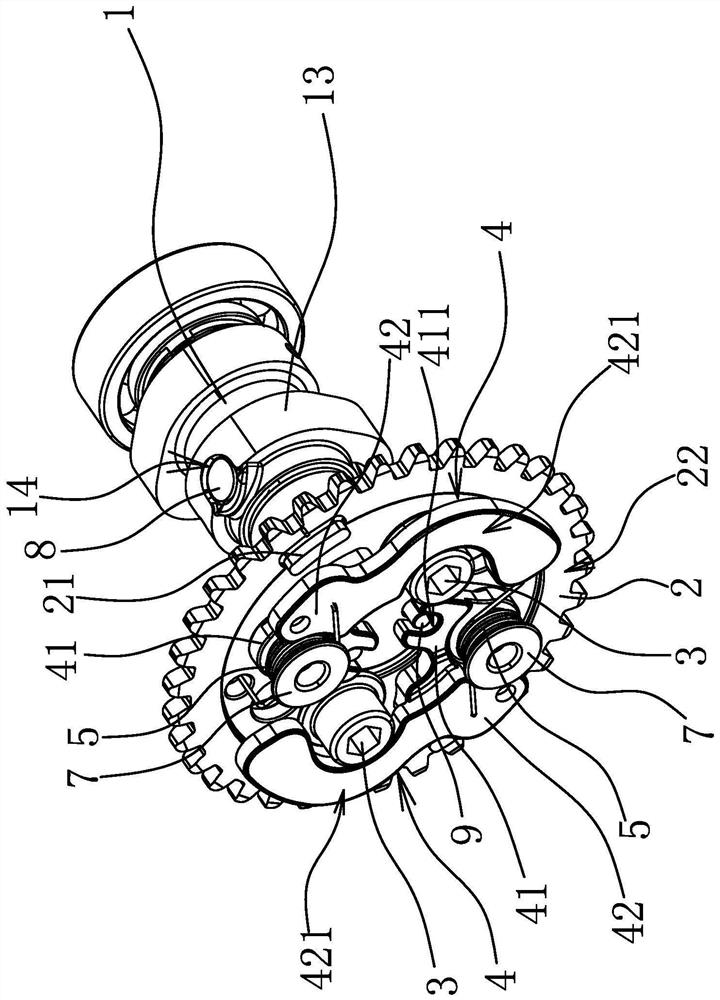

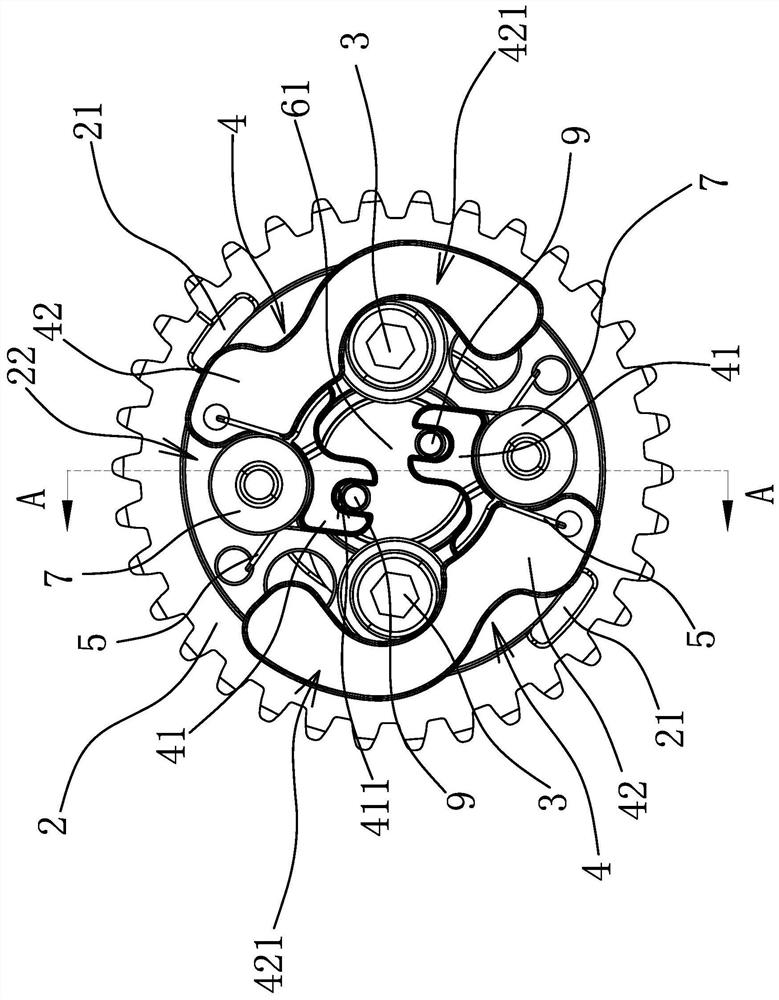

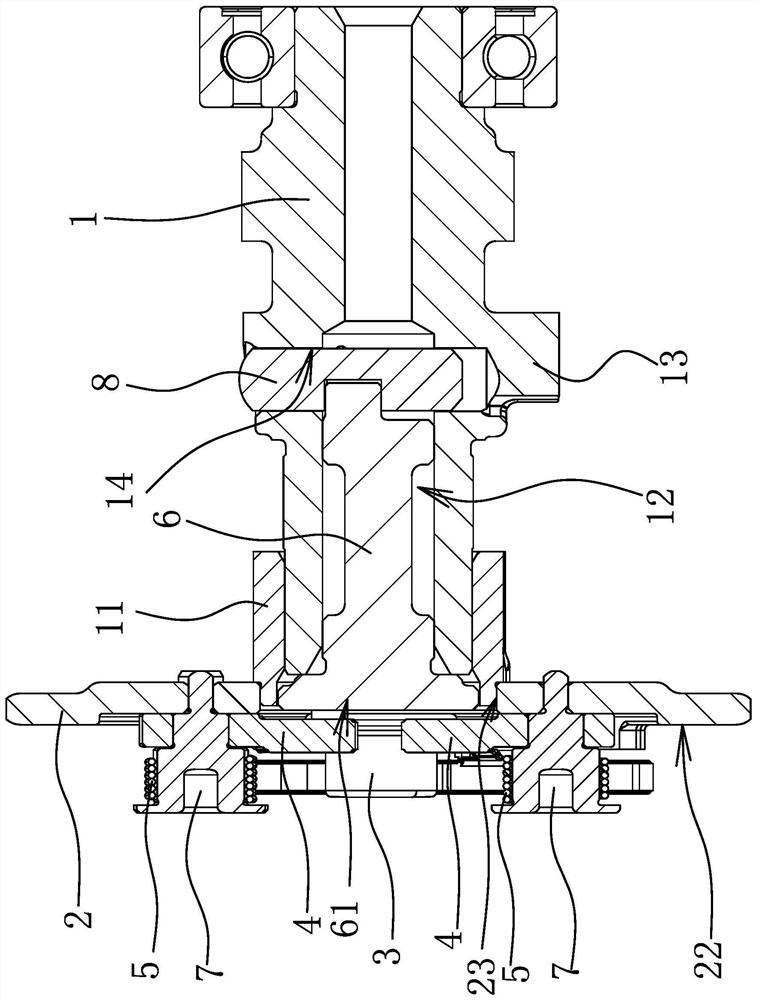

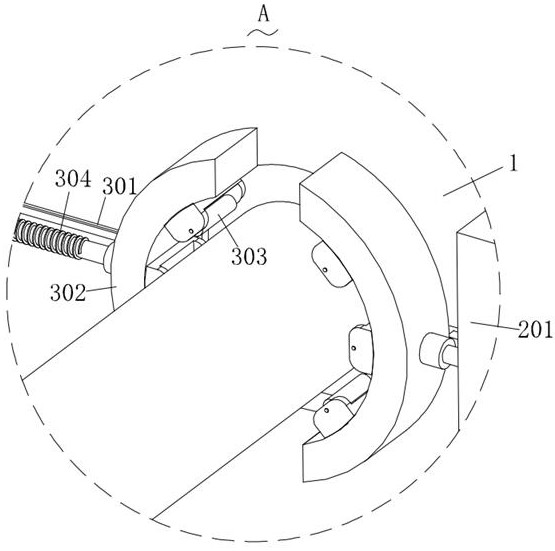

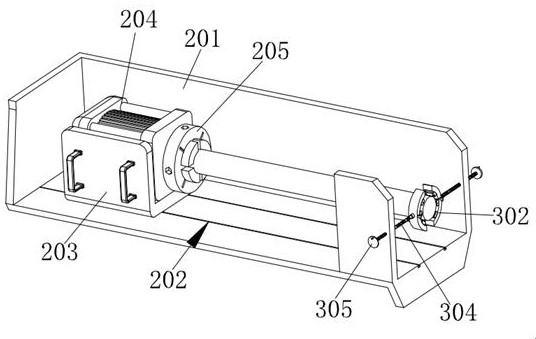

Motorcycle engine starting pressure reduction structure

The invention provides a motorcycle engine starting pressure reduction structure, and belongs to the technical field of motorcycles. The problem that an existing engine starting pressure reduction structure is insufficient in light weight is solved. The motorcycle engine starting pressure reduction structure comprises a cam shaft, a chain wheel and a pressure reduction valve assembly, wherein thechain wheel is provided with a fastener and fixedly connected to the cam shaft through the fastener; the pressure reduction valve assembly comprises a throwing block arranged on the side face of the chain wheel; one end of the throwing block is hinged to the chain wheel, and the throwing block can be thrown out in the radial direction of the chain wheel under the action of centrifugal force; the throwing block is connected with a reset elastic piece; the throwing block abuts against the fastener after being reset under the action of the reset elastic piece; a limiting protrusion is arranged onthe edge of the chain wheel; and after the throwing block is thrown out, the hinged end of the throwing block abuts against the limiting protrusion, and then the throwing stroke of the throwing blockis limited. According to the motorcycle engine starting pressure reduction structure, the light weight design of the chain wheel assembly is achieved, and meanwhile the beneficial effect of the compact structure is achieved.

Owner:ZHEJIANG QIANJIANG MOTORCYCLE

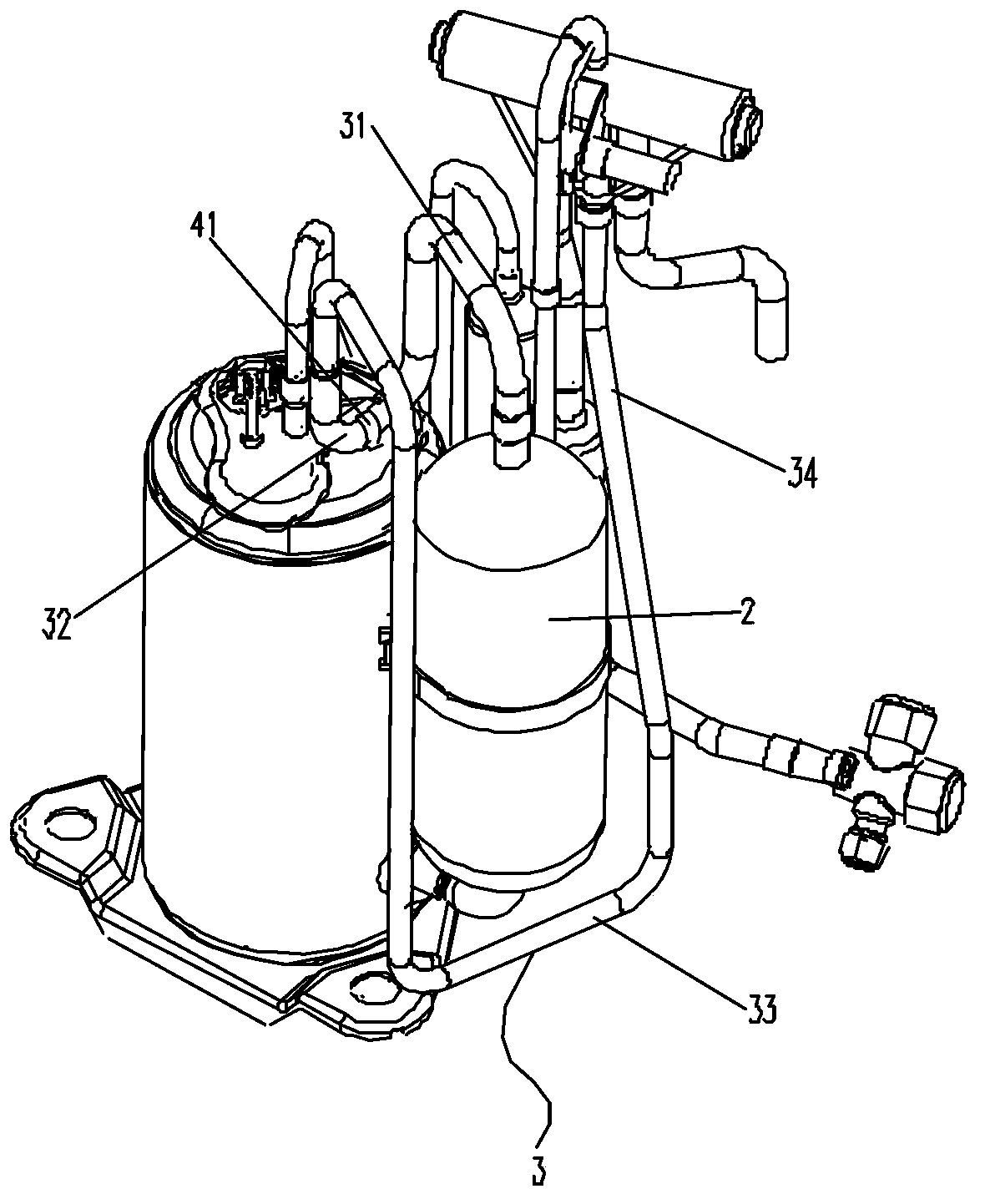

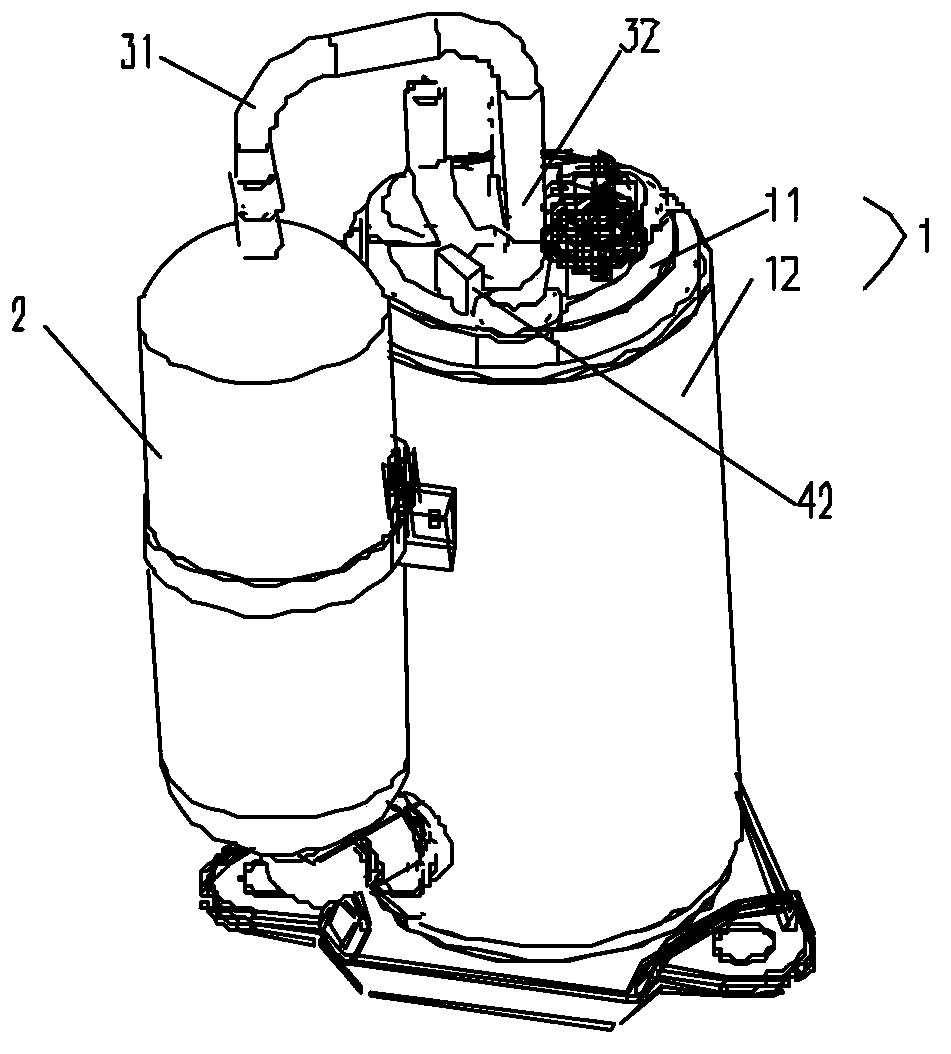

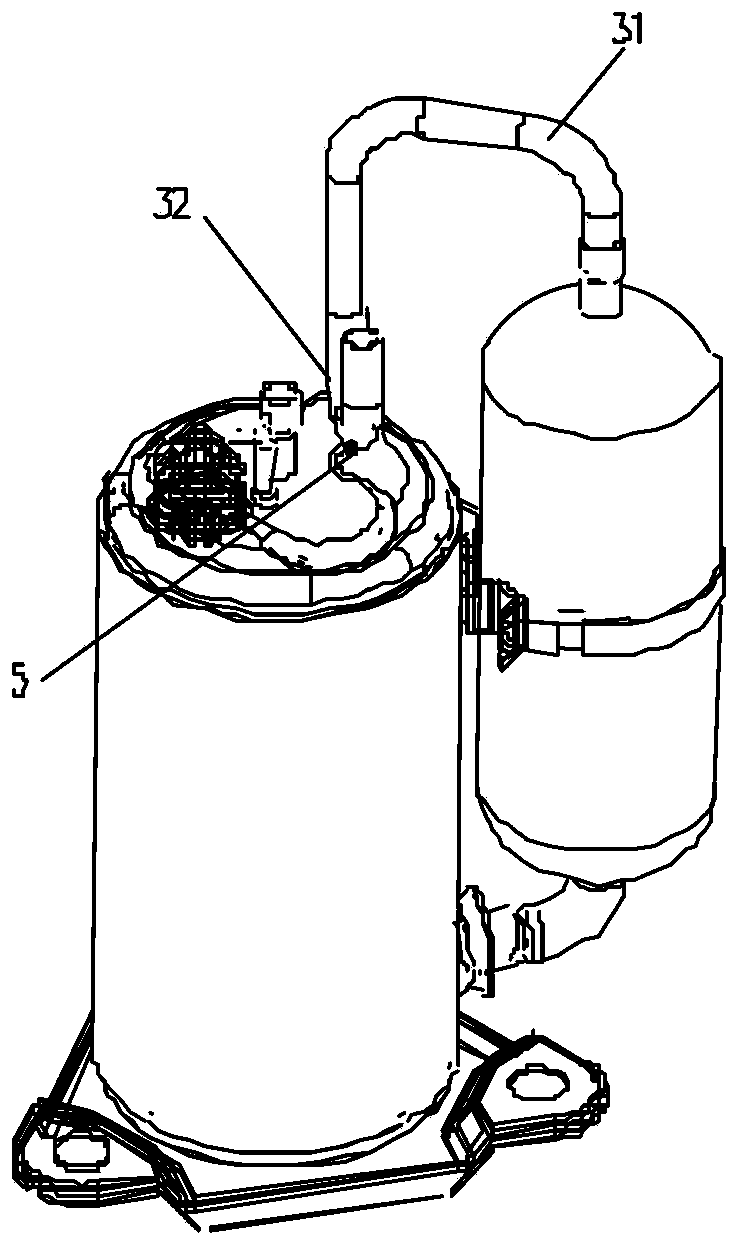

Compressor pipeline assembly and air conditioner

InactiveCN104121162AReduce vibrationReduce stressPositive displacement pump componentsPositive-displacement liquid enginesEngineeringVapor–liquid separator

The utility model discloses a compressor pipeline assembly which comprises a compressor and an air return pipe. The air return pipe comprises a front section connected with a gas-liquid separator, a rear section connected with a valve and a bend section in the middle, wherein the end, close to the bend section in the middle, of the front section is provided with a fixing portion, and the fixing portion of the air return pipe is connected with a shell of the compressor. Due to the fact that the air return pipe is fixed to the shell, close to the rotation center of the compressor, of the compressor, vibration of the air return pipe is reduced, accordingly, eccentric force exerted on the compressor is also reduced, and vibration of the compressor is reduced. Stress borne by the air return pipe is correspondingly reduced, and the reliability of the pipe is improved. The utility model further discloses an air conditioner.

Owner:GREE ELECTRIC APPLIANCES INC

Polishing device for building engineering machine part maintenance

ActiveCN113561029AImprove sanding qualityAvoid the phenomenon of eccentric swingGrinding drivesGrinding machinesSteel tubeScrap

The invention relates to the technical field of polishing devices, in particular to a polishing device for building engineering machinery part maintenance, which comprises a box body, a pushing structure is mounted at one end of the box body, a correcting structure is mounted at one end of the box body, a polishing structure is mounted in the box body, and a height adjusting structure is mounted on one side of the box body; supporting columns are fixedly connected to the bottom end of the box body, a powdered scrap collecting structure is installed at the bottom end of the box body, and the polishing structure comprises a rotating shaft; the surface of a polished round steel pipe fitting can be cleaned through brushes, and meanwhile, the polishing height of a grinding wheel can be adjusted through the height adjusting structure; the phenomenon of eccentric swinging of the other end of the round steel pipe fitting in the rotating process can be prevented through the correcting structure, so that the polishing quality of the round steel pipe fitting is improved; and metal substances in the dust can be separated from common dust through magnetic suction plates.

Owner:江苏淮海新材料科技有限公司

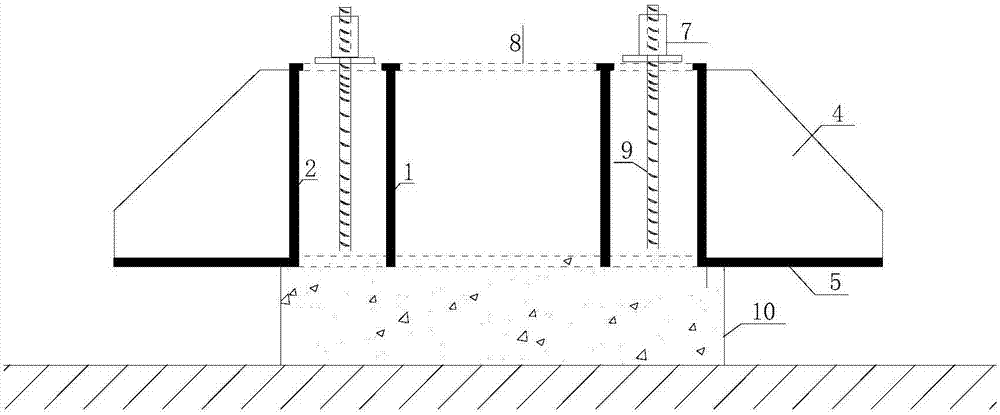

Concrete body confining pressure loading device for drawing experiment of anchor cable

PendingCN110567811AReduce eccentric forceNovel structureMaterial strength using tensile/compressive forcesEngineeringBlind hole

The invention relates to a concrete body confining pressure loading device for a drawing experiment of an anchor cable. The technical scheme is that a cylindrical positioning sleeve which vertically extends upwards is fixed in the center of a base; a blind-hole-shaped positioning hole is formed in the center of the positioning sleeve; symmetrical oil cylinders are vertically arranged on the base at the two sides of the positioning sleeve; a lifting plate is fixed between the movable parts of the oil cylinders; a guide hole for the positioning sleeve to penetrate is formed at the center of thelifting plate; a lower supporting plate is placed on the lifting plate; the lower supporting plate comprises a lower supporting plate body and a supporting sleeve fixedly connected to the lower surface of the lower supporting plate body; and a confining pressure sleeve is disposed on the lower supporting plate body. According to the invention, the eccentric stress of the anchor cable is reduced, the lifting of a concrete test block with huge weight is completed, and a confining pressure is applied to a concrete test block through the confining pressure sleeve, thereby achieving the monitoring,testing and analyzing of mechanical behaviors of a rock test piece in the in-situ environment, and providing a technical support for the supporting theory of mining rock stratum stable control.

Owner:HENAN POLYTECHNIC UNIV

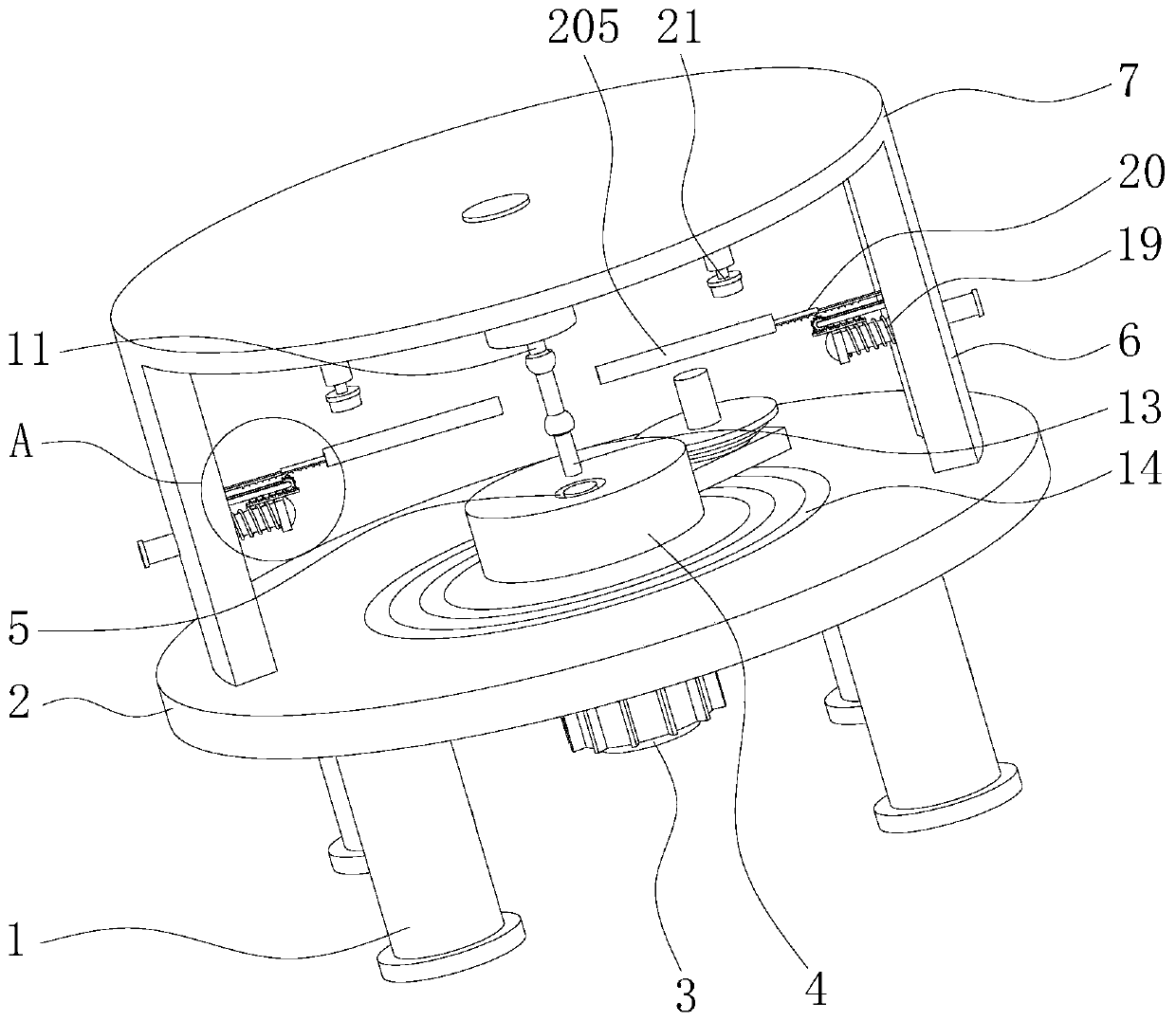

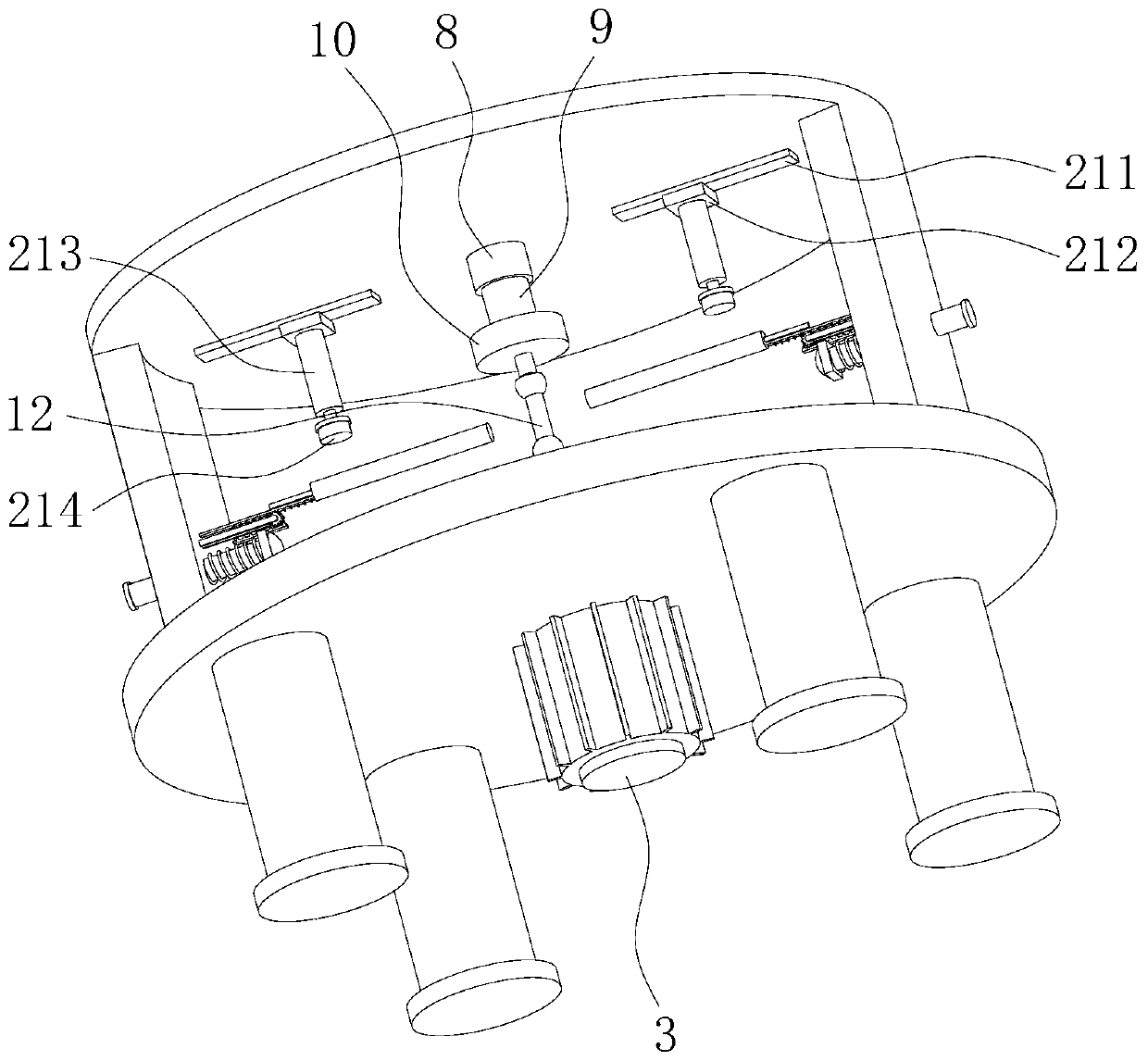

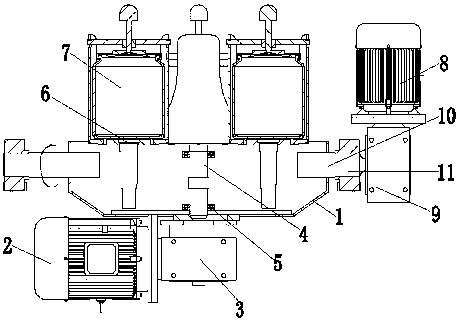

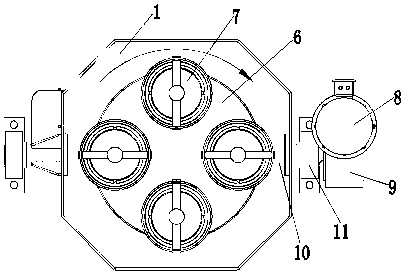

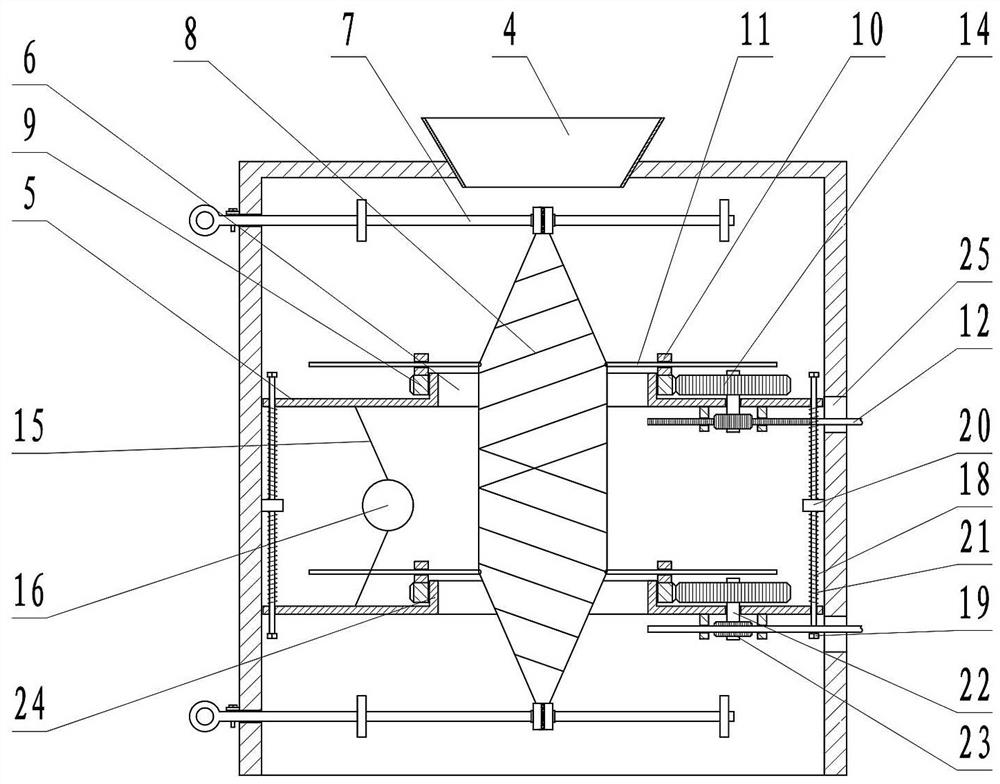

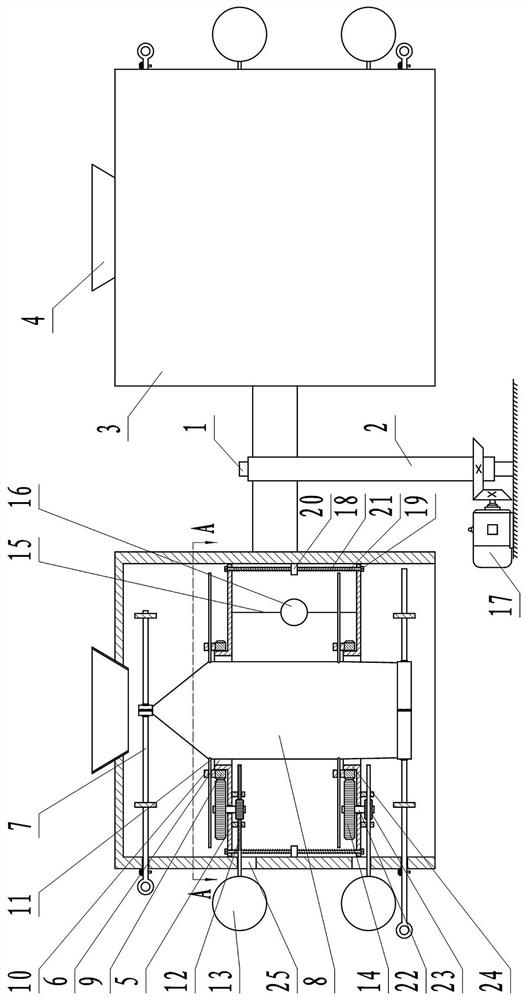

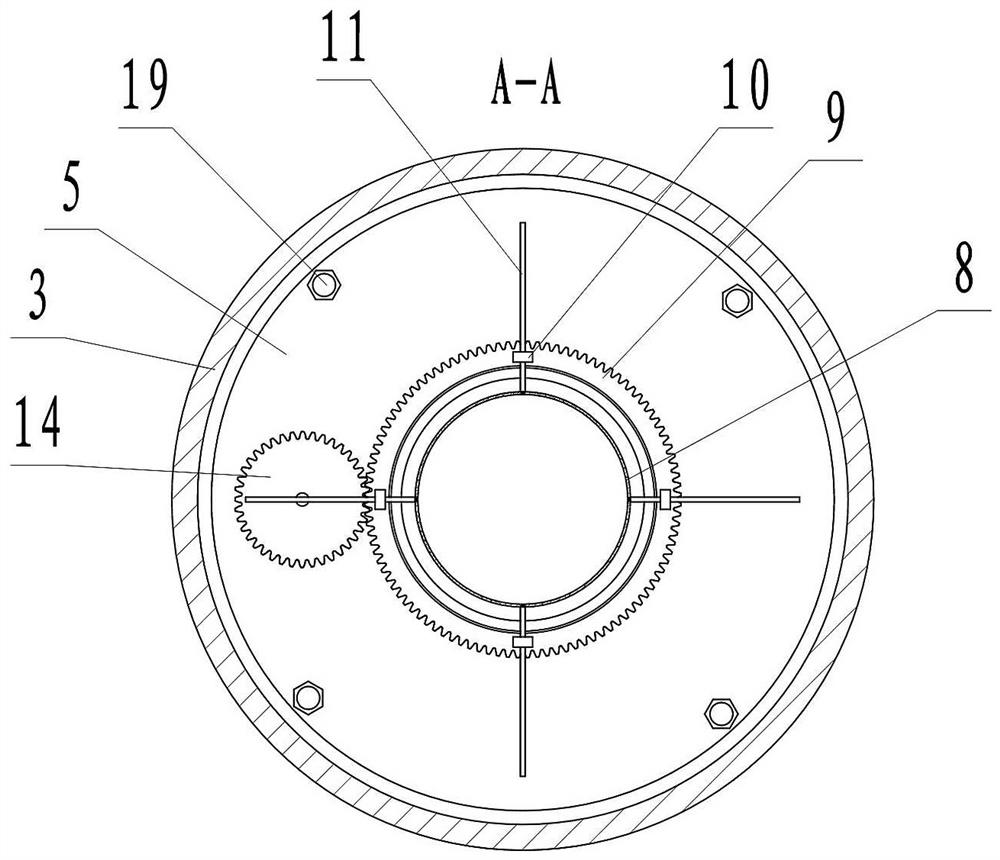

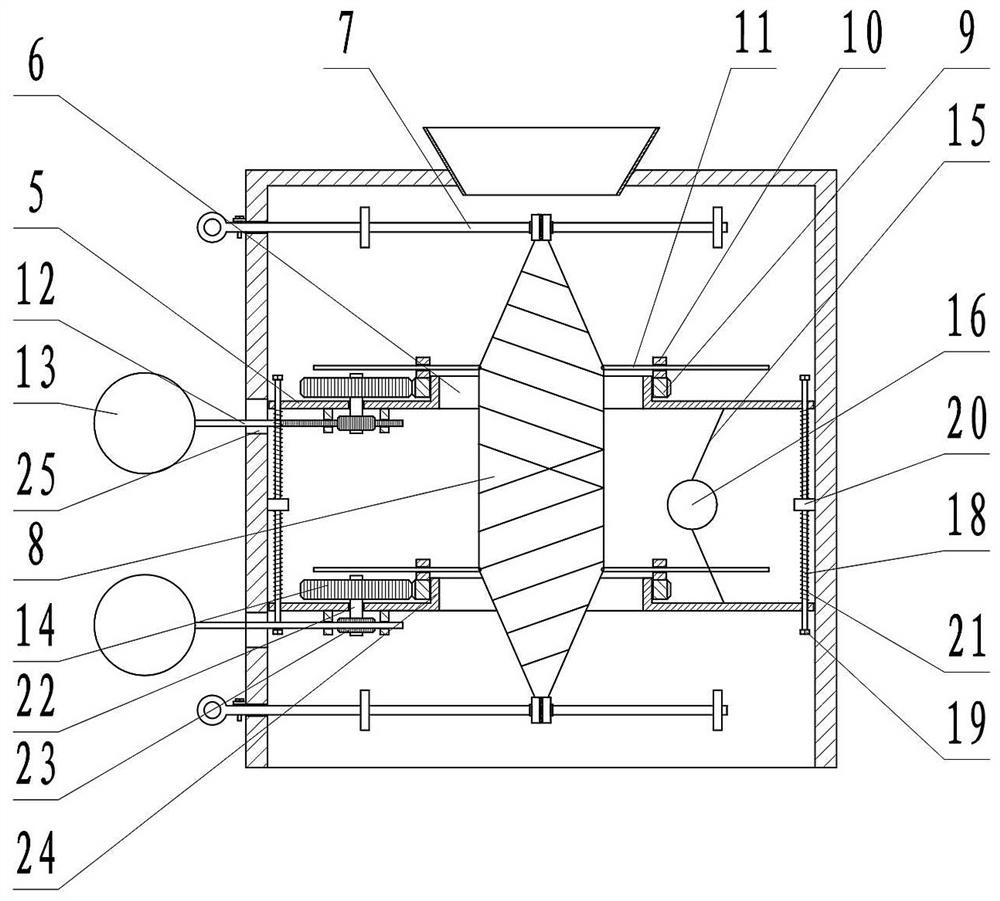

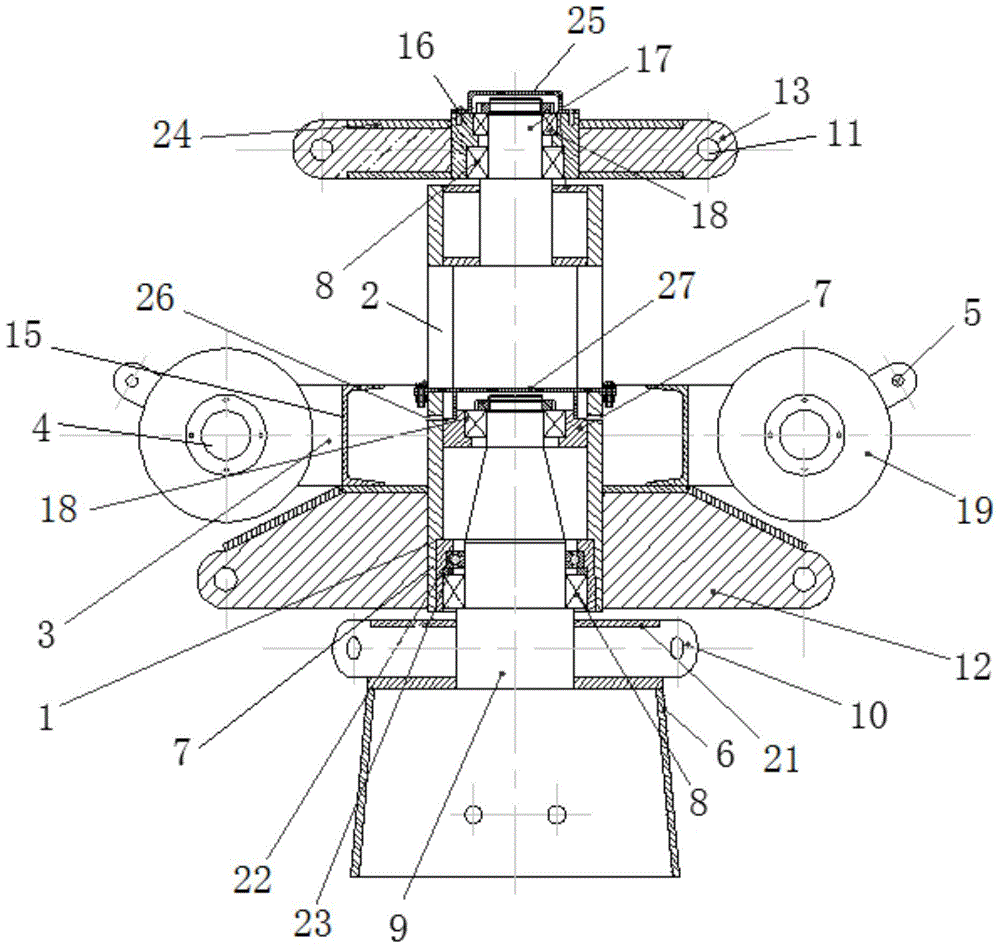

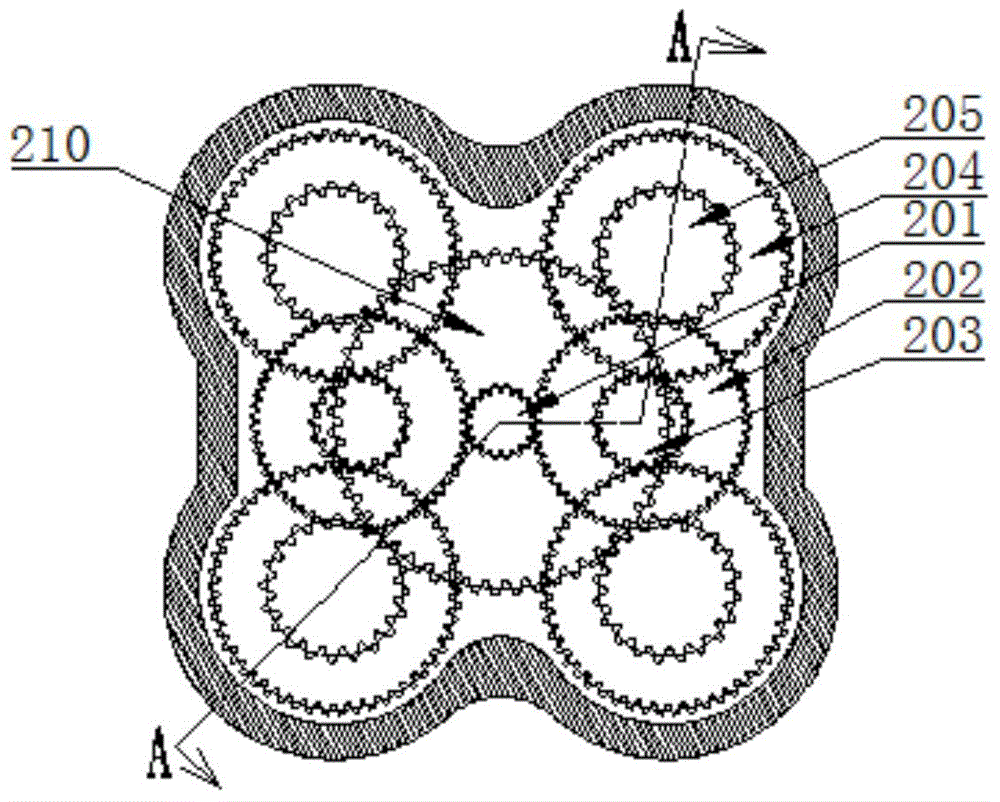

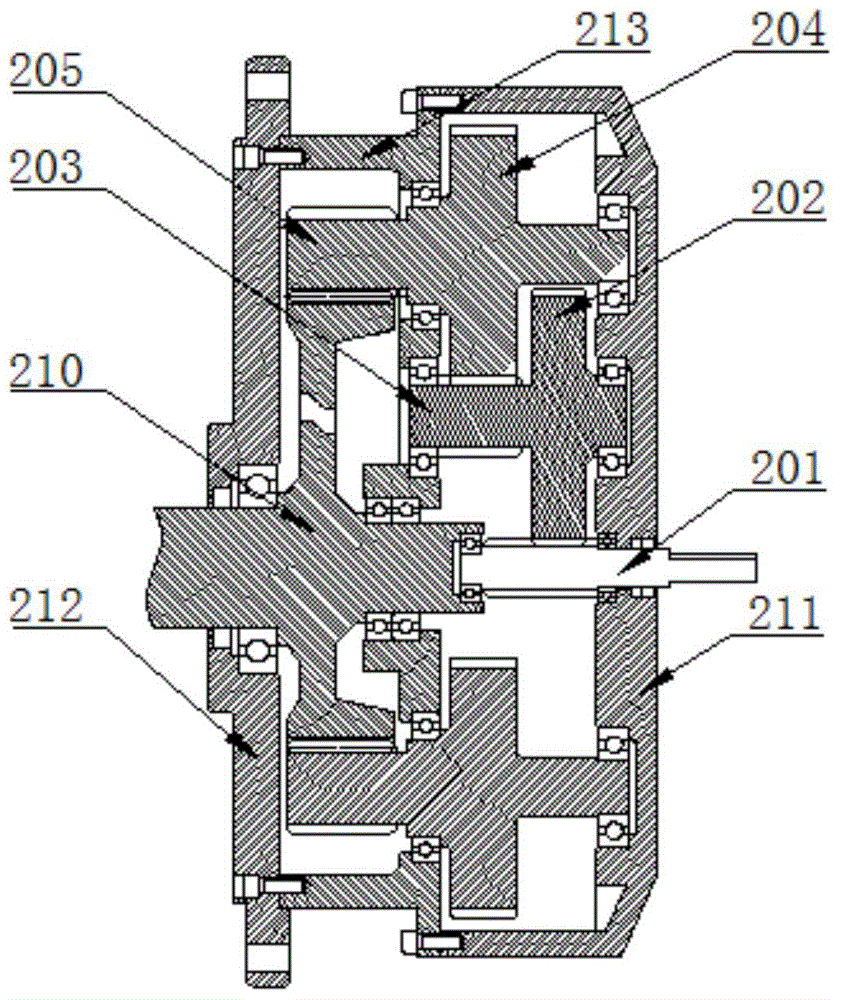

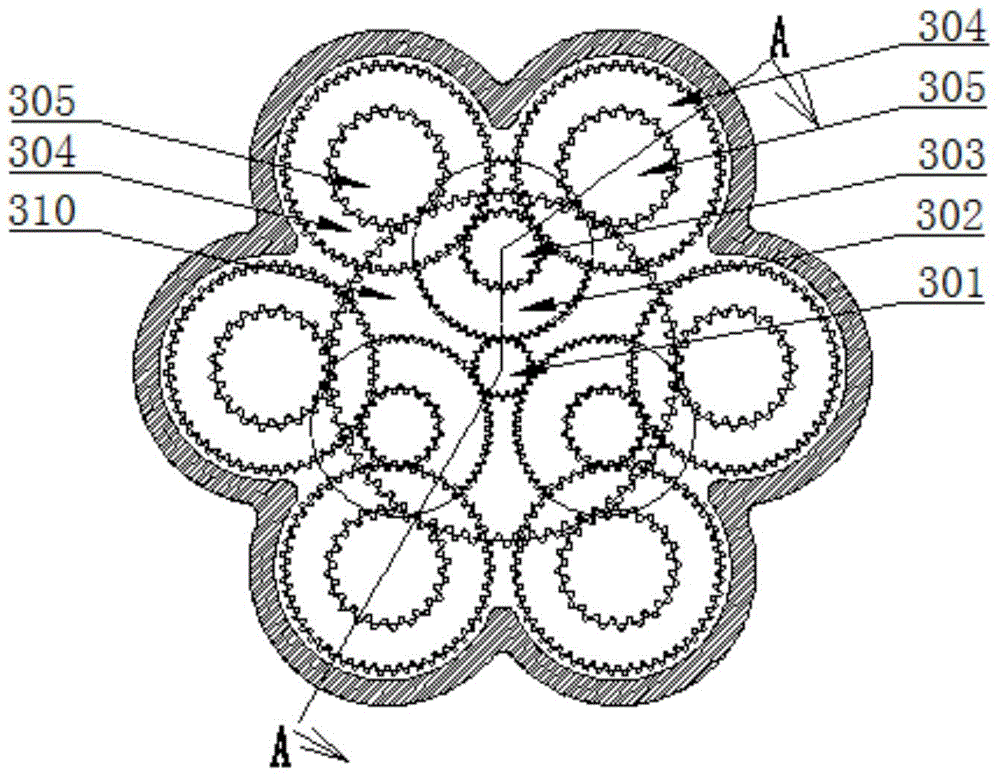

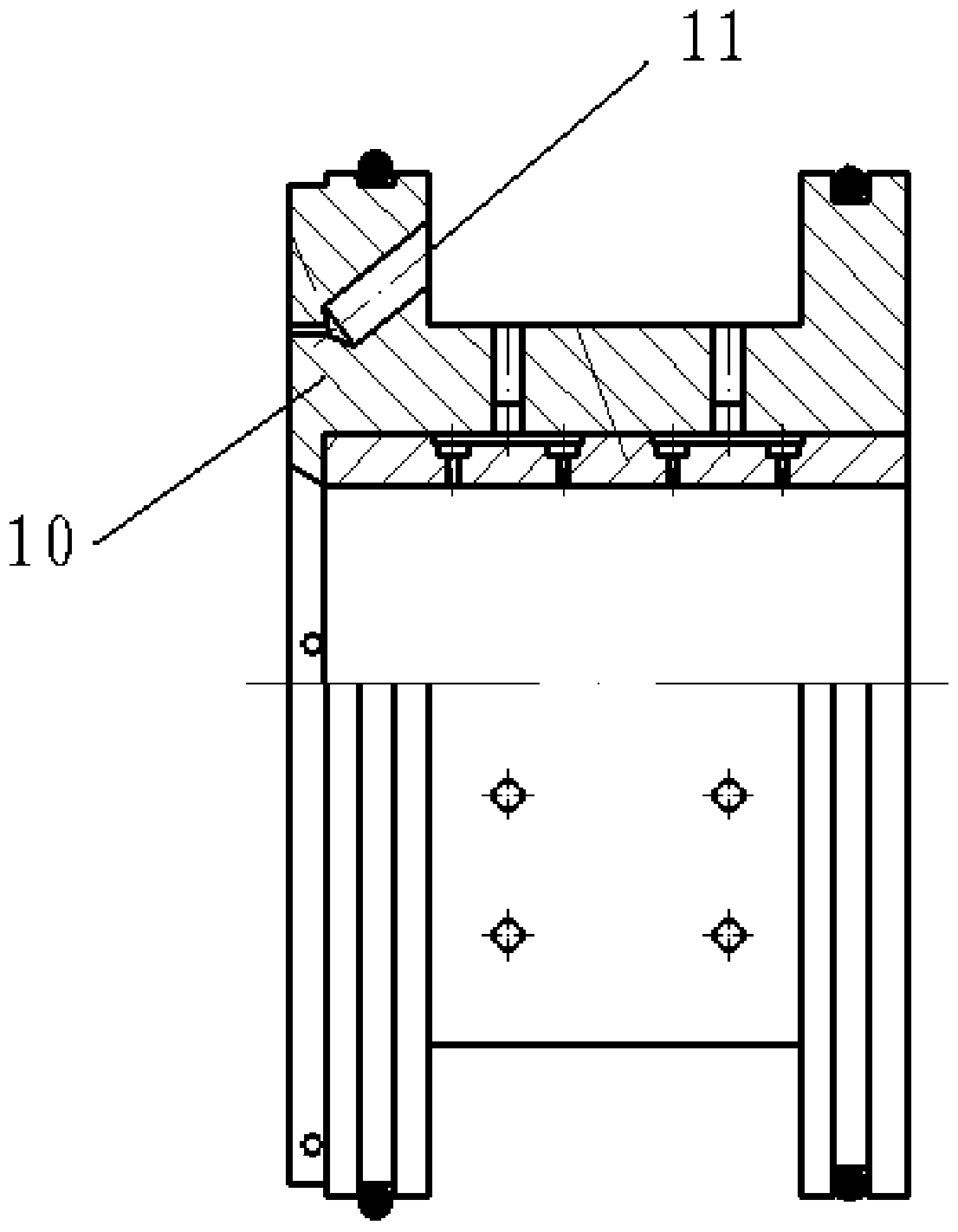

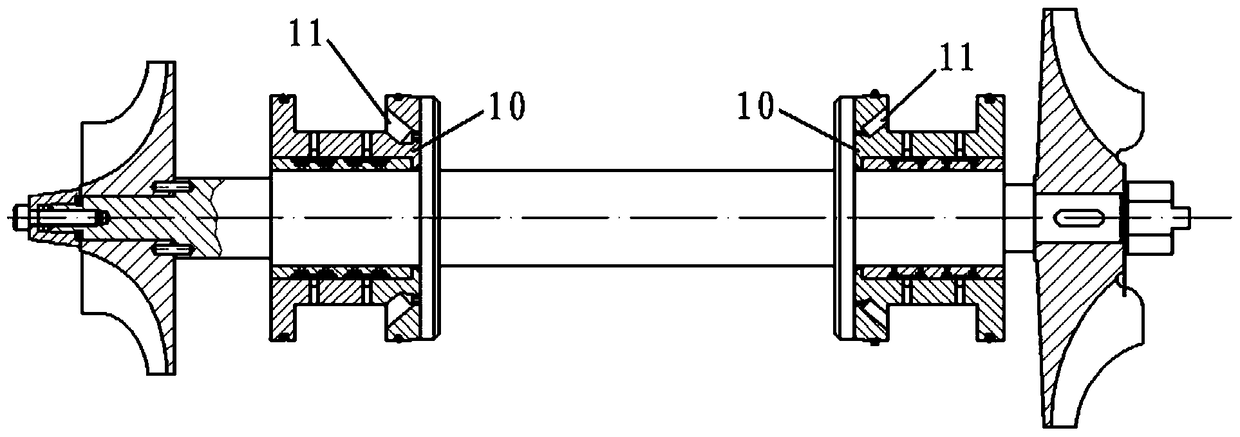

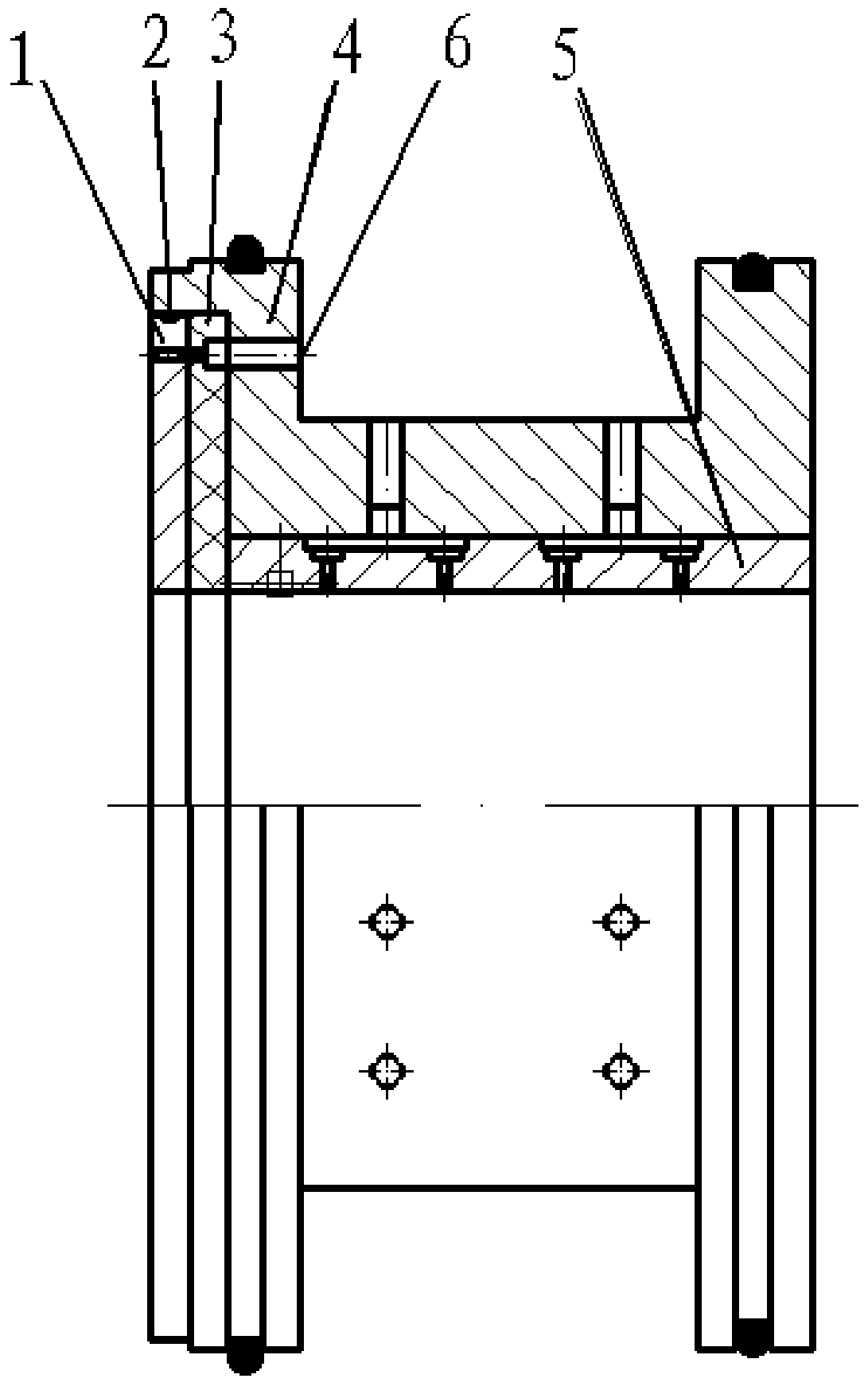

An all-round planetary ball mill directly connected to a geared motor

Owner:CHANGSHA MITR INSTR EQUIP CO LTD

High Frequency Alignment Stimulation Machine

ActiveCN105256466BIncrease acupuncture frequencyReduce vibrationNeedling machinesDrive shaftEngineering

A high-frequency co-location punching machine, including a frame, a net feeding mechanism, a lower web stripping board, an upper web stripping board, a needling mechanism and a pulling mechanism; the upper needling mechanism includes two upper drive shaft assemblies and two upper The needle assembly, the lower acupuncture mechanism includes two lower transmission shaft assemblies and two lower needle assemblies, and is characterized in that: the upper transmission shaft assembly and the lower transmission shaft assembly each include a left half shaft, a right half shaft and a plurality of crankshafts, The crankshaft includes two shaft heads and a boss integrally connected. The boss is cylindrical and its center line deviates from the axis of the shaft head; one crankshaft in the upper transmission shaft assembly corresponds to an upper lifting transmission mechanism, and the upper shaking in the upper lifting transmission mechanism The upper end of the arm is socketed on the boss of the corresponding crankshaft; one crankshaft in the lower transmission shaft assembly corresponds to a lower lifting transmission mechanism, and the lower end of the lower rocker arm in the lower lifting transmission mechanism is socketed on the boss of the corresponding crankshaft. The invention has high acupuncture frequency and small vibration excitation, which is beneficial to improve production efficiency and product quality.

Owner:SHANTOU SANHUI NONWOVEN MACHINERY FACTORY

A stuffing extrusion dehydration device

ActiveCN113287769BAvoid reabsorptionImprove dehydration efficiencyFood treatmentClassical mechanicsStructural engineering

The invention relates to a stuffing extruding and dehydrating device, which effectively solves the problem of incomplete dehydration and difficult cleaning of stuffing; the technical solution is to include a vertical support rod, which is covered with a rotatable sleeve, A plurality of boxes are fixed on the outer circumference of the sleeve; a telescopic rod is connected between the sleeve and the box, and a tension spring is set on the telescopic rod to make the telescopic rod actively shrink; the lower end of the box is open, and the upper end is provided with a feeding port; each Each box is equipped with upper and lower support plates, both of which can move up and down and reset; there is a central hole in the middle of the support plate, and sealing devices are installed on the upper and lower parts of the box respectively. A cloth bag that runs through up and down is installed, the upper end and the lower end of the cloth bag are respectively connected to the upper and lower sealing devices, and the middle part of the cloth bag passes through the upper and lower center holes. The invention twists and squeezes the cloth bag to make the stuffing into a large ball. The shape and size of the filling are not easily damaged, and the moisture inside can be squeezed out.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

A washing machine lifting rib device, a washing machine having the same, and a control method

ActiveCN112899995BReduce eccentric forceStable dehydration processOther washing machinesControl devices for washing apparatusLaundry washing machineControl engineering

The invention provides a lifting rib device for a washing machine, a washing machine having the same, and a control method thereof, wherein the lifting rib device includes a base, a rotating assembly, a telescopic assembly and a lifting rib, and the base is arranged on the inner wall of the inner cylinder of the washing machine; the rotating assembly and the telescopic assembly Under the action, the lifting ribs rotate along the circumferential direction of the inner cylinder and move radially; Clothes position, the weight detection device detects the weight of the clothes in the clothes storage position, and transmits the weight to the washing machine controller, and then the controller controls the movement of the rotating component and telescopic component of the lifting rib device, breaks up the clothes and moves them to the adjacent clothes storage In the position, the weight of clothes in each storage position is similar, avoiding large vibrations caused by uneven distribution of clothes during the dehydration process of the washing machine; the invention has simple structure, high degree of automation, uniform distribution of clothes, and stable operation of the dehydration program of the washing machine.

Owner:GREE ELECTRIC APPLIANCES INC

Vegetable dehydration equipment

ActiveCN113317532BAvoid reabsorptionImprove dehydration efficiencyFood treatmentEngineeringMechanical engineering

The invention relates to a vegetable dehydration equipment, which effectively solves the problem of incomplete dehydration and difficult cleaning of fillings; the technical solution is to include a vertical support rod, the support rod is covered with a rotatable sleeve, and the outer circumference of the sleeve is There are multiple boxes fixed; the lower end of the box is open, and the upper end is provided with a feeding port; each box is equipped with two support plates up and down, both of which can move up and down and reset; the middle of the support plate has a central hole , the upper and lower parts of the box are respectively equipped with sealing devices, and a cloth bag passing through up and down is installed between the upper and lower sealing devices. The center hole; the cloth bag can be twisted and squeezed; the present invention twists and squeezes the stuffing through the cloth bag, making the stuffing into a large ball, and the shape and size of the stuffing is not easy to be damaged.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

Derrick head and derrick device

The invention discloses a derrick head and a derrick device and relates to the technical field of engineering machines. The derrick head and the derrick device aim at solving the problem that eccentric force on a derrick is too large when an iron tower component is lifted and ensuring the stability and the construction safety of the overall derrick. According to the main technical scheme, the derrick head comprises a stand column and pulley set supporting frames, the stand column is of a hollow structure and is installed at the upper end of a derrick body, two through holes which are arranged oppositely are formed in the outer wall of the stand column, the connecting line of the two through holes penetrates through the center of the stand column, and the two through holes are formed in the same horizontal plane. The two pulley set supporting frames are installed on the parts, below the through holes, of the outer wall of the stand column, and pulley assembly installation parts are arranged at the tail ends of the pulley set supporting frames. The invention further discloses the derrick device which comprises the derrick body and the derrick head, and the derrick head is arranged at the top end of the derrick body. The derrick head and the derrick device are mainly used for erecting of high-voltage iron towers and the like in the electric transmission line construction, and stability and the construction safety are good.

Owner:STATE GRID CORP OF CHINA +1

Multi-fold type transmission

The invention discloses a multi-fold type transmission. The transmission comprises a small input gear shaft, a large output gear shaft and at least two paths of change wheels located between the small input gear shaft and the large output gear shaft and used for variable speed transmission. Each path of change wheels at least comprises one first change wheel and two second change wheels connected with the first change wheel. The number of the first change wheels in the multi-fold type transmission is at least twice that of the small input gear shafts, the number of transmission shafts is increased by times, stress, the number of teeth and the modulus of each gear are effectively reduced, and accordingly the size of the transmission is further reduced. Besides, the transmission is more uniform in stress and more stable in use performance. Meanwhile, all transmission is outer tooth transmission, the service life can be prolonged, noise can be reduced, and precision can be improved. Moreover, the multi-fold type transmission does not need a planetary frame, so that the structure is simple, the size and the weight are obviously reduced, machining difficulty is reduced, and the energy-saving effect is remarkable.

Owner:张洲

A thrust surface floating gas static pressure bearing

The invention discloses a gas static pressure bearing with a floating thrust surface. The gas static pressure bearing comprises a bearing body, a bearing lining, a floating thrust surface body and an elastic plate, wherein the bearing body sleeves the bearing lining; one end of the bearing body is connected with one end of the elastic plate in a sealing manner; the other end of the elastic plate is connected with the floating thrust surface body in the sealing manner; the elastic plate and the floating thrust body are connected with one end, in the axial direction, of the bearing body in sequence; a plurality of gas holes which are communicated in a matched manner are formed in the bearing body, the elastic plate and the floating thrust body; the elastic plate is made of an elastic material. According to the technical scheme, the thrust surface is changed to be in a floating type structure, so that a gas film clearance between the gas bearing and a shaft body is uniform, eccentric force of the bearing is reduced, and the axial bearing capacity of the gas bearing is greatly improved; and therefore, the gas bearing can be used for bearing a high axial load and achieving the high flow and the high rotating speed.

Owner:SHANGHAI QIYUAN GAS DEV

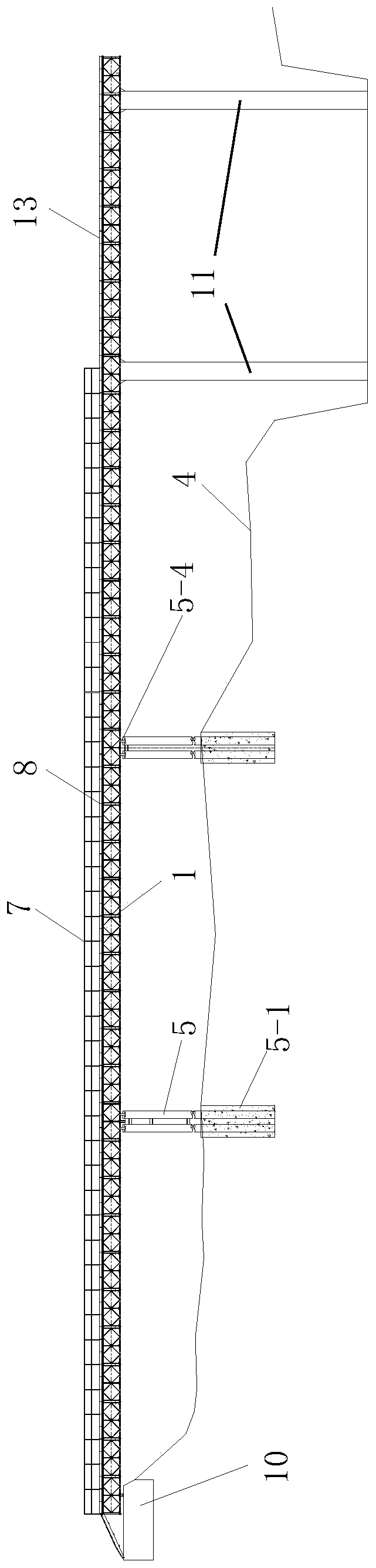

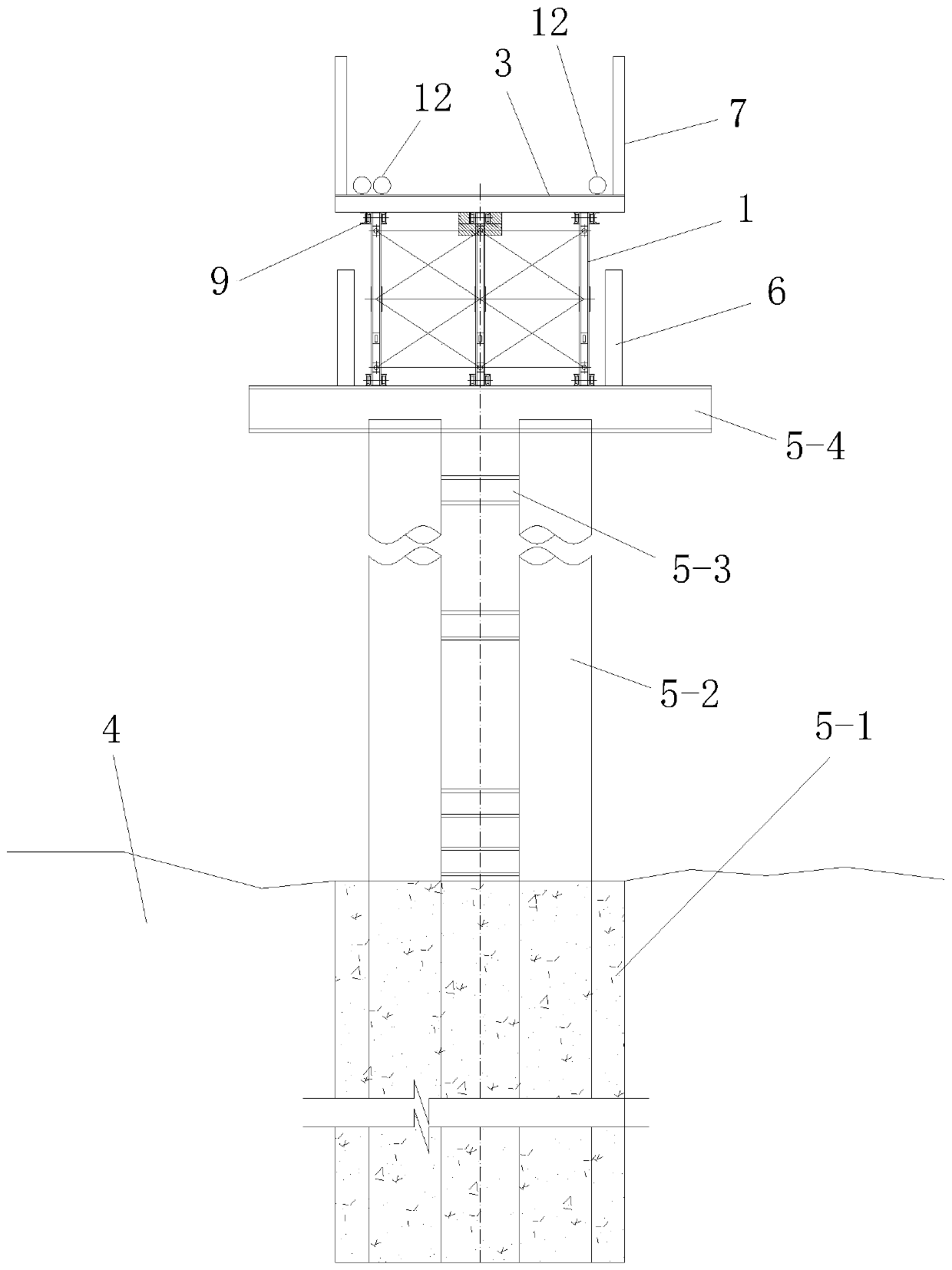

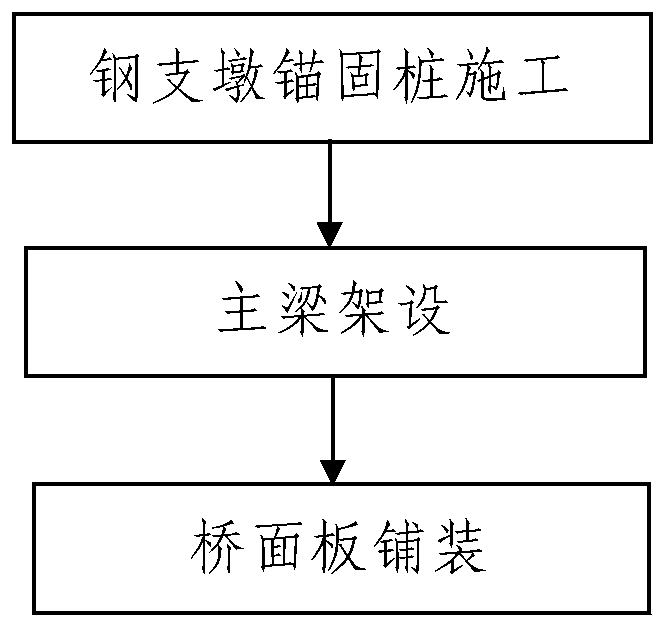

Hard rock and bare rock river bed trestle for deep water high pier and long span bridge construction and construction method

ActiveCN107700366BStrong resistance to flood impactConstruction quality is easy to controlBridge structural detailsBridge erection/assemblyBridge deckCofferdam

Owner:NO 1 ENG LIMITED OF CR20G

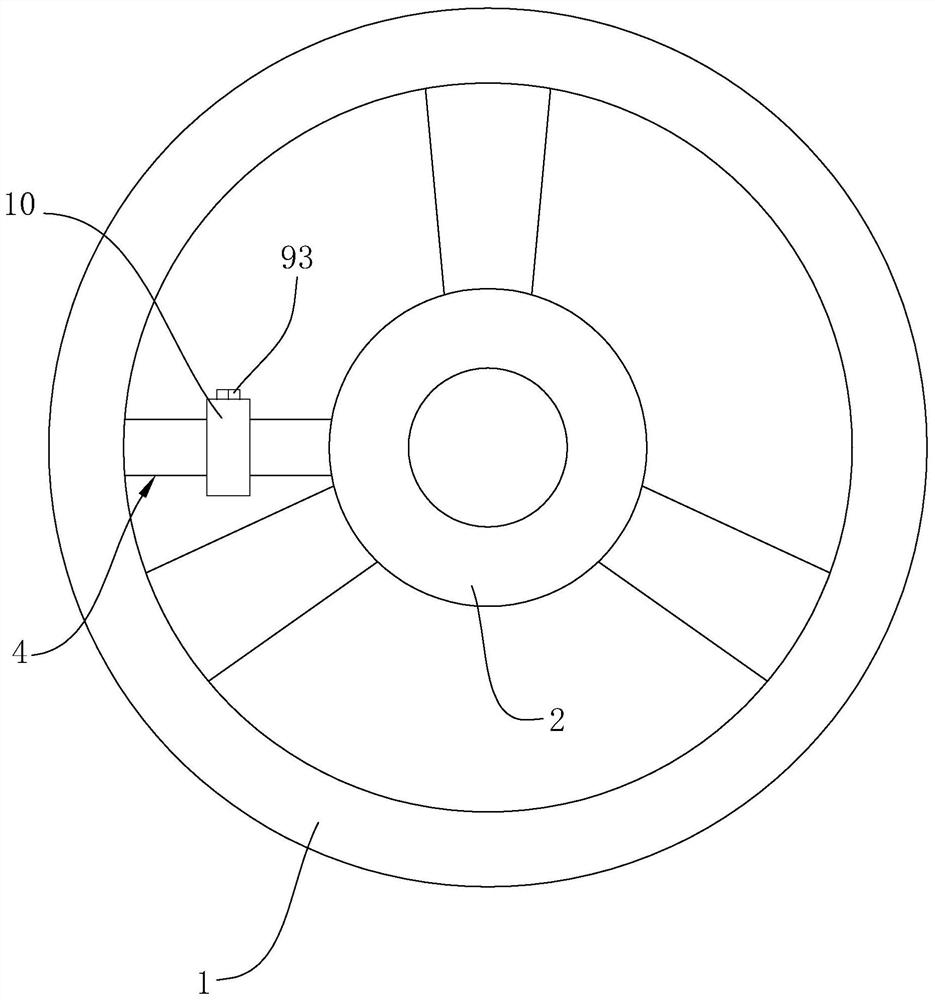

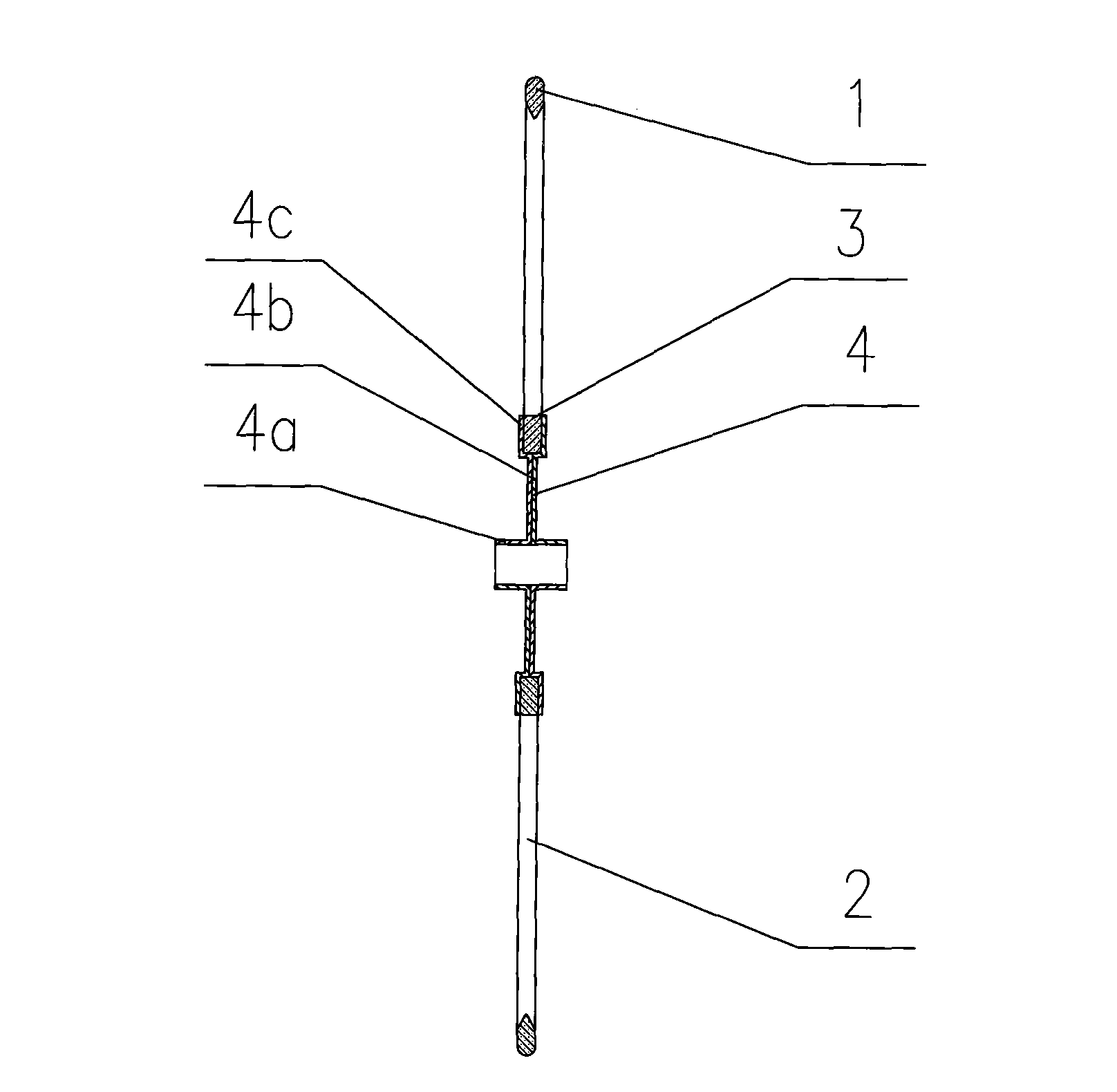

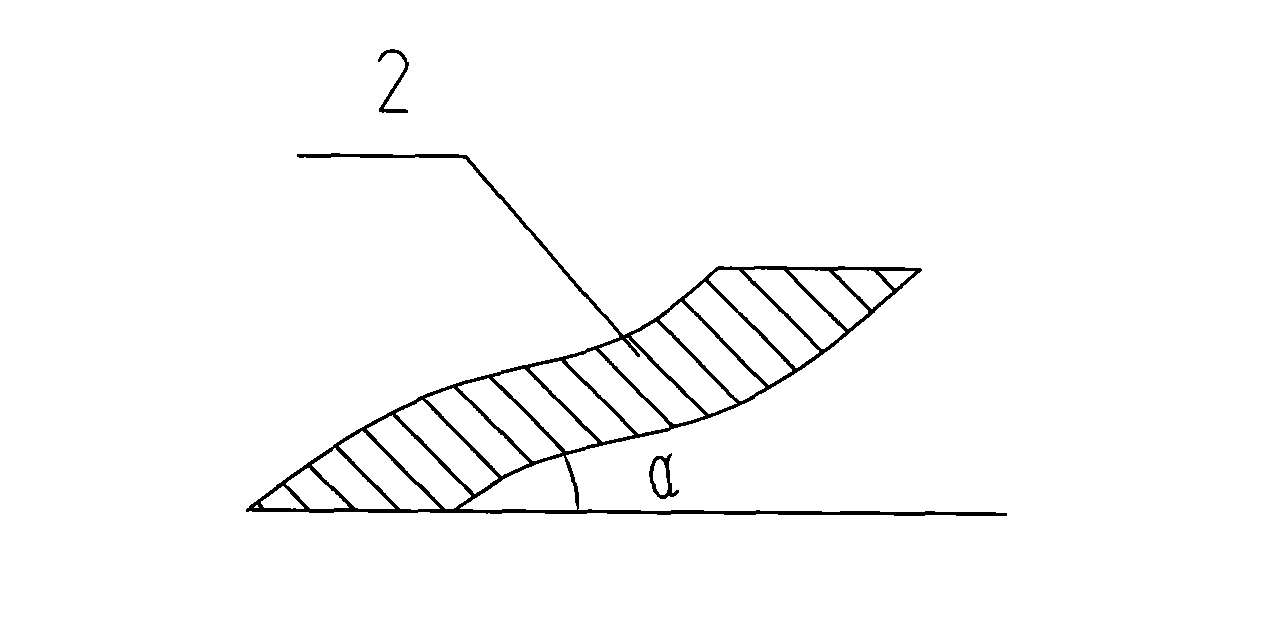

A kind of electric vehicle wheel hub assembly structure

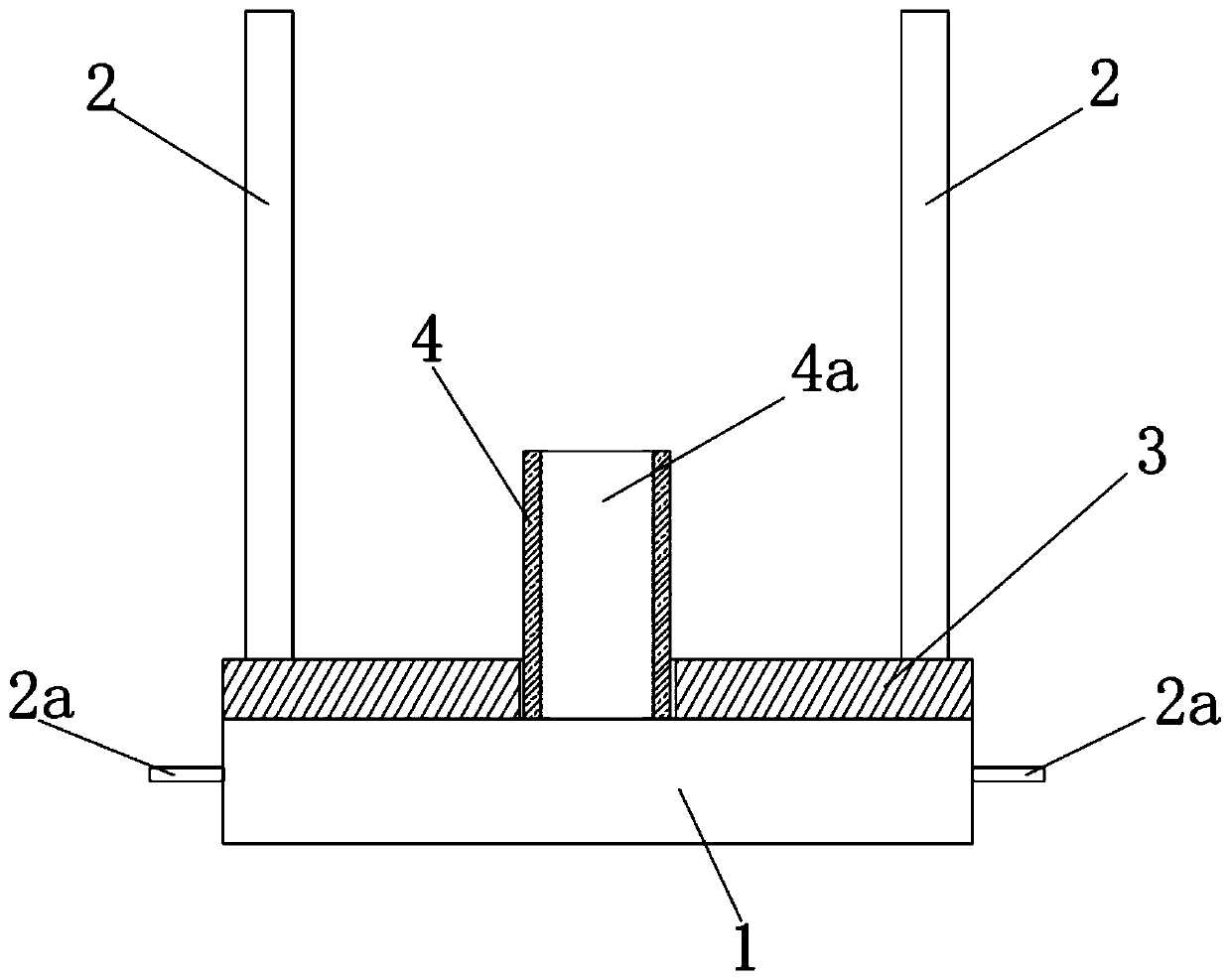

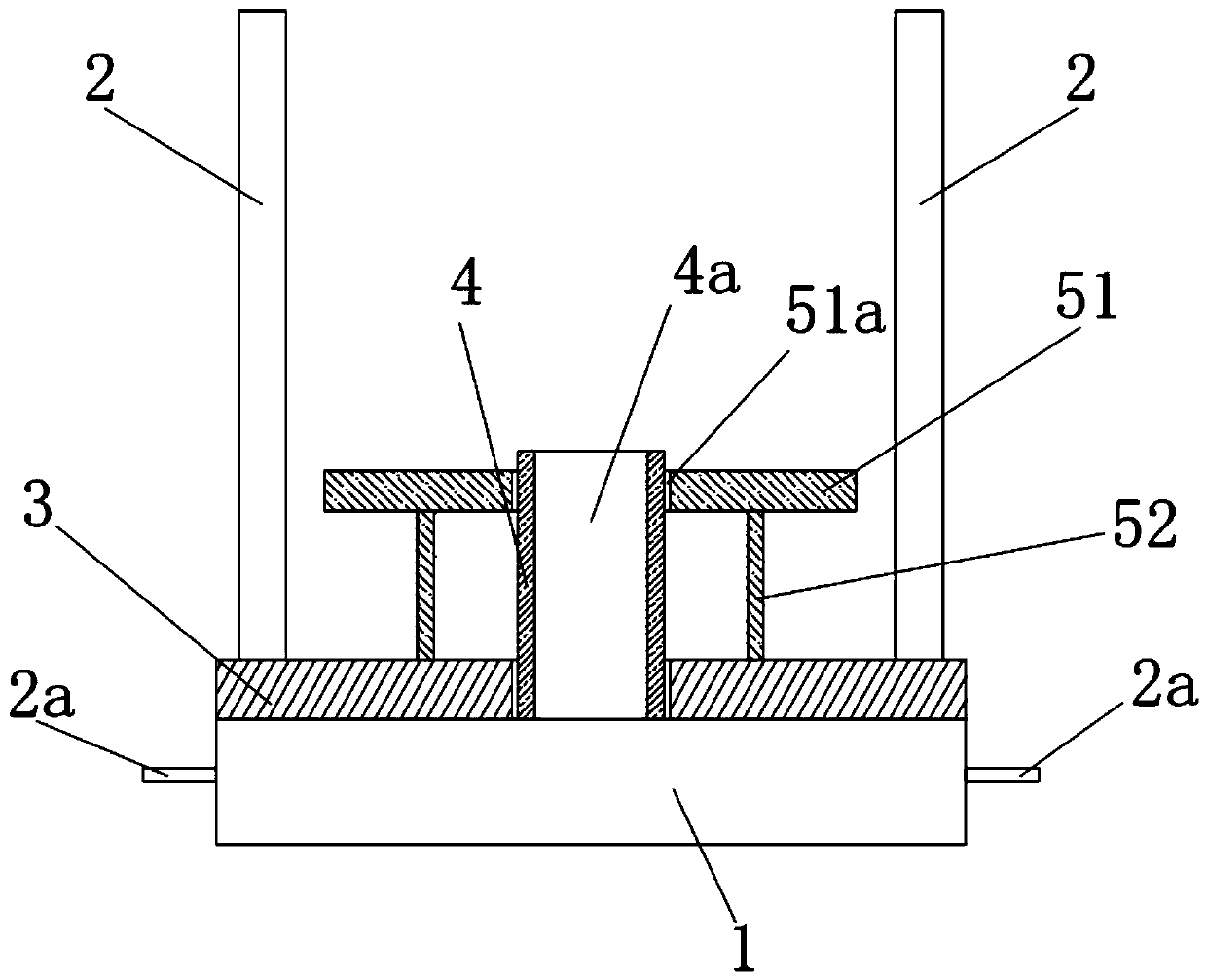

ActiveCN112590454BEasy to adjustReduce eccentric forceWheel-ballasting weightsClassical mechanicsElectric cars

The invention relates to an assembly structure of an electric vehicle wheel hub, comprising a coaxial outer hub 1 and an inner hub 2, spokes are fixed at intervals in the circumferential direction between the outer hub 1 and the inner hub 2, and at the same time, there is a coaxial opening on the inner side of the outer hub 1. The outer slideway 11 is coaxially provided with an inner slideway 21 on the outer side of the inner hub 2, and a slider one 12 is embedded in the outer slideway 11, and a slider two 22 is embedded in the inner slideway 21. A connecting rod assembly 4 is installed between 12 and the second slider 22, the length of the connecting rod assembly 4 can be adjusted in the radial direction of the wheel hub, and a counterweight ring 10 is sleeved on the connecting rod assembly 4, and the counterweight ring 10 is along the The length direction of the connecting rod assembly 4 is slid or fixed, wherein the first slider 12 and the second slider 22 can adopt a block structure, wherein the weight ring can be adjusted around the center of the wheel hub and moved radially, so as to facilitate adjustment and reduce eccentricity force, saving time and manpower.

Owner:XUZHOU XIAOQIANG WHEEL TECH CO LTD

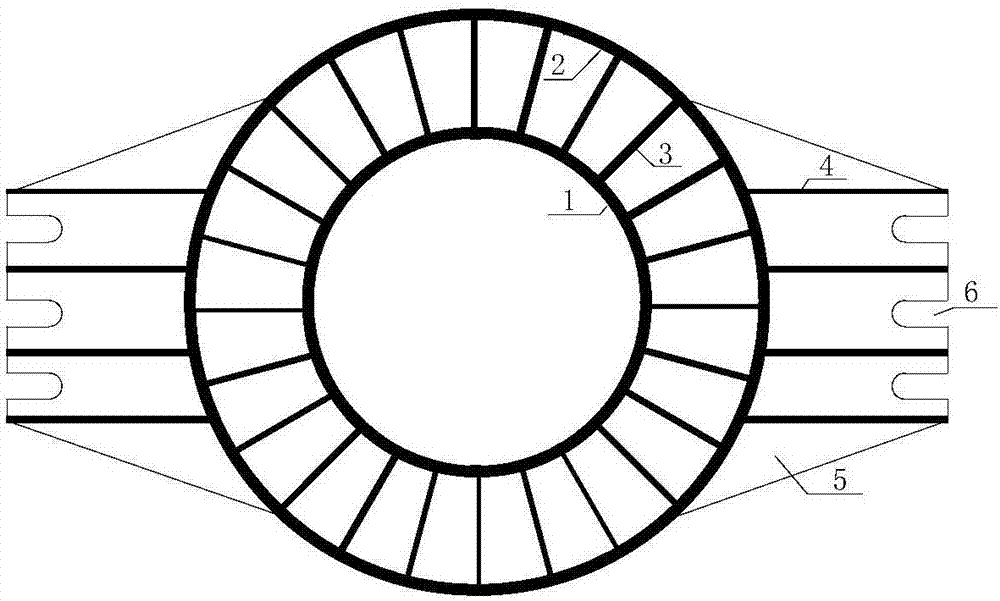

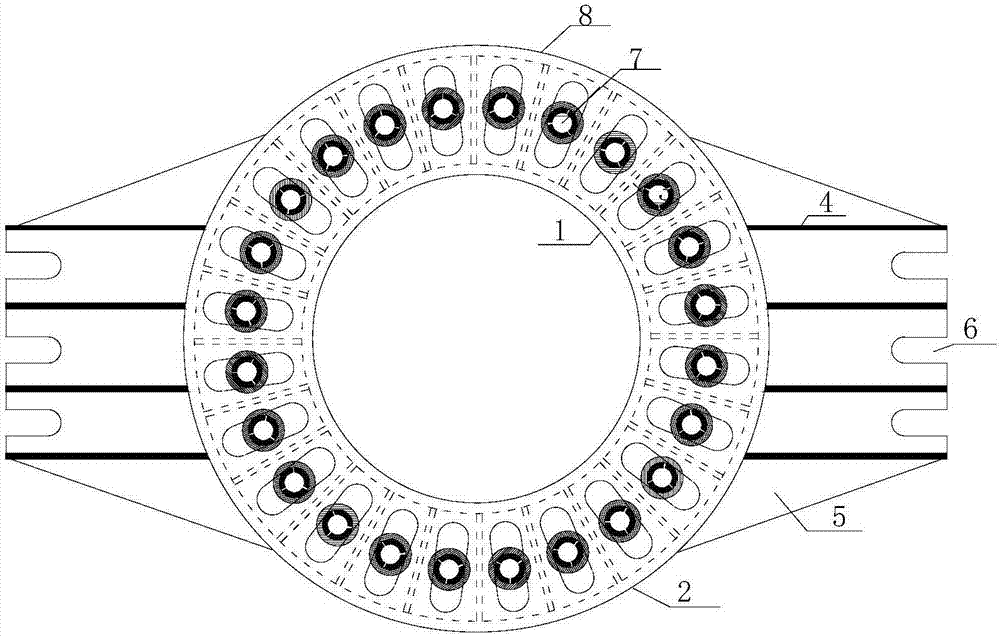

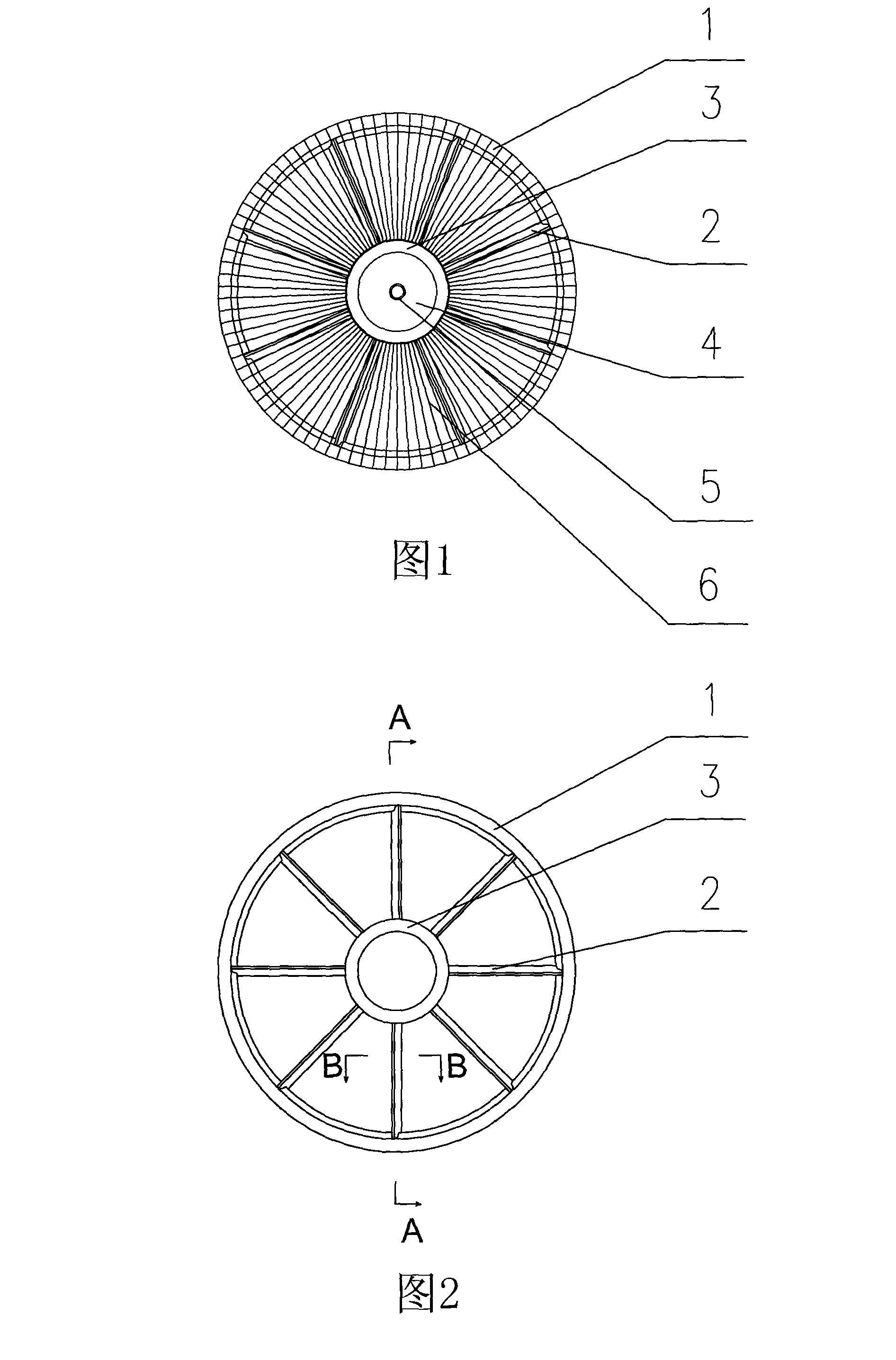

Radial radiation-type rotational filter screen disc and preparation method thereof

ActiveCN101554552BImproved filter structureLower tension coefficientDispersed particle separationBalance performanceMechanical engineering

The invention provides a radial radiation-type rotational filter screen disc and a preparation method thereof. The radial radiation-type rotational filter screen disc comprises an internal rim and an external rim; a radial radiation-type filter screen which is uniformly distributed along the circumference and formed by winding a filter screen wire is arranged between the internal rim and the external rim; two axes center pressing covers are fixedly buckled to the positive surface and the reverse surface of the internal rim; and the center of the axes center pressing cover is provided with a shaft sleeve matched with the output shaft of a motor. The preparation method comprises the following steps of: firstly fixing the front end of the filter screen wire on the internal rim and leading thefront end to attach to the positive surface of the internal rim closely and enwind at the corresponding radial points of the external rim; subsequently leading the front end to closely attach to thereverse surface of the external rim, return in original route and enwind at the adjacent points of the internal rim; rotating the external rim by an angle; subsequently leading the filter screen wireto attach to the positive surface of the internal rim and enwind at another radial corresponding point of the external rim; repeatedly carrying out the above operations till all filter screen wires are uniformly weaved by one ring; and subsequently fixing the tail end of the filter screen wire on the external rim and finally using the two axes center pressing covers to clamp the internal rim fromthe positive surface and the reverse surface. The method has the advantages of good running stability and balance performance, high efficiency of intercepting dust and granules and long service life.

Owner:武汉创新环保工程有限公司

Vibration damping device for laundry treatment equipment and laundry treatment equipment

ActiveCN109423827BReduce vibrationReduce vibration amplitudeOther washing machinesTextiles and paperLaundry washing machineProcess engineering

Owner:CHONGQING HAIER WASHING MASCH CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com