A washing machine lifting rib device, a washing machine having the same, and a control method

A technology for lifting ribs and washing machines, which is applied in the control device, washing device, other washing machines and other directions of washing machines, can solve the problems of poor vibration reduction effect of the inner cylinder and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0058]

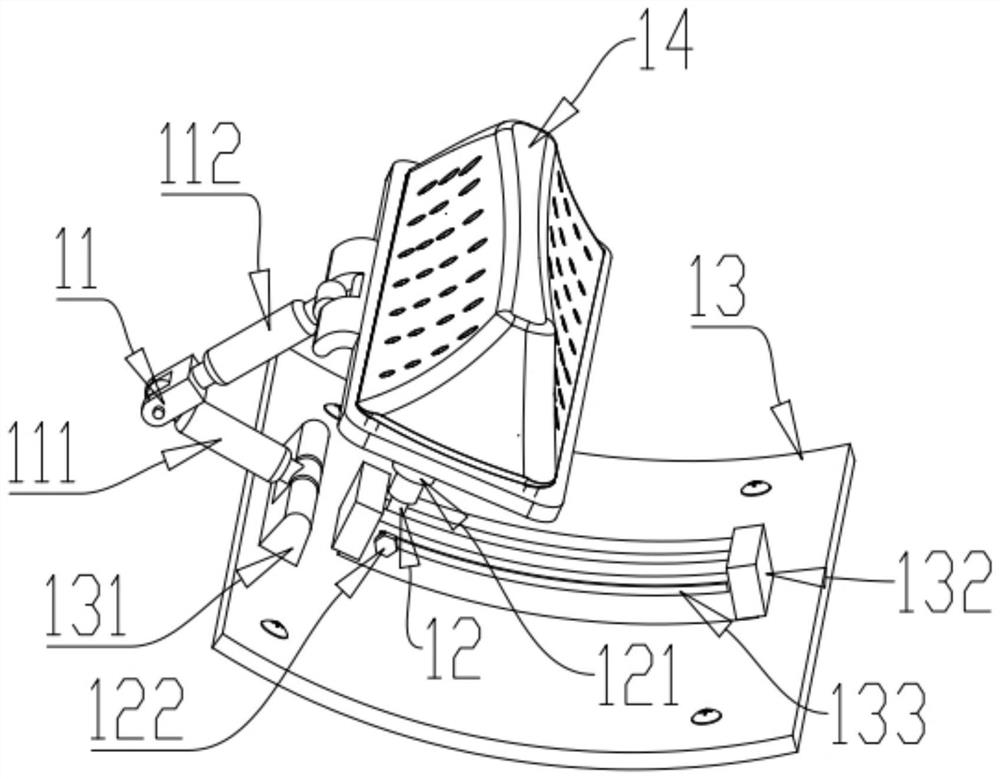

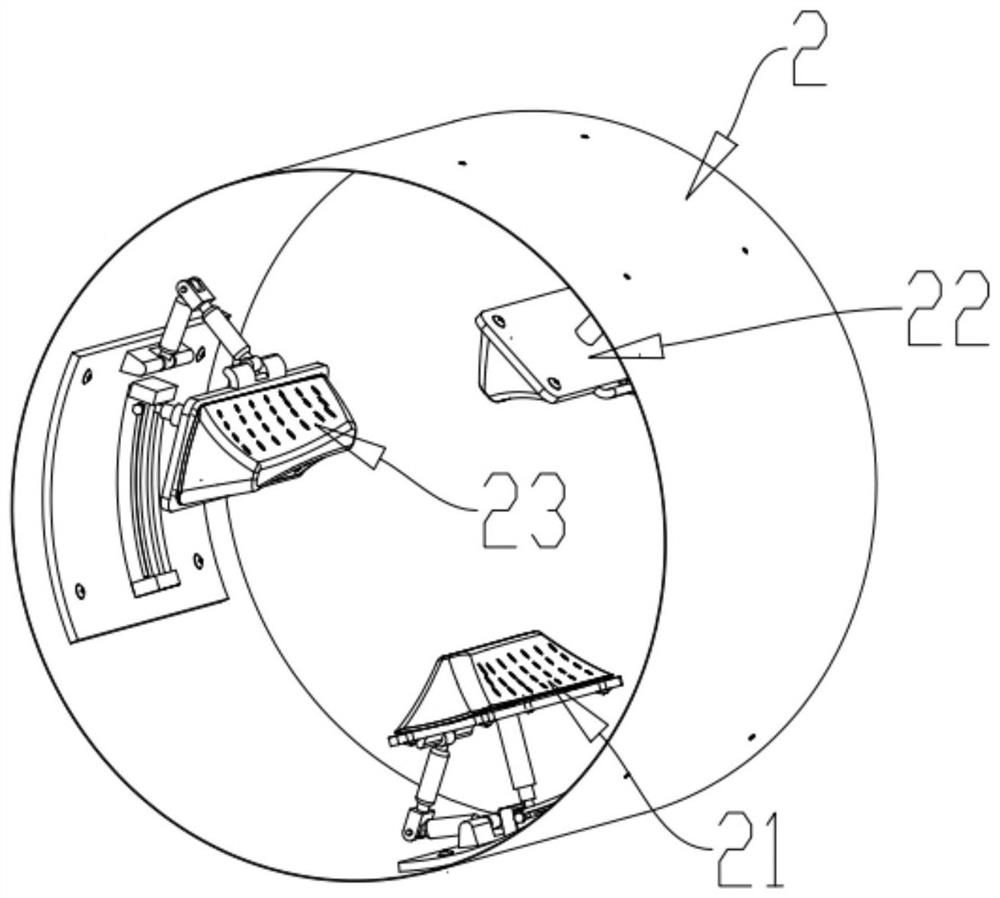

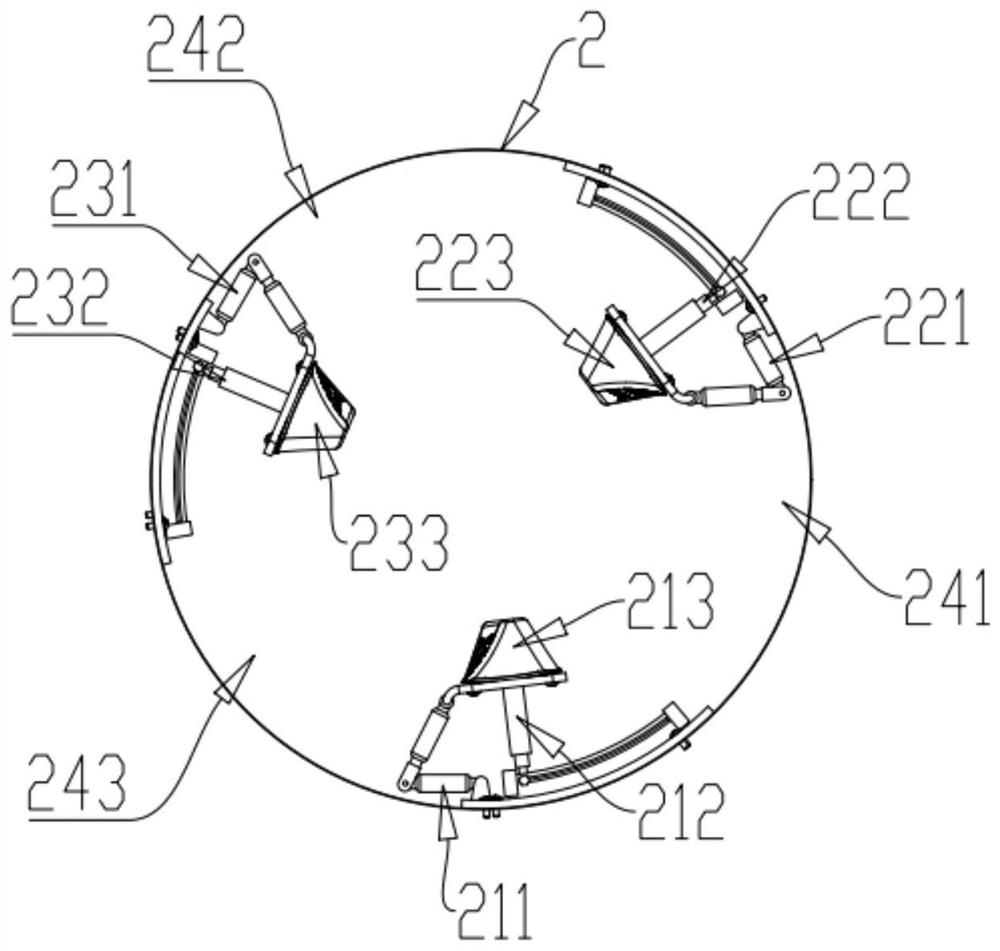

[0059] Such as figure 1 As shown, the present embodiment provides a lifting rib device for a washing machine. The washing machine has an inner cylinder 2; the lifting rib device is arranged on the inner wall of the inner cylinder 2, and includes a driving assembly and a lifting rib 14; The other end is drivingly connected with the lifting rib 14; under the action of the driving assembly, the lifting rib 14 can rotate along the circumferential direction of the inner cylinder 2 and move radially.

[0060] Preferably, the driving assembly includes a rotating assembly 11 and a telescopic assembly 12; the rotating assembly 11 is used to adjust the position of the lifting rib 14 along the circumferential direction of the inner cylinder 2, and the telescopic assembly 12 is used to adjust the position of the lifting rib 14 along the radial direction of the inner cylinder 2.

[0061] Preferably, the drive assembly also has a base 13, the base 13 is arranged on the inner wall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com