Radial radiation-type rotational filter screen disc and preparation method thereof

A technology of rotating filter discs and manufacturing methods, which is applied in separation methods, chemical instruments and methods, and separation of dispersed particles. Problems such as accumulation and blockage of fine dust particles, pressure loss and large power consumption can be achieved to avoid blockage of fine dust particles, maintain a good balance state, and reduce the tension coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below in conjunction with accompanying drawing and a preferred embodiment the present invention is described in further detail:

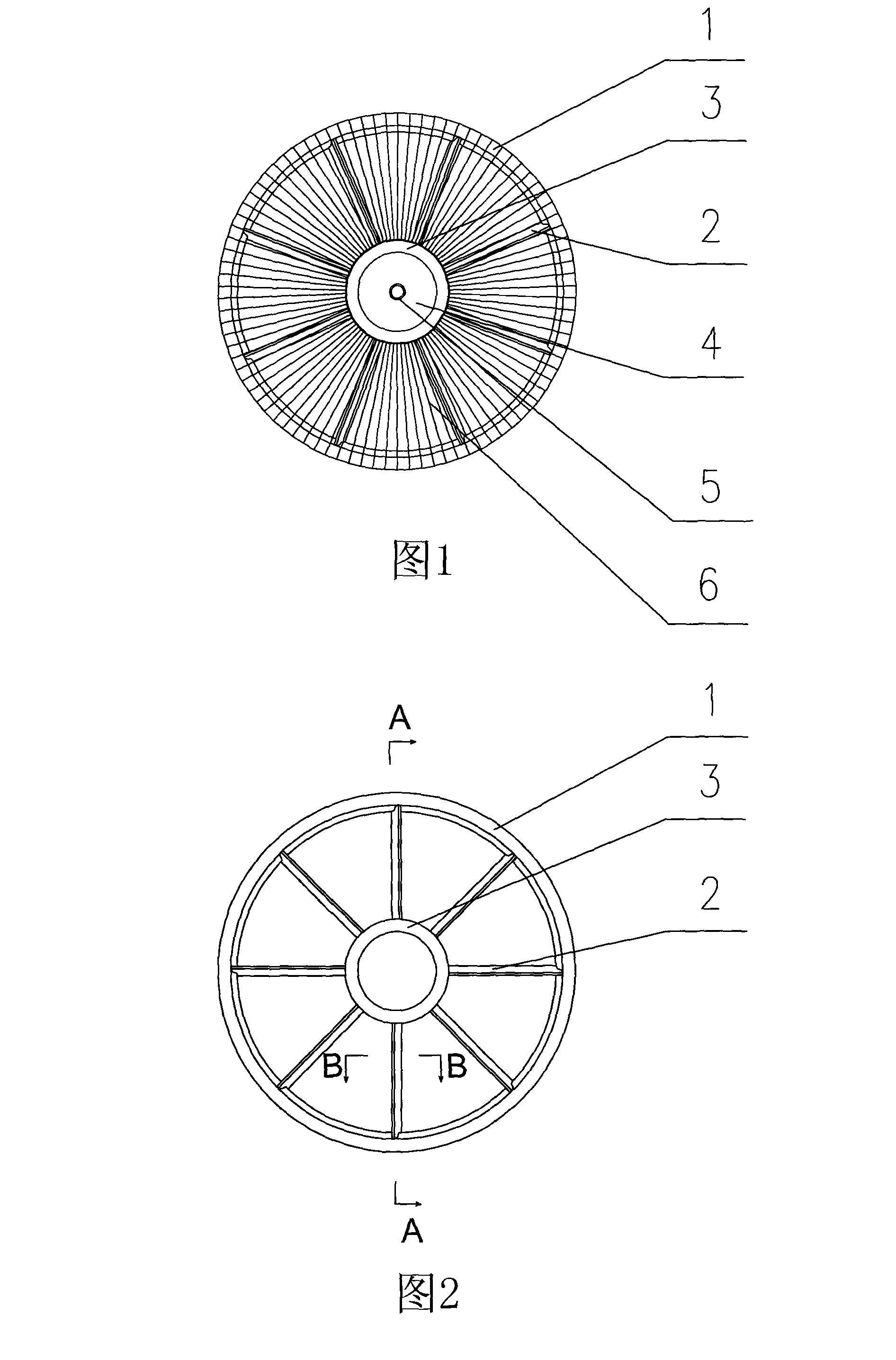

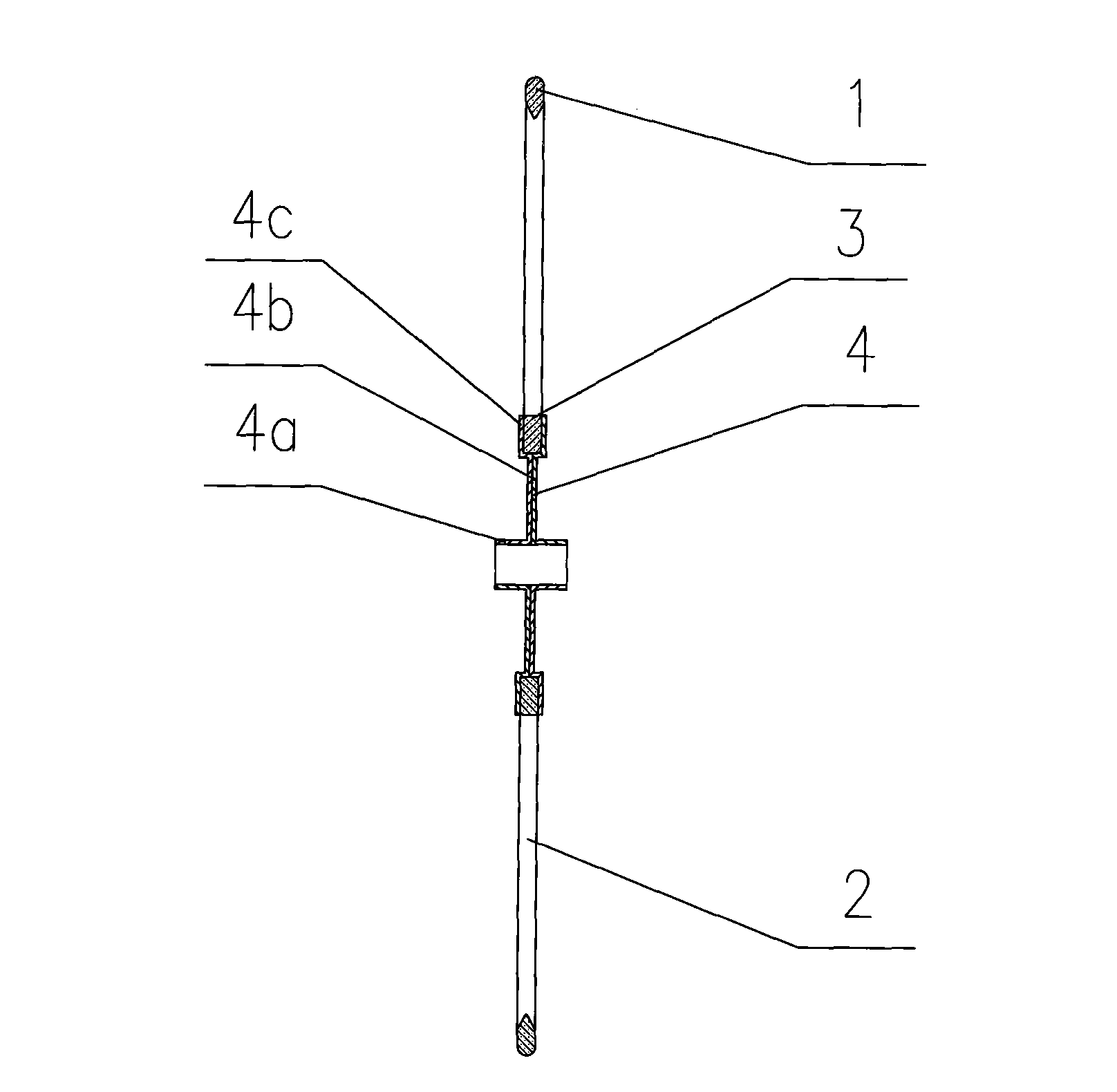

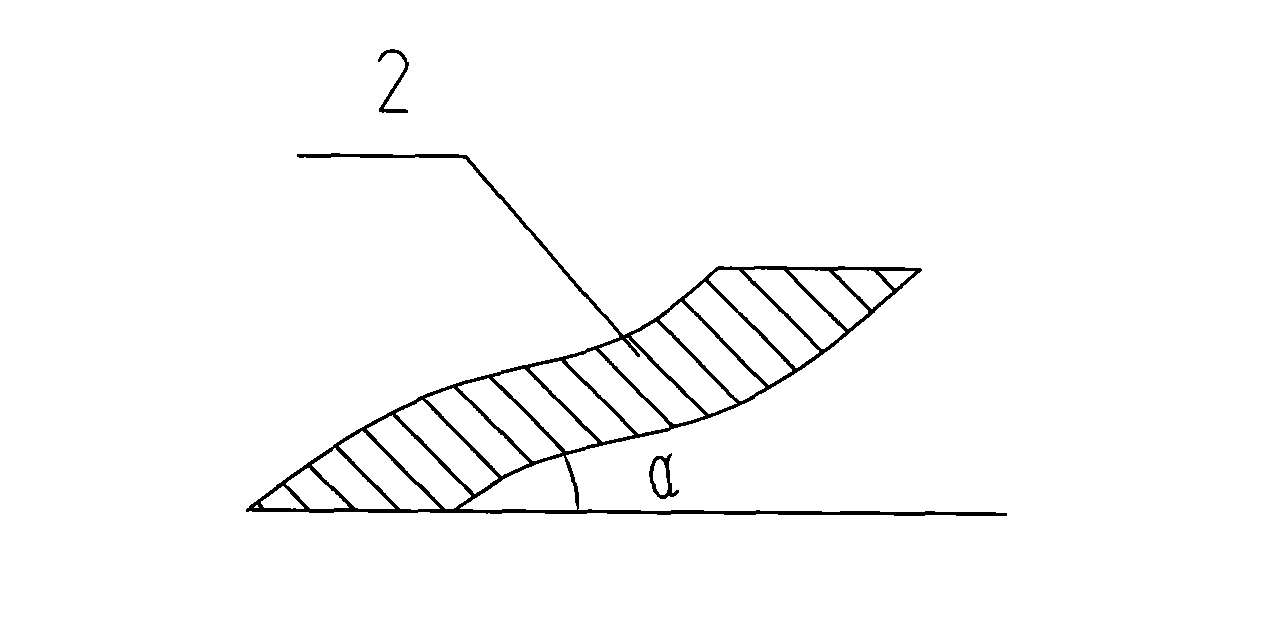

[0035] Such as Figure 1 to Figure 4 As shown, the radial radial rotating filter disc of the present invention has an outer rim 1 and an inner rim 3, and the outer rim 1 and the inner rim 3 are connected by eight uniformly arranged radial support ribs 2. The cross-section of the support rib 2 is wavy, and the wavy cross-section is inclined relative to the disk plane of the outer rim 1 and the inner rim 3. The inclination angle is generally α=20-35°, and the best inclination angle α= 25-28°, which can not only produce a certain draft and drainage effect, effectively reduce wind resistance and energy consumption, but also prevent dust particles from adhering and accumulating, and ensure the balance and stability of the filter plate.

[0036] The annular area between the outer rim 1 and the inner rim 3 is a radial radial filter mesh uniformly d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com