High-frequency raising needling machine

A cashmere needle and high-frequency technology, which is applied in the field of high-frequency cashmere needlelooms, can solve the problems of heavy rotating mass, restriction of acupuncture frequency of acupuncture mechanism, large reciprocating inertial force of work, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

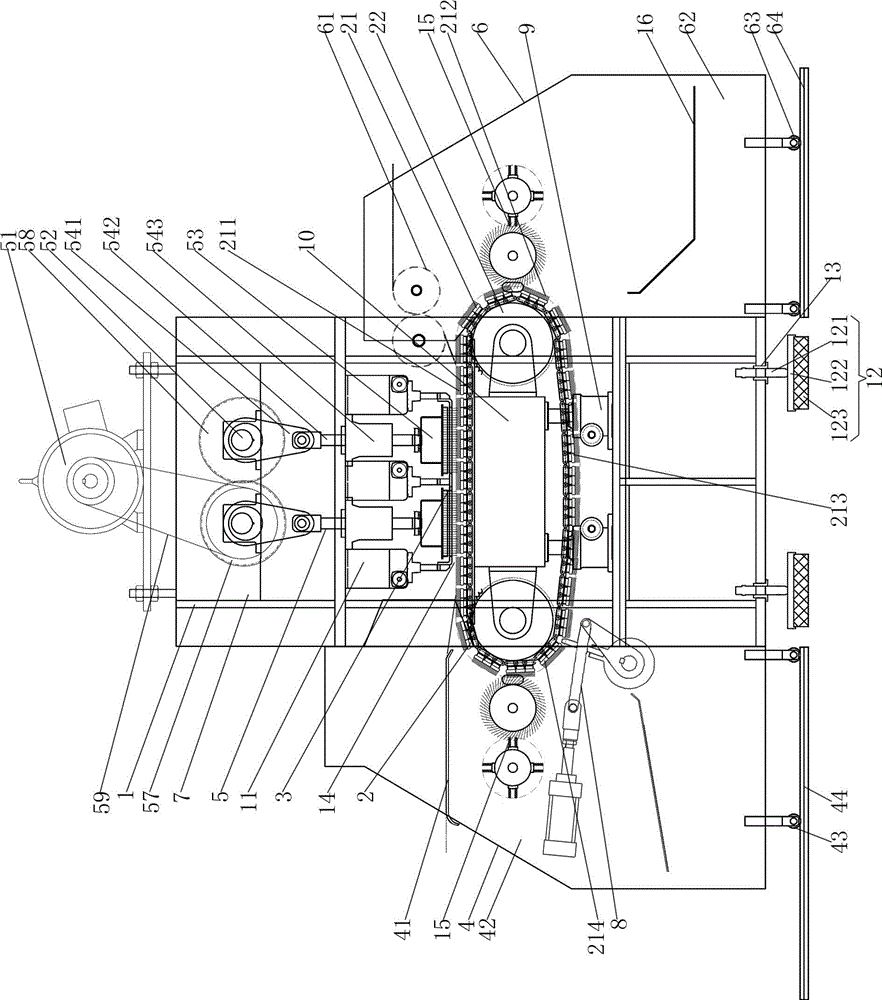

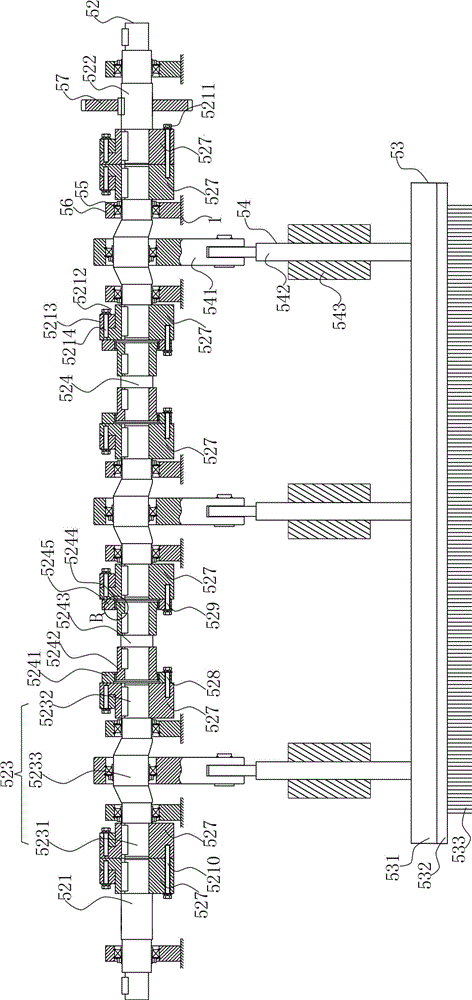

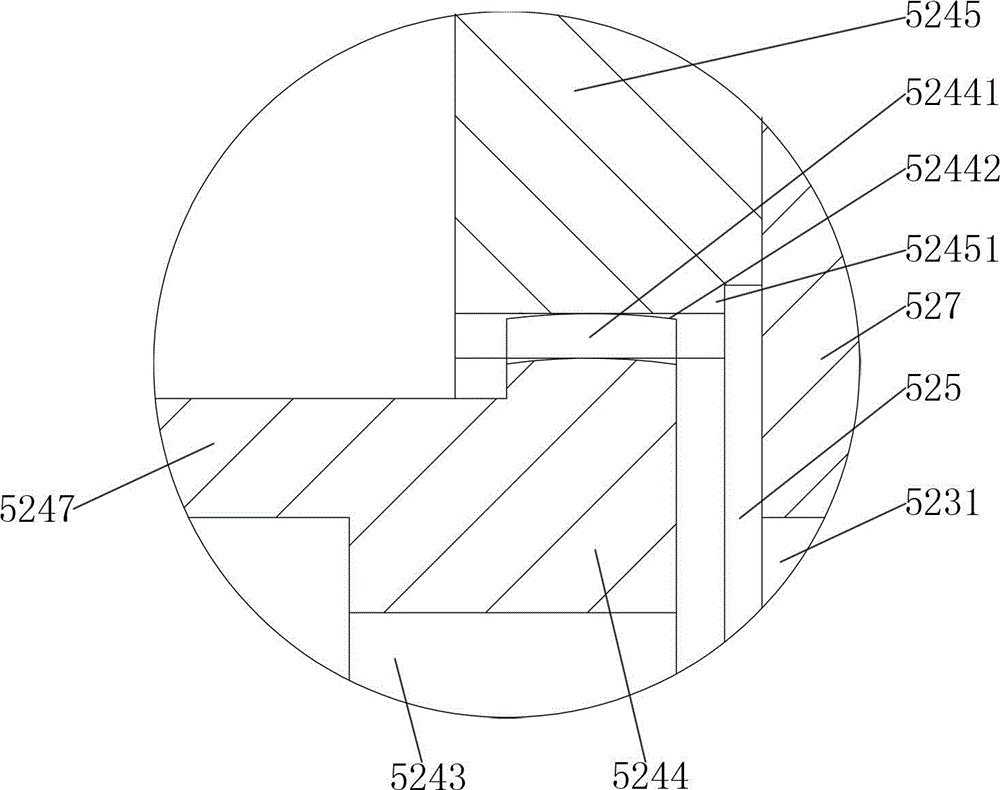

[0049] Such as figure 1 As shown, this high-frequency fleece needling machine includes a frame 1, a feeding mechanism 4, a brush ring curtain 2, a stripping board 3, an acupuncture mechanism 5 and a pulling mechanism 6, and the stripping board 3 is in the Above the brush ring curtain 2, the acupuncture mechanism 5 is located above the mesh stripping plate 3, the feeding mechanism 4 is arranged in front of the acupuncture mechanism 5, and the pulling mechanism 6 is arranged behind the acupuncture mechanism 5.

[0050] The brush ring curtain 2 includes an annular brush curtain 21 formed by connecting a plurality of brushes in sequence, and two sprockets 22 arranged on the inner side of the annular brush curtain 21 and jointly tensioning the annular brush curtain 21, wherein A sprocket 22 is transmission connected with a brush curtain driving device. Driven by the brush curtain driving device, the annular brush curtain 21 runs continuously. The ring-shaped brush curtain 21 incl...

Embodiment 2

[0077] Such as Figure 7 As shown, the main differences between this embodiment and Embodiment 1 are: (1) four sprockets 22 that jointly tension the annular brush curtain 21 are provided on the inner side of the annular brush curtain 21; (2) there is no Brush cleaning device 8. Refer to Embodiment 1 for the rest of the structure of this embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com