Eccentric connecting component and needling machine with same

A technology of connecting components and eccentricity, which is used in acupuncture machines, mechanical equipment, rolling contact bearings, etc., can solve the problem that the machining accuracy, rigidity and positioning accuracy of acupuncture machines cannot reach the ideal effect, and the needling frequency only reaches 1000- 1200/min and other problems, to achieve the effect of increasing the frequency of acupuncture, avoiding the loss of clearance and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings, wherein the "front" in this specification refers to the attached Figure 4 on the left side, correspondingly, the "rear" side mentioned in the instructions refers to the attached Figure 4 on the right side of the .

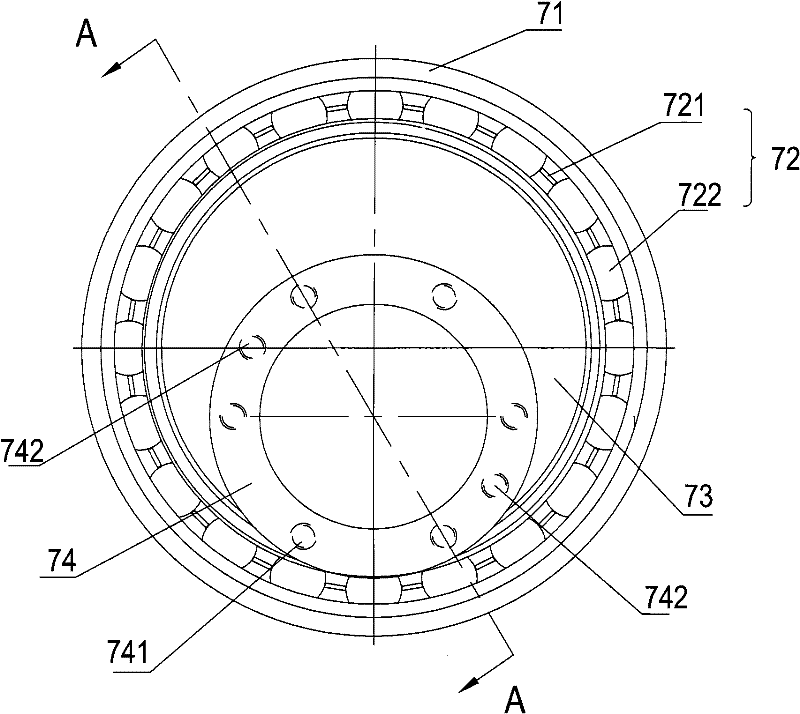

[0027] The invention discloses an eccentric connection assembly, see the attached image 3 And attached Figure 4 As shown, it includes: an outer ring 71, an inner ring 73 coaxially rotated inside the outer ring 71, a rolling member 72 arranged between the outer ring 71 and the inner ring 73, the rolling The member 72 includes a cage 721 and a plurality of rolling elements 722 rotatably connected to the cage 721 . The inner ring 73 is provided with a tapered hole at a place deviated from the axis. The tapered hole extends from the rear end of the inner ring 72 to the front end, and the diameter gradually becomes smaller. The tapered hole is provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com