High Frequency Alignment Stimulation Machine

It is a high-frequency alignment technology, which is applied in the field of high-frequency alignment alignment, and can solve problems such as large reciprocating inertial force, large vibration excitation, and large eccentric wheel size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

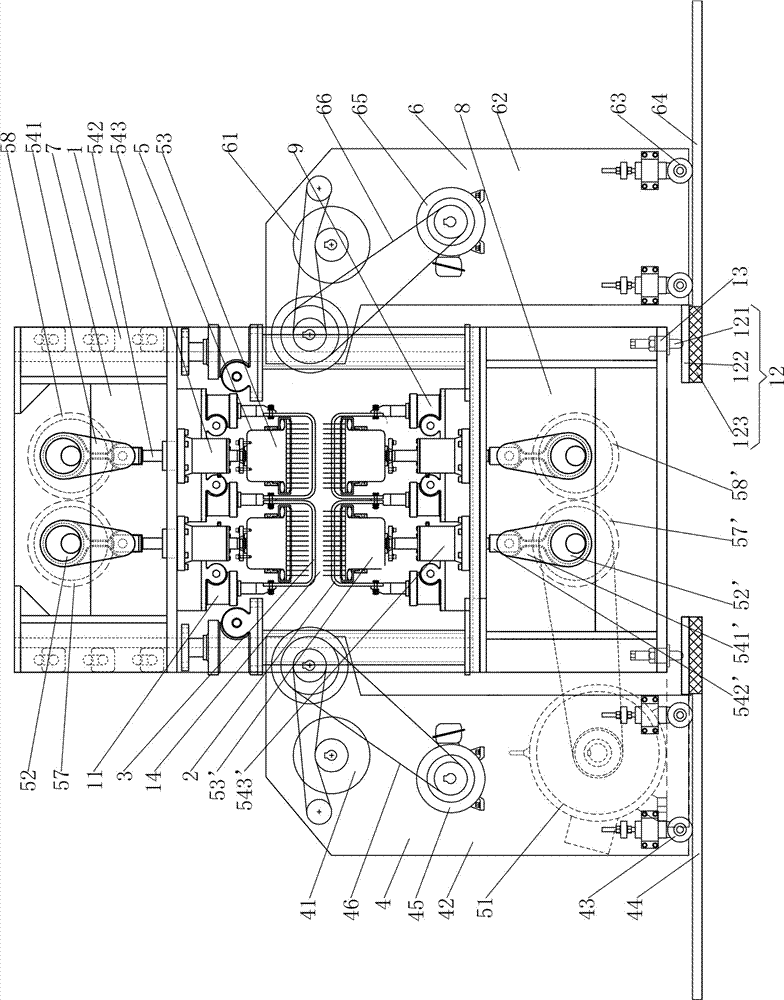

[0040] like figure 1 As shown, this high-frequency co-located punching machine includes a frame 1, a mesh feeding mechanism 4, a lower stripping mesh plate 2, an upper stripping mesh plate 3, a needle punching mechanism 5 and a pulling mechanism 6; the upper stripping mesh plate 3 is located at the bottom Above the screen stripping plate 2; the acupuncture mechanism 5 includes a needling driving device, an upper acupuncture mechanism and a lower acupuncture mechanism, the upper acupuncture mechanism is located above the upper stripping screen plate 3, and the lower acupuncture mechanism is located below the lower stripping screen plate 2 ; The net feeding mechanism 4 is located in front of the acupuncture mechanism 5, and the pulling mechanism 6 is located in the rear of the acupuncture mechanism 5.

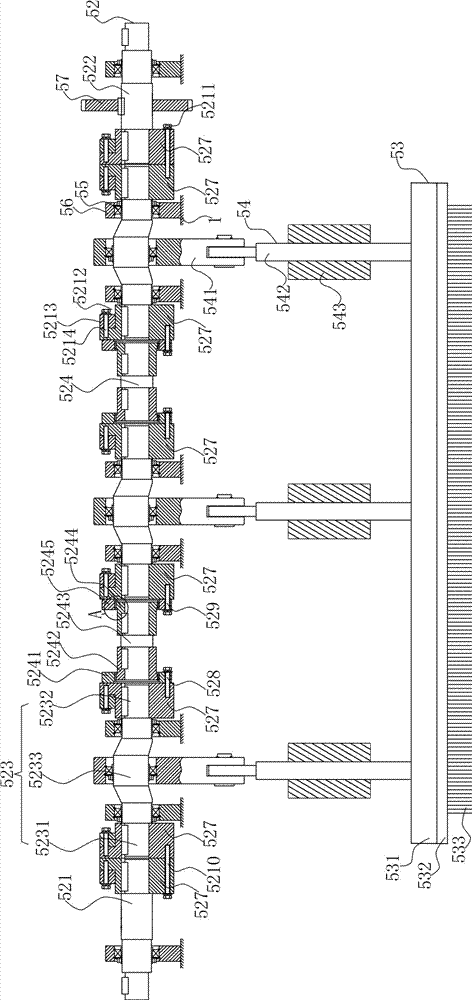

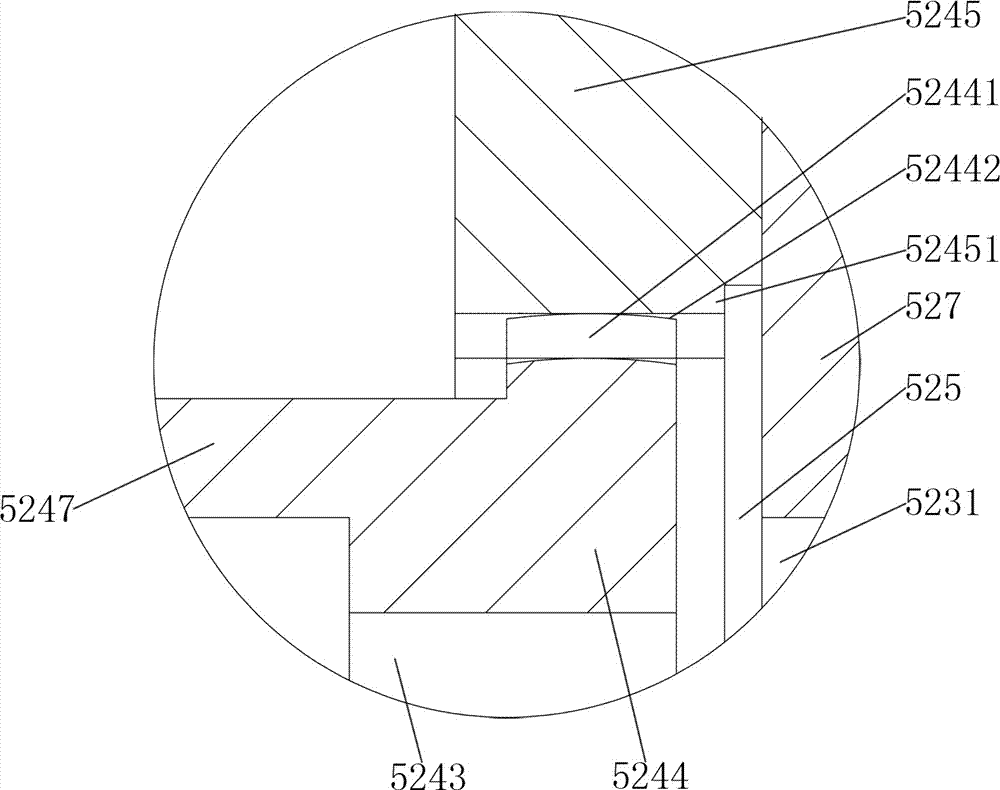

[0041] like figure 1 and figure 2As shown, the upper acupuncture mechanism includes two upper drive shaft assemblies 52 side by side and two upper needle assemblies 53 side by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com