Net supporting and stripping device of needling machine

A technology of needle punching machine and stripping screen, which is applied in the field of needle punching machine, and can solve problems such as complex structure of the whole machine, vibration of the lifting and lowering adjustment mechanism of the supporting bed, and large installation space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

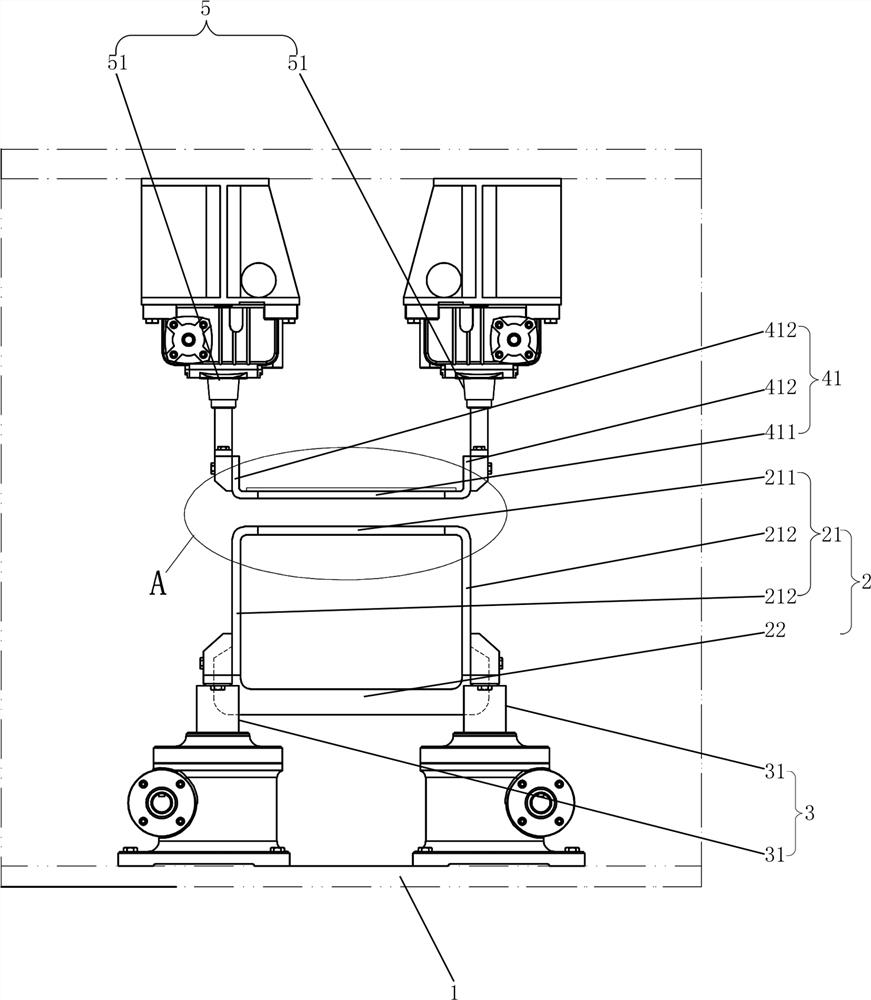

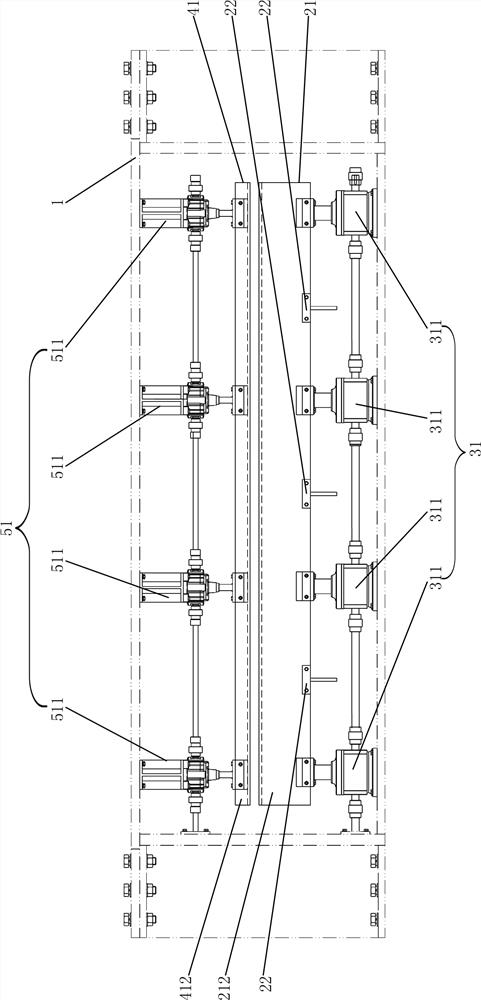

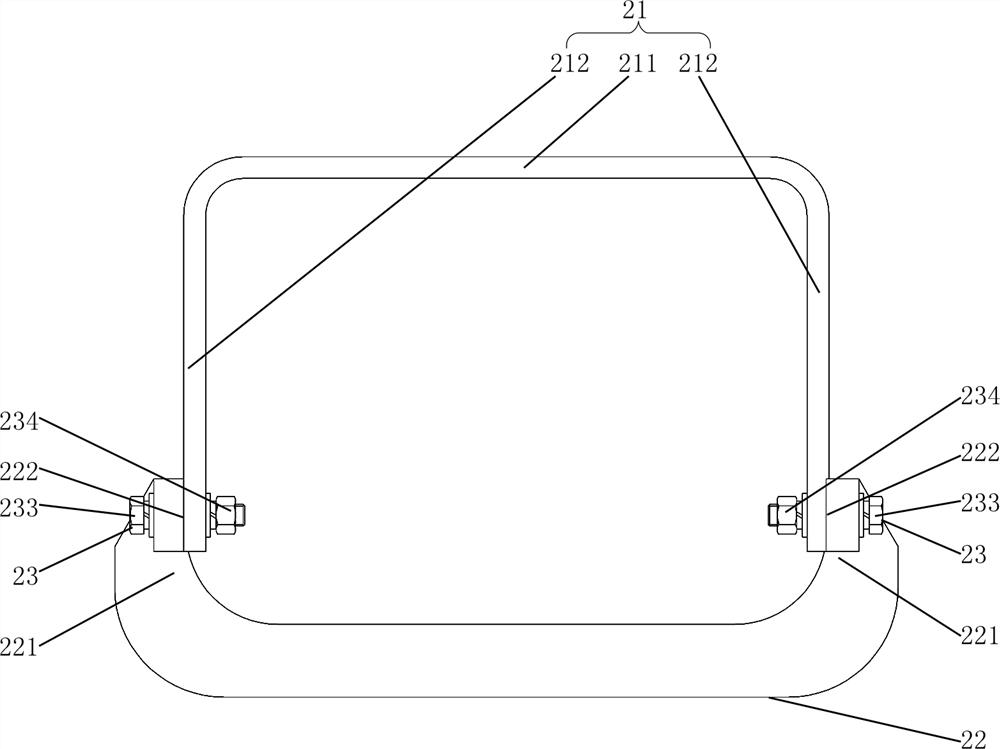

[0025] like Figure 1-Figure 4 As shown, the supporting net stripping device of this acupuncture machine includes a frame 1, a supporting net board 2, a net supporting board lifting mechanism 3, a net stripping board 4 and a net stripping board lifting mechanism 5, a net supporting board lifting mechanism 3, a stripping net board lifting mechanism The net lifting mechanism 5 is installed on the frame 1, and the stripping net plate 4 is arranged on the top of the net support plate 2; the net support plate 2 includes a first U-shaped plate 21 and at least one reinforcing frame 22, and the first U-shaped plate 21 includes a first horizontal plate 211 and two first vertical plates 212, the first horizontal plate 211 is provided with a plurality of first needle through holes (not shown in the figure), and the upper edges of the two first vertical plates 212 are respectively It is connected with the left edge and the right edge of the first horizontal plate 211, and the two first ve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com