Transmission balance mechanism of needling machine

A technology of balancing mechanism and acupuncture machine, applied in acupuncture machine, textile and papermaking, non-woven fabric, etc., can solve the problems of unsuitable structure, limitation, machine can not work normally, etc., to increase the frequency of acupuncture and improve the efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

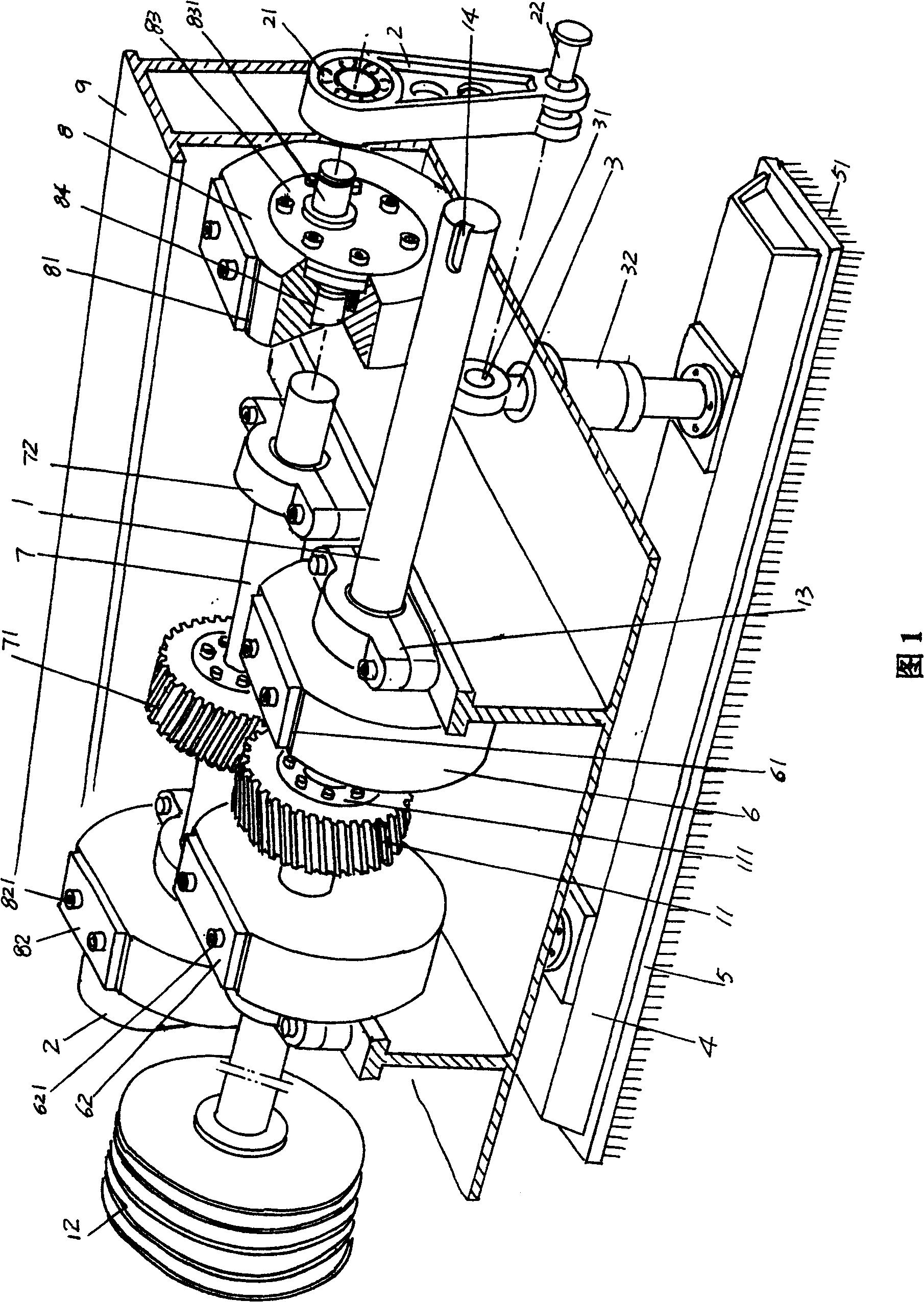

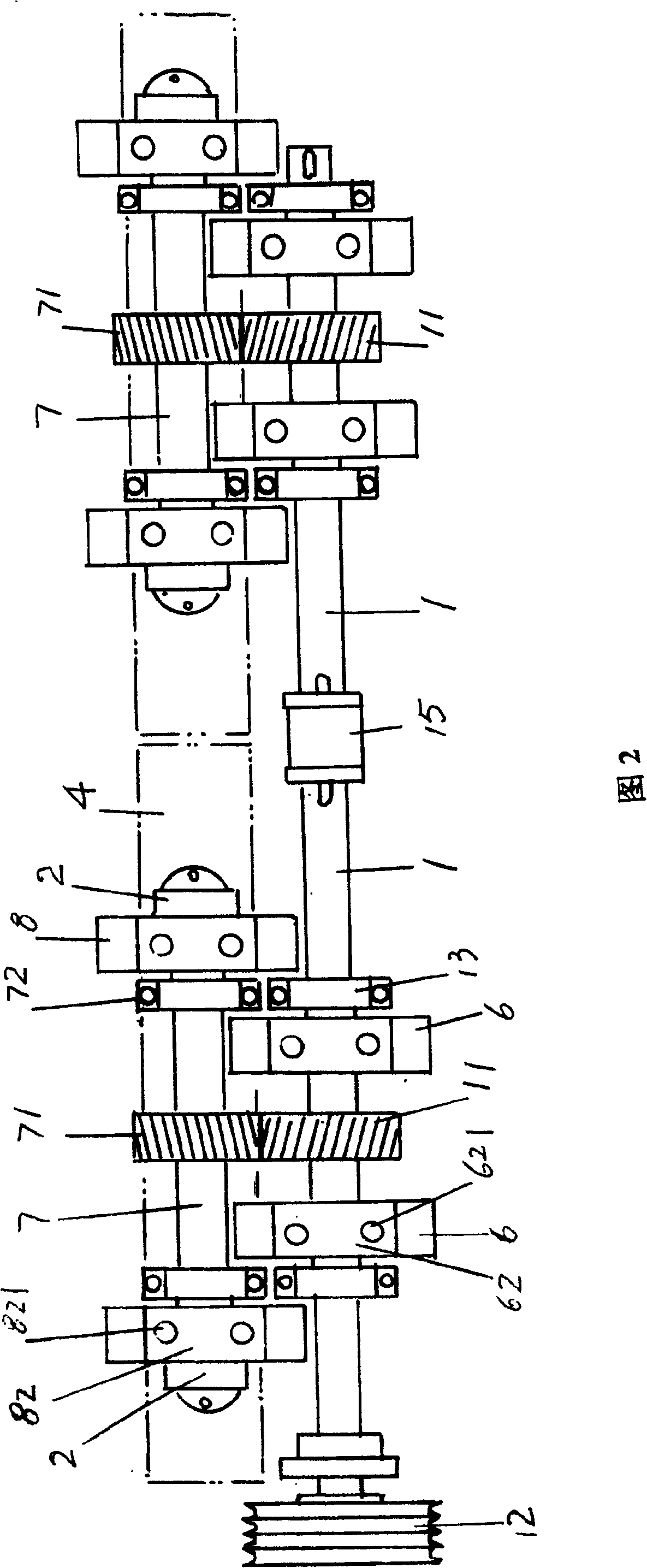

[0018] In Fig. 1 and Fig. 2, in order to facilitate understanding applicant has provided frame 9 in Fig. 1, main shaft 1 is pivoted on frame 9 by a pair of main shaft bearing seat 13, at one end of main shaft 1 (illustration The left end) is fixed with a pulley 12, and the other end of the main shaft 1 is preset with a connecting shaft groove 14. It goes without saying that the function of connecting shaft groove 14 is to connect the main shaft 1 of another unit, which can be relieved from FIG. 2 and realized with connecting sleeve 15 . The connecting rod 2 is changed from the setting position in the prior art, that is, in the prior art, it is connected to the main shaft 1 through a large-diameter deep groove bearing, but in the structure of the present invention, it is arranged on the countershaft balance wheel through a cylindrical bearing 21. 8 on. First fix the auxiliary shaft balance wheel 8 with the auxiliary shaft 7 through the expansion sleeve 84, then connect the upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com