A double-spindle transmission mechanism of a high-speed acupuncture machine

A transmission mechanism and acupuncture machine technology, which is applied to acupuncture machines, transmission devices, mechanical equipment, etc., can solve problems such as large resistance, hindering acupuncture frequency, and small center distance of connecting rods, so as to increase and reduce acupuncture frequency. The effect of setting the number and improving the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

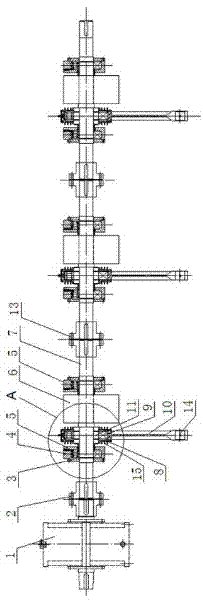

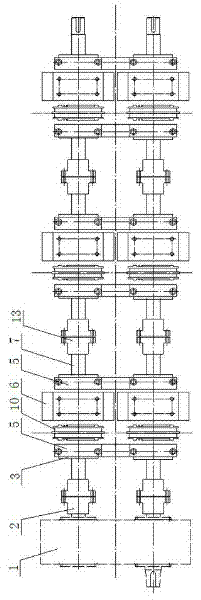

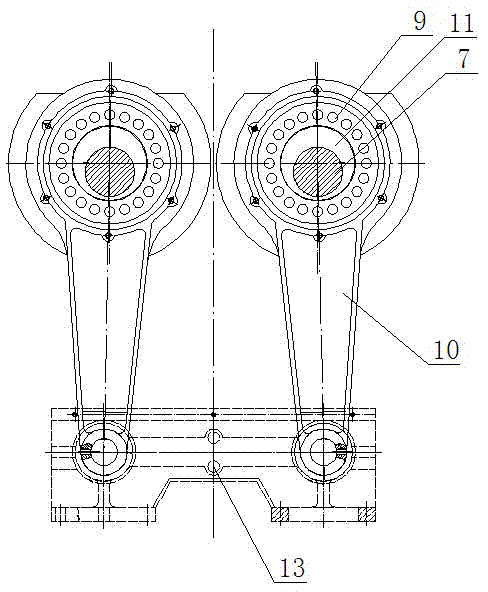

[0017] like figure 1 , 2 , 3, and 4 show the double-spindle transmission mechanism of the high-speed acupuncture machine, including the transfer case 1 and three groups of camshafts 7 arranged in pairs, and the camshafts 7 of the two adjacent groups are respectively connected by the second coupling 13 , two camshafts 7 of each group are arranged in parallel. The two output ends of the transfer case 1 are respectively connected to the camshafts 7 at the ends through the first coupling 2, and each camshaft 7 is respectively arranged on the same side of the transfer case 1, and the two camshafts 7 of each group The direction of rotation is reversed.

[0018] Two bearing housings 5 fixedly connected with the frame are respectively arranged on each camshaft 7, and each bearing housing 5 is connected on the corresponding camshaft 7 through the first bearing 4 respectively, and the cam on one side of each first bearing 4 Bearing seat covers 3 are respectively arranged on the sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com