A multi-stage composite buffer device for optoelectronic mirrors

A composite buffer and photoelectric technology, applied in the field of buffer devices, can solve the problems of easy failure and poor buffer adaptability, and achieve the effects of good hardenability, shortening vibration period and increasing wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with the accompanying drawings, the specific embodiments of the present invention are described in detail as follows:

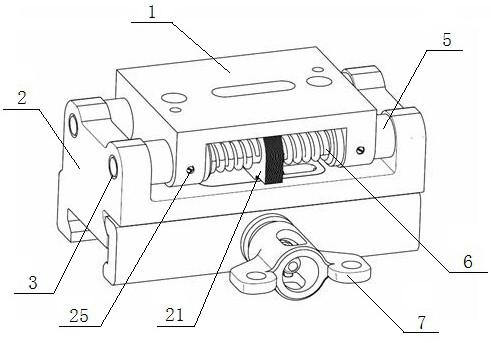

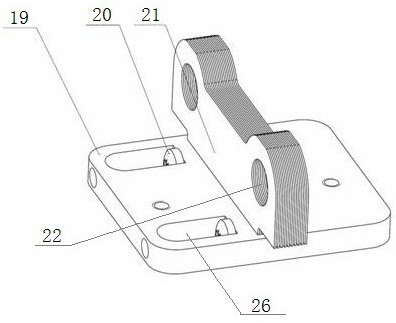

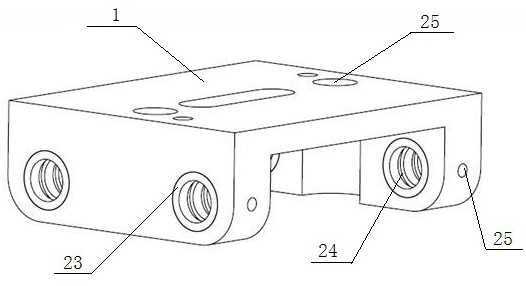

[0028] see Figure 1-8 , a multi-stage composite buffer device for optoelectronic mirrors in this embodiment, including a transition seat 1, a connecting seat 2, a damping shaft pressure ring 3, a damping shaft 4, a rubber pad 5, a damping spring 6, a locking Nut 7, connecting screw 8, spring 9, ejector pin 10, pressure block 11, limit screw 12, screw 13, elastic washer 14, flat washer 15, retaining ring 16, sealing ring 17, shrapnel assembly 18, base 19, tightening Set screw 20 , shrapnel 21 , shaft hole 22 , brass sleeve 23 , annular oil storage groove 24 , mounting hole 25 , through groove 26 , annular boss 27 , groove 28 , vertical groove 29 .

[0029] The middle part of the connection base 2 is installed with a spring plate assembly 18. The spring plate assembly 18 includes a base 19. A plurality of spring plates 21 are insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com