Aviation high-speed generator rotor structure

A high-speed generator and rotor structure technology, which is applied in the field of aviation high-speed generator rotor structure and high-speed aviation generator rotor structure, can solve the problems of increased bearing load, large friction loss on the rotor surface, and increased eccentric force, so as to reduce friction Loss issues, improved reliability, effects of reduced eccentric force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

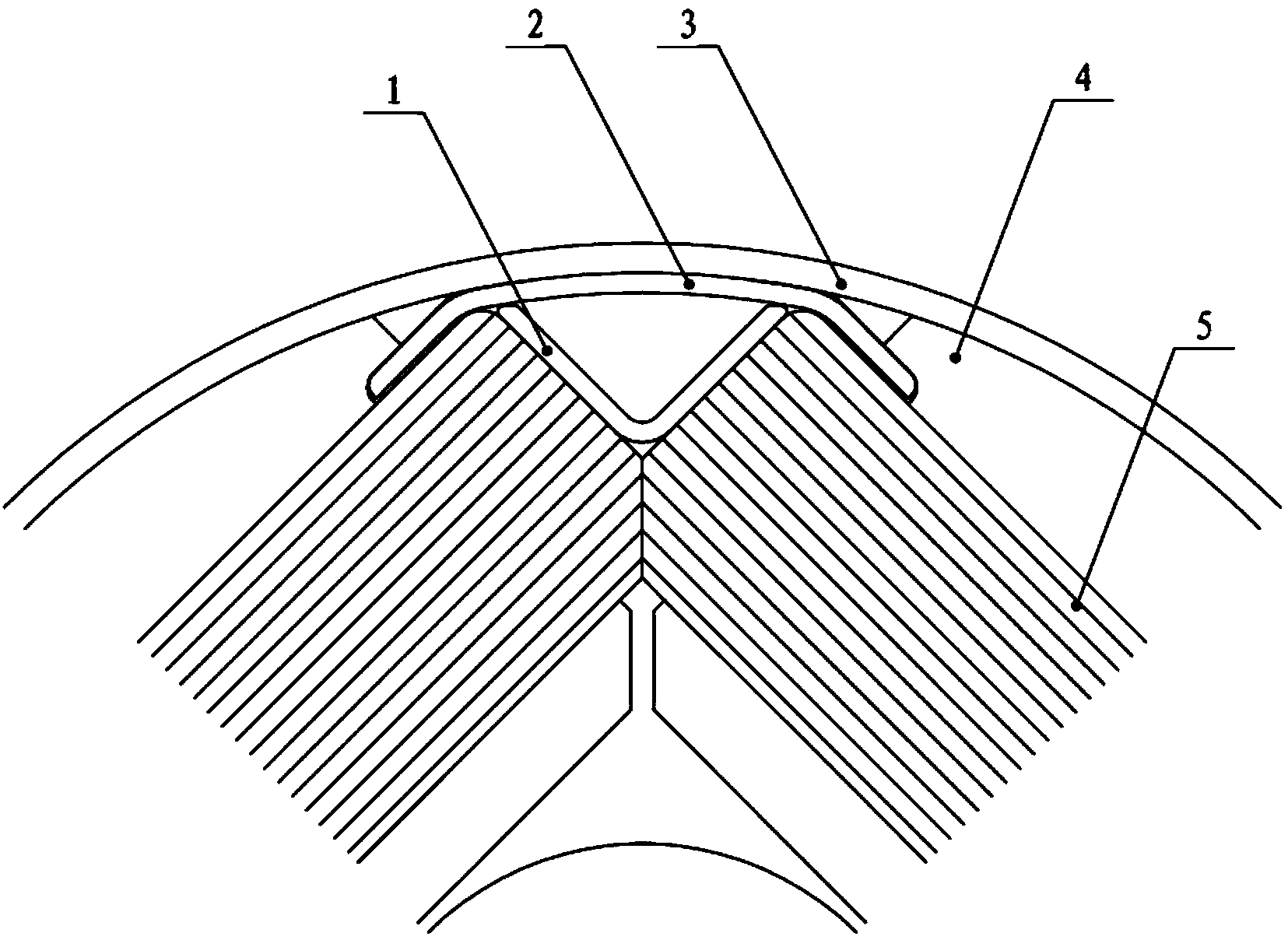

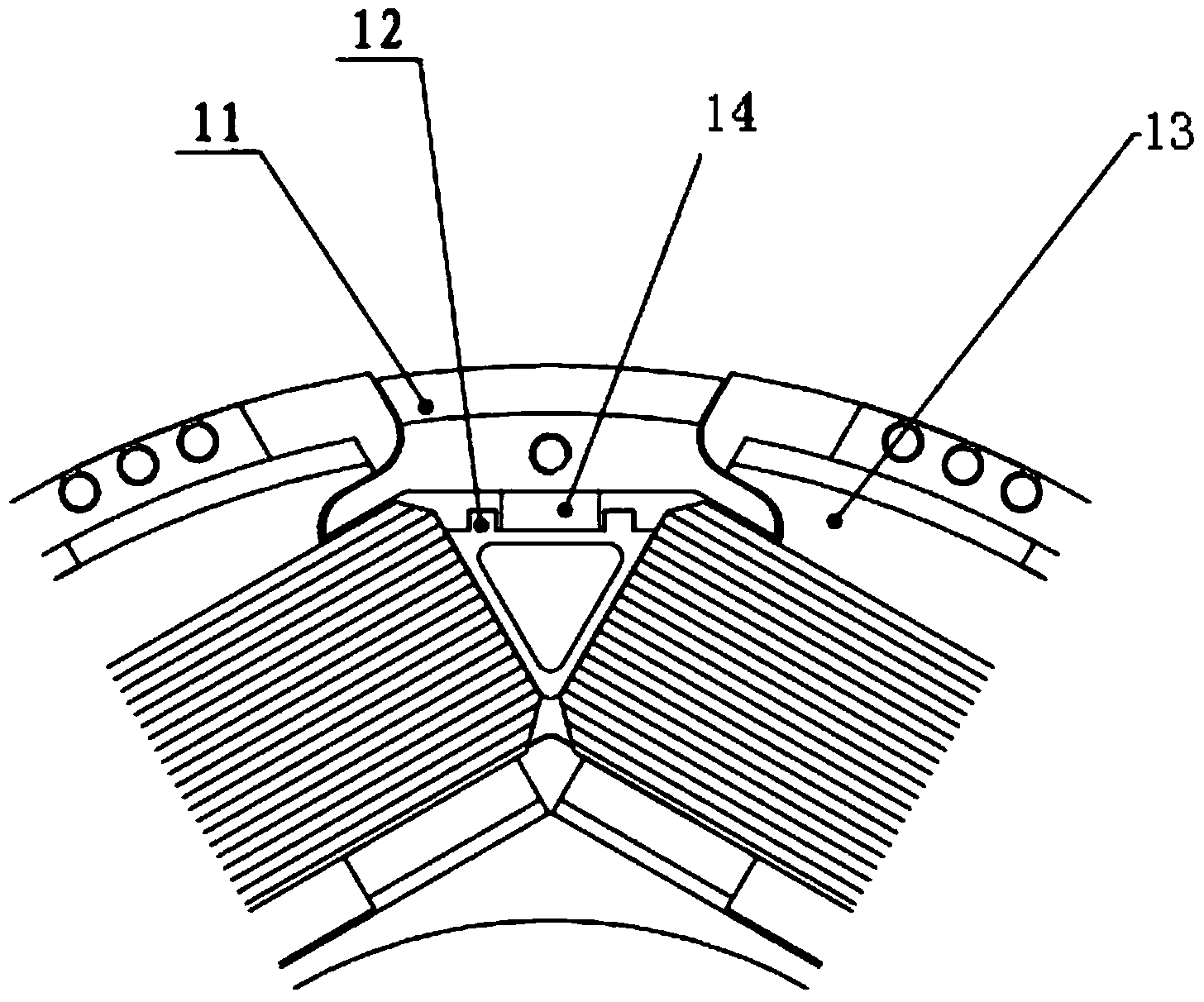

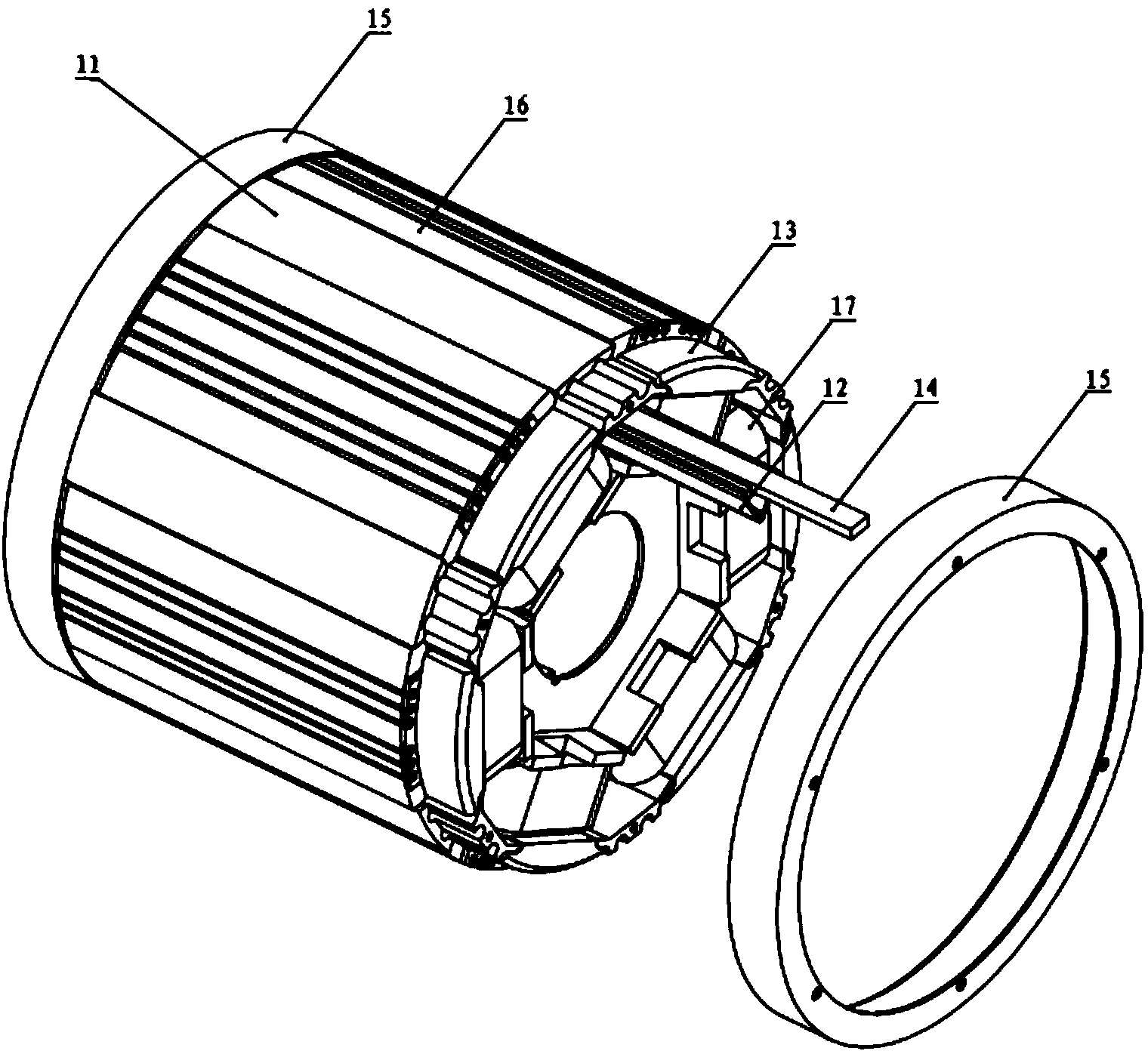

[0022] The rotor structure of the aviation high-speed generator proposed in this embodiment adopts 6 to 8 poles, and each main rotor includes two hoops 15 . Change the V-shaped slot wedge in the prior art into a triangular slot wedge 12, and set a wedge 14 on the triangular beam; make the upper surface of the wing-shaped slot wedge in the prior art flush with the outer circle of the pole core. See figure 2 .

[0023] Each pole includes a wing-shaped slot wedge 11, a triangular slot wedge 12, an insulating support 13 and two wedges 14, the insulating support 13 is assembled on both ends of the pole core 16, and after the excitation winding 5 is wound, the triangular slot wedge 12 Press the field winding from the side, the wing-shaped slot wedge 11 is inserted between the salient pole rotor pole shoe 16a and the winding, the wing-shaped slot wedge 11 presses the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com