A stuffing extrusion dehydration device

A technology for extrusion dehydration and filling, applied in application, food science, food processing, etc., can solve the problems of difficult cleaning, incomplete dehydration of fillings, etc., to prevent re-absorption, improve dehydration efficiency, and facilitate feeding and unloading. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

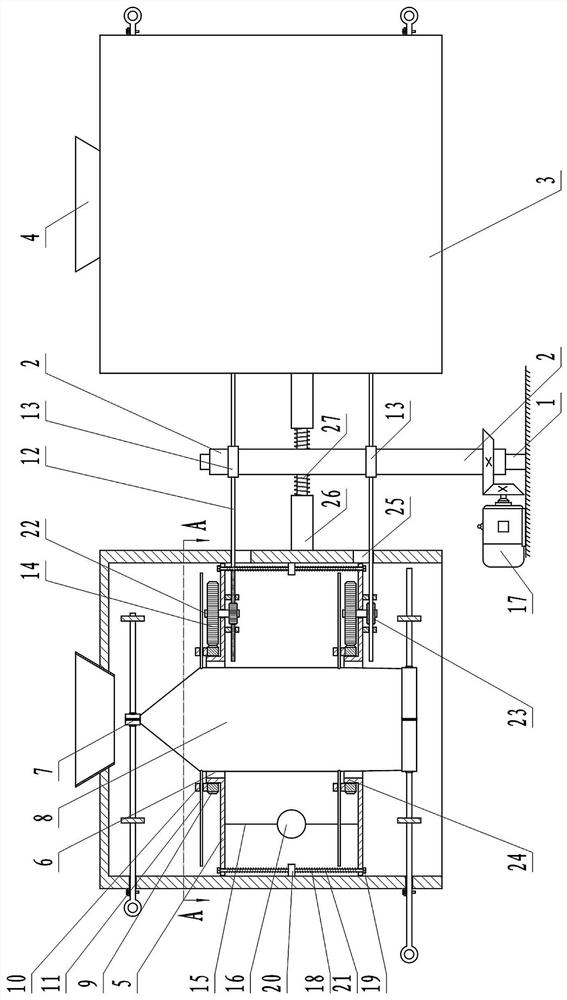

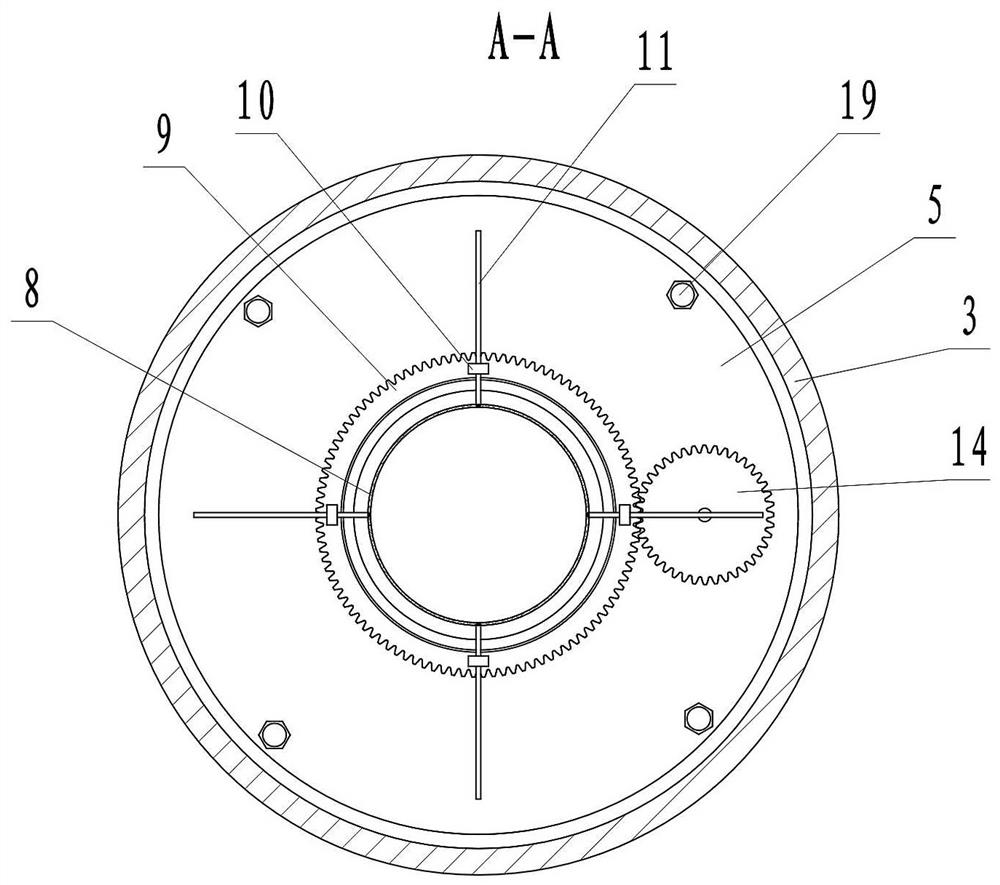

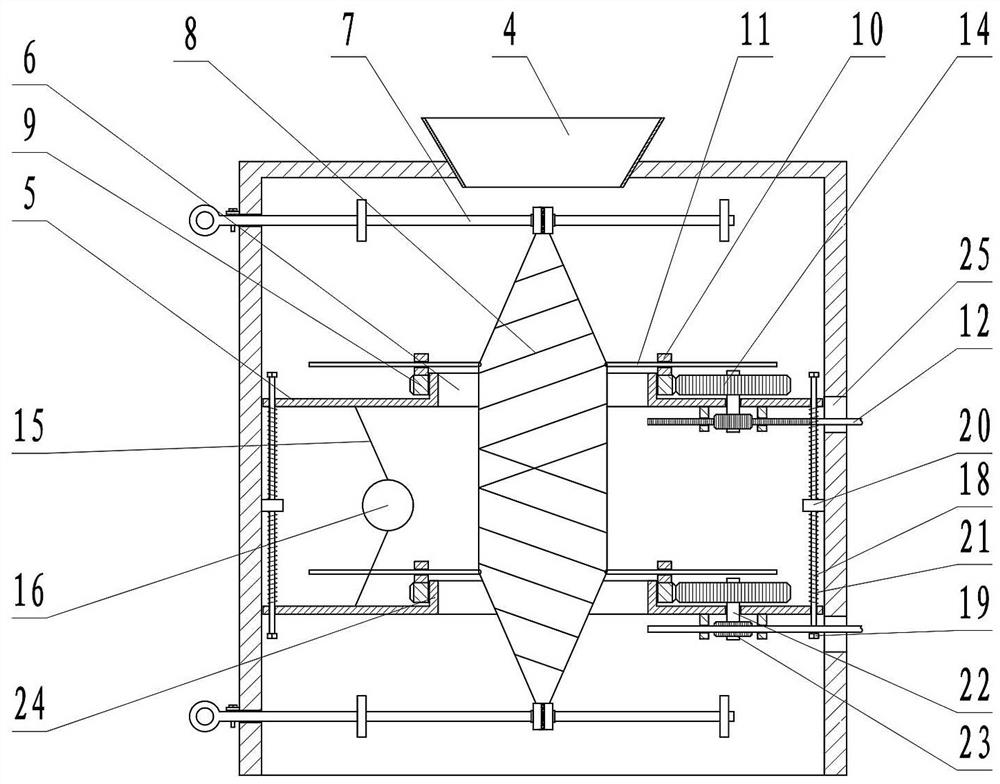

[0023] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0024] Depend on Figure 1 to Figure 4 Given, the present invention includes a vertical support rod 1, the support rod 1 is covered with a rotatable sleeve 2, and the outer circumference of the sleeve 2 is fixed with a plurality of boxes 3; the sleeve 2 and the box 3 are connected with The telescopic rod 26 is covered with a tension spring 27 that makes the telescopic rod 26 actively shrink; the lower end of the box body 3 is open, and the upper end is provided with a feeding port 4; each box body 3 is provided with two upper and lower support plates 5 , the two support plates 5 can move up and down and reset; the middle part of the support plate 5 has a central hole 6, the upper and lower parts of the box body 3 are respectively equipped with a sealing device 7, and the upper and lower sealing devices 7 are installed be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com