Single-phase white-emitting phosphor based on near ultraviolet excitation and preparation method thereof

A technology of near-ultraviolet light and fluorescent powder, which is applied in chemical instruments and methods, luminescent materials, and the use of gas discharge lamps. It can solve problems affecting lumen efficiency and color reproduction performance, and achieve the effect of overcoming color imbalance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

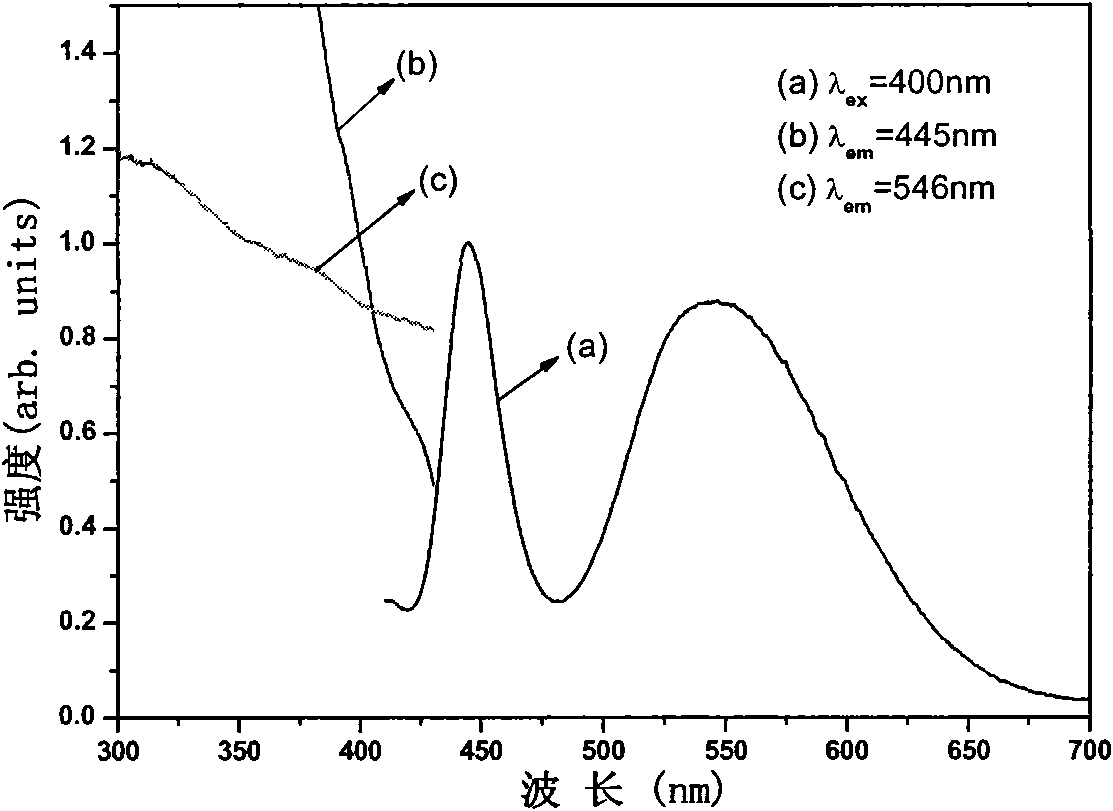

[0019] Preparation of Sr 4.90 (SiO 4 ) 2 Cl 2.0 :Eu 2+ 0.10 (i.e. when Sr 5-m-n Zn n (SiO 4 ) 2 Cl 2 :Eu 2+ m When m=0.10, n=0.00) phosphor.

[0020] Weigh SrCO according to stoichiometric ratio 3 2.8782 g, SrCl 2 .6H 2 O1.5972 grams [due to SrCl 2 .6H 2 O has a low melting point (873°C), and the calculated excess is 20%], SiO 2 0.6008 g, Eu 2 o 3 0.0880 g, put it into an agate mortar and grind it; put it into a corundum crucible, cover it, put it in a high-temperature furnace, under CO or H 2 Under a reducing atmosphere, burn at a temperature of 1100-1200°C for 3-5 hours; after natural cooling and grinding, the chemical formula is 8r 4.90 (SiO 4 ) 2 Cl 2.0 :Eu 0.10 single-phase white phosphors. Its color coordinates are x=0.3262, y=0.4386; the color temperature is T c =5710K; the color rendering index is Ra=56.0.

Embodiment 2

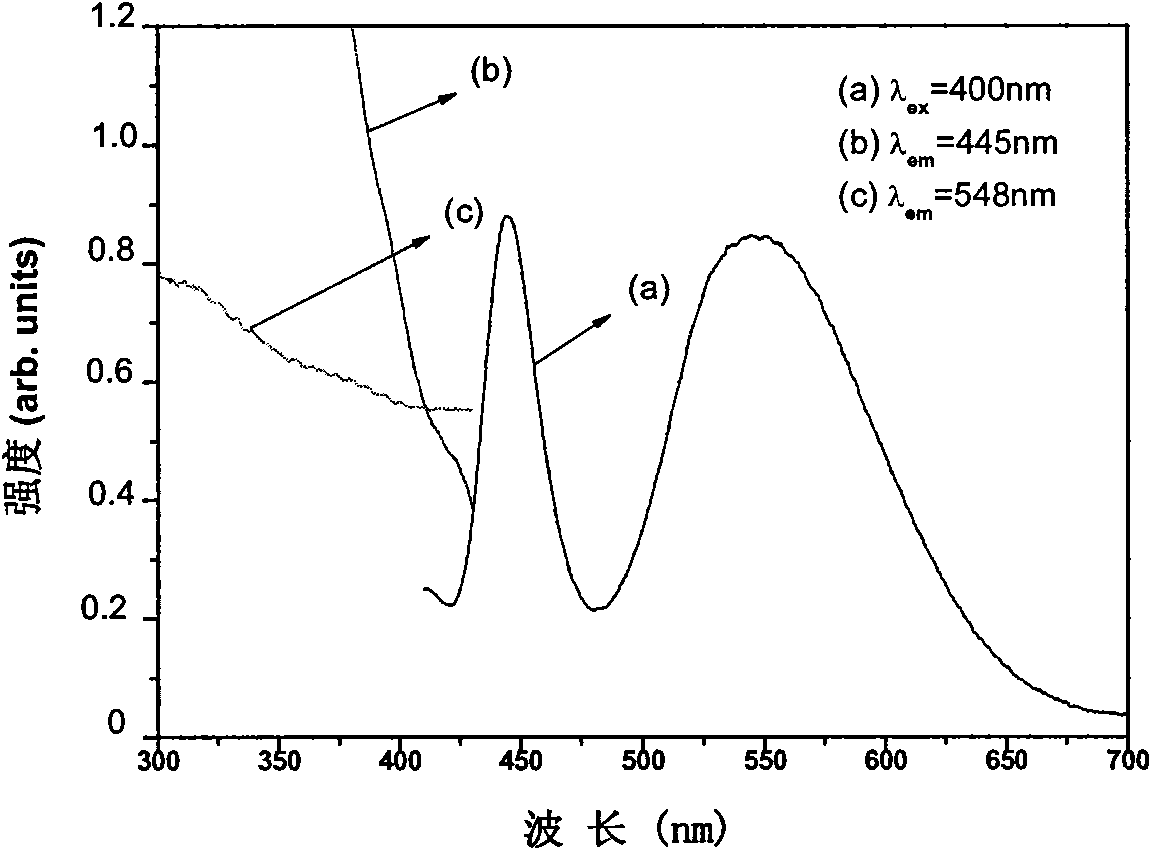

[0022] Preparation of Sr 4.70 Zn 0.20 (SiO 4 ) 2 Cl 2 :Eu 0.10 2+ (i.e. when Sr 5-m-n Zn n (SiO 4 ) 2 Cl 2 :Eu 2+ m When m=0.10, n=0.20) phosphor.

[0023] Weigh SrCO according to stoichiometric ratio 3 2.7306 g, SrCl 2 .6H 2 O 1.4641 grams [according to the calculated amount in excess of 10%], ZnO0.0814, SiO 2 0.6008 g, Eu 2 o 3 0.0880 g, put it into an agate mortar and grind it; put it into a corundum crucible, cover it, put it in a high-temperature furnace, under CO or H 2 Under reducing atmosphere, burn at 1100-1200°C for 3-5 hours; after natural cooling, grind to obtain the chemical formula Sr 4.70 Zn 0.20 (SiO 4 ) 2 Cl 2 :Eu 0.10 2+ single-phase white phosphors. Its color coordinates are x=0.3293, y=0.4061; the color temperature is T c =5829K; the color rendering index is Ra=64.0. .

Embodiment 3

[0025] Preparation of Sr 4.88 (SiO 4 ) 2 Cl 2 .:Eu 2+ 0.12 (i.e. when Sr 5-m-n Znn (SiO 4 ) 2 Cl 2 :Eu 2+ m When m=0.12, n=0.00) phosphor.

[0026] Weigh SrCO according to stoichiometric ratio 3 2.8634 g, SrCl 2 .6H 2 O 1.5972 g [20% excess calculated], SiO 2 0.6008 g, Eu 2 o 3 0.1056 g, put it into an agate mortar and grind it; put it into a corundum crucible, cover it, put it in a high-temperature furnace, and burn it at 1100-1200°C for 3-5 hours in a reducing atmosphere of CO or H2; naturally Grinding after cooling, the chemical formula is Sr 4.88 (SiO 4 ) 2 Cl 2 .:Eu 2+ 0.12 single-phase white phosphors. Its color coordinates are x=0.3370, y=0.4074; the color temperature is T c =6067K; the color rendering index is Ra=61.7.

PUM

| Property | Measurement | Unit |

|---|---|---|

| color rendering index | aaaaa | aaaaa |

| color rendering index | aaaaa | aaaaa |

| color rendering index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com