Process method and process system for preparing solid fuel through biomass and sludge

A technology of solid fuel and process method, applied in the field of solid waste recycling, can solve the problems of difficult drying of sludge briquette semi-finished products, insufficient solid fuel strength, uneven fuel properties, etc., so as to facilitate large-scale industrial production and realize resource utilization. The effect of chemical utilization and fast processing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

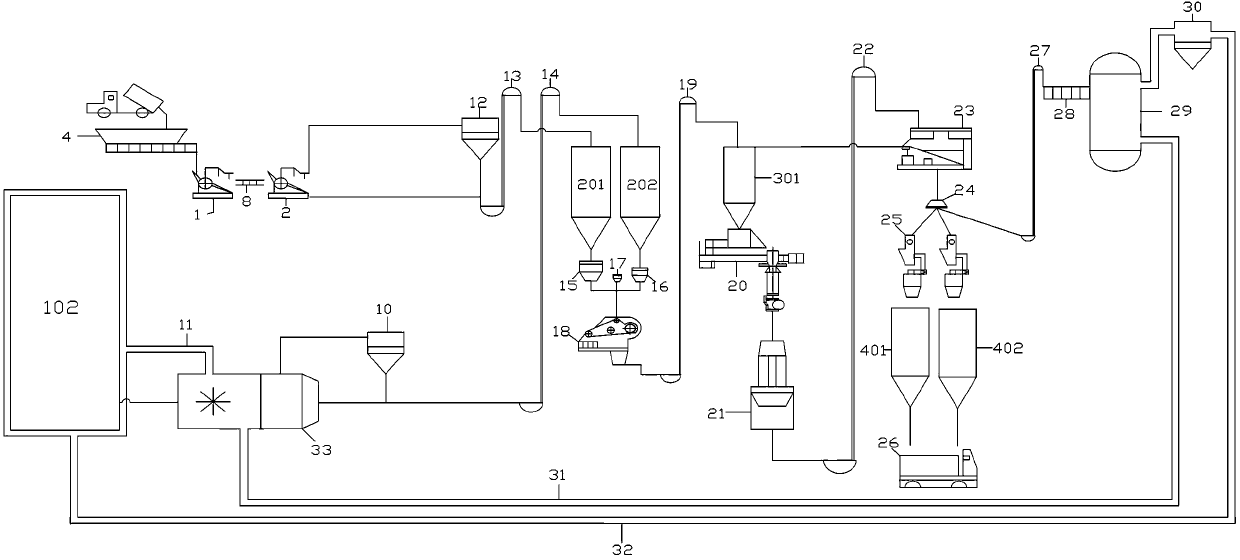

[0044] A system for preparing solid fuel from biomass and sludge of the present invention, such as figure 1 As shown, the system includes raw material processing system, molding system, storage and packaging system and boiler system. The raw material processing system includes a glass greenhouse (the entire glass greenhouse is used as a sludge drying room 102), a feed hopper 4, a coarse biomass pulverizer 1, a fine biomass pulverizer 2, and a sludge drying and pulverizing integrated machine 33 (that is, a paddle type Dryer), the first gas delivery pipeline 11, the first dust remover 10, the second dust remover 12, the biomass drying raw material bin 201 and the sludge drying raw material bin 202. In the raw material processing system, the sludge drying room 102 is provided with a first material output port, a first gas input port and a second gas input port (namely, the first gas input port and the second gas input port of the glass greenhouse), and the sludge The drying and ...

Embodiment 2

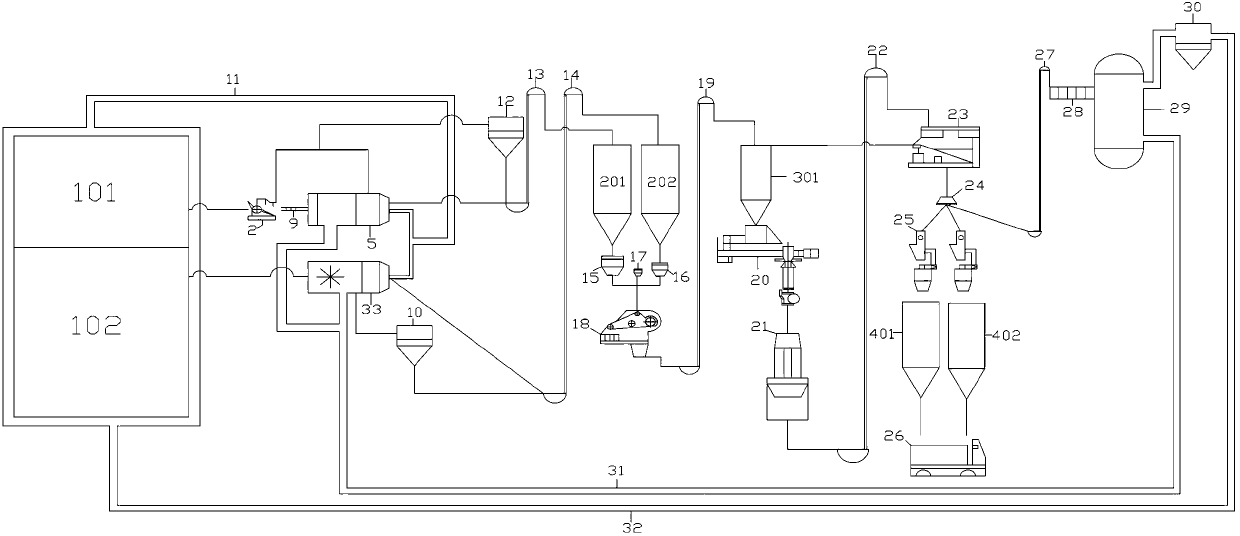

[0059] A system for preparing solid fuel from biomass and sludge of the present invention, such as figure 2 As shown, the system includes raw material processing system, molding system, storage and packaging system and boiler system. The raw material processing system includes a glass greenhouse (with a biomass drying room 101 and a sludge drying room 102), a biomass fine pulverizer 2, a biomass dryer 5 (that is, a drum dryer), and a sludge drying and crushing integrated machine 33 (that is, the paddle dryer), the first gas delivery pipeline 11, the first dedusting machine 10, the second dedusting machine 12, the biomass drying raw material bin 201 and the sludge drying raw material bin 202. In the raw material processing system, the glass greenhouse is provided with a first gas input port and a second gas input port, and the gas sent from the first gas input port and the second gas input port of the glass greenhouse can spread throughout the biomass drying room 101 and the s...

Embodiment 3

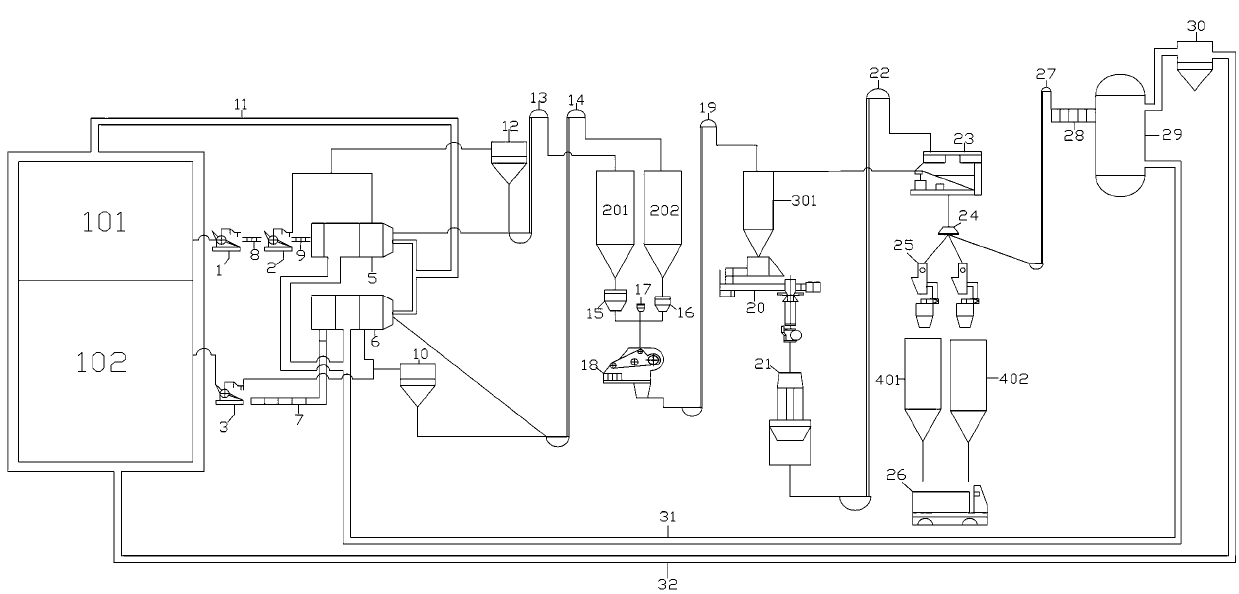

[0074] A system for preparing solid fuel from biomass and sludge of the present invention, such as image 3 As shown, the system includes raw material processing system, molding system, storage and packaging system and boiler system. The raw material processing system includes a glass greenhouse (with a biomass drying room 101 and a sludge drying room 102), a coarse biomass pulverizer 1, a fine biomass pulverizer 2, and a biomass dryer 5 (that is, a tumble dryer) , sludge pulverizer 3, sludge dryer 6, first gas conveying pipeline 11, first dust remover 10, second dust remover 12, biomass drying raw material bin 201 and sludge drying raw material bin 202. In the raw material processing system, the glass greenhouse is provided with a first gas input port and a second gas input port, and the gas sent from the first gas input port and the second gas input port of the glass greenhouse can spread throughout the biomass drying room 101 and the sludge The drying room 102 is used to p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com