Main shaft of photovoltaic tracking support

A main shaft and photovoltaic technology, applied in the direction of control using feedback, can solve the problems of increasing eccentric force, increasing distance, increasing cost, etc., and achieve the effect of good practical application value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

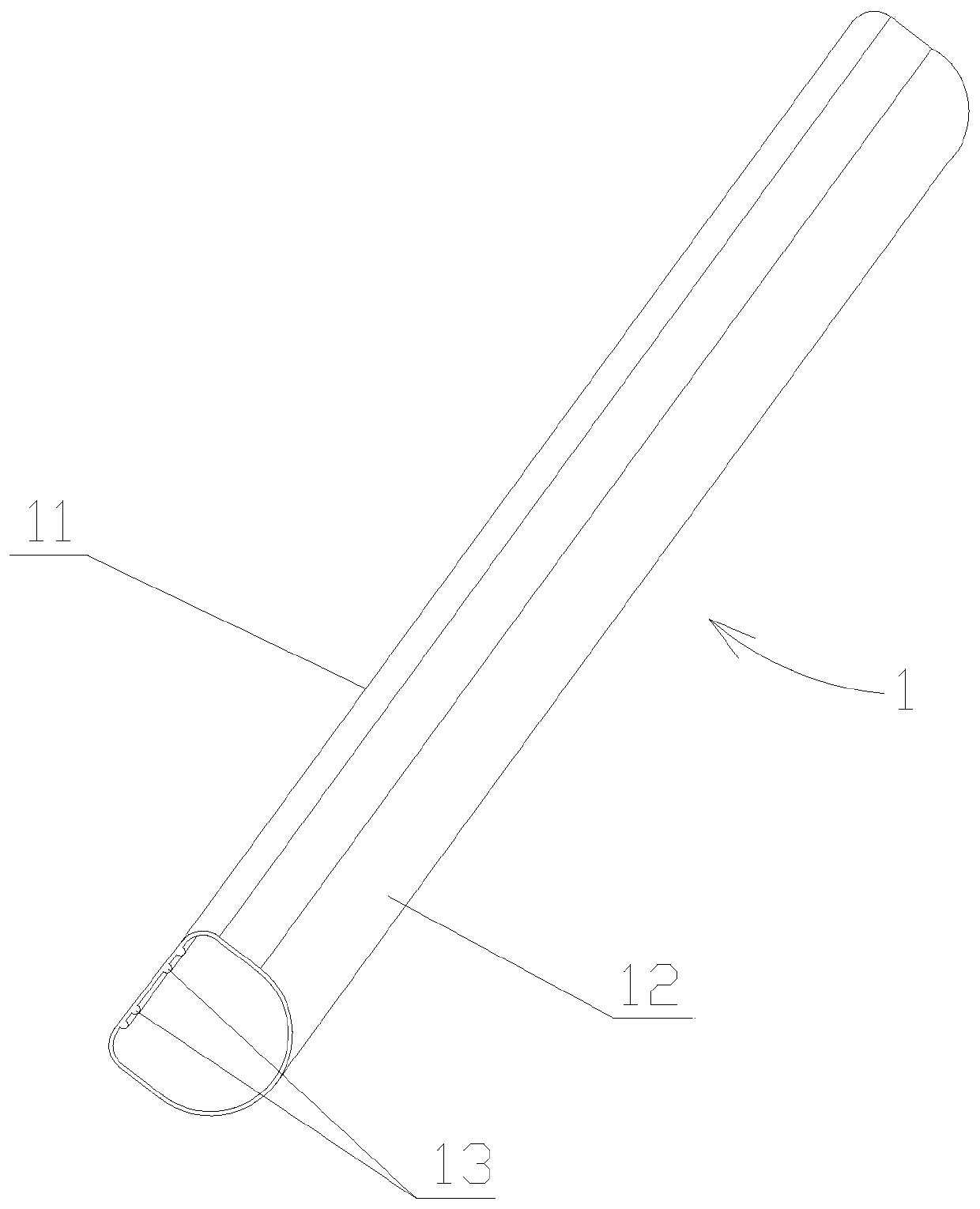

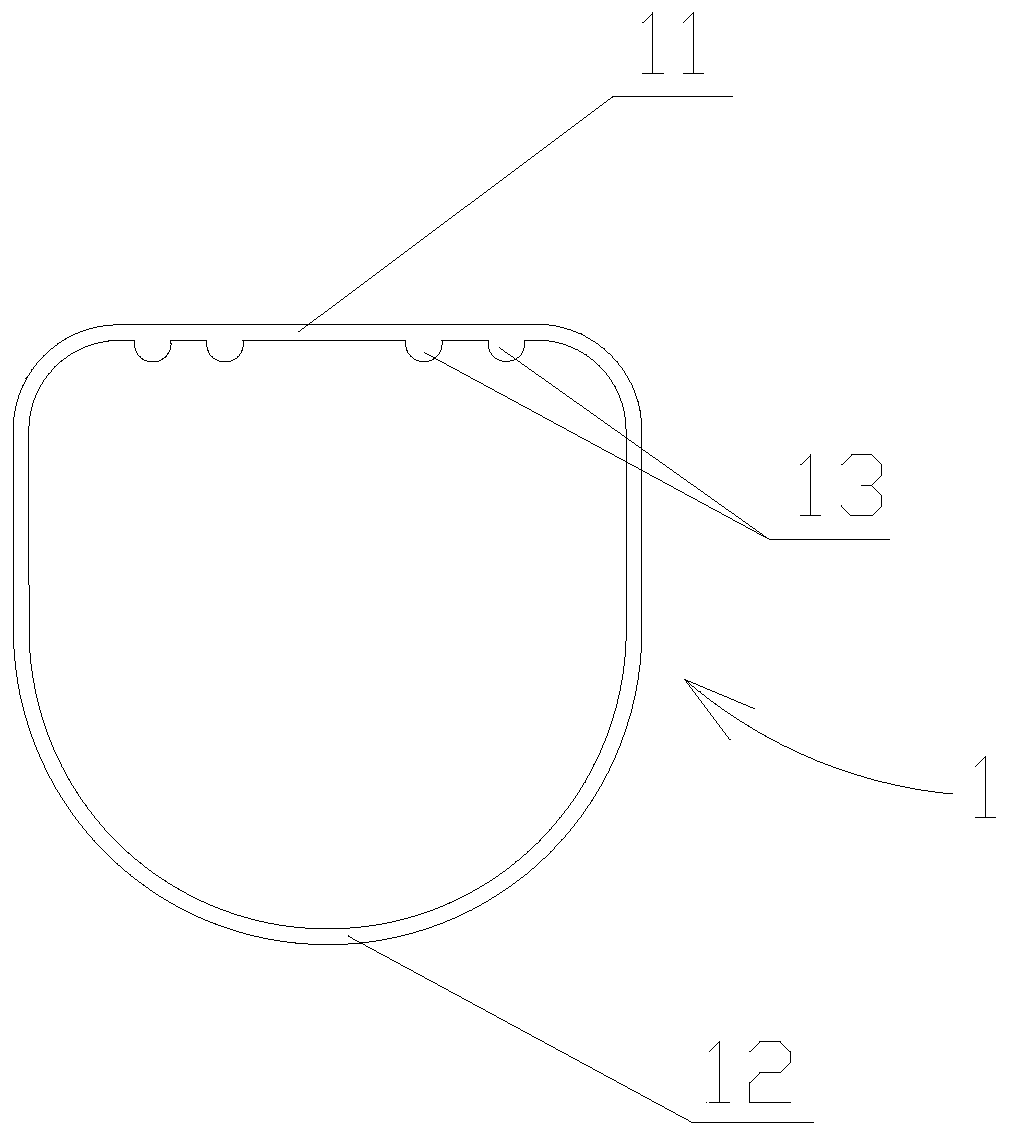

[0029] figure 1 and figure 2 Schematically shows the main axis of the photovoltaic tracking bracket according to an embodiment of the present invention. As shown, the main shaft 1 is made of a tube with a closed section.

[0030] The installation surface 11 on one side of the main shaft 1 for installing purlins is a plane.

[0031] Both sides of the main shaft 1 are perpendicular to the mounting surface 11 .

[0032] The side of the main shaft 1 opposite to the mounting surface 11 is an arc surface 12 .

[0033] Spindle 1 has the same width on both sides.

[0034] The mounting surface 11 and the arcuate surface 12 are respectively disposed on the plane member 21 and the arcuate member 22 .

[0035] The inner wall of the installation surface 11 is provided with a strengthening device, and the reinforcement device is used to strengthen the strength of the installation surface 11 . Since the installation surface 11 needs to be connected with purlins, holes are usually open...

Embodiment 2

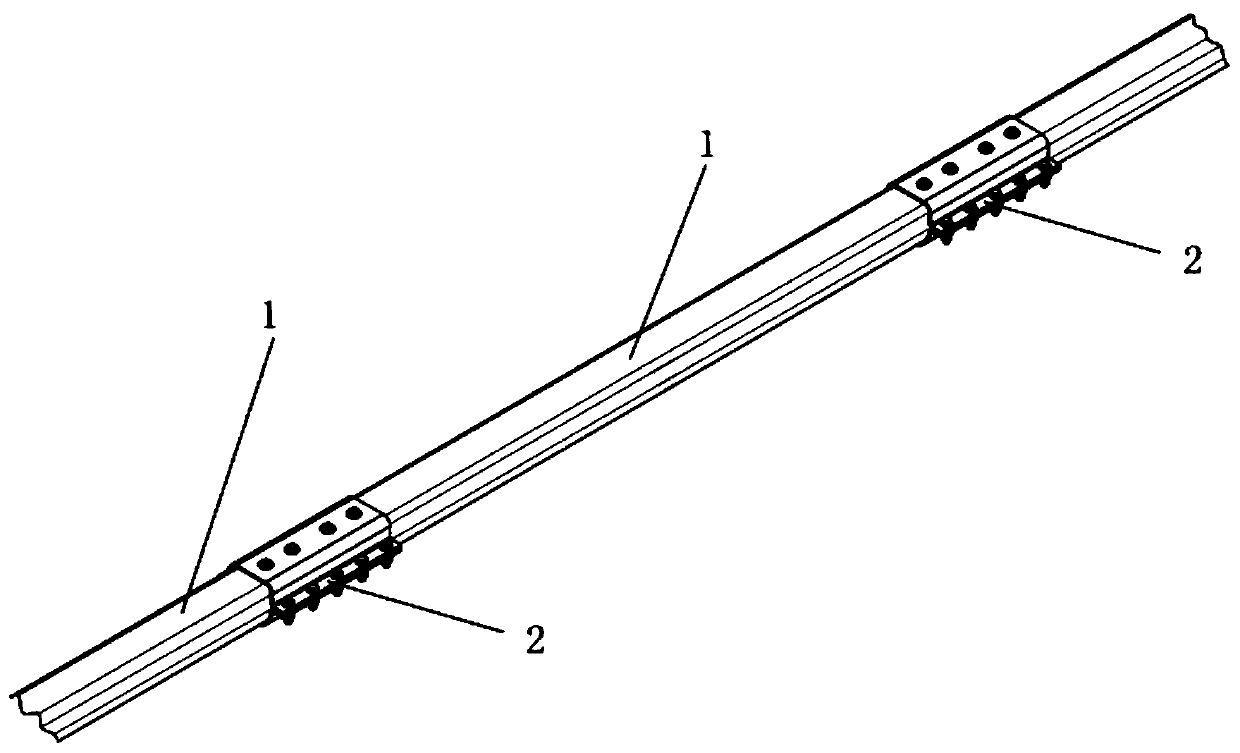

[0044] Figure 3 to Figure 5 It schematically shows the main axis of the photovoltaic tracking bracket according to another embodiment of the present invention. As shown in the figure, the difference from Embodiment 1 is that a plurality of main shafts are connected to one coaxial center through a main shaft connecting piece.

[0045] The main shaft connecting piece 2 is sleeved and fixed at the joint with the main shaft 1 .

[0046] The main shaft connecting piece 2 is composed of a plurality of planar pieces 21 and curved surface pieces 22 .

[0047] The mounting surface 11 and the circular arc surface 12 are respectively disposed in the plane member 21 and the arc surface member 22 .

[0048] The plane piece 21 and the arc surface piece 22 are fixedly connected and enclosed into a closed tubular shape.

[0049] The span of a single row of photovoltaic tracking brackets is usually long, and the entire main shaft is mostly formed by multi-segment locking. The spindle is f...

Embodiment 3

[0054] Figure 6It schematically shows the main axis of the photovoltaic tracking bracket according to another embodiment of the present invention. As shown in the figure, the difference from Embodiment 1 is that the reinforcing means is provided with several grooves 14 on the installation surface 11 .

[0055] The groove 14 is recessed into the main shaft 1 and its axial direction coincides with the axial direction of the main shaft 1 . The groove 14 can not only strengthen the strength of the installation surface 11 , but also increase the elasticity of the installation surface 11 , thereby buffering the instantaneous impact force of the purlin on the main shaft 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com