Ring lock scaffold opening portion bracket supporting system

A support system and scaffolding technology, applied in the direction of house structure support, house structure support, formwork/formwork/work frame, etc., can solve the problems of insufficient bearing capacity, large eccentric distance and eccentric moment, and poor overall stability of the support system, etc. Achieve the effect of reducing eccentric force, improving work efficiency and shortening the demolition period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

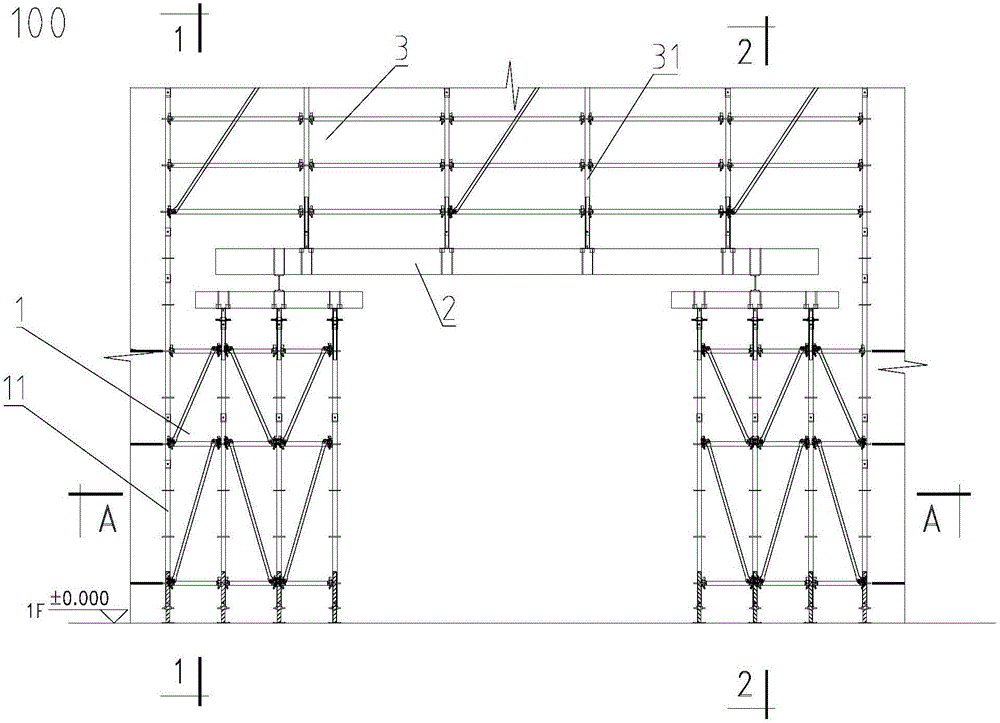

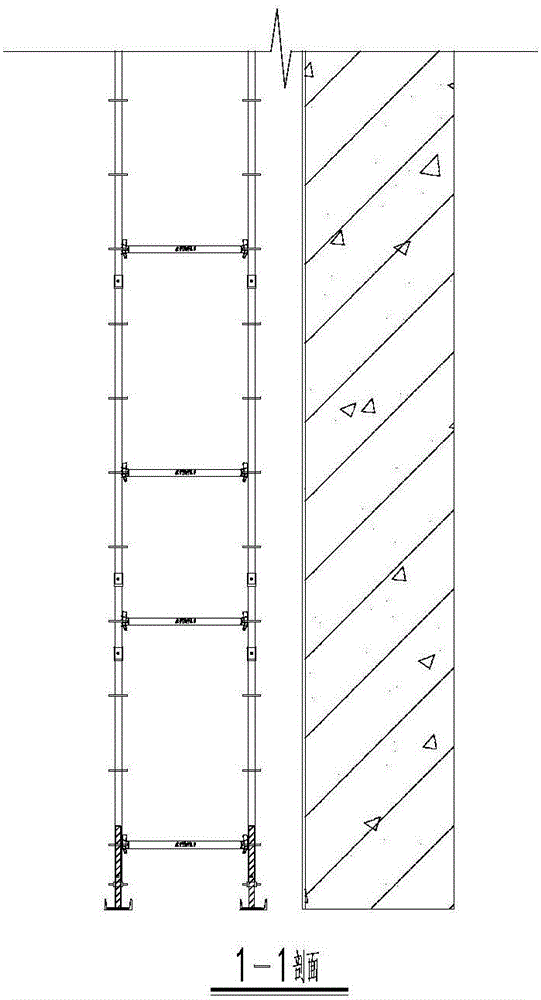

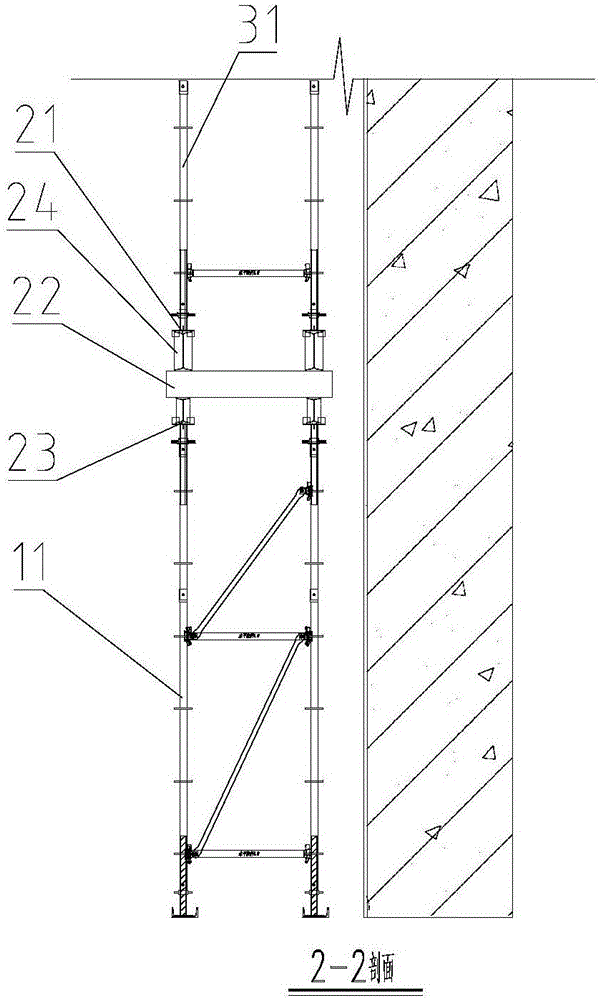

[0022] The support system of the bracket for the door opening of the coil-type scaffolding provided by the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. The advantages and features of the present invention will be more apparent from the following description and claims. It should be noted that all the drawings are in very simplified form and use inaccurate scales, which are only used to facilitate and clearly assist the purpose of illustrating the embodiments of the present invention.

[0023] refer to Figure 1 to Figure 4 , this embodiment discloses a support system 100 for brackets at the door opening of a ring-type scaffolding, which is a support structure built by a ring-type scaffolding tube. The door opening includes encrypted formwork brackets 1 on both sides of the door opening, The upper formwork support 3 and the new support beam 2. The lower vertical rods 11 in the encrypted for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com