Patents

Literature

34results about How to "Orientation structure is simple" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

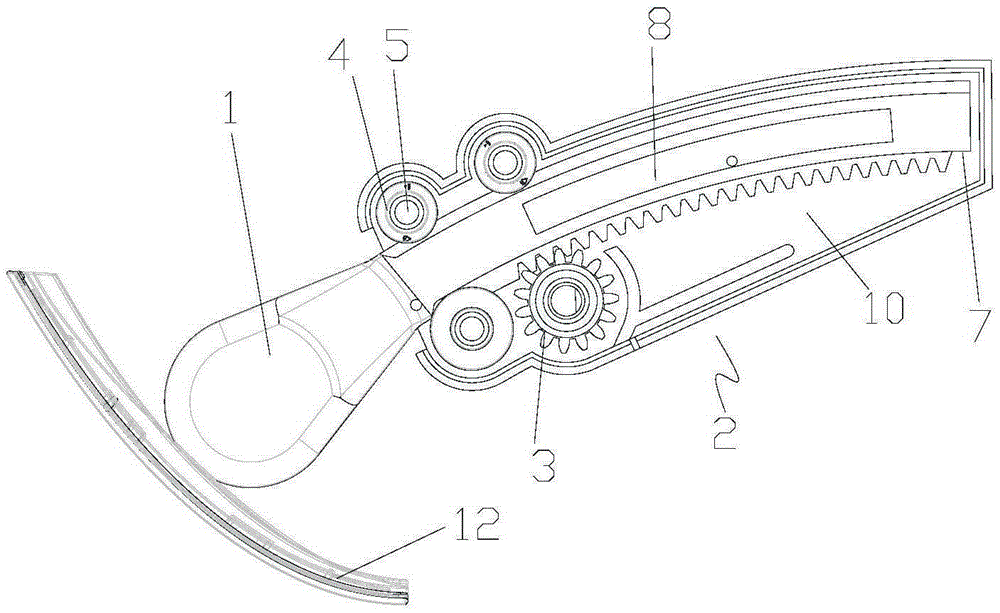

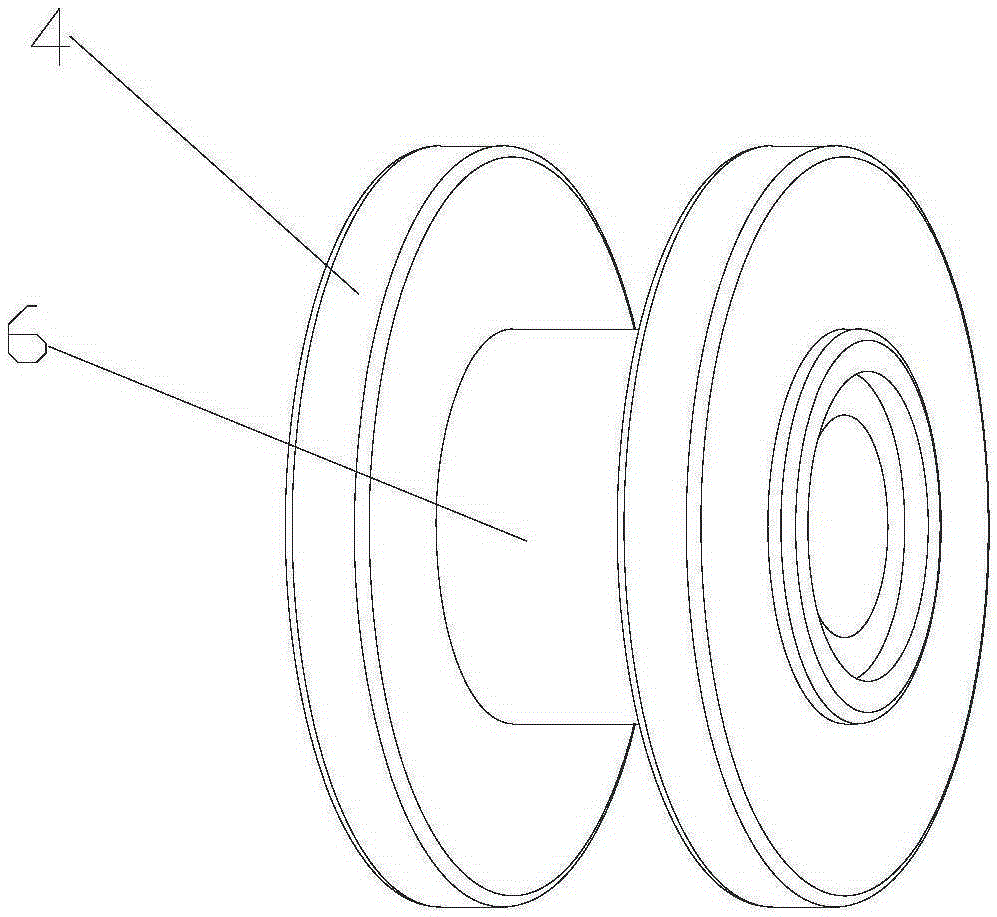

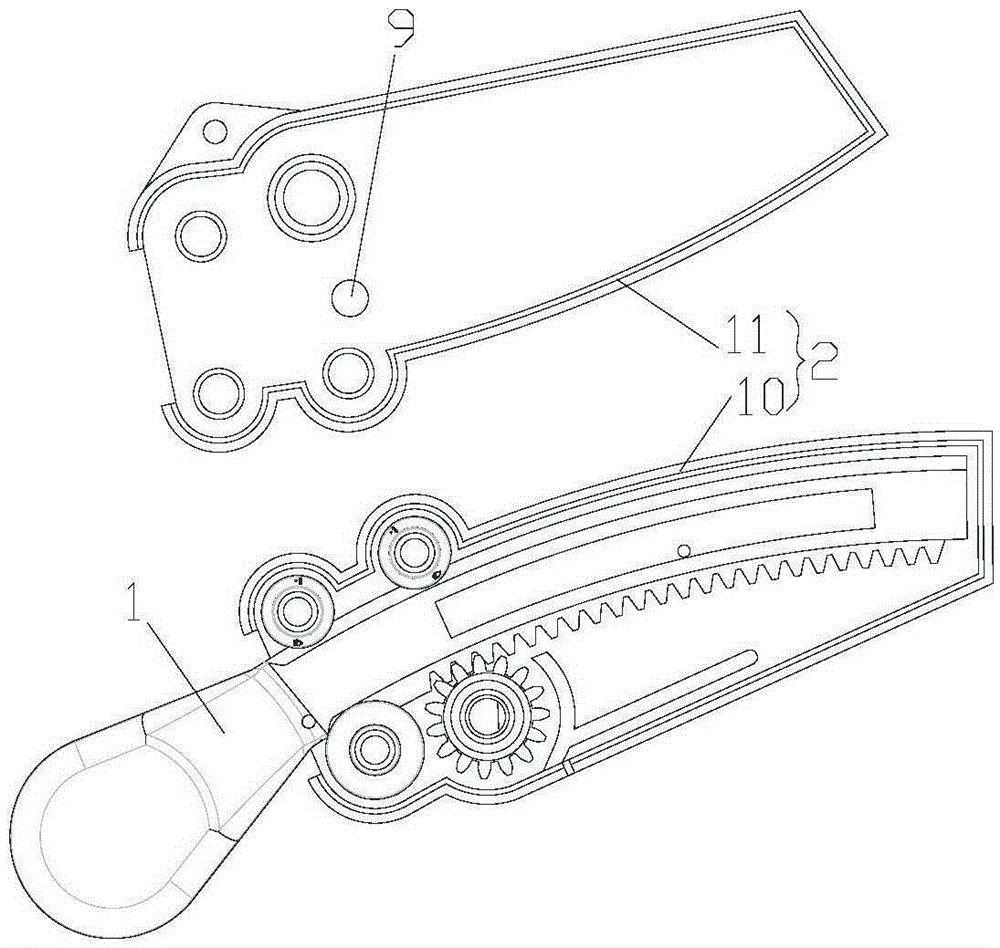

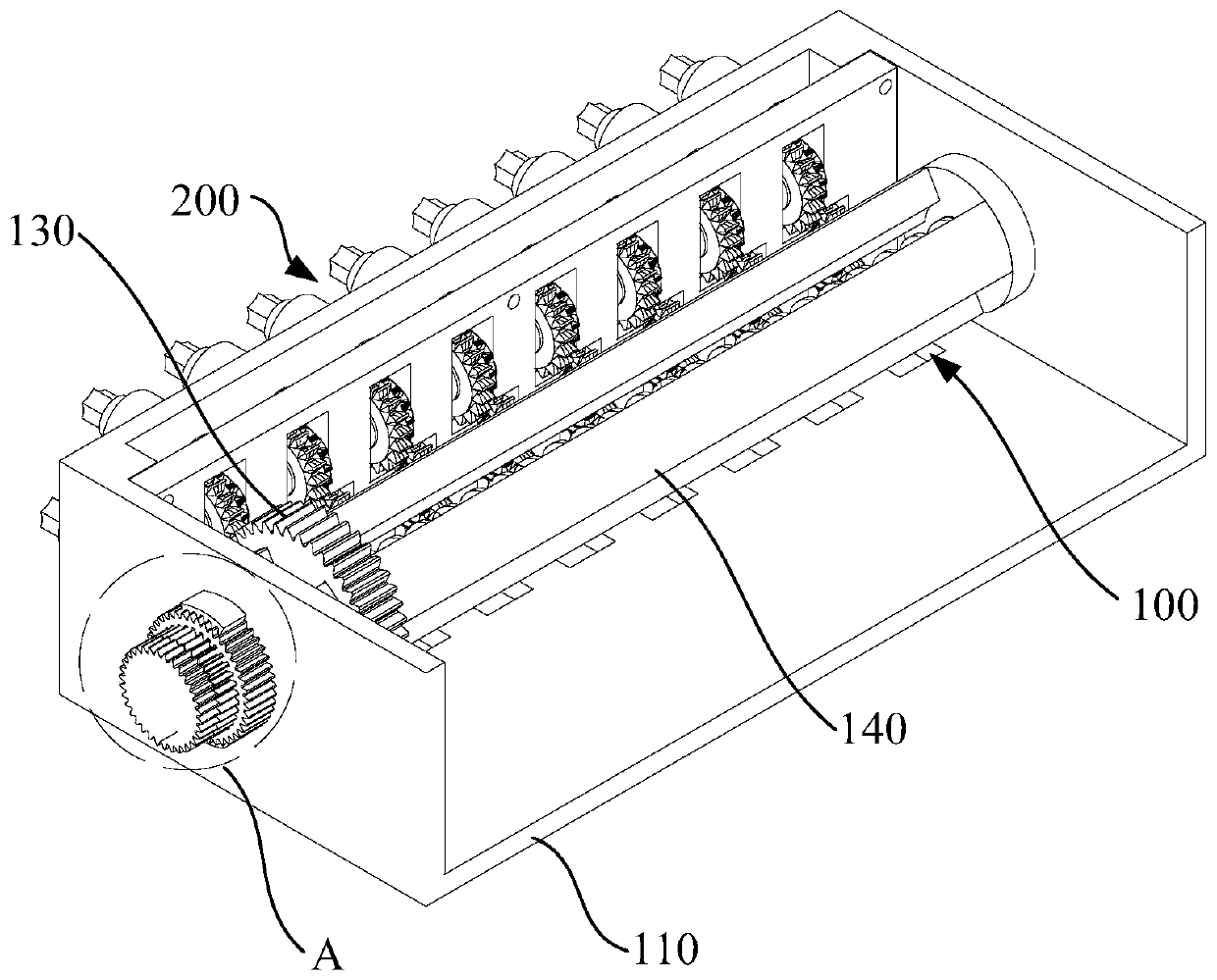

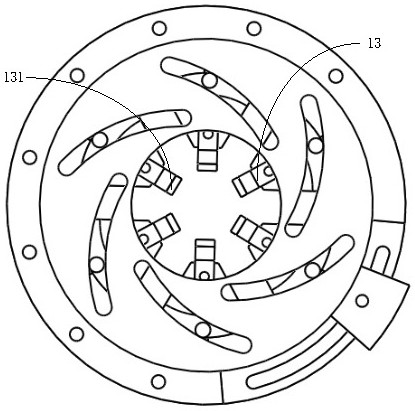

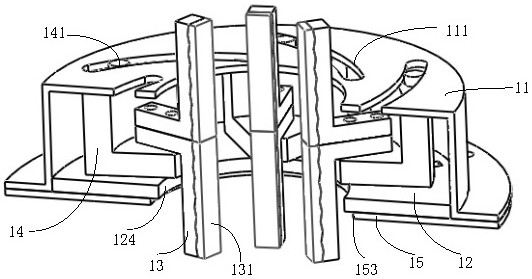

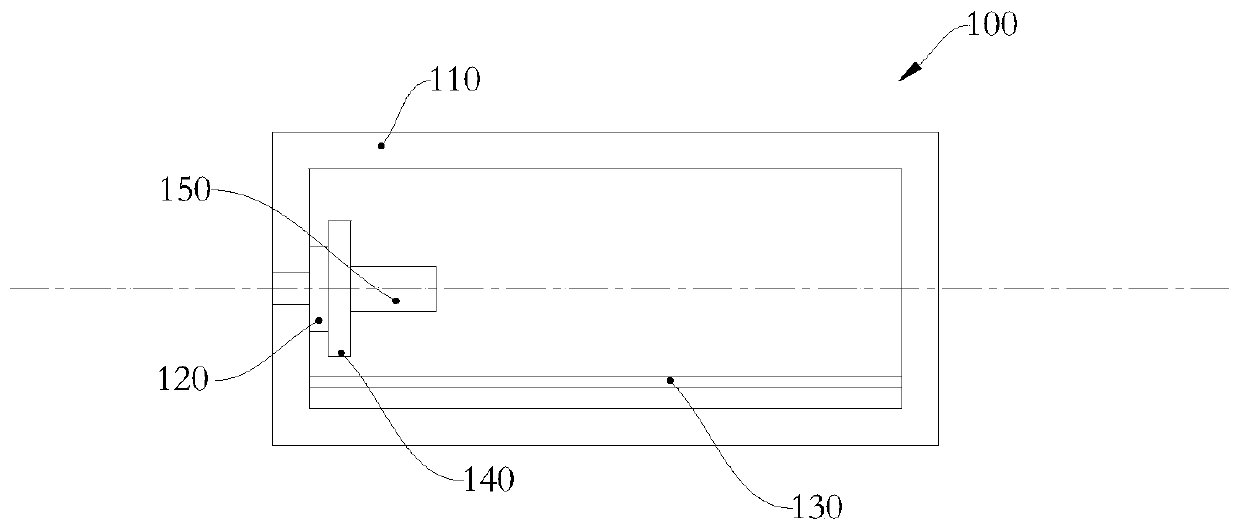

Air deflector driving mechanism and wall-hanging air conditioner

ActiveCN105402873ALow movement resistanceOrientation structure is simpleLighting and heating apparatusAir-flow control membersEngineeringGasket

Owner:GREE ELECTRIC APPLIANCES INC OF ZHUHAI

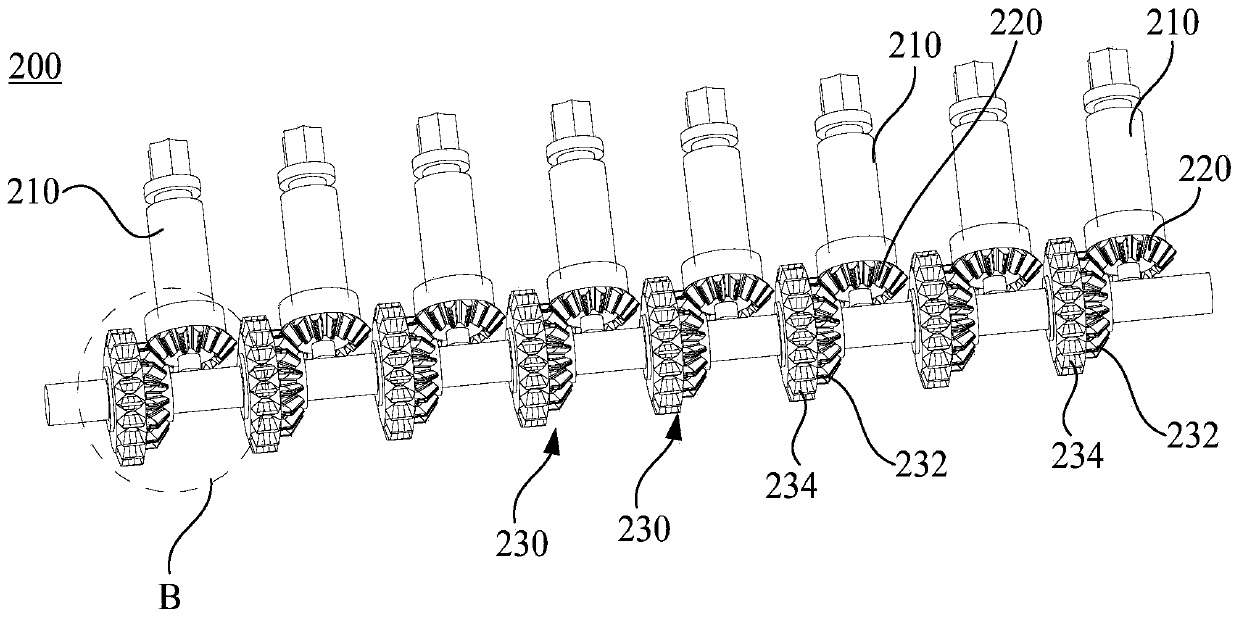

Antenna, transmission device and switching mechanism

Owner:COMBA TELECOM TECH (GUANGZHOU) CO LTD

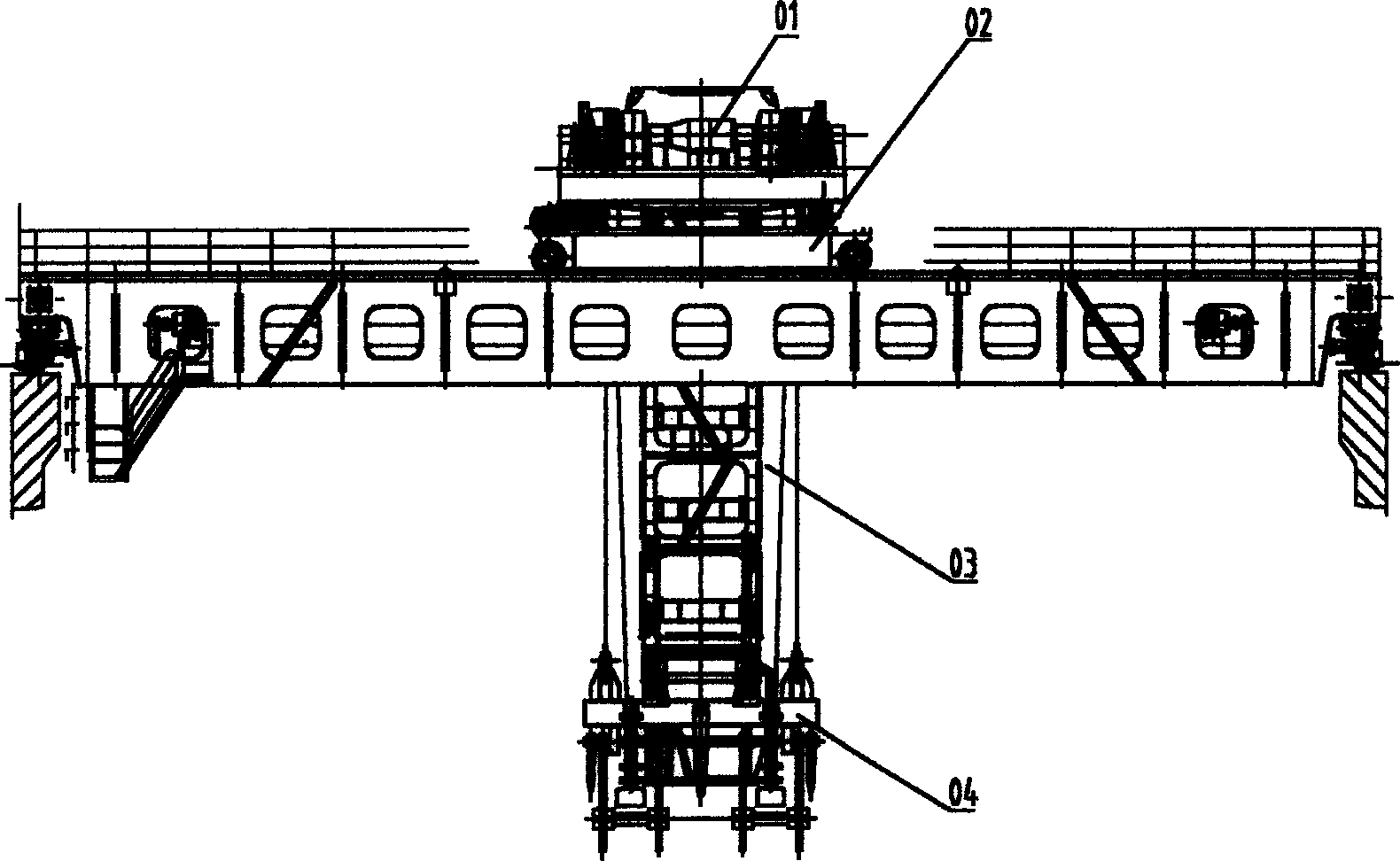

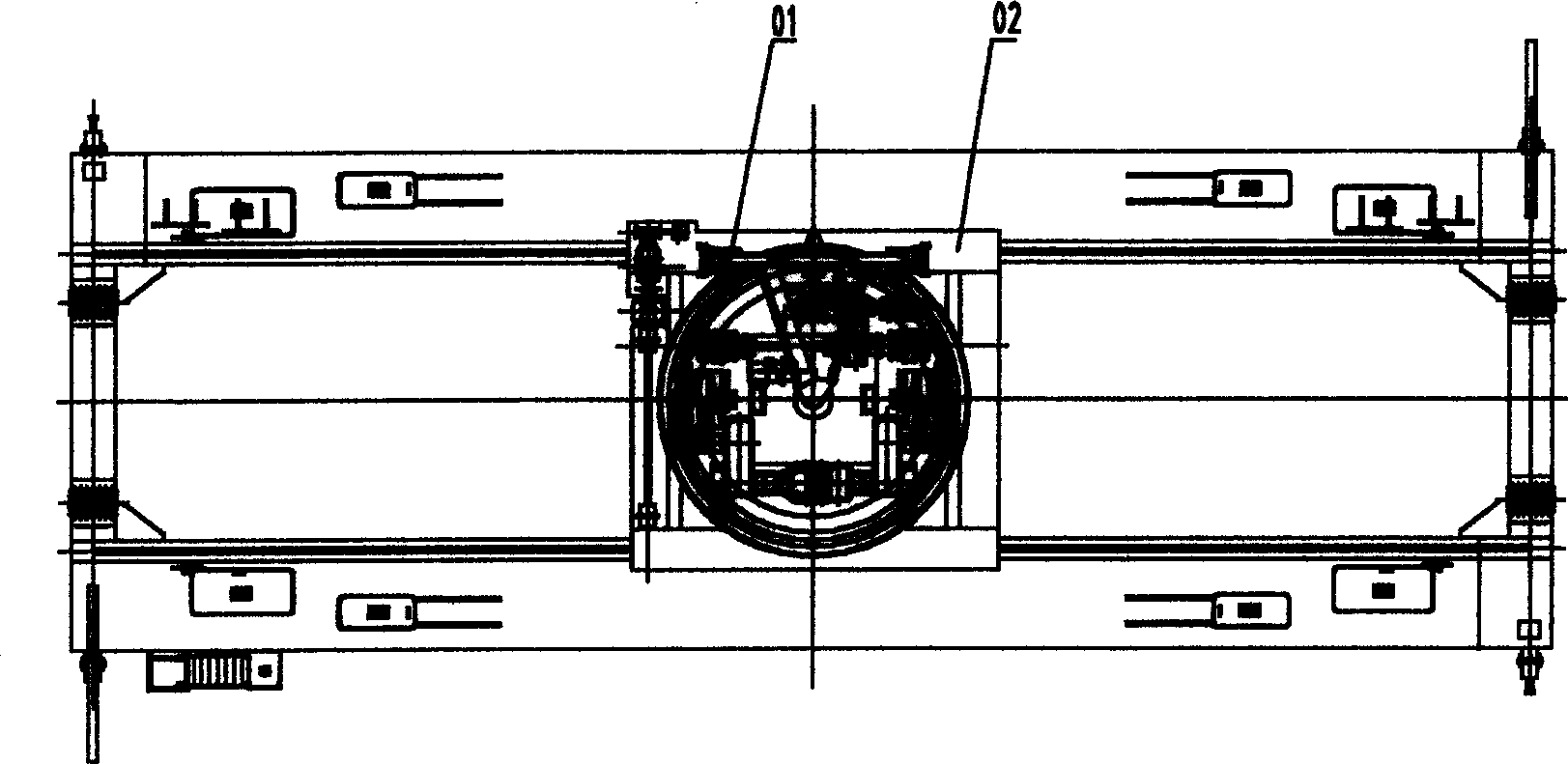

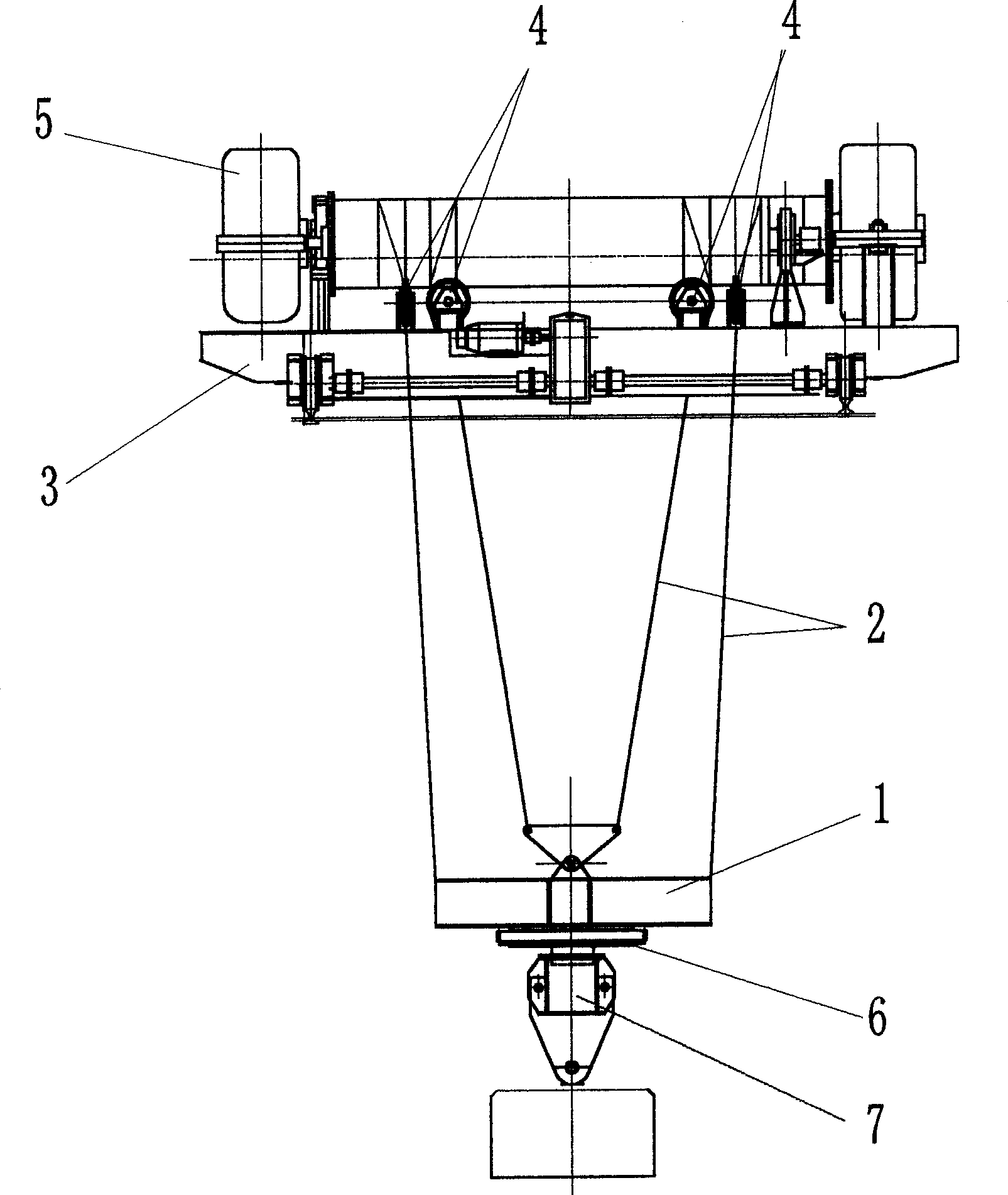

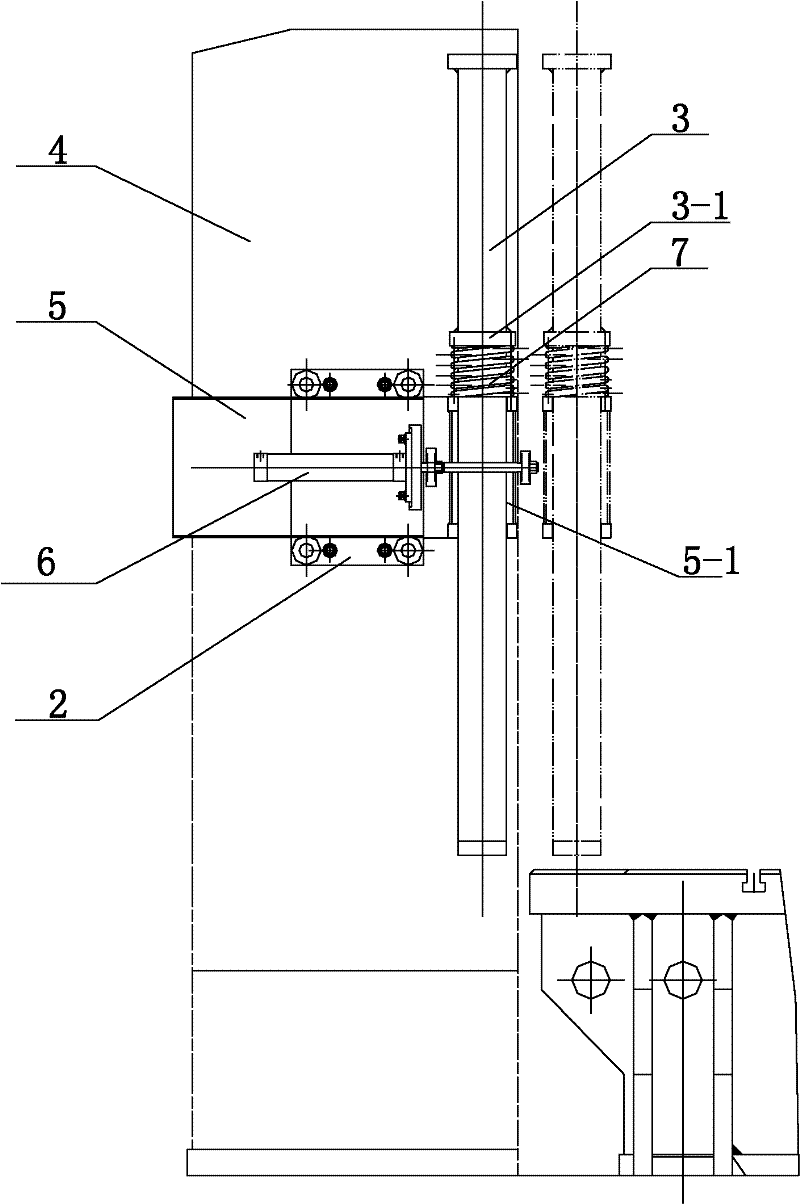

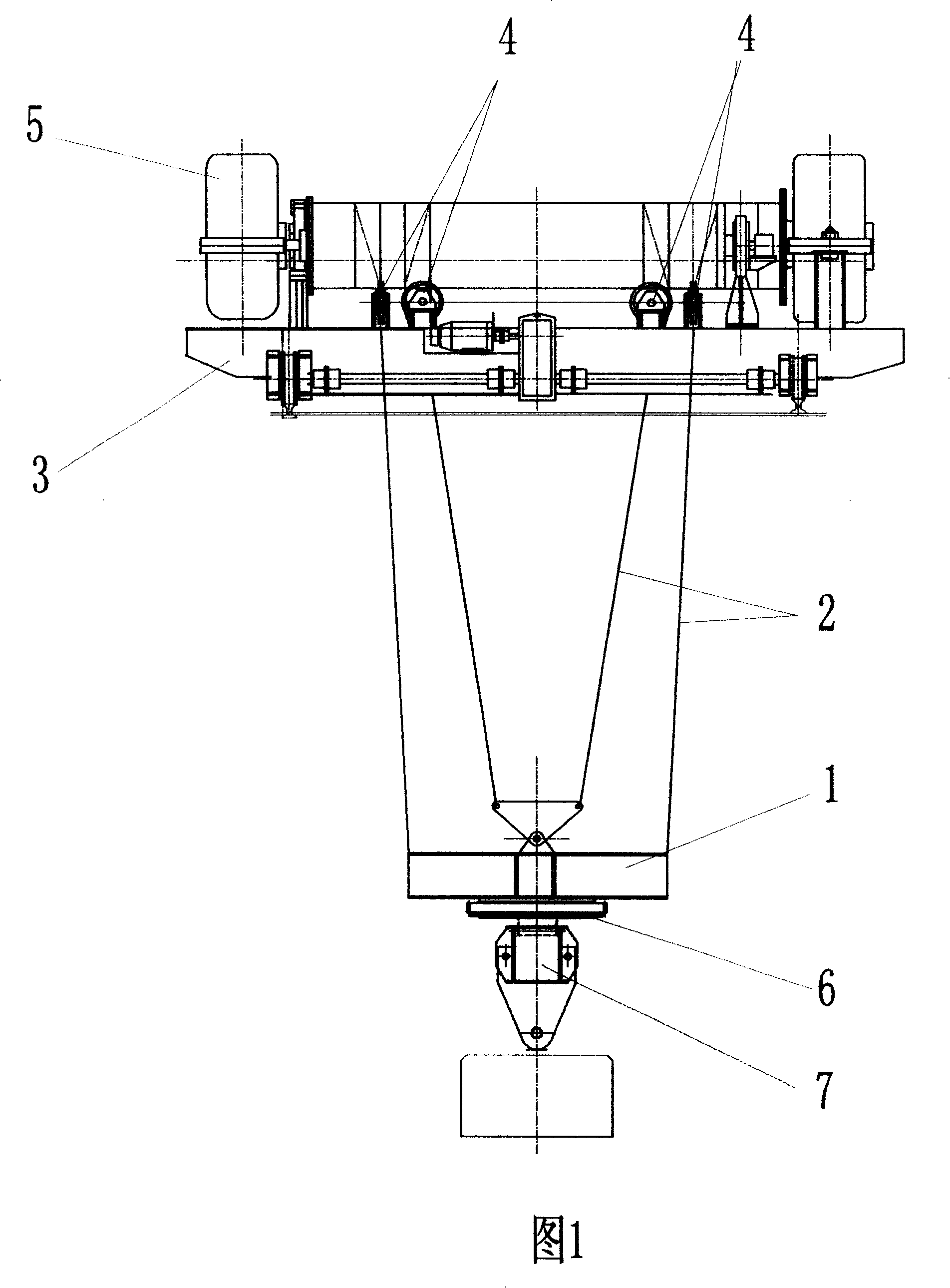

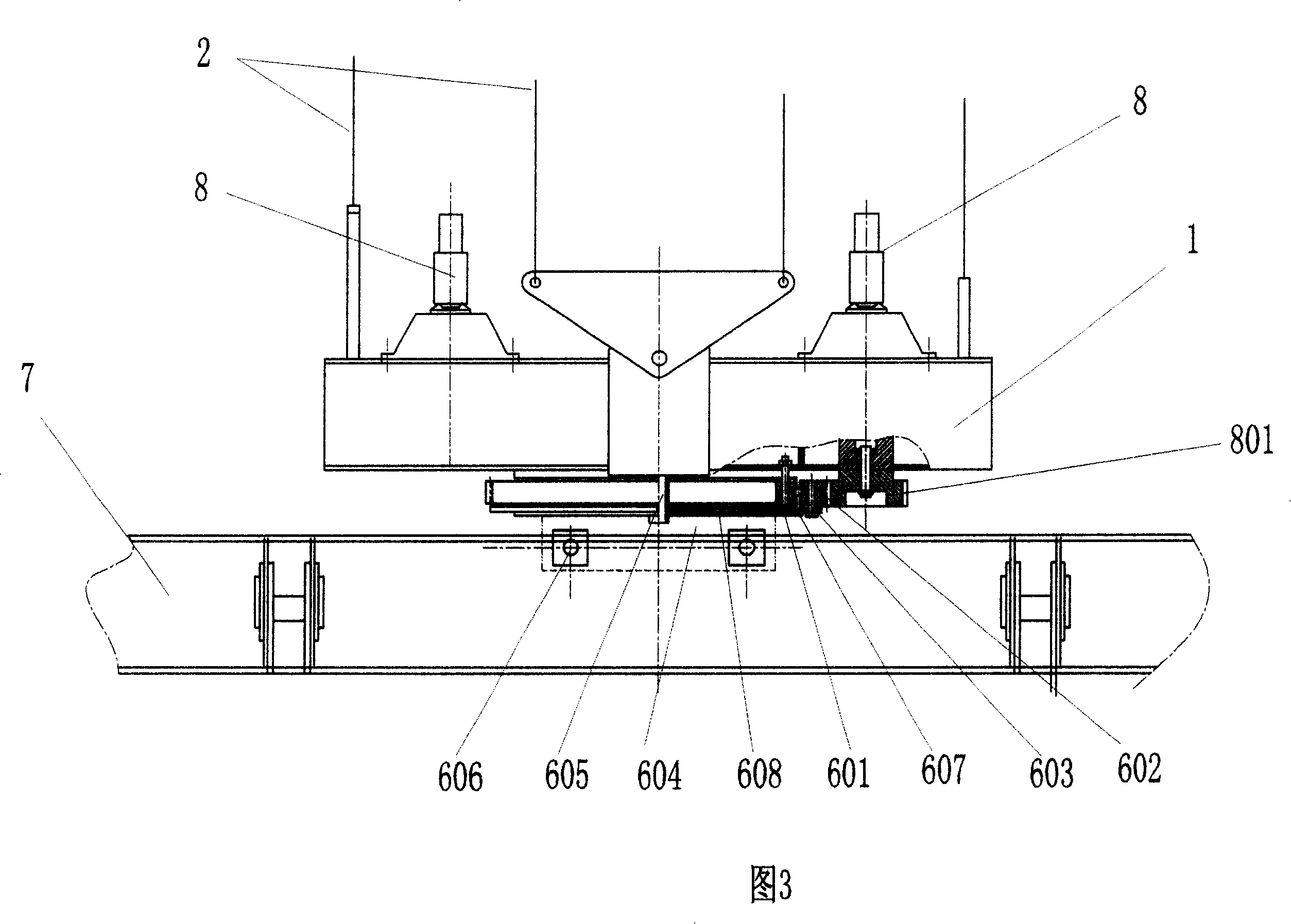

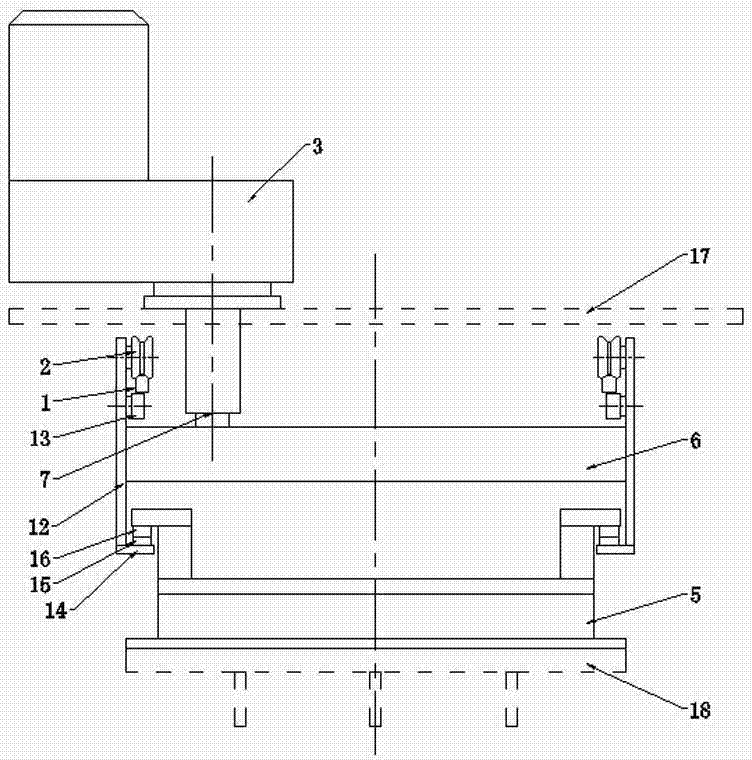

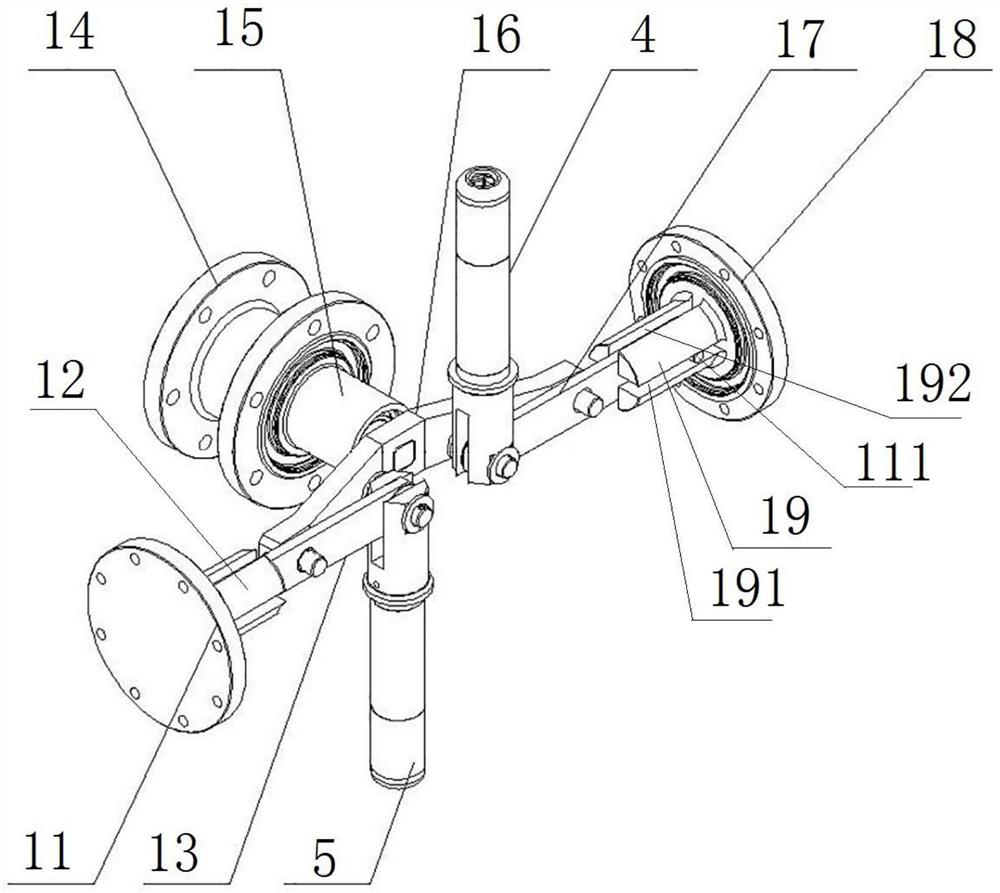

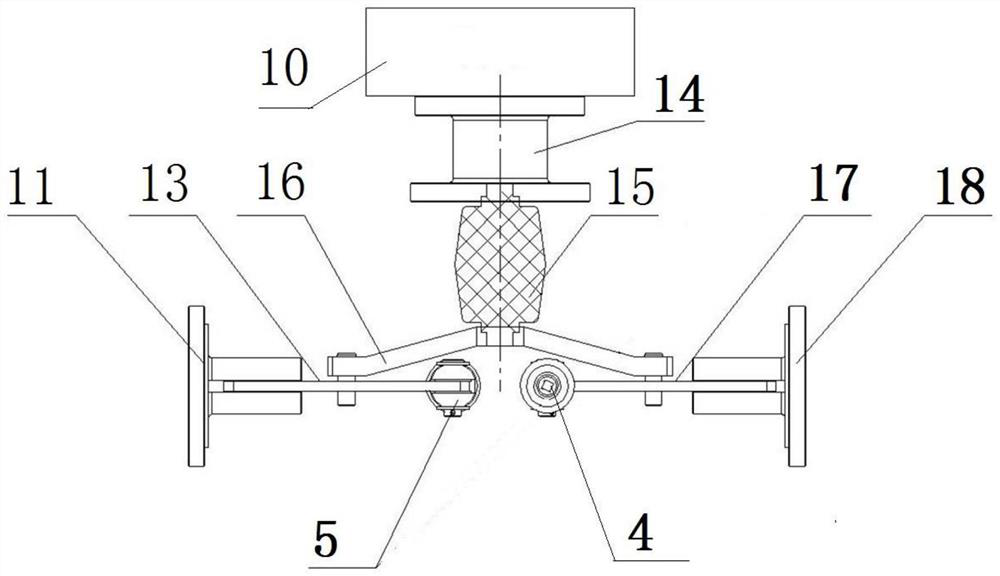

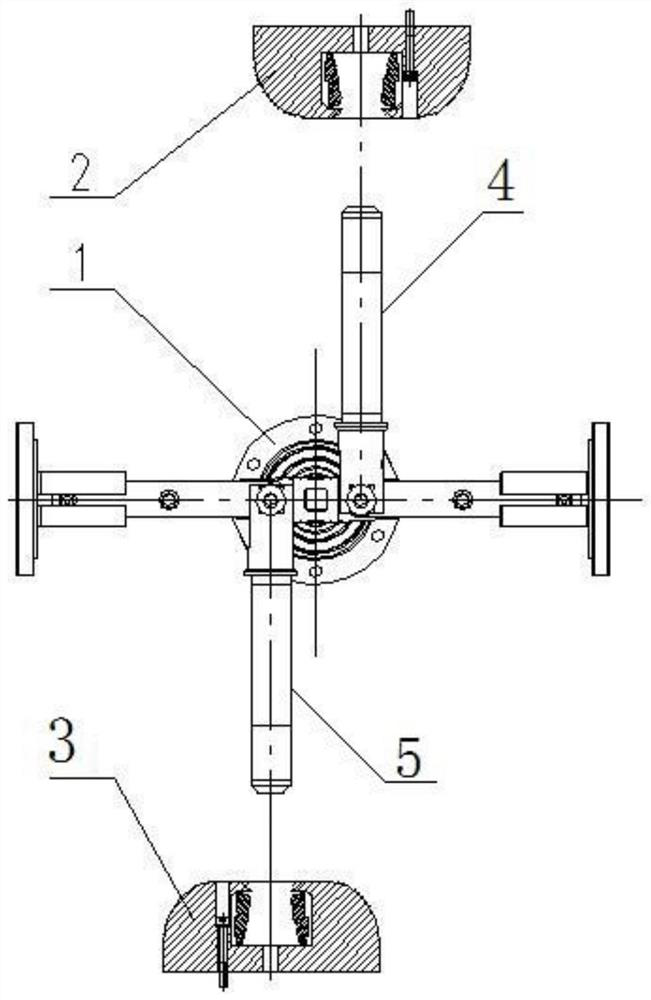

Guide and rotation mechanism for crane hanger

This invention relates to a guide and rotation machine of lift sling, which comprises guide mechanism, rotation mechanism and crossbeam; it has following peculiarities: a) guide mechanism is formed by cruciform girder, steel rope and block device disposed vertically on the small carriage; b) the steel ropes circling down from the block device of heize mechanism are connected with four girder ends of cruciform girder separately to form a crisscross to position the cruciform girder at parallel and vertical direction; c)the rotation mechanism mounted in the cruciform girder is connected with sling crossbeam.

Owner:TAIYUAN HEAVY IND

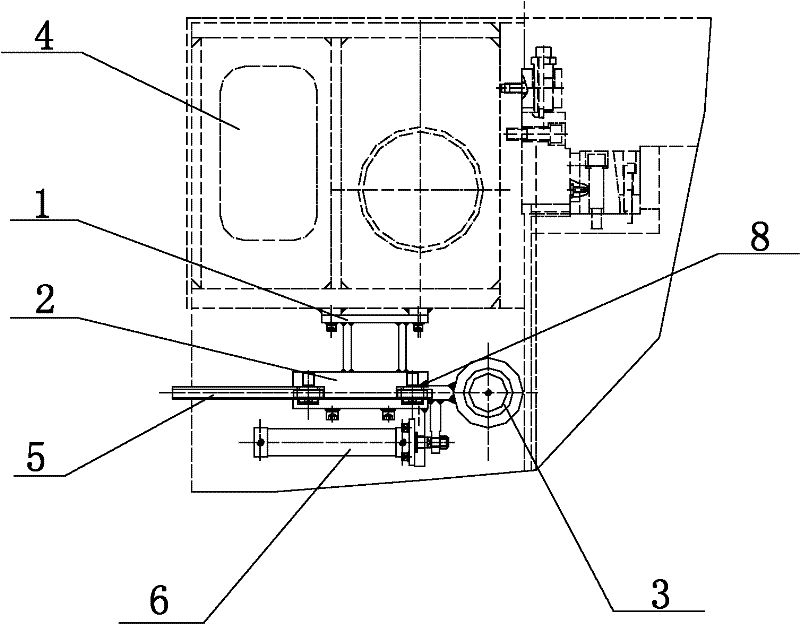

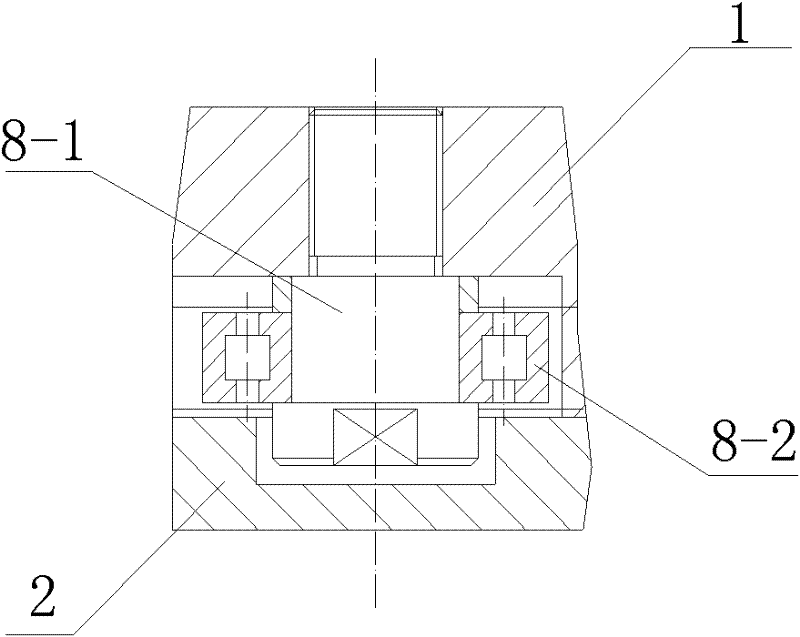

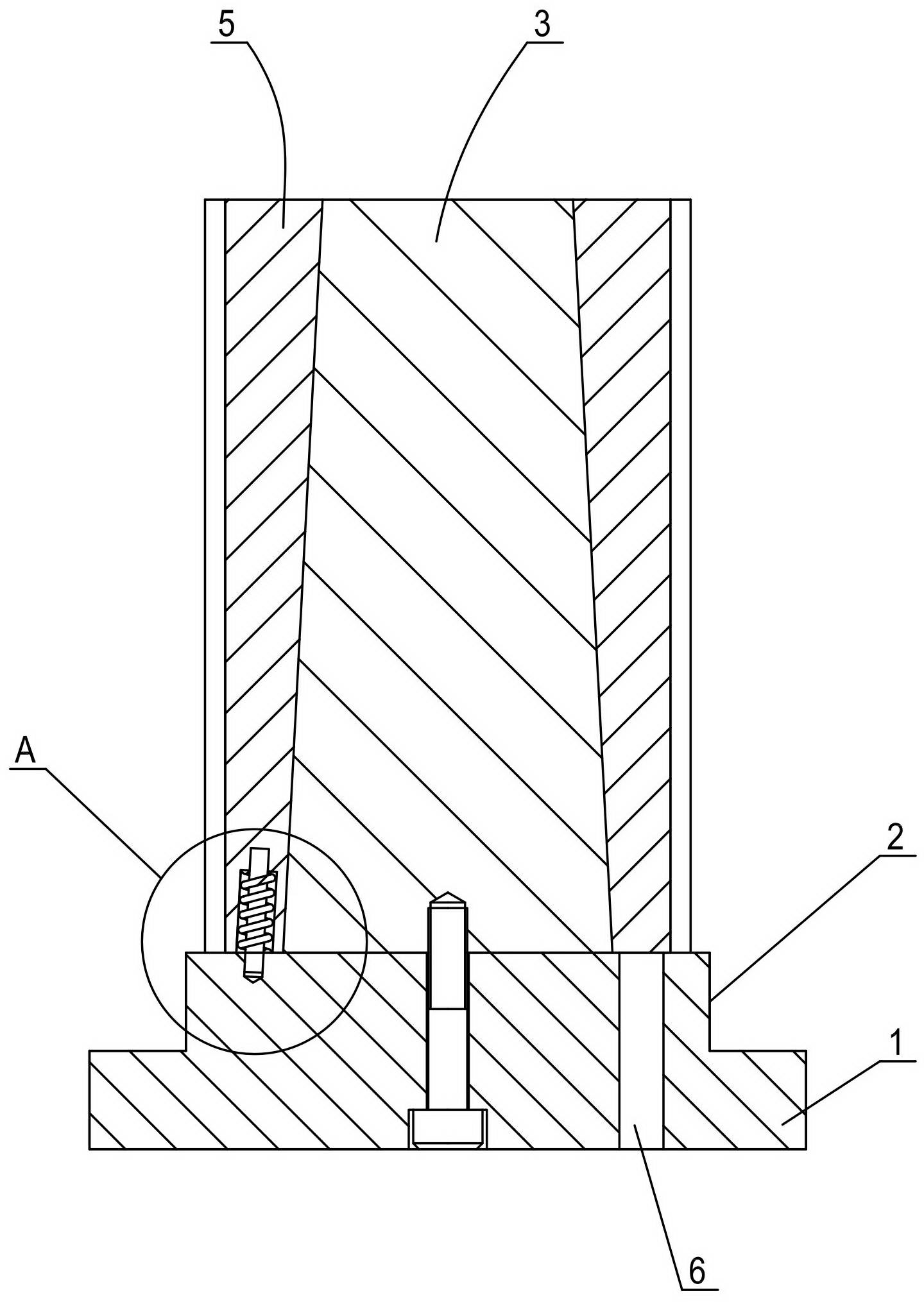

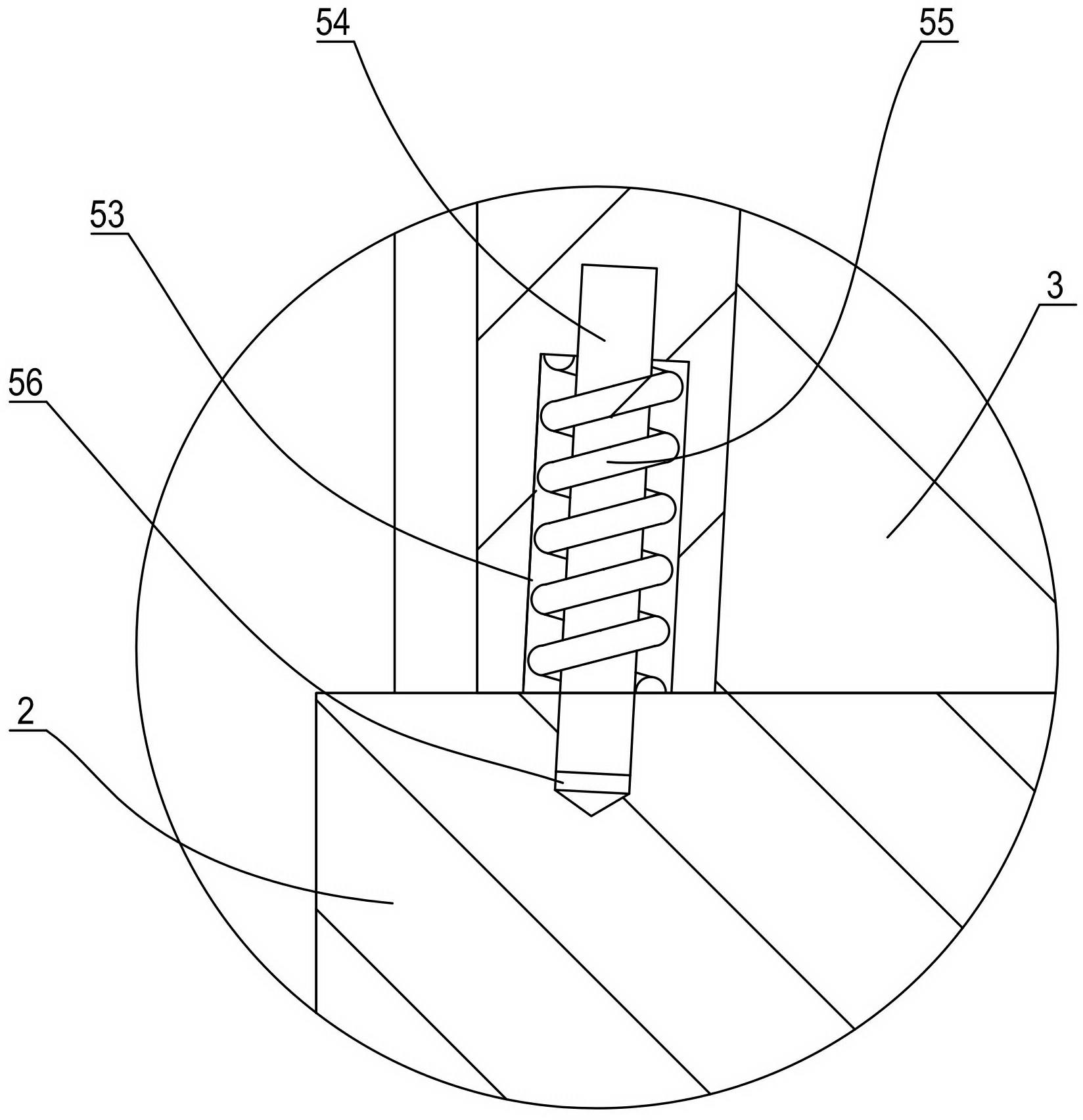

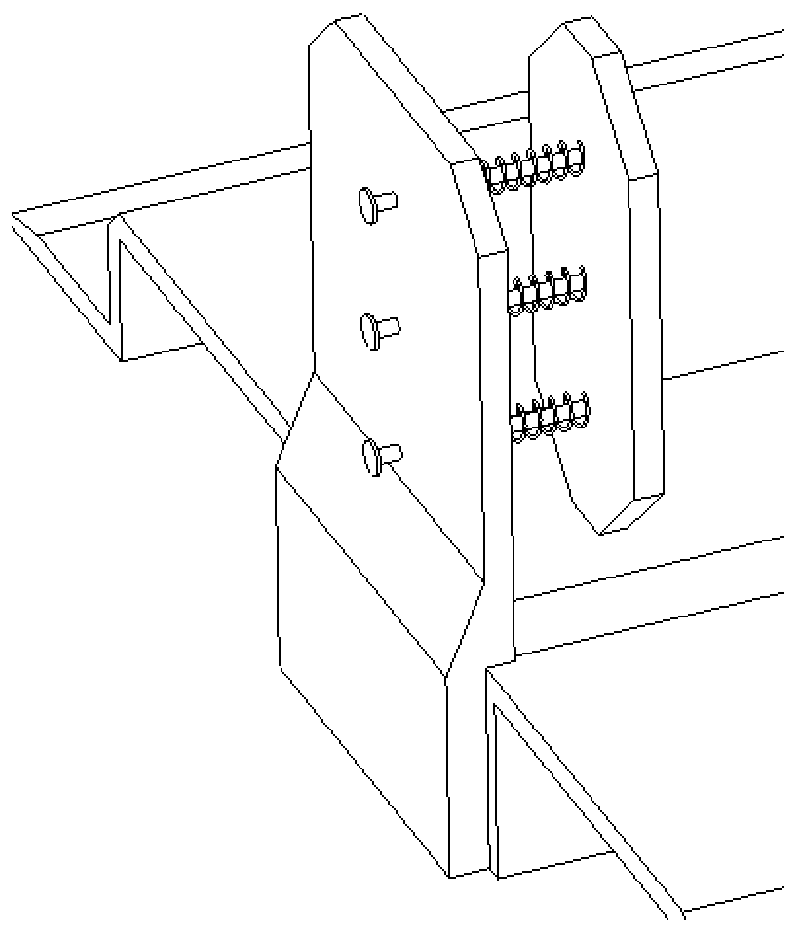

Plug pin type safety device for hydraulic machine

The invention relates to a plug pin type safety device for a hydraulic machine, which is characterized by mainly comprising a support frame, a cover plate, a safety bolt and an air cylinder, wherein the support frame is fixedly arranged on the side wall of an upright post of the hydraulic machine, the cover plate is fixedly arranged at the outer side of the support frame, a rectangular groove is formed by the cover plate and the support frame, a plug pin plate is arranged in the rectangular groove and is connected with a piston rod of the air cylinder, the air cylinder is fixedly arranged on the cover plate, the end part of the plug pin plate is provided with an installing hole, the safety bolt is arranged in the installing hole in a penetrating way, a support spring is sheathed on the safety bolt, the lower end of the support spring is seated and arranged on the plug pin plate, a position limiting ring is arranged on the safety bolt, and a guide device is arranged between the plug pin plate arranged in the rectangular groove and the inner wall of the rectangular groove. Compared with the prior art, the plug pin type safety device has the advantages that the structure is simple, the installation and the use are convenient, in addition, the occupied space is small, the maintenance is easy, the safety performance is high, and the like.

Owner:TIANJIN TIANDUAN PRESS CO LTD

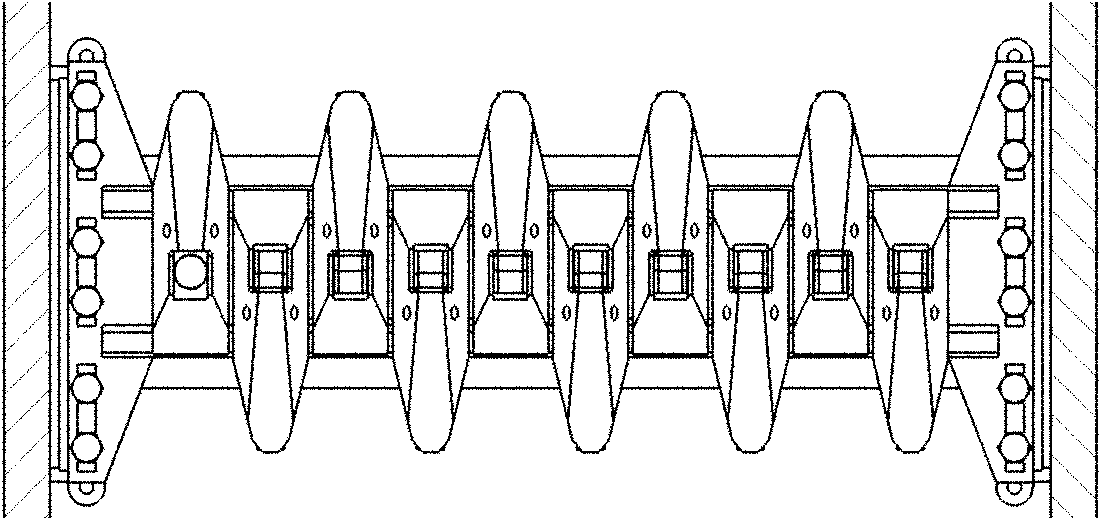

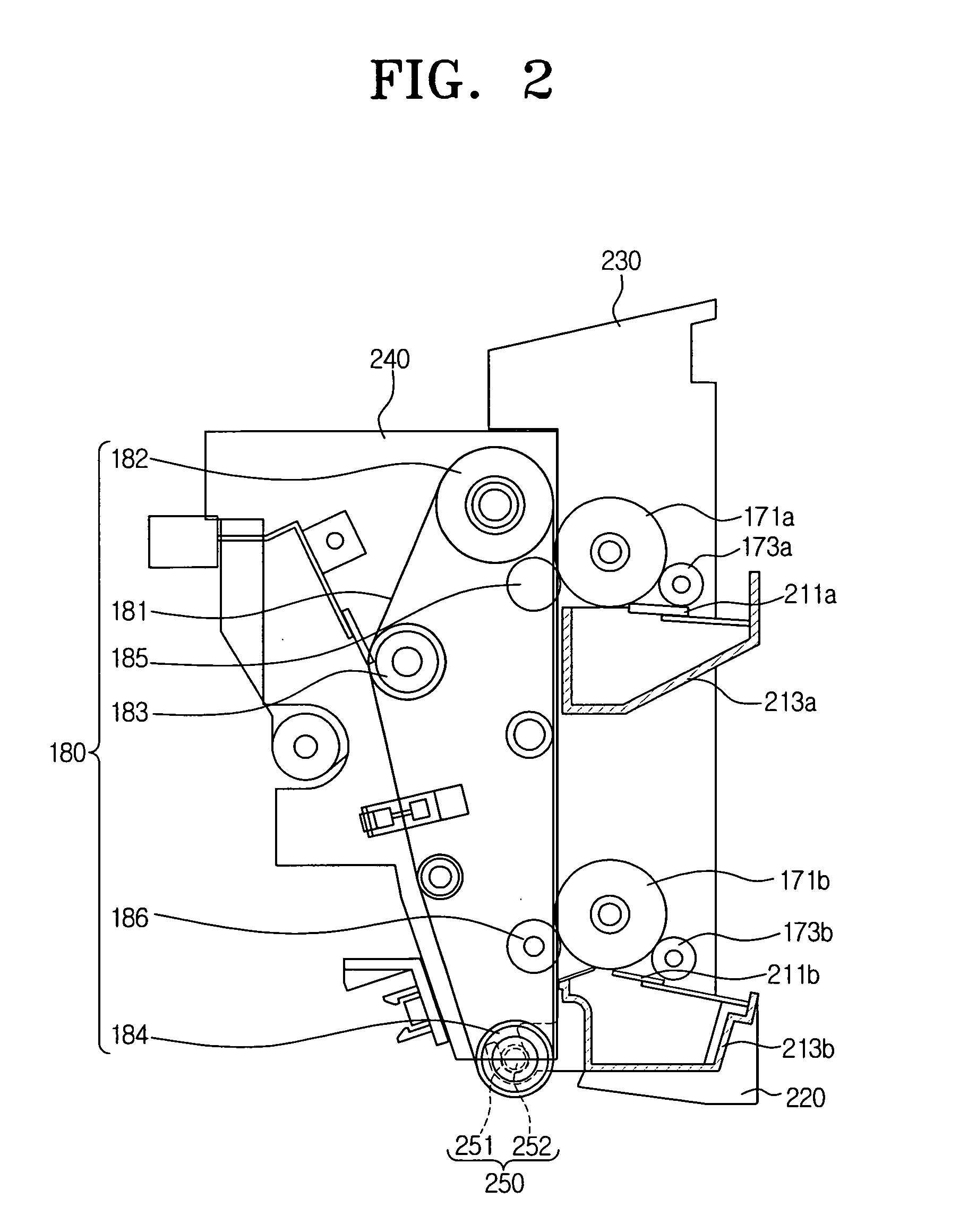

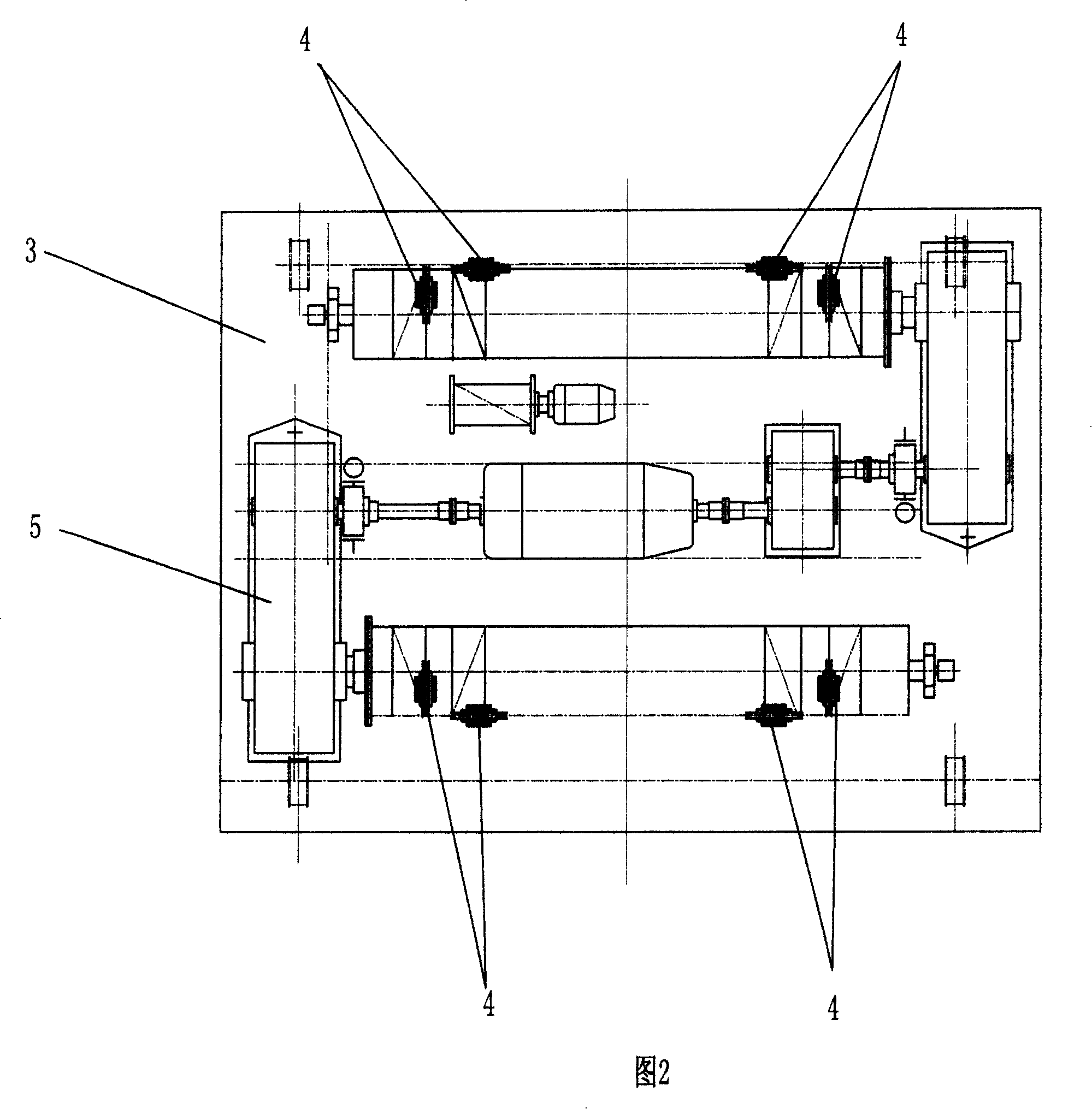

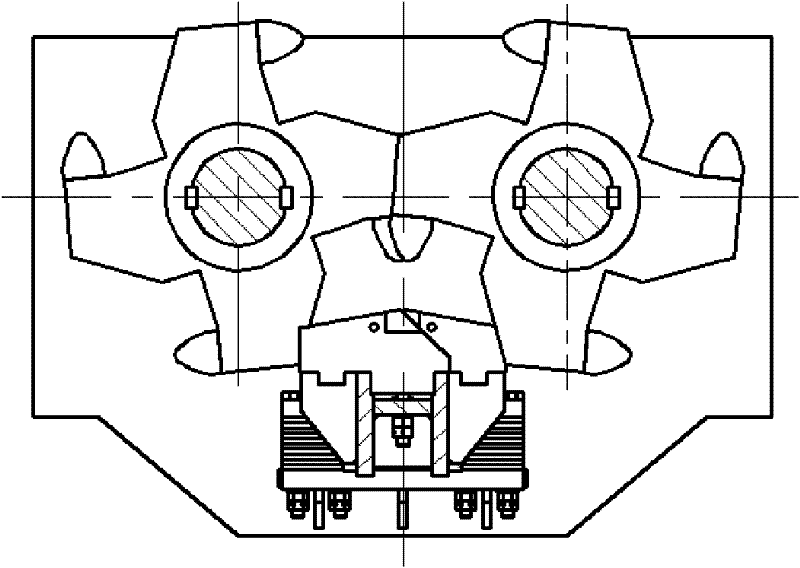

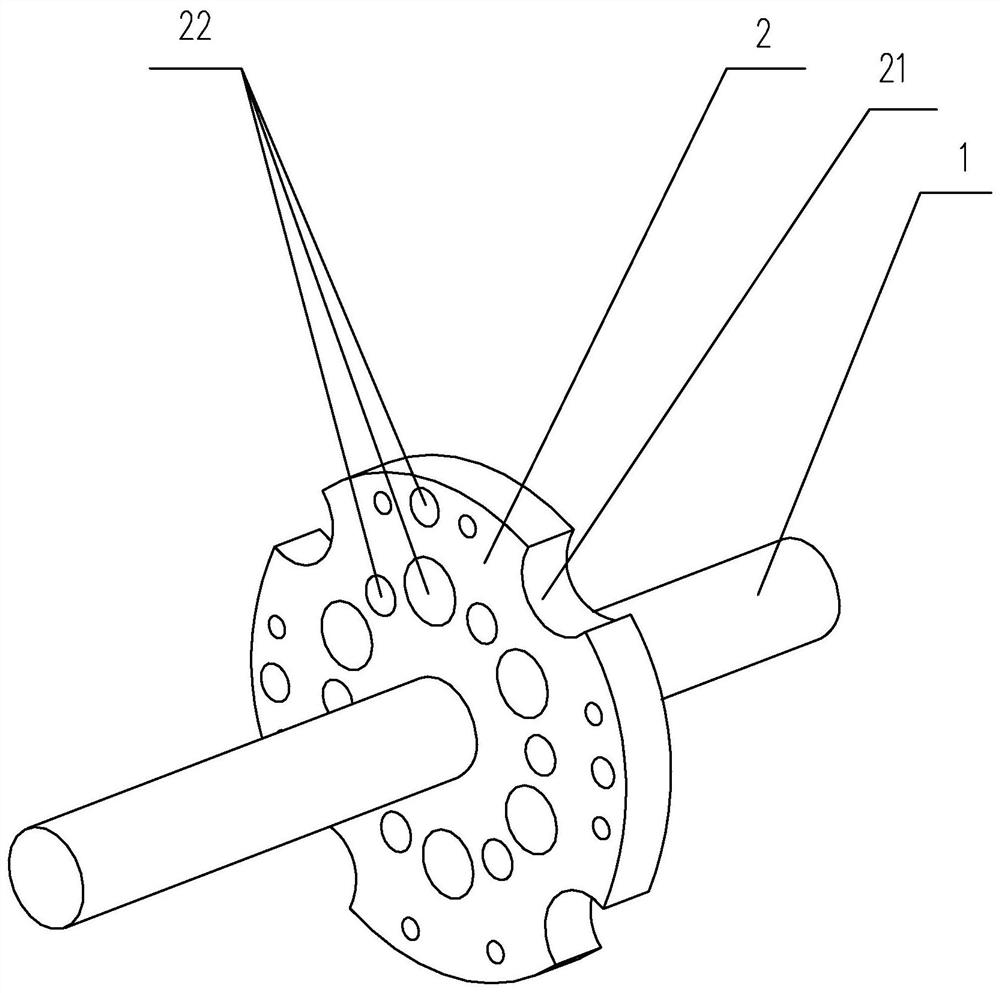

Crushing beam combined structure of double-tooth roller crusher

InactiveCN102091666AOrientation structure is simpleEasy to assembleGrain treatmentsDouble teethEngineering

The invention discloses a crushing beam combined structure of a double-tooth roller crusher applied in the industry of crushing equipment. The structure consists of a rack, an adjusting gasket, a bolt, a crushing beam, a crushing tooth cap, a tooth cap cover, a guide element, a stop block, a bolt for the stop block, and a bolt; a crushing beam assembly of the double-tooth roller crusher is positioned below two crushing tooth rollers of the crusher, and the crushing beam assembly is assembled on the rack through the bolt; two ends of the crushing beam are provided with a guide groove C and a guide groove D respectively; the guide element is arranged on the rack; the crushing beam assembly is placed on the rack along the guide groove C and the guide groove D and assembled through the bolt; and the adjusting gasket is provided with a plurality of U-shaped grooves, the opening directions of the U-shaped grooves and the side of the adjusting gasket from inclination angles, and the sides of the inclination directions of the U-shaped grooves are provided with unfilled corners parallel to the opening directions of the U-shaped grooves, so that the adjusting gasket is obliquely inserted into the long and narrow space more deeply. The guide structure of the crushing beam of the device is simple, so that the crushing beam assembly is convenient to install; and by combining the adjusting gasket structure with large bearing area, the stress state of the crushing beam assembly is effectively improved.

Owner:SHENYANG HEAVY MACHINERY GROUP

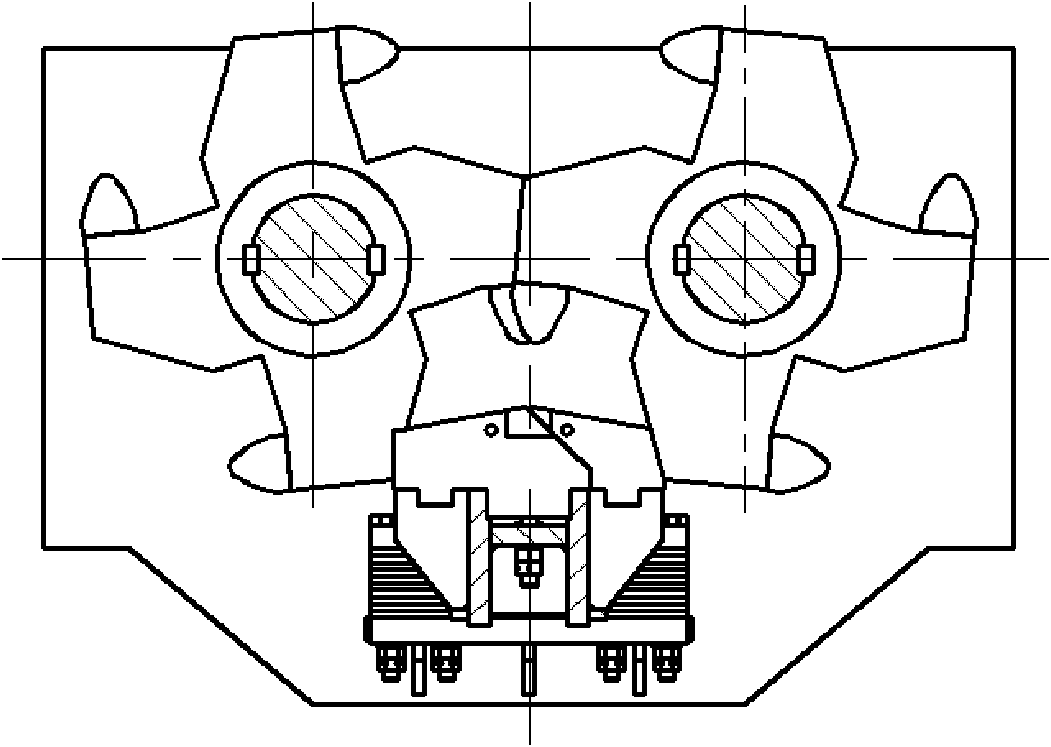

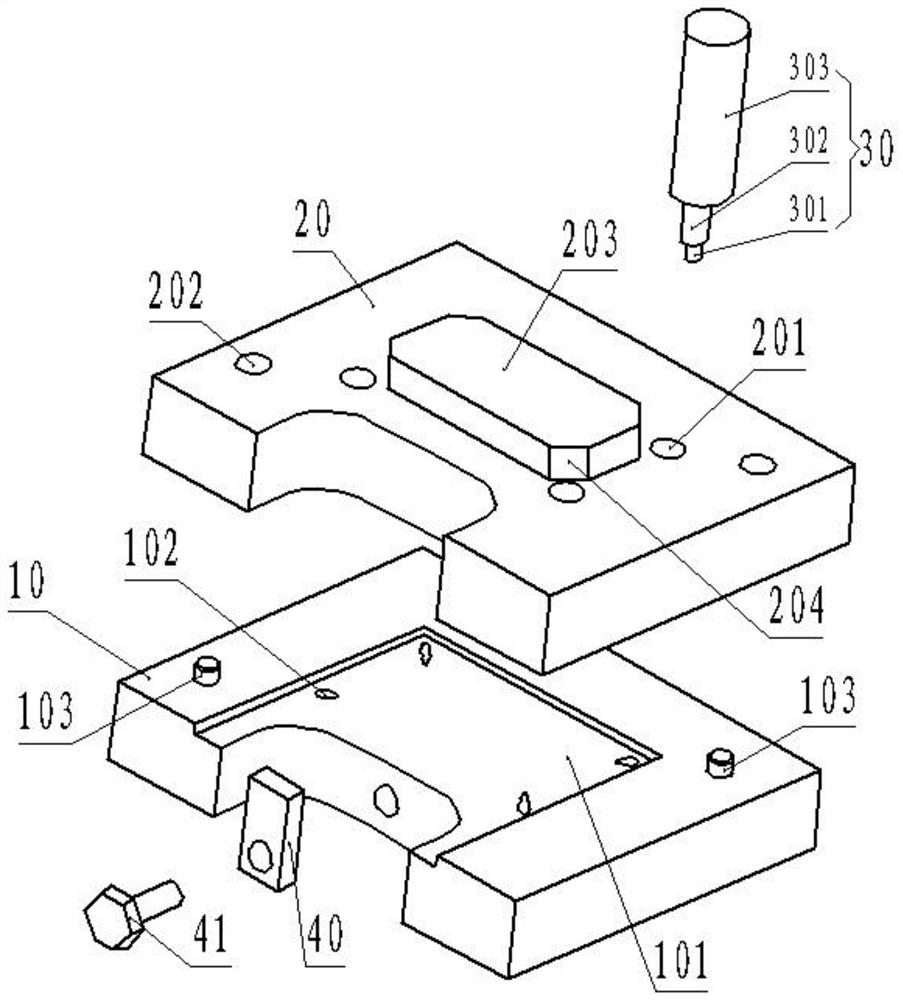

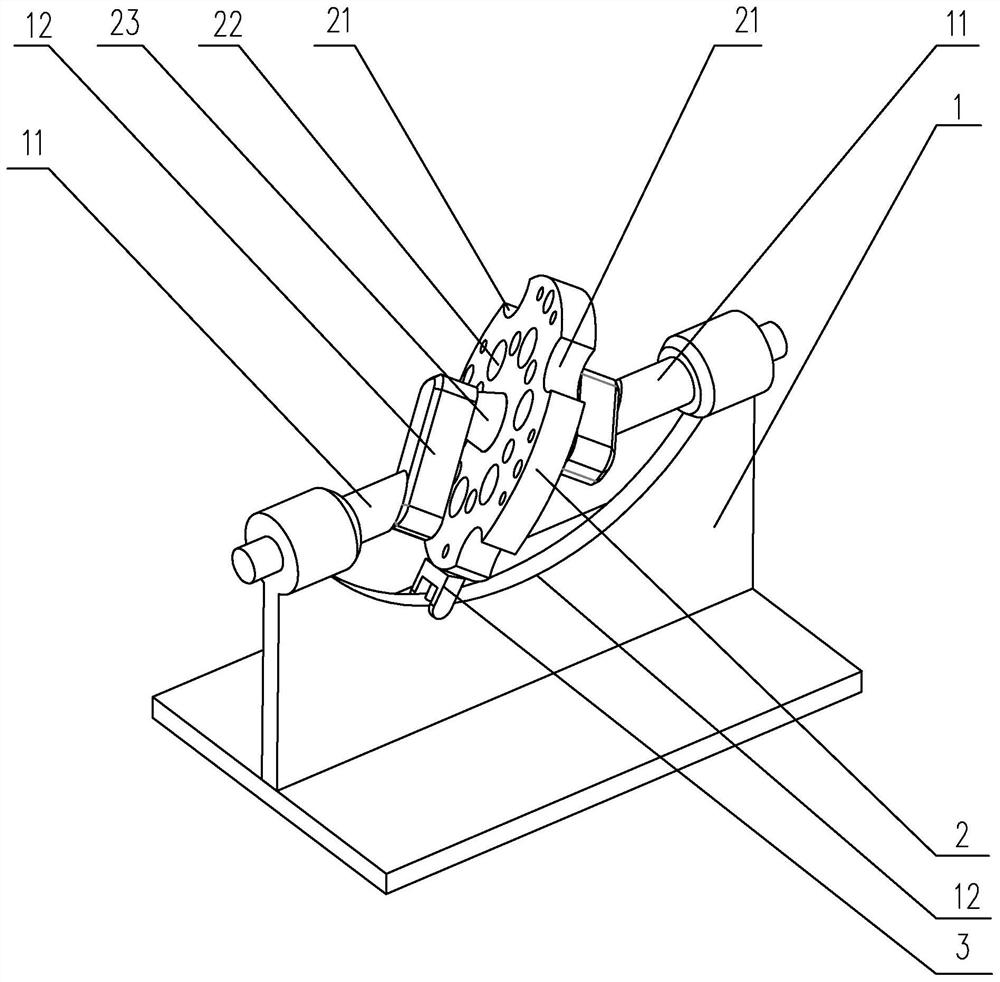

Clamping mechanism and clamping device

ActiveCN113997101AImprove versatilitySave layout spaceWork holdersPositioning apparatusMechanical engineeringPhysics

Owner:TONGJI UNIV

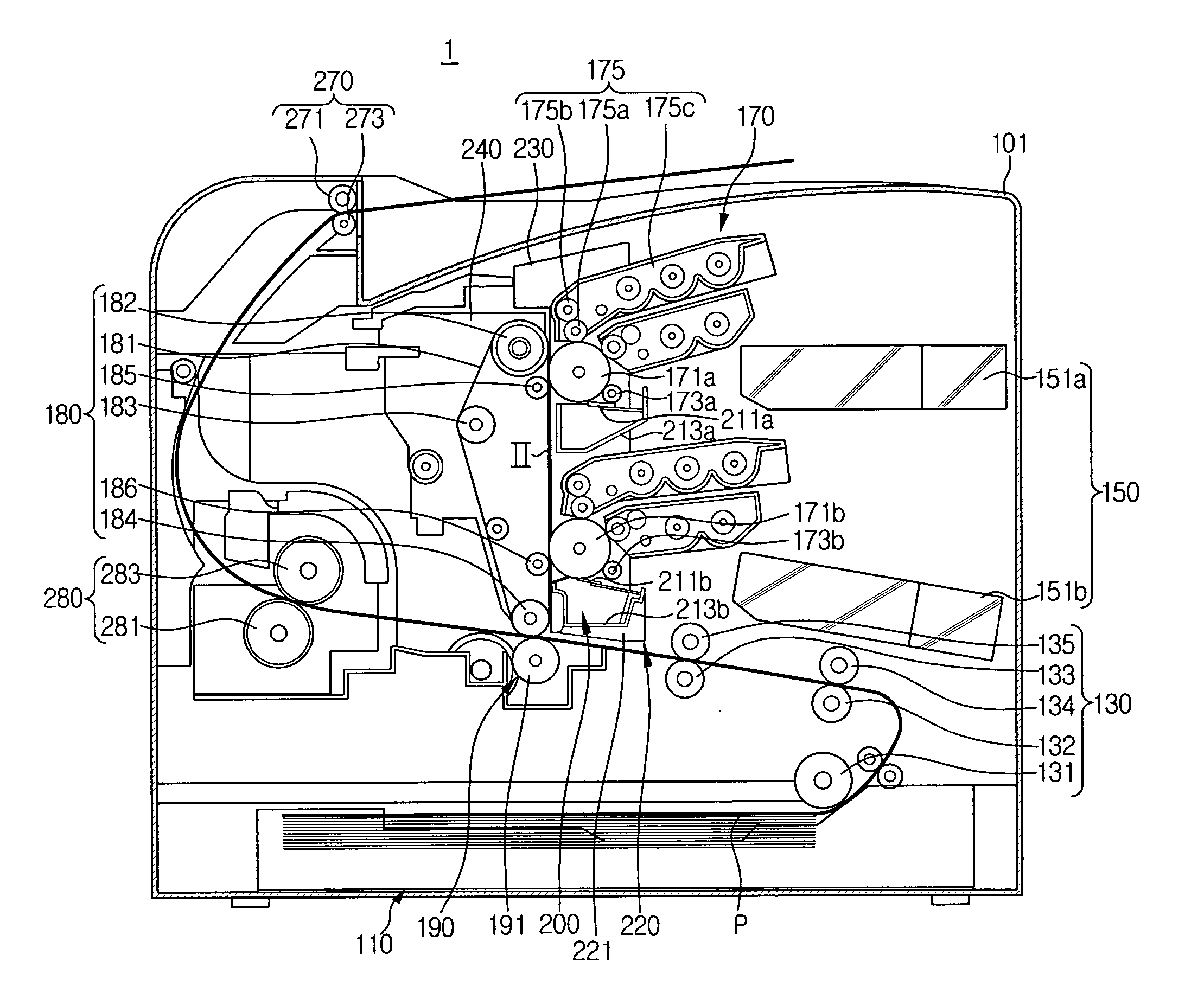

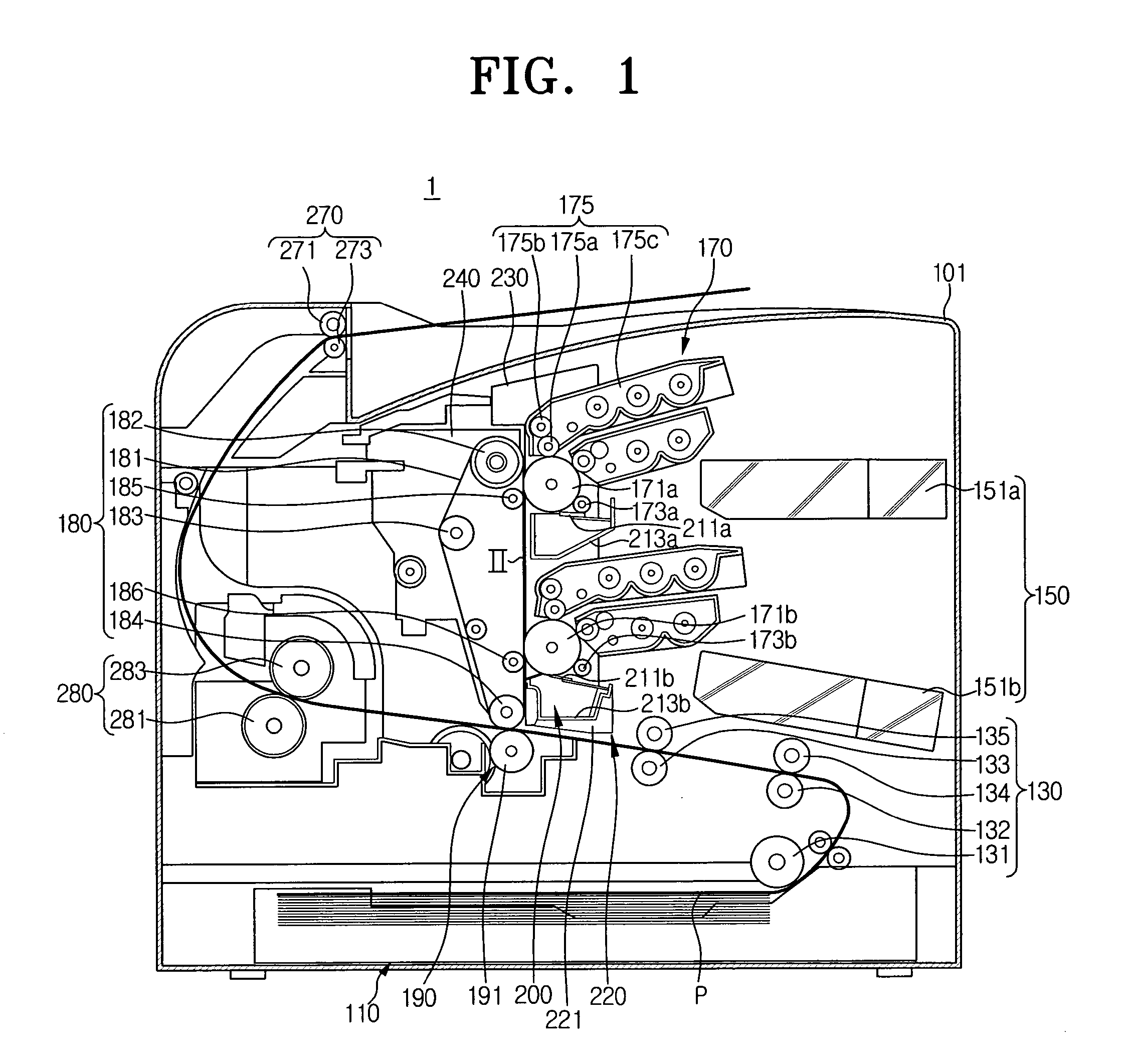

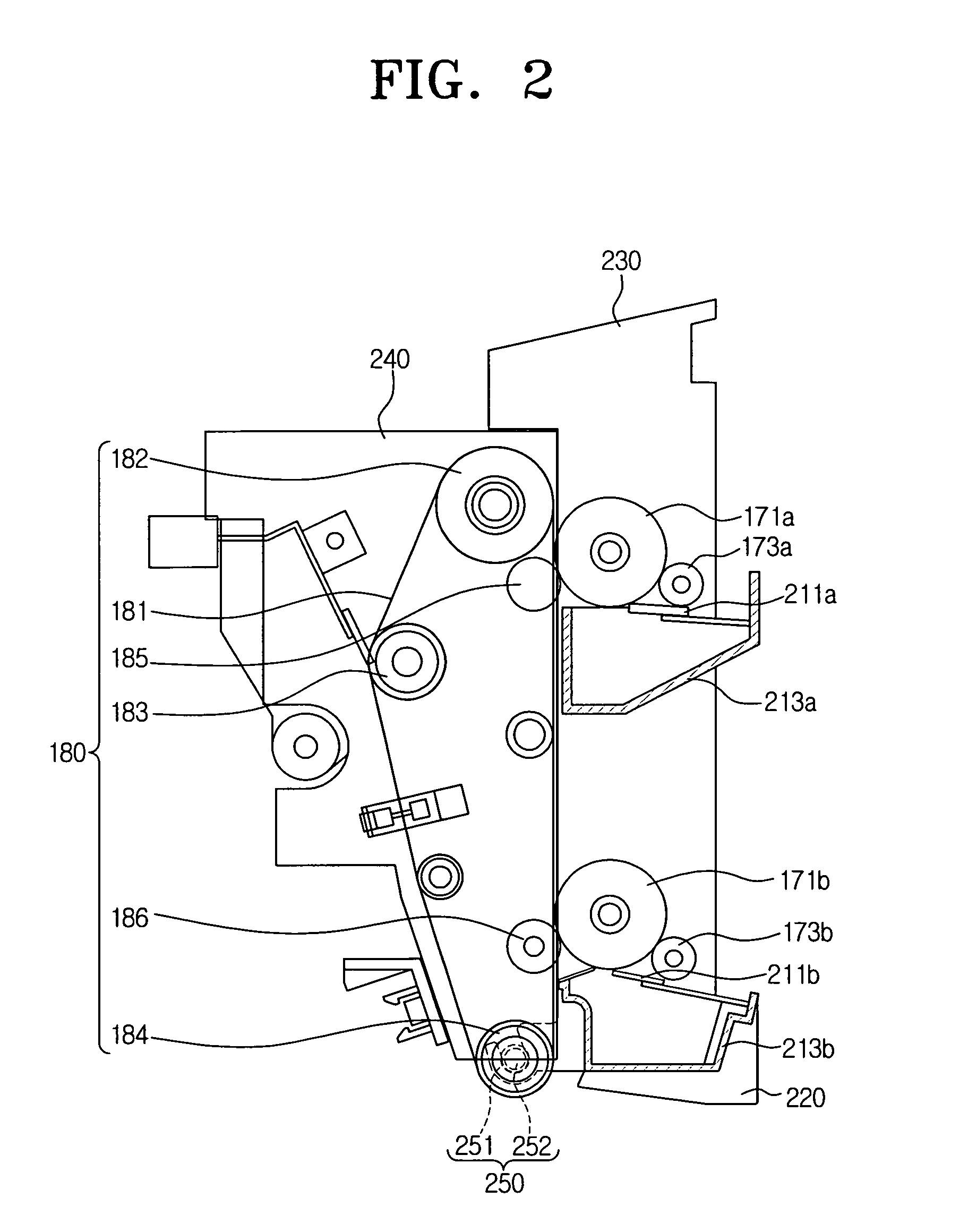

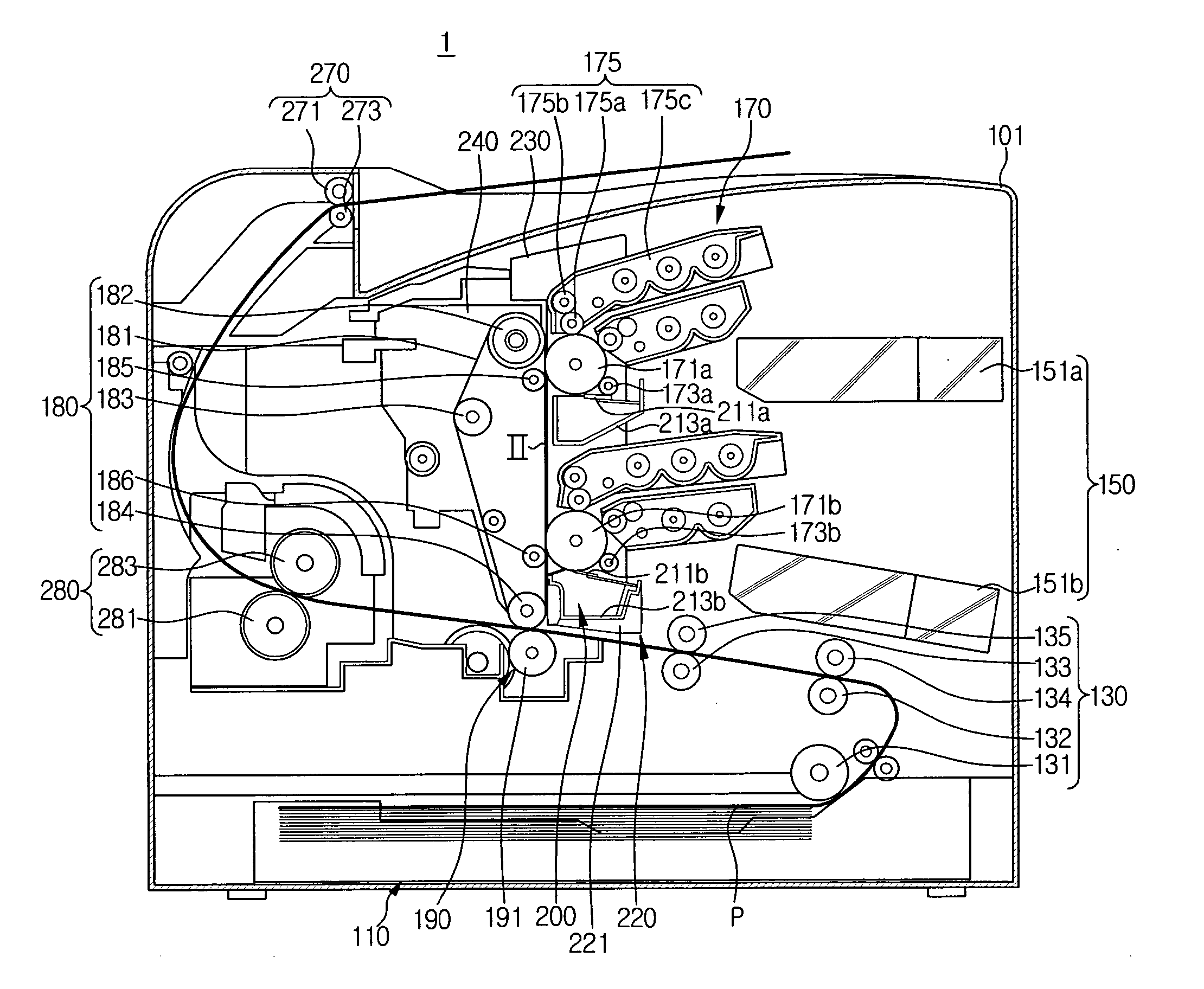

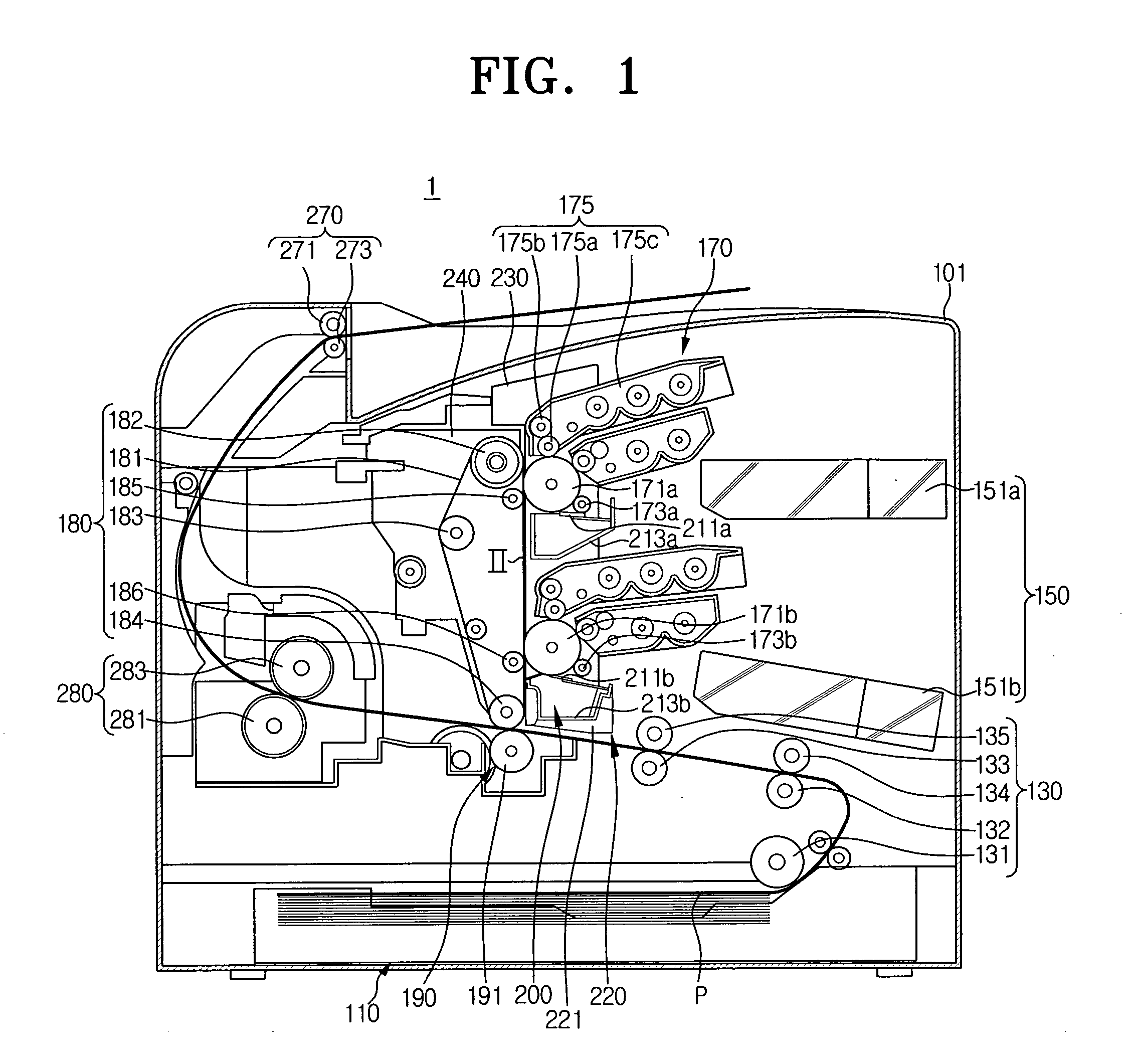

Image forming apparatus with printing medium guide

InactiveUS7437118B2Improve transmission efficiencyOrientation structure is simpleElectrographic process apparatusImage transferLatent image

An image forming apparatus has a photosensitive body on which an electrostatic latent image is formed. A developing unit develops the electrostatic latent image on the photosensitive body with a developer to form a developer image. The developer image on the photosensitive body is transferred onto an intermediate transfer belt in an intermediate transfer unit. The transfer unit transfers the developer image transferred on the intermediate transfer belt onto a printing medium. A cleaning unit cleans any developer remaining on the photosensitive body, and a printing medium guide unit is disposed on the cleaning unit to guide the printing medium until the printing medium enters the transfer nip between the intermediate transfer belt and the transfer unit.

Owner:HEWLETT PACKARD DEV CO LP

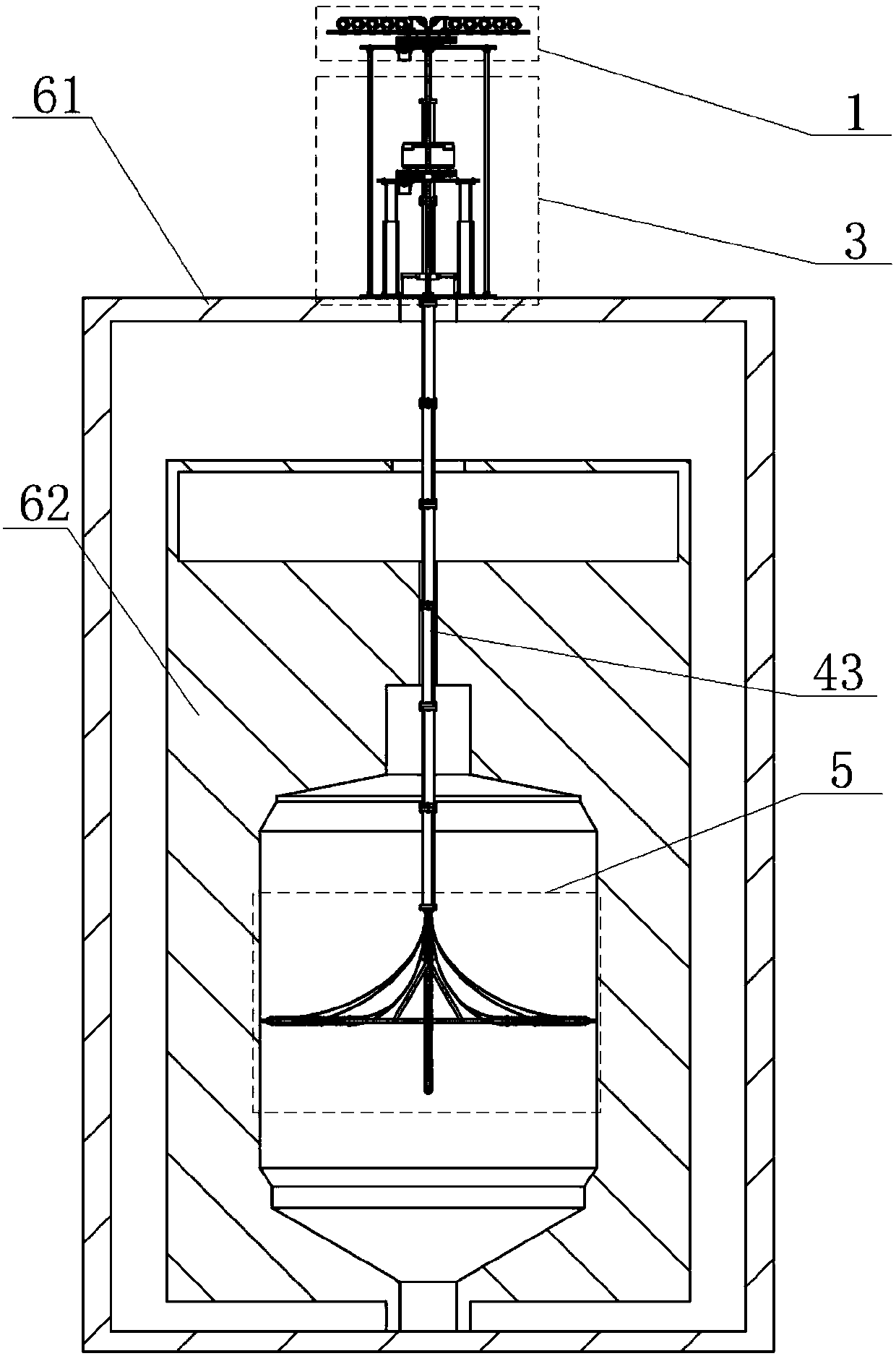

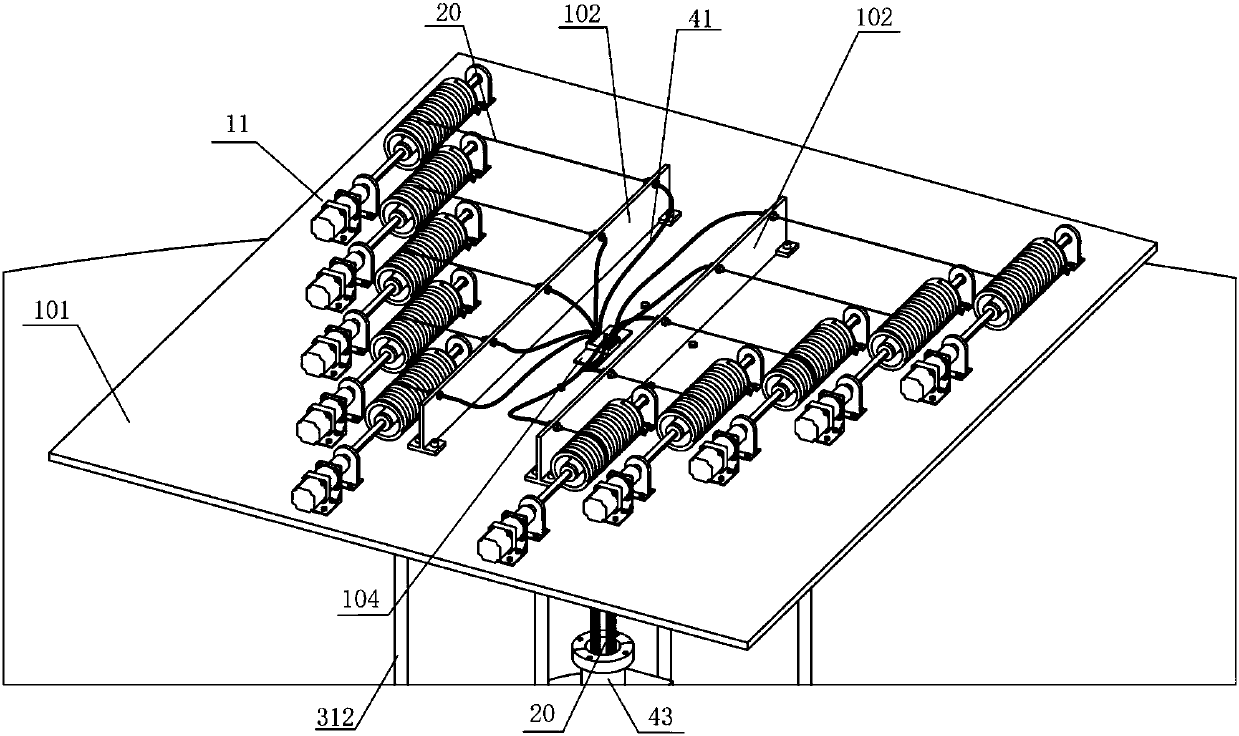

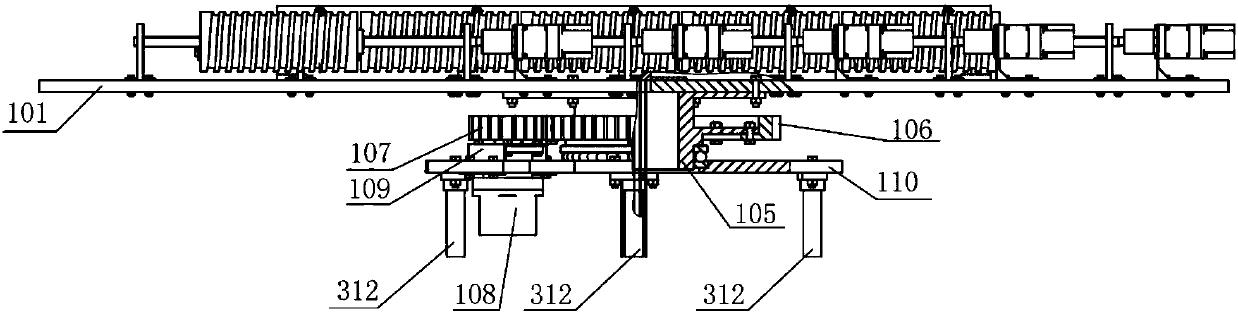

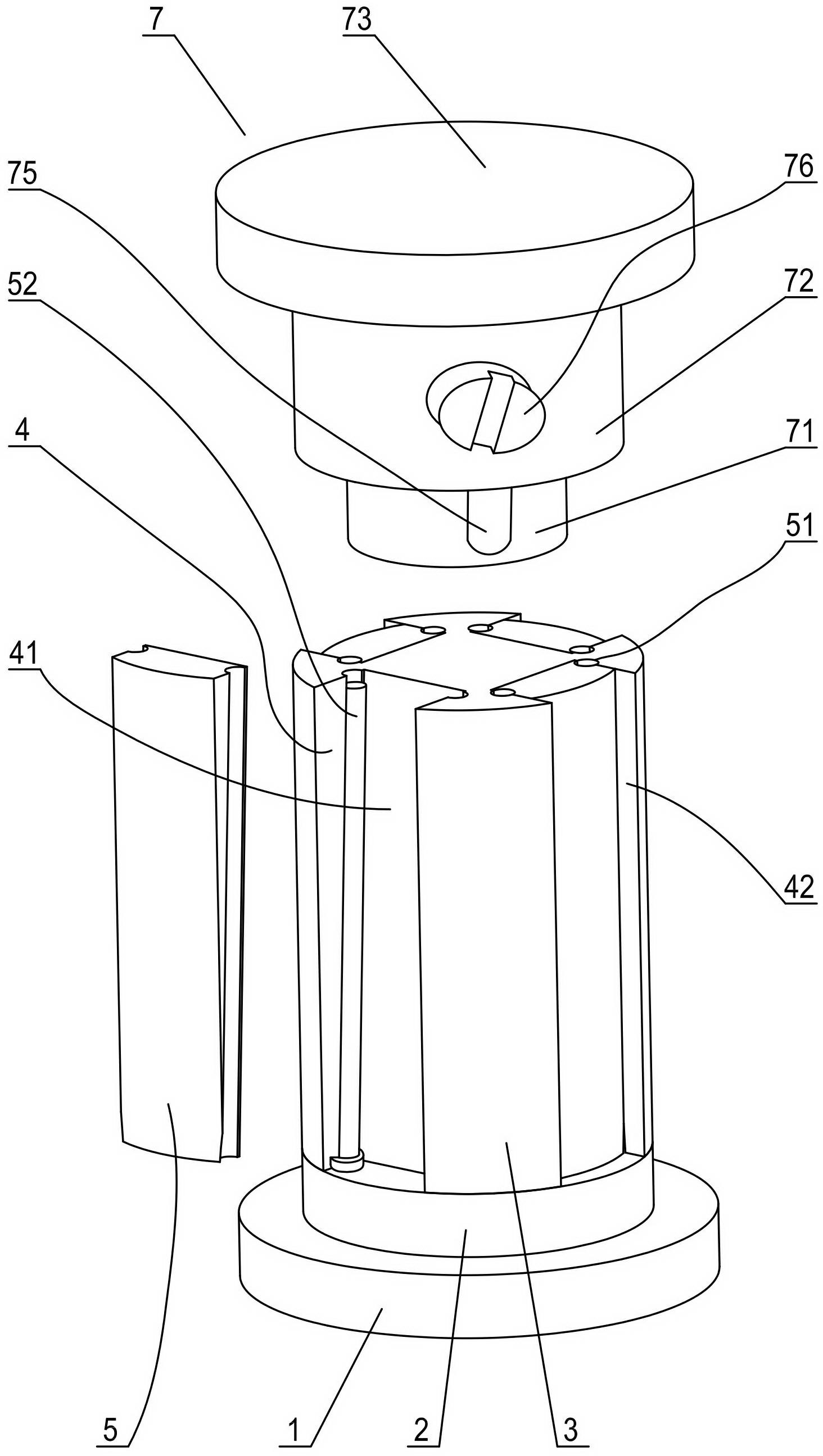

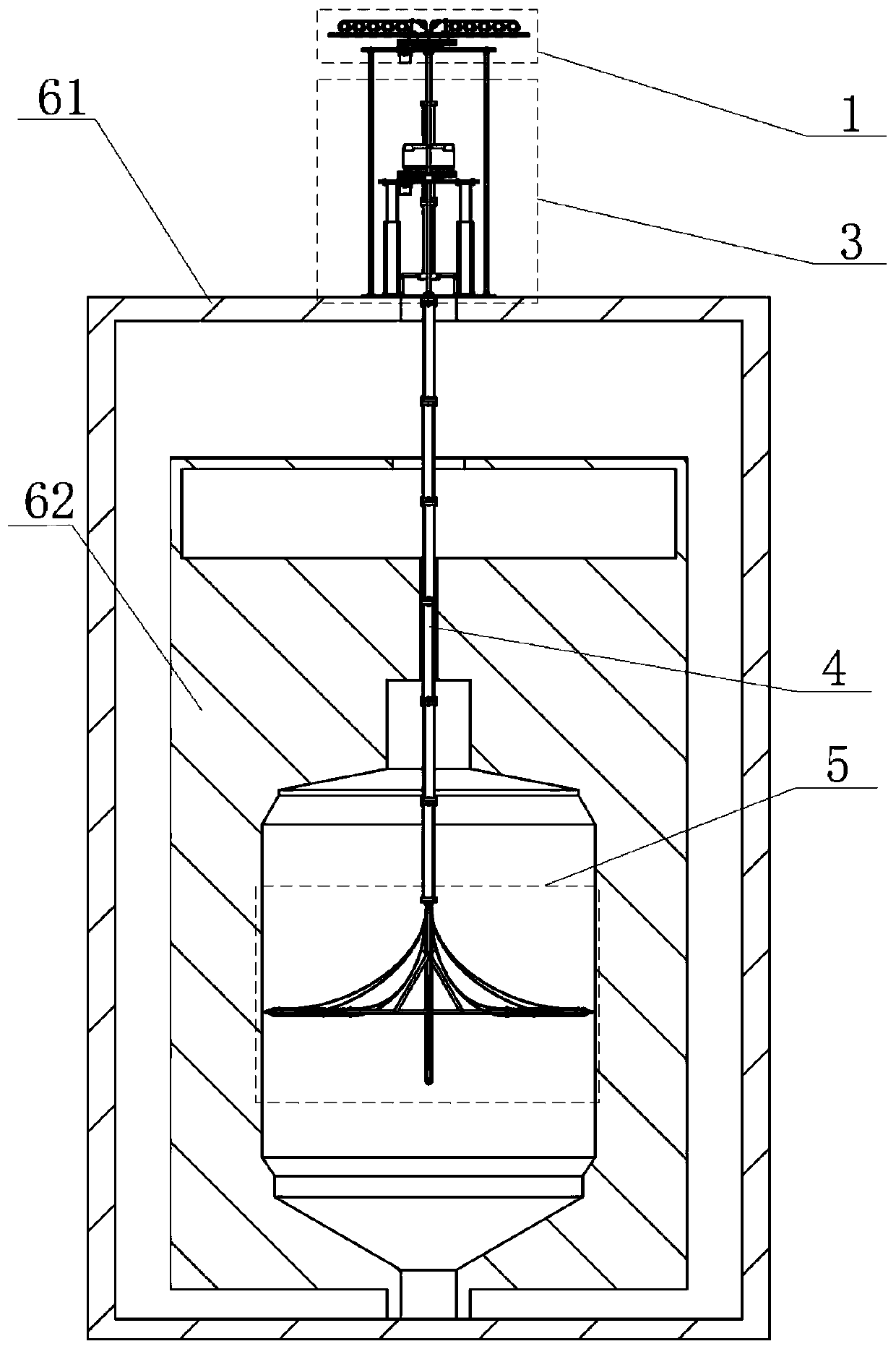

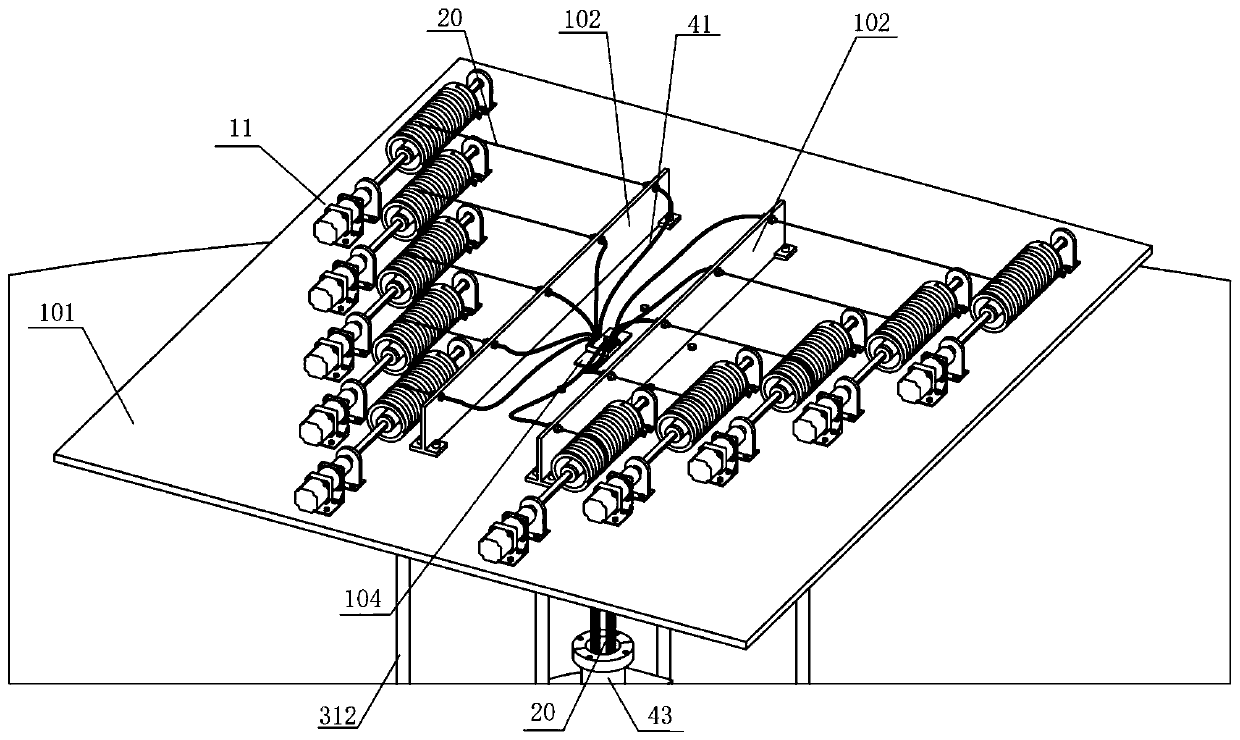

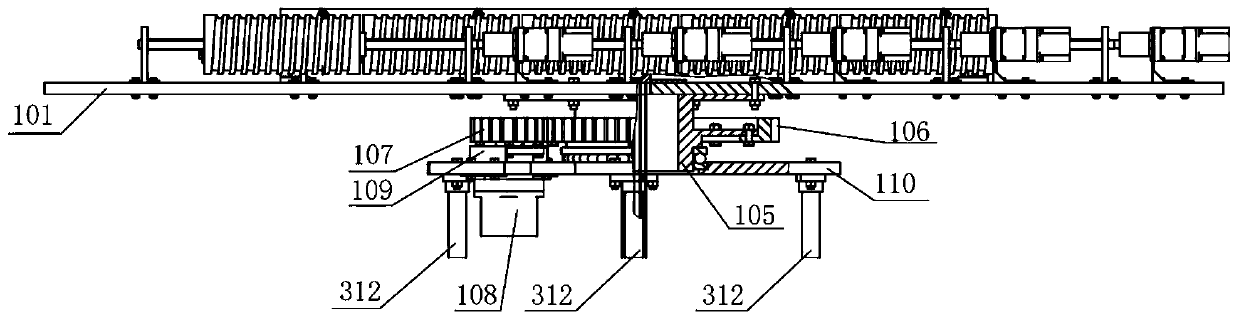

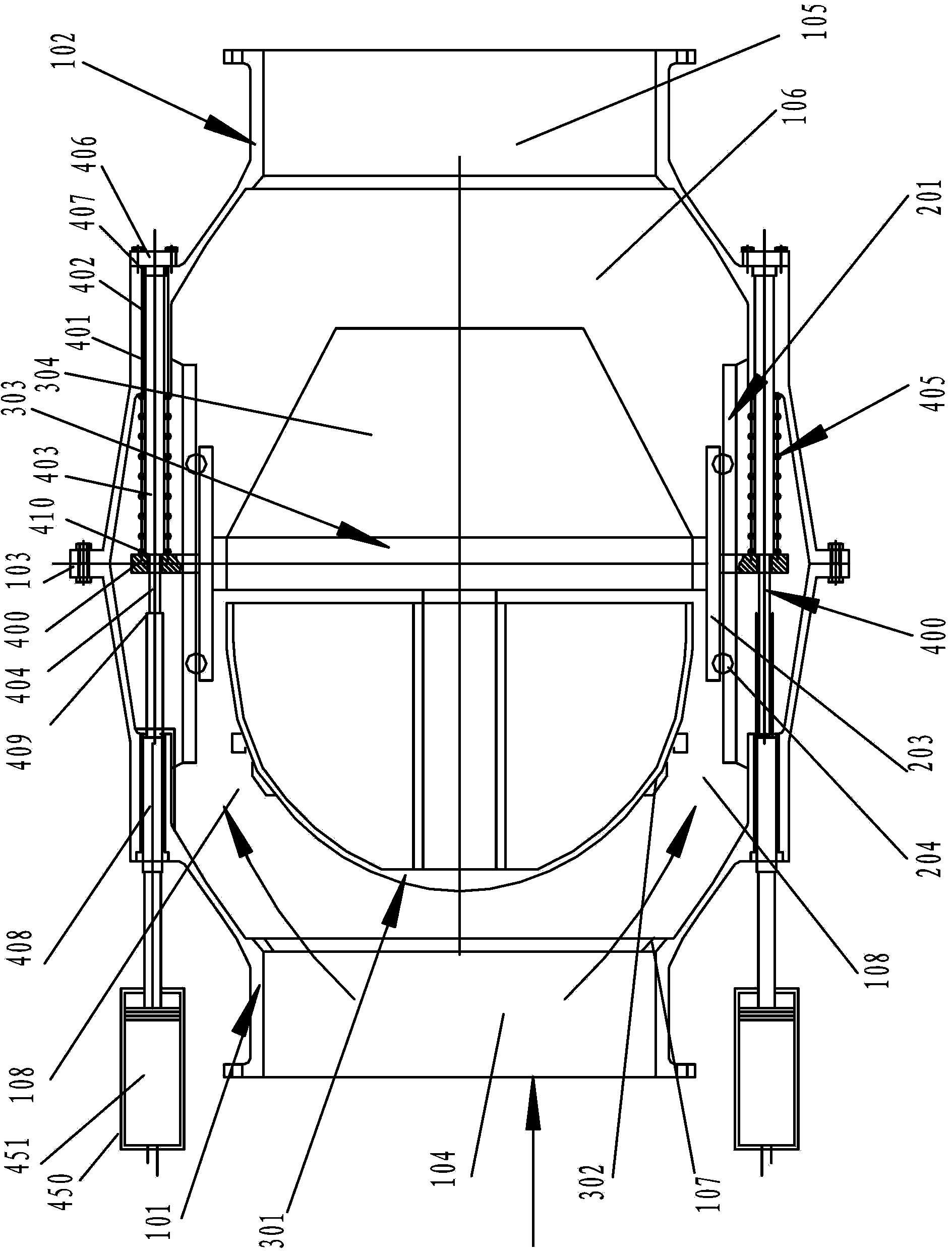

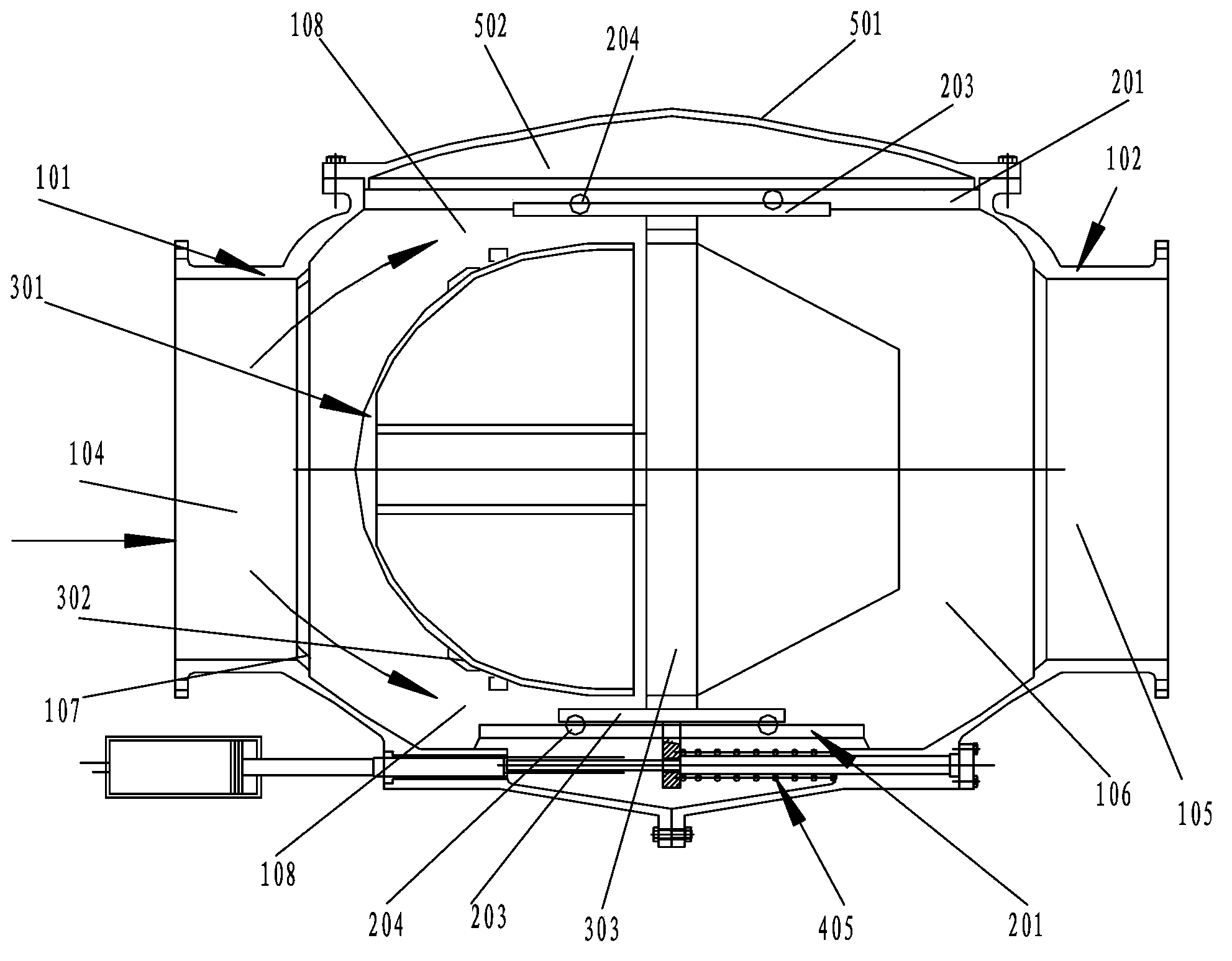

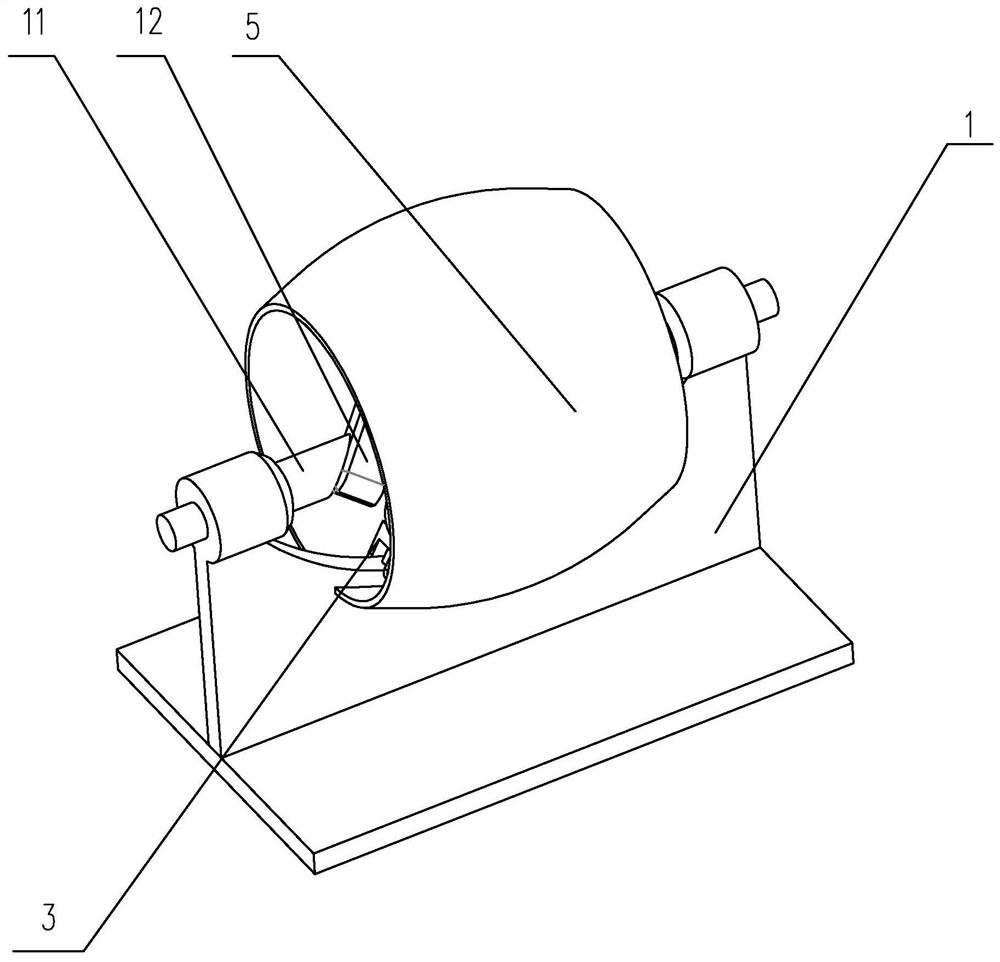

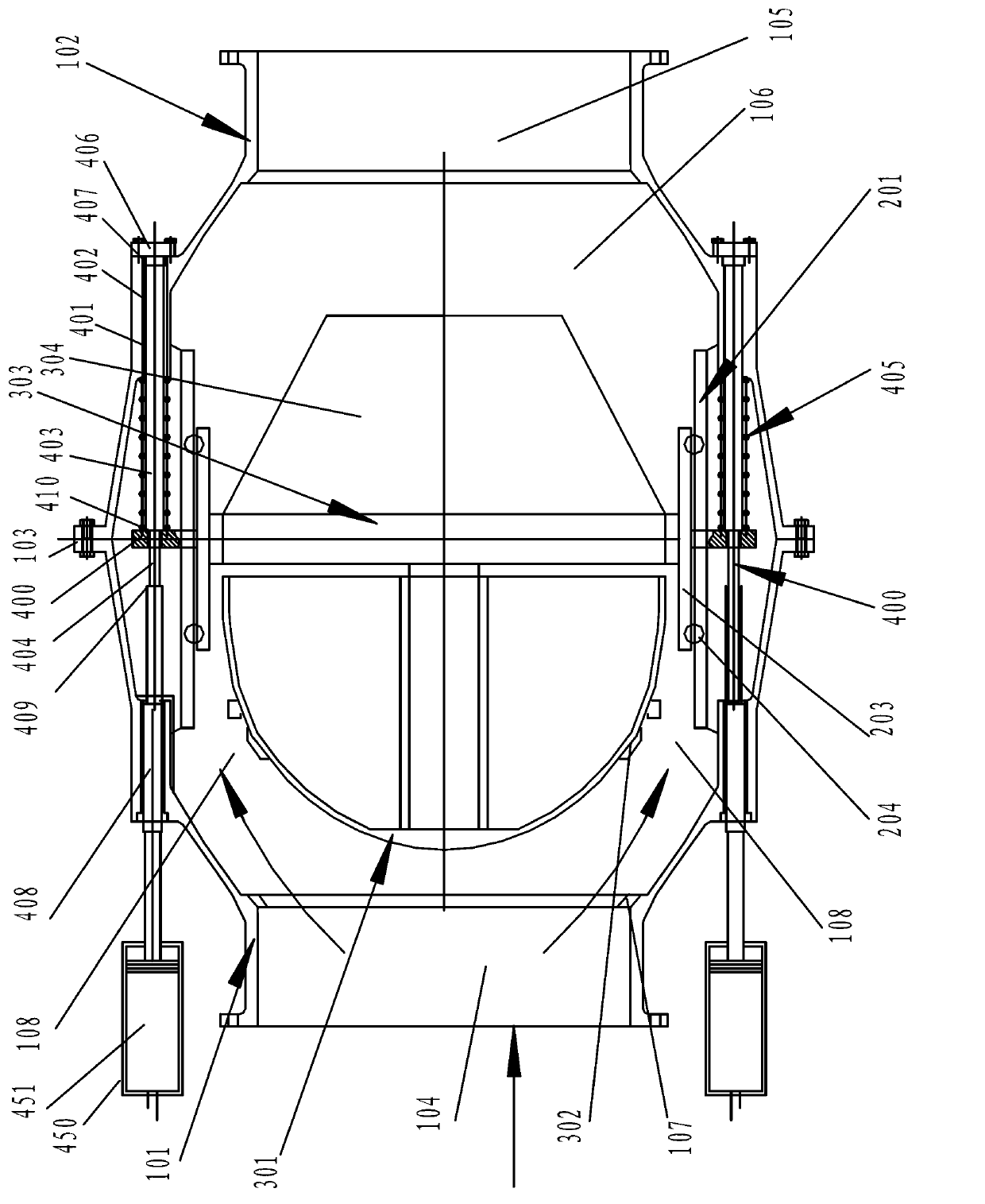

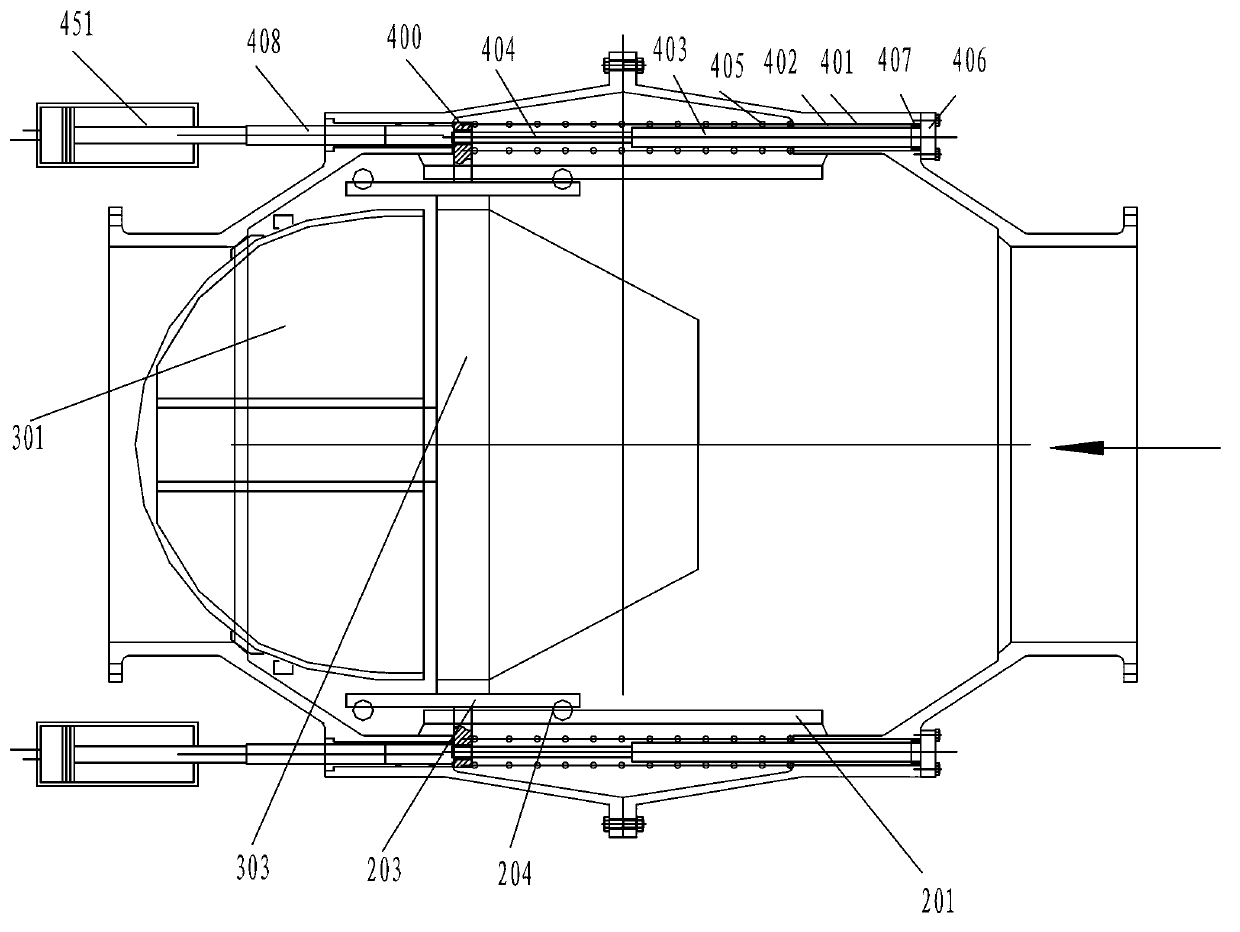

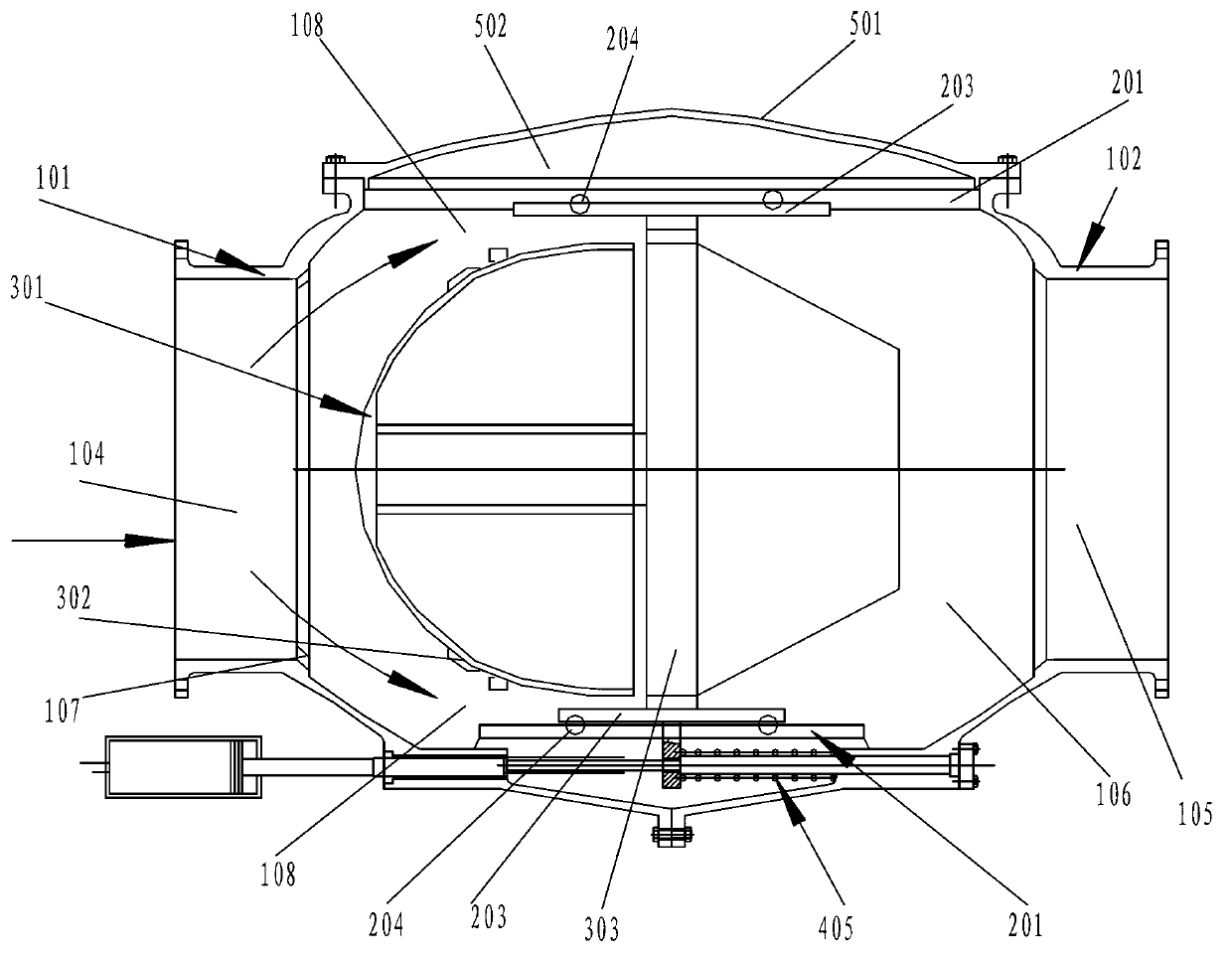

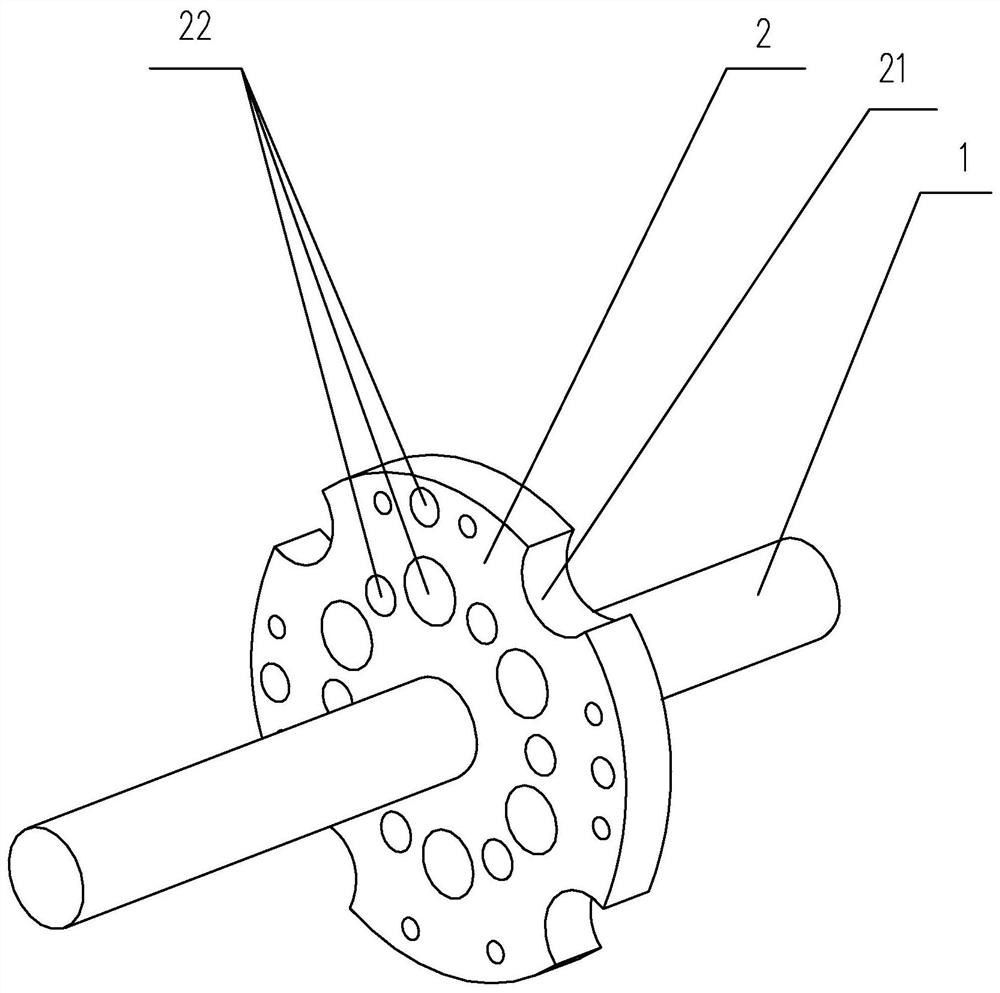

Robot device for visually detecting component in core cavity of pebble bed reactor

ActiveCN107866814AImprove reliabilityOrientation structure is simpleNuclear energy generationNuclear monitoringRadiationGraphite

A robot device for visually detecting a component in a core cavity of a pebble bed reactor comprises a driving unit, a lifting rotating mechanism, a connecting pipe assembly and a visual detection robot device body. According to the robot device, a mechanical arm is driven in a rope driving manner, so that the reliability of the visual detection robot device body working in high-temperature and radiation conditions in the core cavity can be improved, and meanwhile, the location and posture of a shooting system can be flexibly conveniently changed to achieve accuracy detection on the componentin the core cavity; in addition, an upper guide pipe set and a lower guide pipe set are used during rope driving, so that a guide structure of a rope is simplified; a main rod, a main rod sliding block, a crank and the mechanical arm form a crank sliding block mechanism which can be folded while passing through a small-size graphite fuel ball feeding channel and can be unfolded while entering a big-size core cavity, so that the robot device has the characteristic of being adapting to the core cavity being narrow in an entrance and wide in inside. The robot device is simple in structure, and capable of visually detecting the component in the core cavity of the pebble bed reactor.

Owner:TSINGHUA UNIV

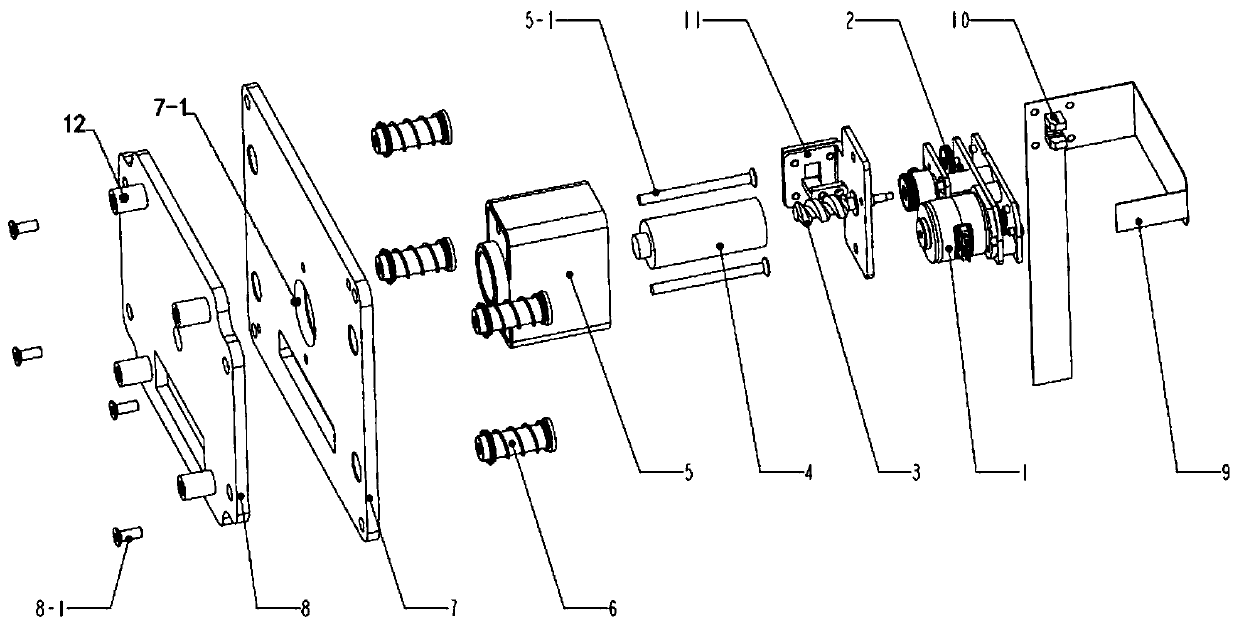

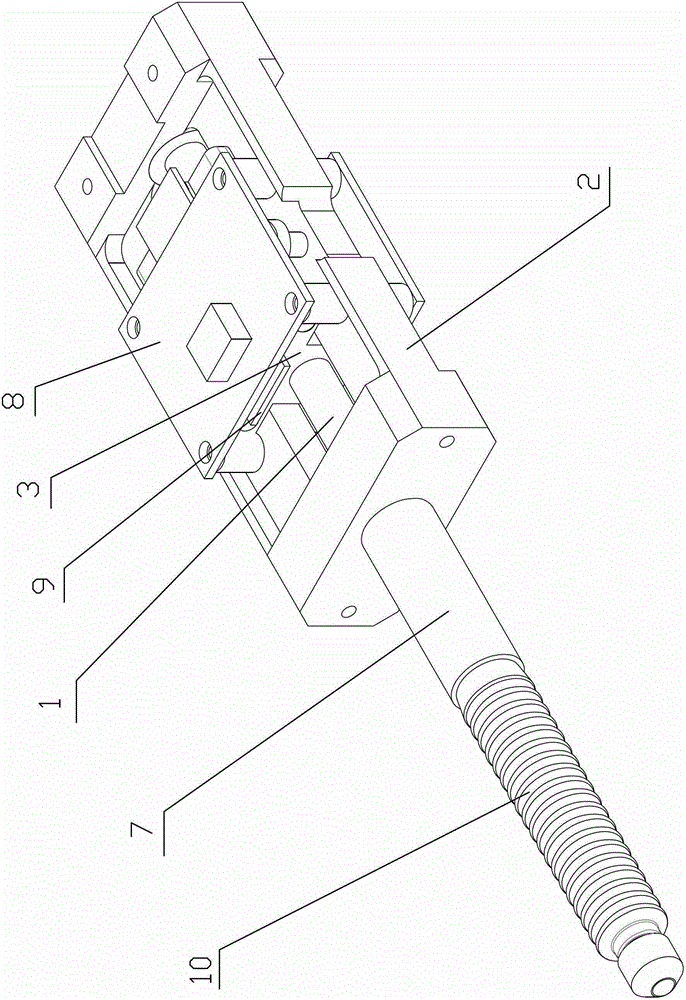

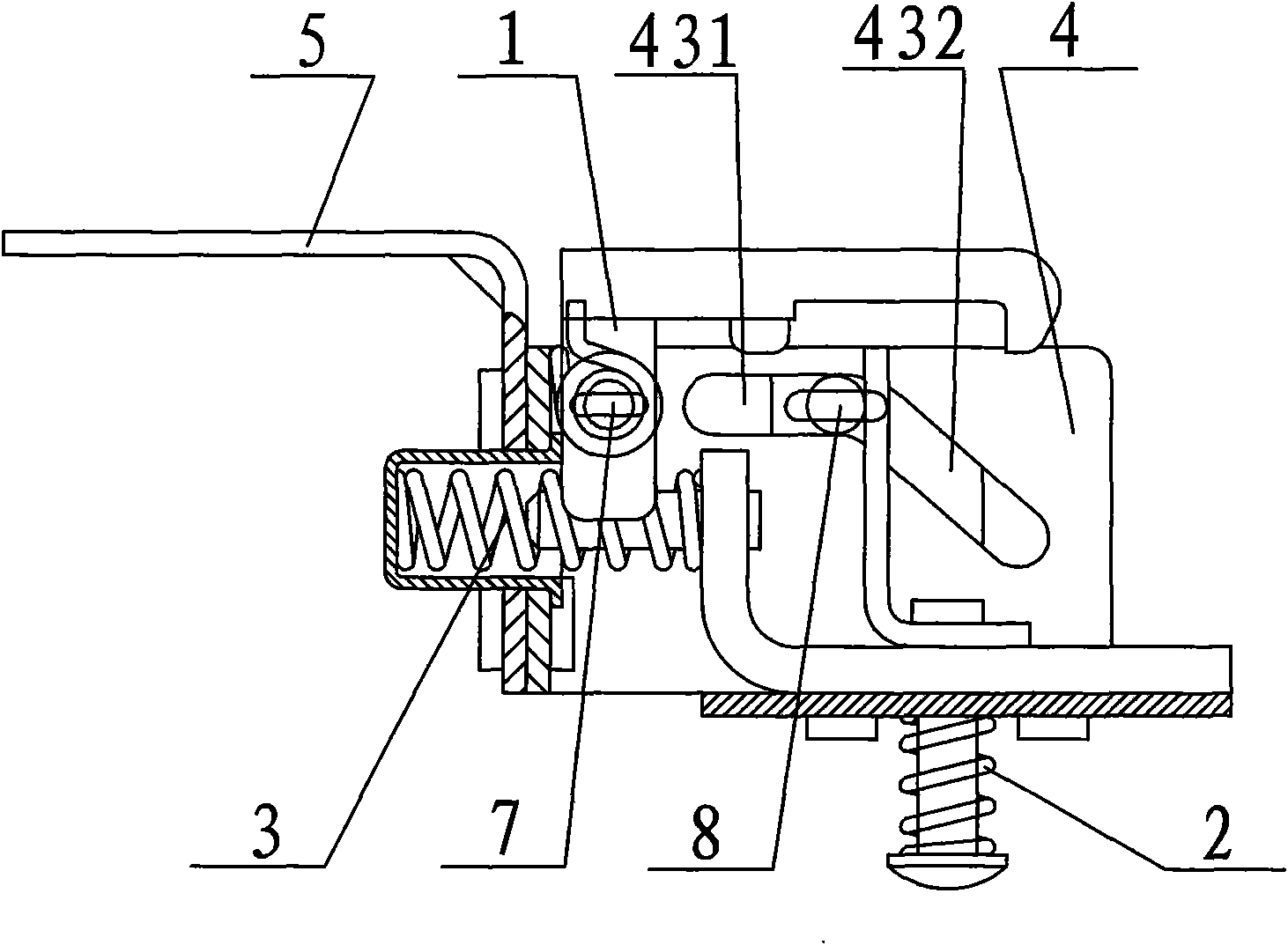

Back focus adjusting mechanism and a gun type camera applying the same

PendingCN109803083AOrientation structure is simpleMeet the precision requirementsTelevision system detailsColor television detailsGear wheelElectric machinery

The invention provides a back focus adjusting mechanism and a gun type camera applying the same. The back focus adjusting mechanism comprises a driving motor, a reduction gear set and a positioning guide assembly. The positioning guide assembly comprises a mounting plate, a fixing plate and a guide assembly, the guide assembly is mounted on the mounting plate, and the mounting plate is connected with the fixing plate; The guide assembly comprises a guide rod, a transmission screw rod and a guide seat fixedly connected with the mounting plate; a central hole for inserting the guide rod is formed in the guide seat; A threaded hole for inserting one end of the transmission screw is formed in the guide rod, the other end of the transmission screw is connected with an output gear of the reduction gear set, and the output gear of the reduction gear set drives the transmission screw to rotate coaxially; The driving motor is connected with the reduction gear set, the reduction gear set drivesthe transmission screw to rotate to drive the guide rod to move, and the guide rod penetrates through the fixing plate to push the mounting plate. The back focus adjusting mechanism provided by the invention has a simpler guide structure under the condition of meeting the requirement of pushing the fixing plate.

Owner:重庆紫光华山智安科技有限公司

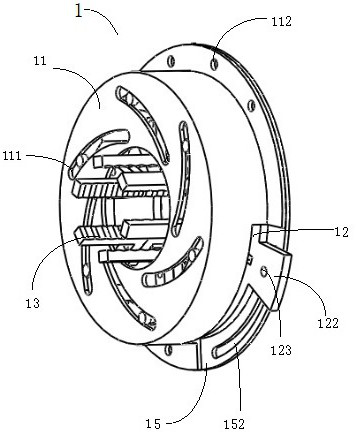

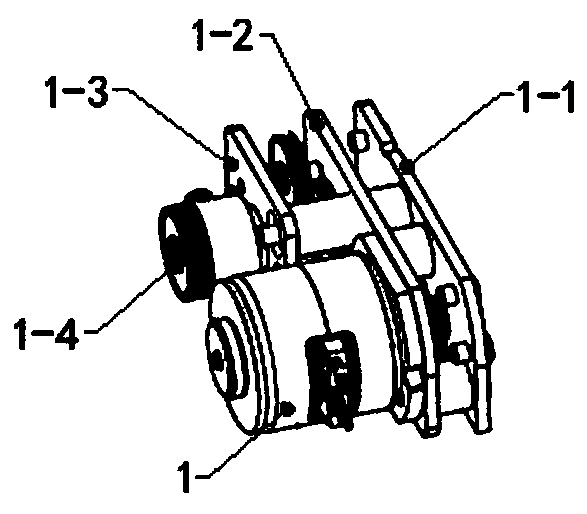

Magnetic tile adhering clamp for direct-current motor

InactiveCN102684401AGuaranteed positioning accuracyIncrease the length dimensionManufacturing stator/rotor bodiesManufacturing cost reductionCurrent meter

The invention discloses a magnetic tile adhering clamp for a direct-current motor. The magnetic tile adhering clamp comprises a base, and an elevated column with the diameter matched with the inner diameter of a body of the direct-current motor is arranged on the upper surface of the base. The elevated column is provided with a positioning cylinder which is of a split structure, the outer diameter of the positioning cylinder is matched with the inner diameter of the body of the direct-current motor, an even number of U-shaped through grooves extending from the position of the upper end face to one side of the positioning cylinder are equally arranged on the outer side face of the positioning cylinder, sliding blocks are arranged in the U-shaped through grooves, sliding guiding structures are arranged between the sliding blocks and the U-shaped through grooves, the outer side faces of the sliding blocks are cambered surfaces matched with the inner side faces of magnetic tiles, the outer side face of each sliding block and the left side face and the right side face of each U-shaped through groove jointly form one magnetic tile positioning groove, and the inner side bottom surfaces of the U-shaped through grooves attached to the sliding blocks are locking slopes inclined outwards from top to bottom. The magnetic tile adhering clamp can guarantee positioning accuracy of the magnetic tiles in adhesion, and is favorable for increasing length dimensions of the magnetic tiles through splicing structures so as to manufacture the direct-current motor with large torque. The guiding structures of the clamp are simplified, thereby being favorable for reduction of manufacturing cost.

Owner:宁波市北仑恒峰电机制造有限公司

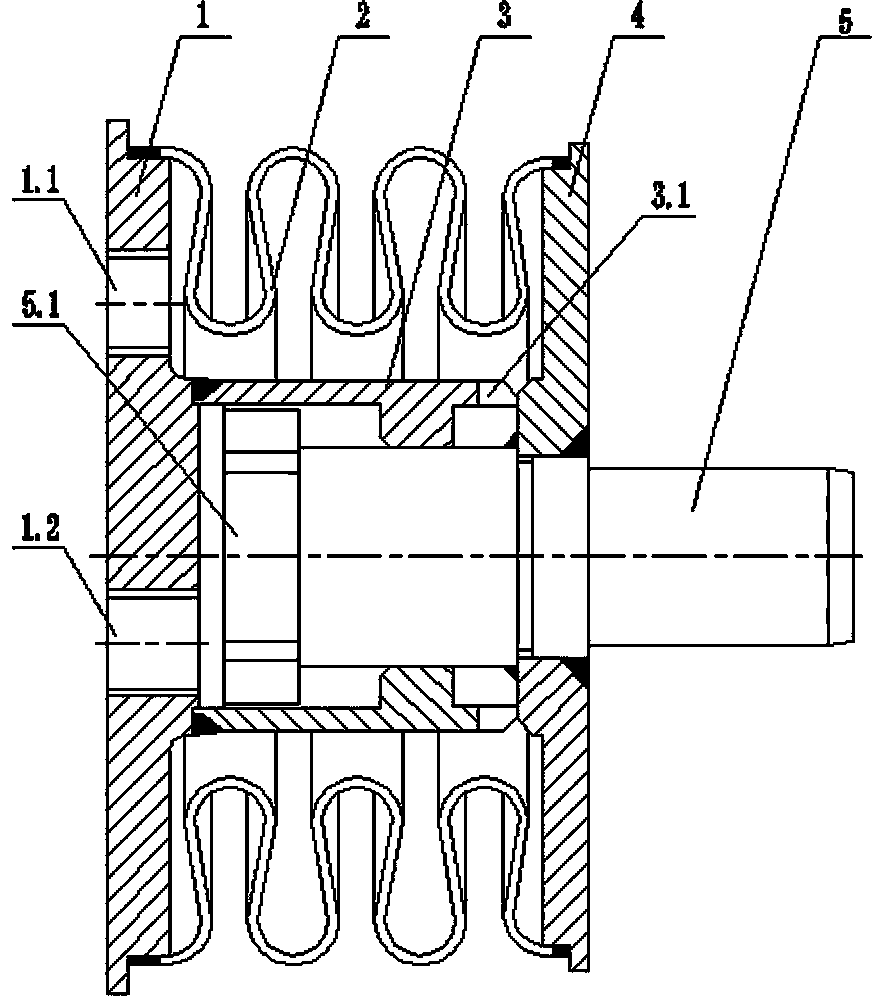

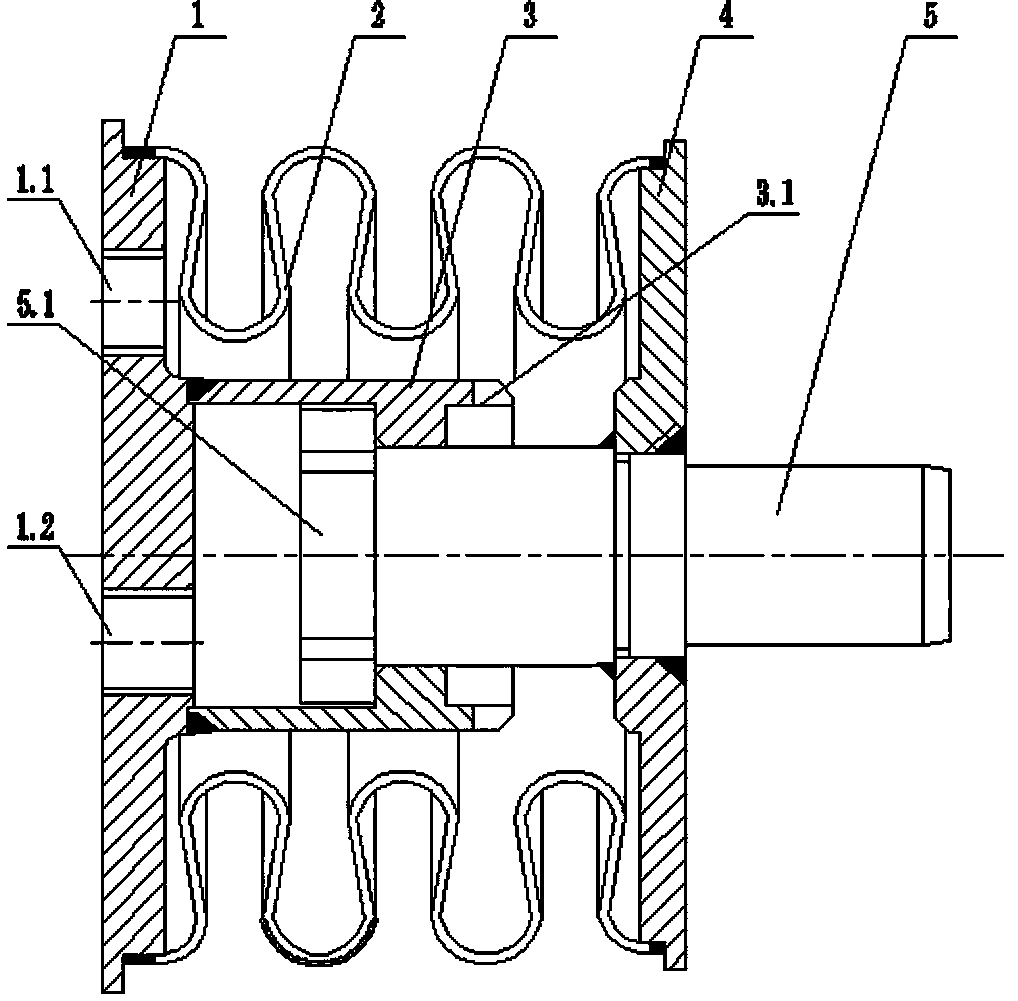

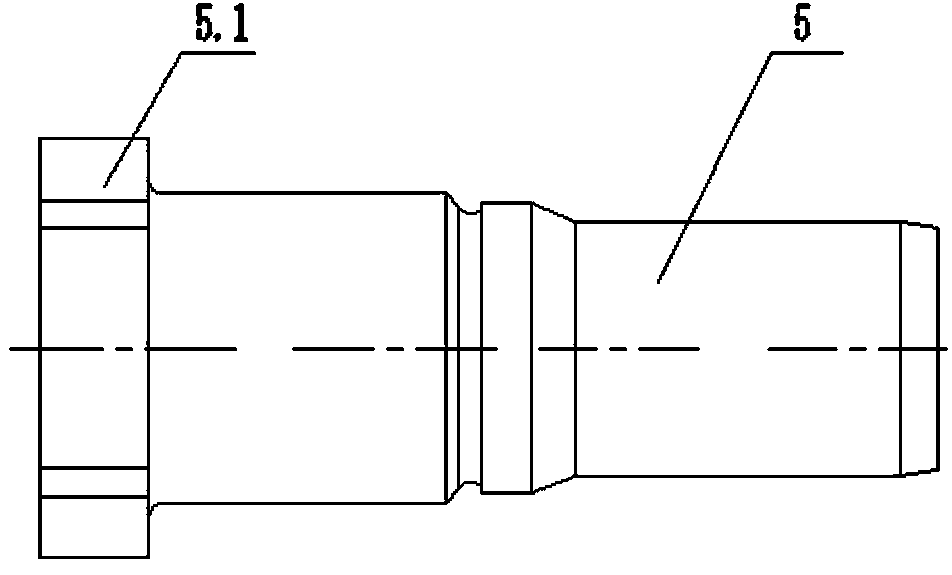

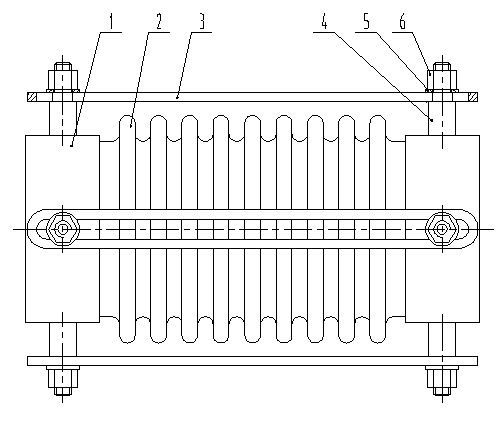

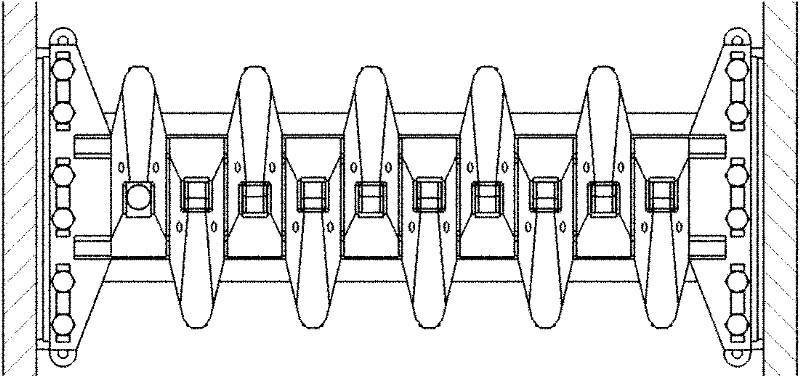

Guiding type corrugated limiter

InactiveCN103883826AUniform elastic deformationStrong ability to withstand pressurePipeline expansion-compensationThin walledEngineering

The invention discloses a guiding type corrugated limiter which is composed of a cover plate, corrugated tubes, a guiding sleeve, a base plate and a core shaft. The guiding sleeve is a thin wall shaft sleeve internally provided with a circular bead, a notch is formed in the opening portion of the right end of the guiding sleeve, the corrugated tubes are arranged outside the centered guiding sleeve, and the core shaft is arranged in the guiding sleeve in a clearance fit mode. The cover plate is respectively connected with the left end face of the guiding sleeve and the left end faces of the corrugated tubes in a sealed mode, and the base plate is installed on the core shaft in a sleeved mode, abuts against the right end face of the guiding sleeve, and is respectively connected with the right ends of the corrugated tubes and the core shaft in a sealed mode to form a linkage structure. The circular bead arranged in the guiding sleeve is of the structure that concave portions and convex portions are alternatively arranged on the same circumference, the shape of the cross section of the large end face of the core shaft is the same as the shape of the circular bead arranged in the guiding sleeve, and the core shaft is in clearance fit with the guiding sleeve to form an anti-torque structure for straight going of the core shaft. The waveform axial sections of the corrugated tubes in the guiding type corrugated limiter are in omega shapes, the tube walls of the corrugated tubes are smooth, thick, reasonable in stress and even in elastic deformation, limitation is accurate, and the corrugated tubes are particularly suitable for working under the high-temperature and high-pressure working conditions.

Owner:JIANGSU SHUGUANG PRESSURE VESSEL

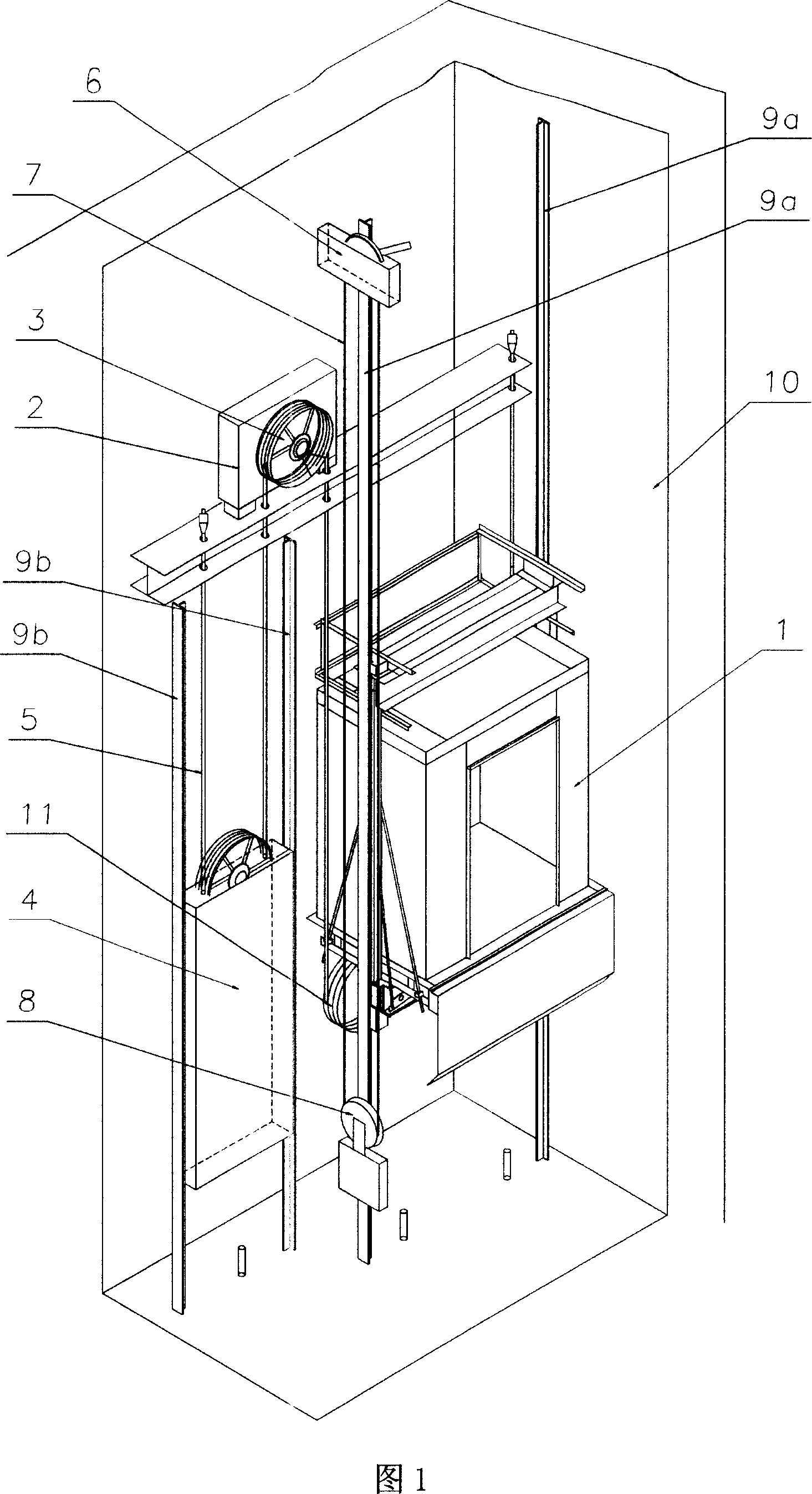

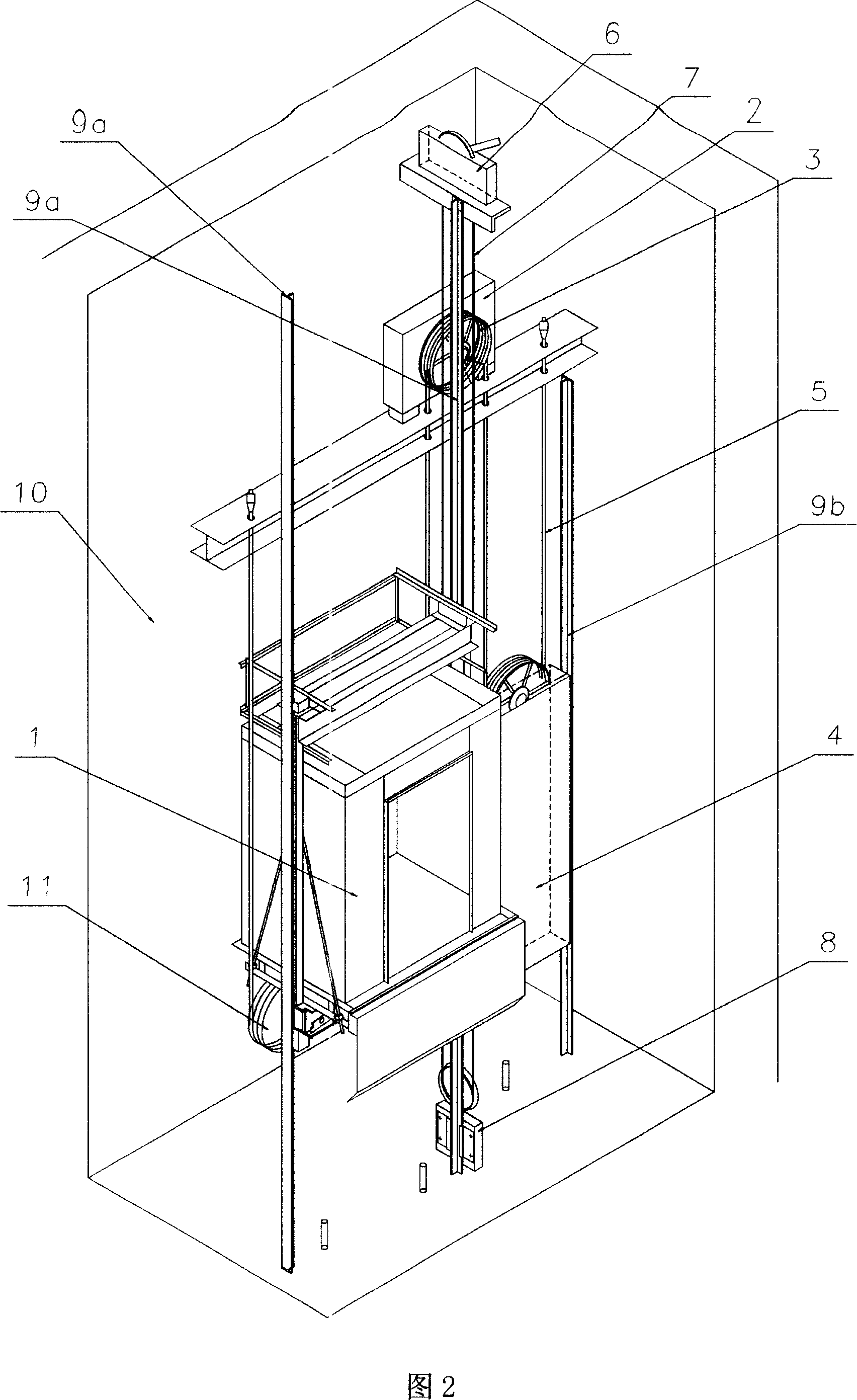

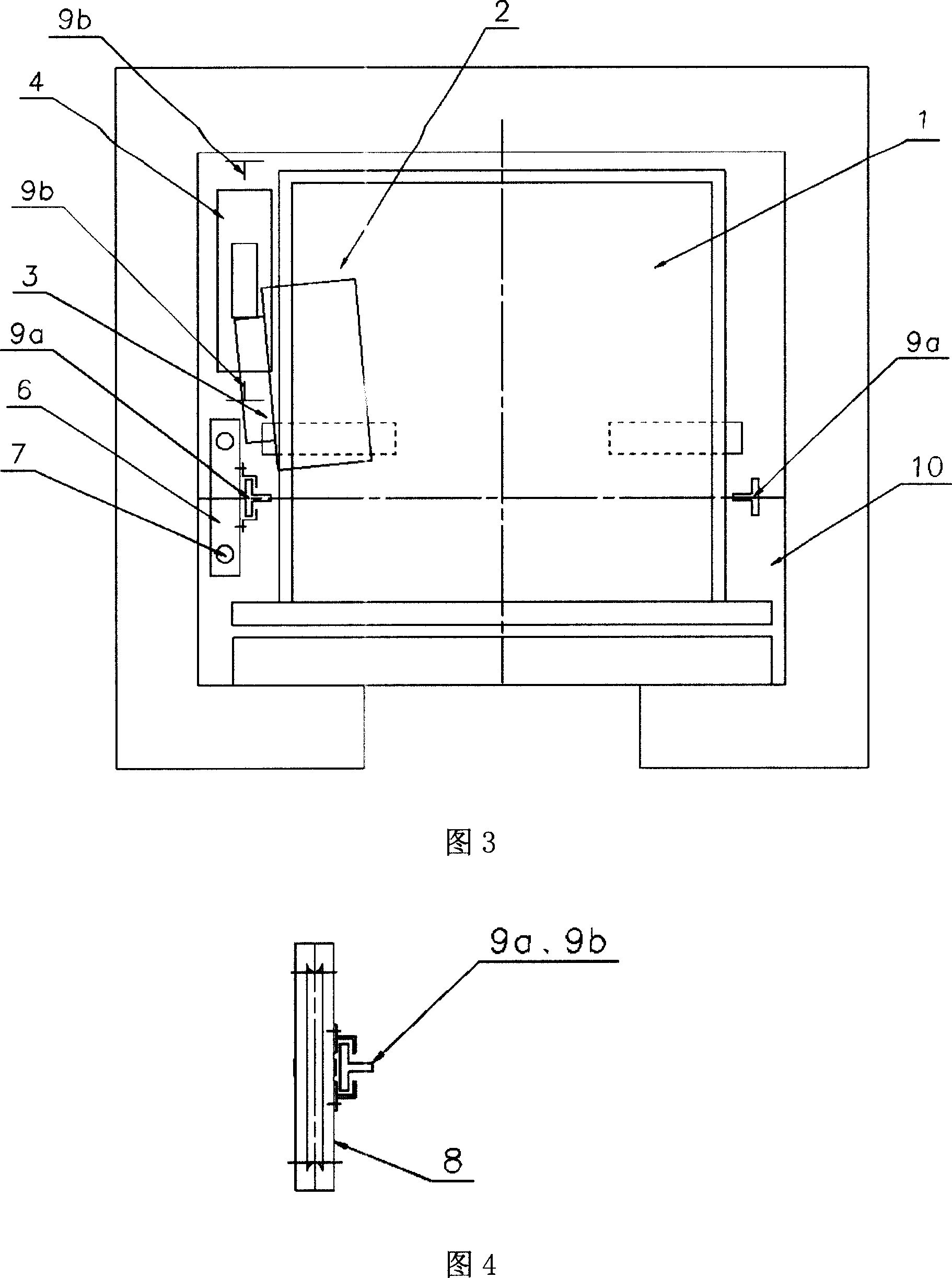

Elevator device

ActiveCN101143672AReduce eccentric forceOrientation structure is simpleElevatorsBuilding liftsEngineeringMechanical system

The invention discloses an elevator device, which includes a car, a drive device, a counterweight or cable tightening device, a cable connecting the car and the counterweight or cable tightening device, a speed limiter for monitoring the speed of the car, a limiter cable for transmitting the motion of the car, a limiter cable tightening device, a car guide rail and a counterweight guide rail for leading the car and a counterweight to move, and a lifting channel for containing the car, the drive device, the counterweight or cable tightening device and the cable, wherein, the limiter cable tightening device is arranged at the lower end of the lifting channel with the car or the counterweight guide rail as the a leading guide rail. The invention can make sure the eccentric force of a guide shoe and the guide rail, simplifies a guide structure of the limiter cable tightening device, reduces the cost, and meanwhile, results in more flexible structure deployment of the mechanical structure of the elevator and reduces the civil engineering dimension.

Owner:SHANGHAI MITSUBISHI ELEVATOR CO LTD

Image forming apparatus

InactiveUS20060104680A1Improve transmission efficiencyOrientation structure is simpleElectrographic process apparatusEngineeringElectrical and Electronics engineering

An image forming apparatus has a photosensitive body on which an electrostatic latent image is formed. A developing unit develops the electrostatic latent image on the photosensitive body with a developer to form a developer image. The developer image on the photosensitive body is transferred onto an intermediate transfer belt in an intermediate transfer unit. The transfer unit transfers the developer image transferred on the intermediate transfer belt onto a printing medium. A cleaning unit cleans any developer remaining on the photosensitive body, and a printing medium guide unit is provided at the cleaning unit to guide the printing medium until the printing medium enters the transfer nip between the intermediate transfer belt and the transfer unit. The printing medium guide unit is formed at a side of the cleaning unit adjacent to the printing medium conveying path. According to this structure, the printing medium can be stably conveyed to the transfer unit so that the transfer efficiency is increased and the guide structure of the printing medium is simpler.

Owner:HEWLETT PACKARD DEV CO LP

Compensator with guiding corrugated pipes

InactiveCN104019315ALow costOrientation structure is simplePipeline expansion-compensationElectrical and Electronics engineering

Owner:江苏晨光波纹管有限公司

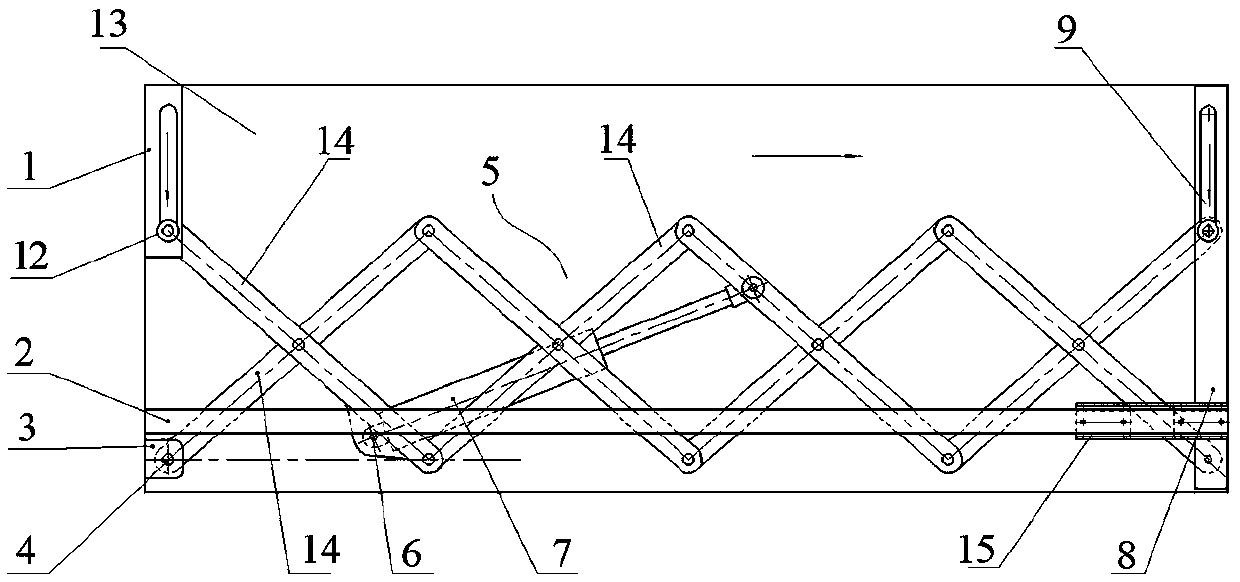

Scissor type rubbish pushing and pressing structure and rubbish collecting box adopting same

Owner:HENAN SENYUAN HEAVY IND

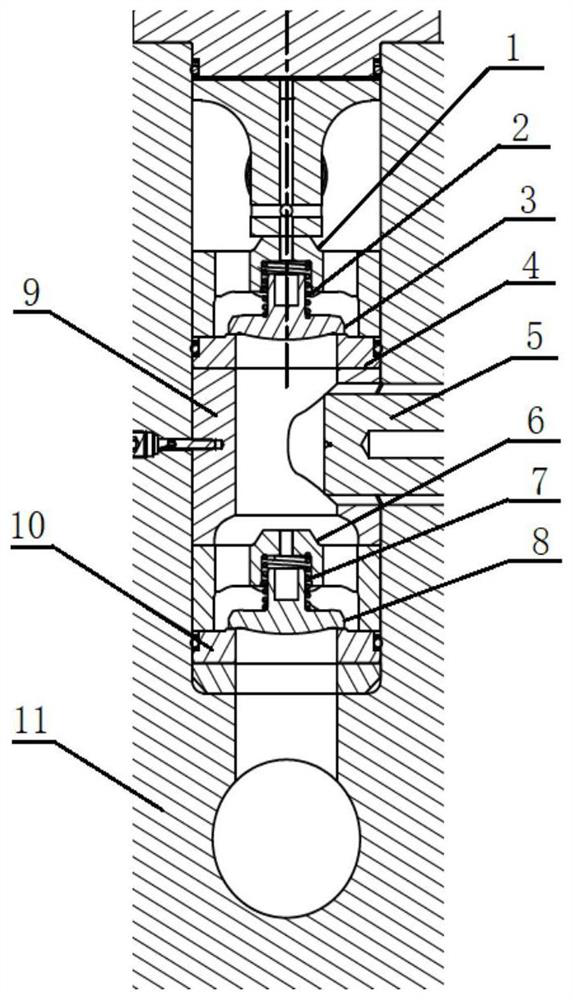

Liquid suction and drainage valve and working method thereof

PendingCN111608903ACompact structureOrientation structure is simplePositive displacement pump componentsLiquid fuel engine componentsCoalEngineering

The invention relates to a liquid suction and drainage valve and a working method thereof, and belongs to the technical field of coal mines. The liquid suction and discharge valve is linearly arranged, so that the structure is more compact; the guide structure is simple and the friction force is smaller; two sides of a valve seat can be used, so that the service life is longer; the valve seat is in clearance fit with a mounting hole and is convenient to replace; due to medium-flow-rate design, cavitation is reduced; and a liquid suction valve and a liquid discharge valve can be interchanged for use, so that fewer spare parts are realized.

Owner:BEIJING HUAHAI MACHINERY

Robotic device for visual inspection of internal components of pebble bed reactor core cavity

ActiveCN107866814BImprove reliabilitySure easyNuclear energy generationNuclear monitoringSimulationVisual inspection

Owner:TSINGHUA UNIV

Guide and rotation mechanism for crane hanger

This invention relates to a guide and rotation machine of lift sling, which comprises guide mechanism, rotation mechanism and crossbeam; it has following peculiarities: a) guide mechanism is formed by cruciform girder, steel rope and block device disposed vertically on the small carriage; b) the steel ropes circling down from the block device of heize mechanism are connected with four girder ends of cruciform girder separately to form a crisscross to position the cruciform girder at parallel and vertical direction; c)the rotation mechanism mounted in the cruciform girder is connected with sling crossbeam.

Owner:TAIYUAN HEAVY IND

Diversion damper slowly-closed check valve

ActiveCN103133729BEasy to installOrientation structure is simpleCheck valvesValve members for absorbing fluid energyEngineeringCheck valve

The invention discloses a diversion damper slowly-closed check valve which comprises a valve body provided with medium circulation tubes at two ends. A valve seat is arranged in the valve body. The diversion damper slowly-closed check valve further comprises a diversion body check valve core arranged in the valve body, a support moving structure for supporting the diversion body check valve core, a sliding block connected with the diversion body check valve core, a sliding rod connected with the sliding block, and a non-return driving structure with one end contacted with the sliding block and used for driving the sliding block to perform non-return movement. The other end of the sliding rod is connected with a moving damper structure. The diversion body check valve core in the diversion damper slowly-closed check valve adopts a movable structure, namely the diversion effect and the sealing effect are played, the whole structure is convenient to install, the support moving structure is used for supporting the diversion body check valve core, the supporting is stable, and operation is stable. The moving damper structure can produce resistance to movement of the sliding block and the diversion body check valve core, quick movement is avoided, and dismantle of a pipeline water hammer and protection of a pipeline and a water pump are achieved through slow closing.

Owner:WUHAN DAYU VALVE

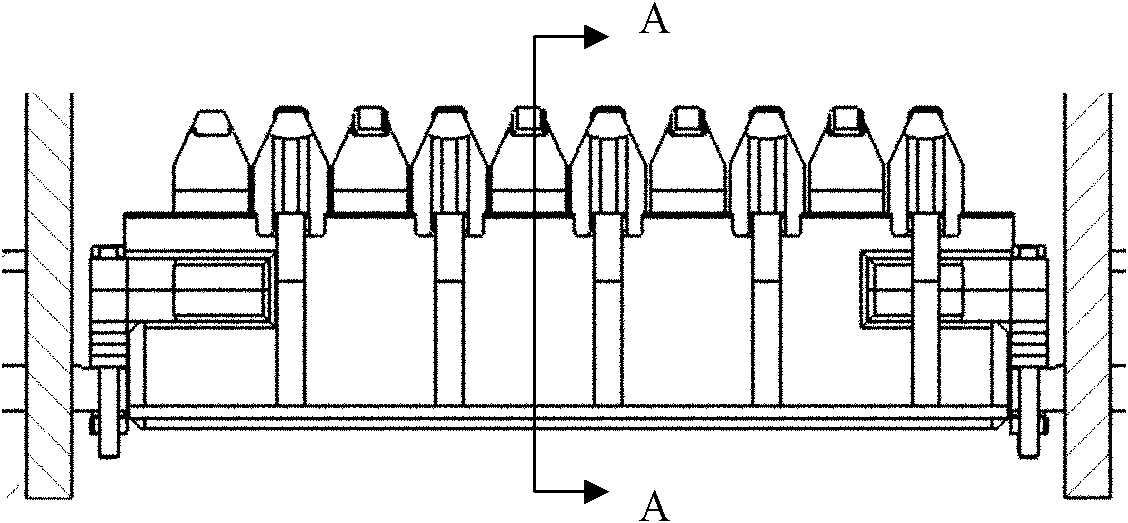

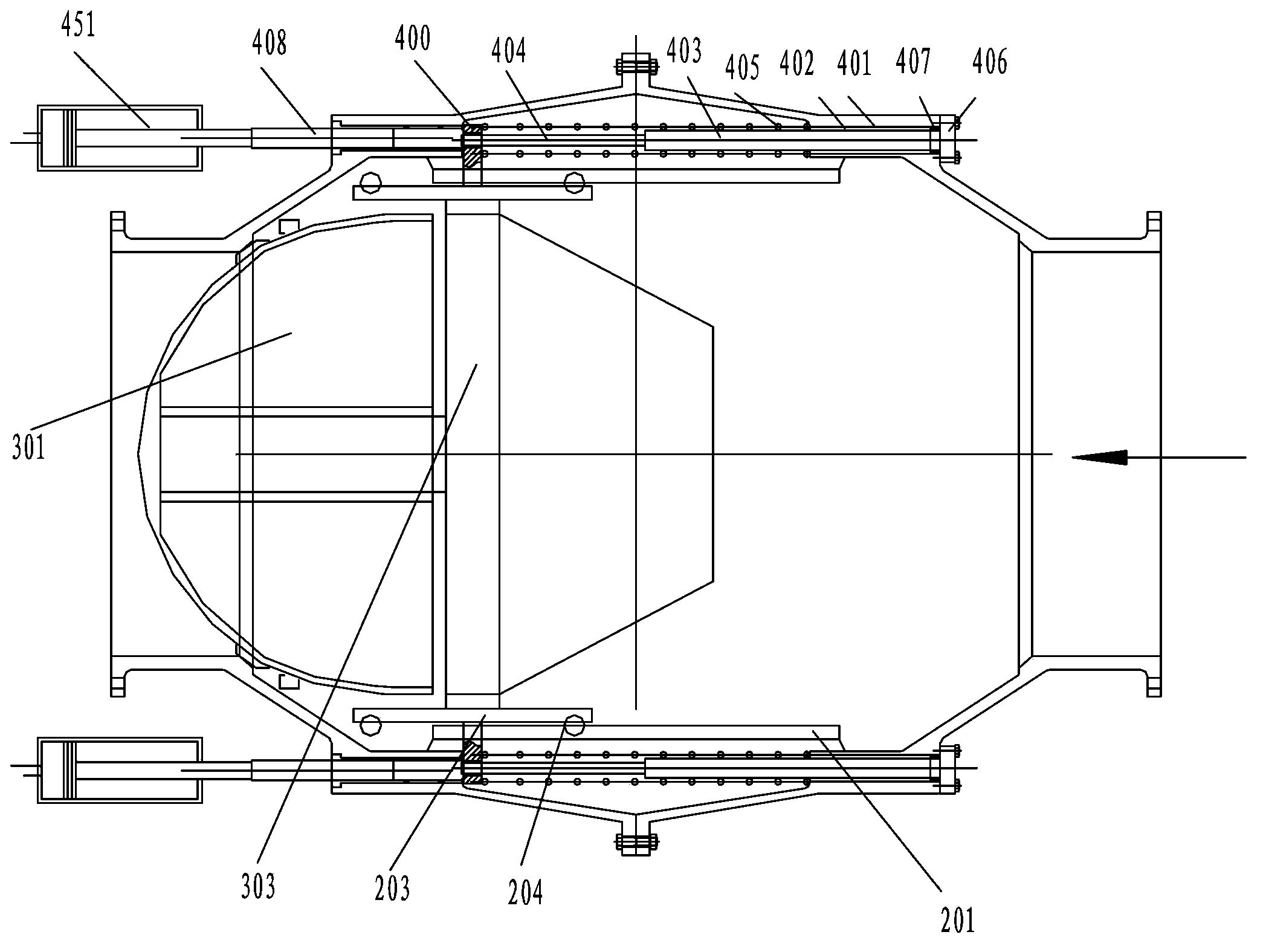

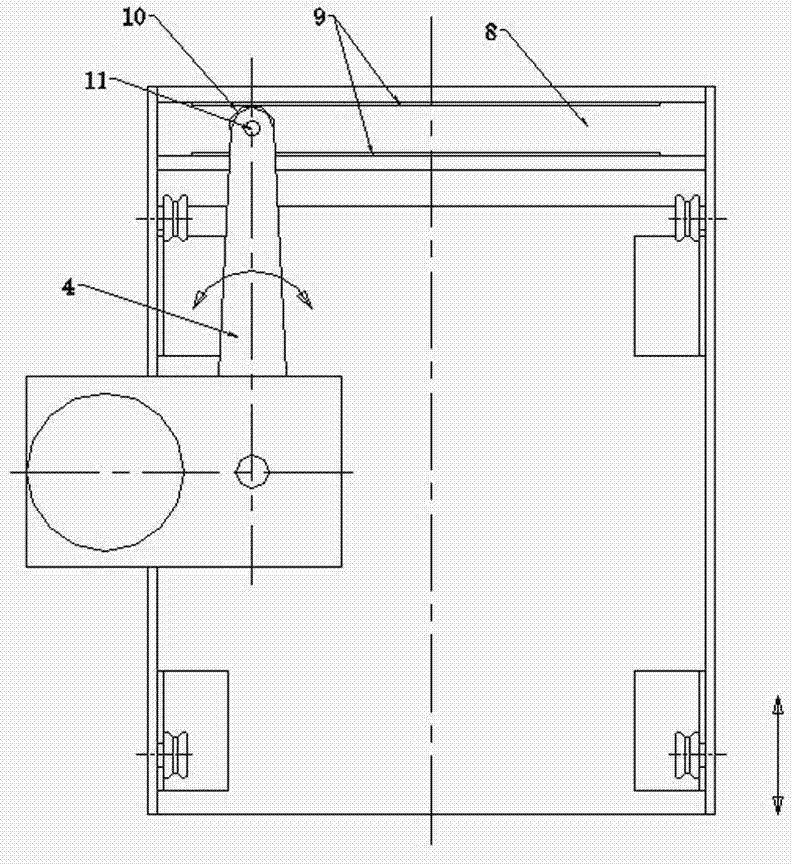

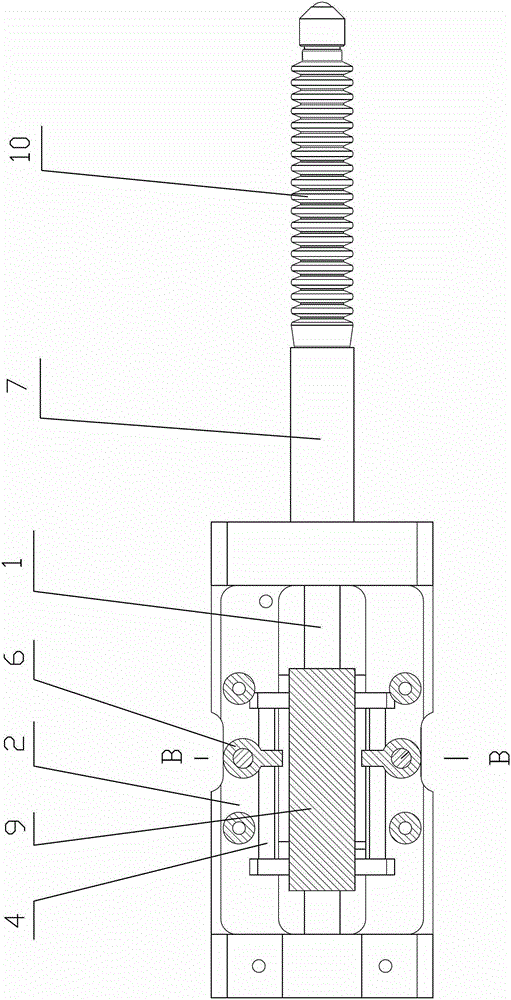

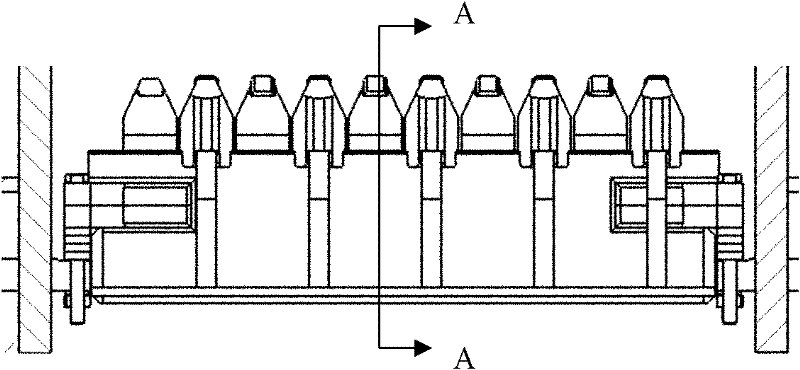

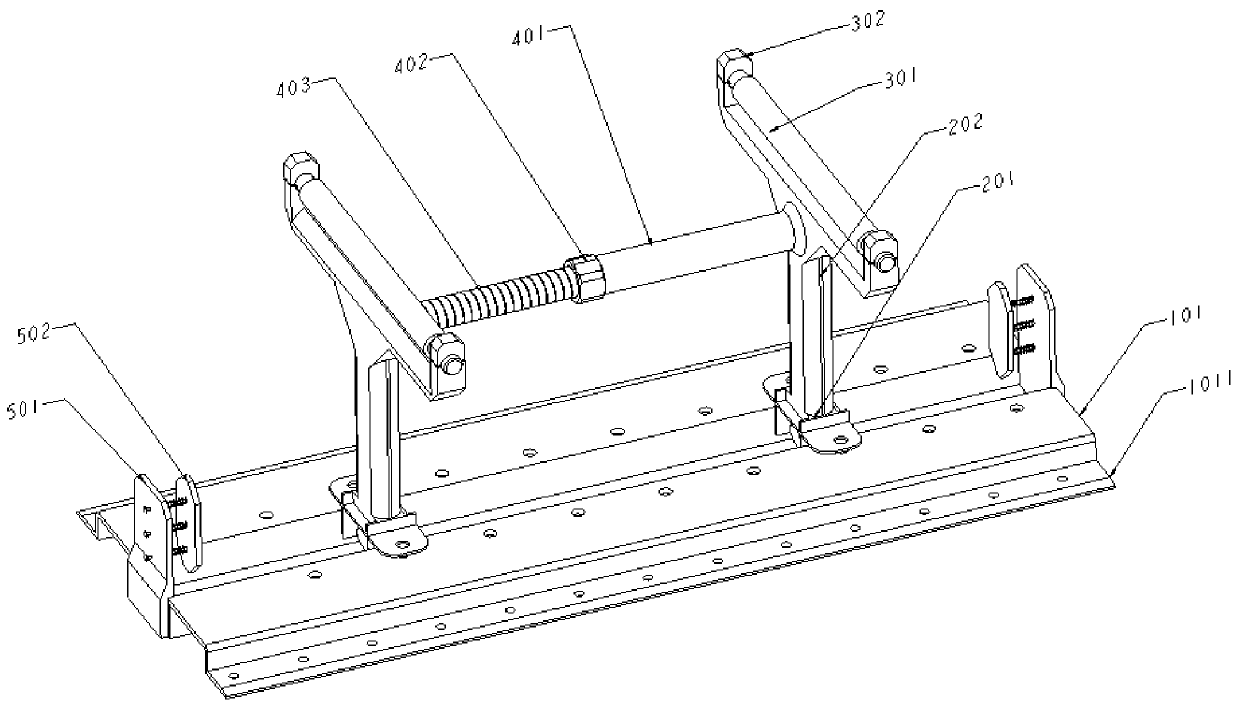

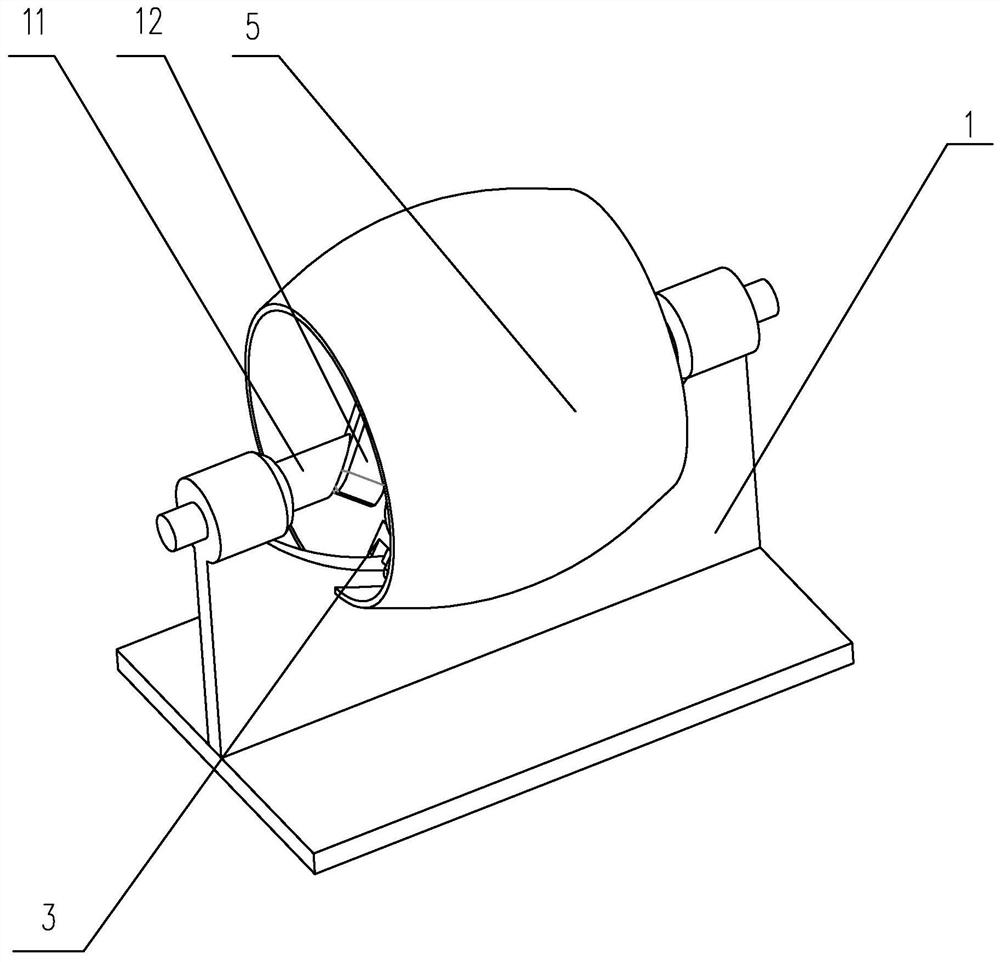

Driving mechanism for gas blowing cover of core-making machine

ActiveCN103317098BNo layout space requiredLayout does not affectFoundry mouldsMoulding machinesControl mannerControl mode

The invention discloses a driving mechanism for a gas blowing cover of a core-making machine. The mechanism is composed of a driving device and a guiding device, wherein the guiding device comprises a pair of guide rails which are arranged in parallel along a motion direction of the gas blowing cover and guiding wheels matched with the guiding rails; the device is characterized in that the driving device comprises a rotational power outputting mechanism, a swinging arm and a gas blowing trolley; an output shaft of the rotational power outputting mechanism is vertically arranged; a guiding groove perpendicular to the directions of the guide rails is formed in one end of the gas blowing trolley; a roller is rotatably connected with the swinging arm and is positioned in the guiding groove and is in contact with the guiding groove in a rolling mode to be limited; the guide rails are linear guide rails of which the tops of the cross sections are in an inverted V shape; the guiding wheels are V-shaped wheels matched with the tops of the guide rails. According to the driving mechanism, surplus arrangement spaces are not needed to be occupied; by reducing rotation speed, speed reduction in place is realized, the mechanism is in place stably without impact, the controlling mode is simple, a guiding structure is simple and the service life is long.

Owner:SUZHOU MINGZHI TECH

Absolute measurement linear micrometer made with capacitive grid sensor

ActiveCN102853755BHigh measurement accuracyLong effective measurement rangeUsing electrical meansCapacitanceMicrometer

The invention discloses an absolute measurement linear micrometer produced by adopting a capacitance sensor, and the absolute measurement linear micrometer comprises a measurement rod, a framework body, and a main grid and an auxiliary grid of the capacitance sensor, wherein a rear section rod body of the measurement rod is installed inside the framework body through a front support, a rear support, a single orientation mechanism a double-orientation mechanism, the front section of the measurement rod stretches out of the framework body, a main grid seat is installed on the rear section rod body of the measurement rod, the capacitance sensor comprises a calibration sensor and a measurement sensor with absolute measurement functions, the calibration sensor and the measurement sensor are respectively arranged on the front surface and the back surface of the framework body or in front and behind the front surface of the framework body, a main grid of the calibration sensor and a main grid of the measurement sensor are arranged on the measurement rod through the main grid seat, an auxiliary grid of the calibration sensor and an auxiliary grid of the measurement sensor are arranged on the framework body, and a reasonable sensing clearance is formed between each main grid and each auxiliary grid. The absolute measurement linear micrometer has the absolute measurement function with exclusive measurement result, so that the measurement precision is improved, the effective measurement range is long, the cost is low, and the production process is simple.

Owner:GUILIN JINGZHUN MEASUREMENT & CONTROL TECH

Crushing beam combined structure of double-tooth roller crusher

InactiveCN102091666BOrientation structure is simpleEasy to assembleGrain treatmentsDouble teethStressed state

The invention discloses a crushing beam combined structure of a double-tooth roller crusher applied in the industry of crushing equipment. The structure consists of a rack, an adjusting gasket, a bolt, a crushing beam, a crushing tooth cap, a tooth cap cover, a guide element, a stop block, a bolt for the stop block, and a bolt; a crushing beam assembly of the double-tooth roller crusher is positioned below two crushing tooth rollers of the crusher, and the crushing beam assembly is assembled on the rack through the bolt; two ends of the crushing beam are provided with a guide groove C and a guide groove D respectively; the guide element is arranged on the rack; the crushing beam assembly is placed on the rack along the guide groove C and the guide groove D and assembled through the bolt; and the adjusting gasket is provided with a plurality of U-shaped grooves, the opening directions of the U-shaped grooves and the side of the adjusting gasket from inclination angles, and the sides ofthe inclination directions of the U-shaped grooves are provided with unfilled corners parallel to the opening directions of the U-shaped grooves, so that the adjusting gasket is obliquely inserted into the long and narrow space more deeply. The guide structure of the crushing beam of the device is simple, so that the crushing beam assembly is convenient to install; and by combining the adjusting gasket structure with large bearing area, the stress state of the crushing beam assembly is effectively improved.

Owner:SHENYANG HEAVY MACHINERY GROUP

Unbonded steel strand degreasing device

ActiveCN113089350BScrape off quicklyAchieve removalRope making machinesCleaning using toolsMechanical engineeringMaterials science

Owner:CHINA CONSTR FIFTH ENG DIV CORP LTD +1

Cloth pulling device for plaiter

PendingCN110950144AOrientation structure is simplePlay a guiding roleFolding thin materialsWebs handlingEngineeringScrew thread

Owner:TIANJIN XUHUIHENGYUAN PLASTIC PACKAGING CORP

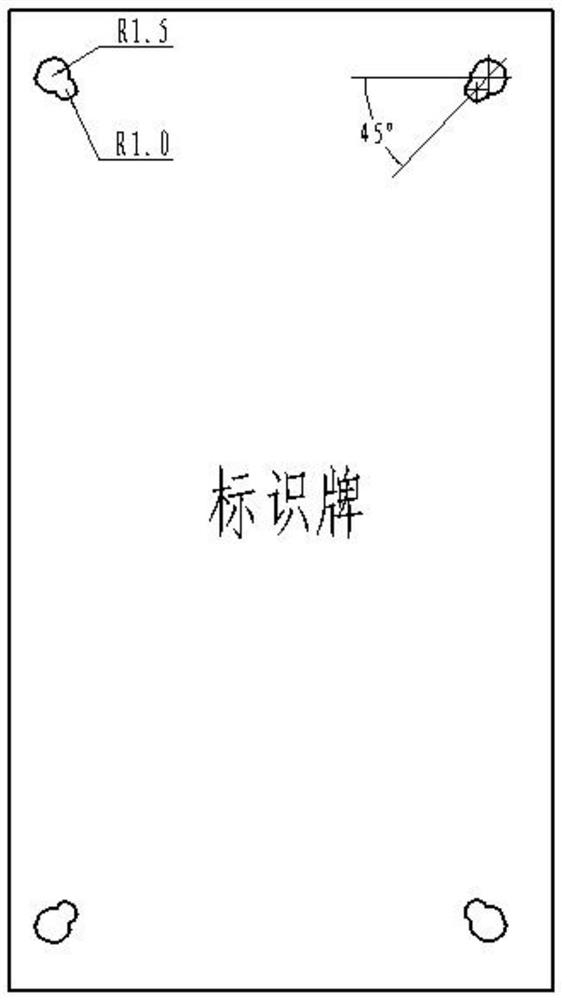

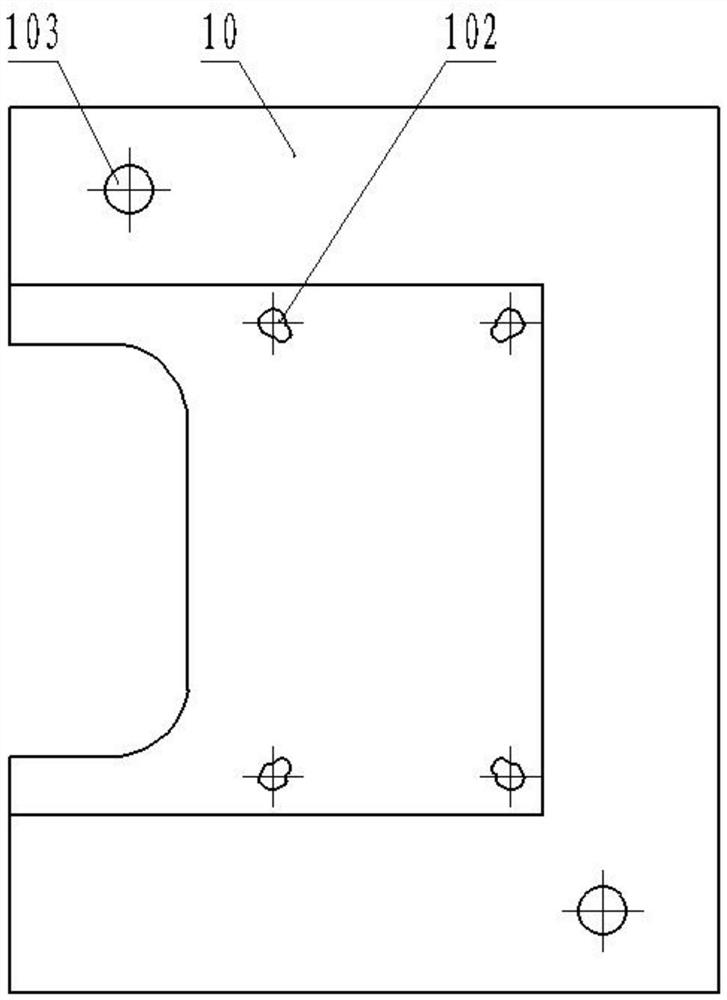

Machining device and machining method for aluminum signboard special-shaped round hole

The invention discloses a machining device for an aluminum signboard special-shaped round hole which comprises a base, a cover plate and a punch. A clamping groove used for containing a signboard to be machined is formed in the base, the depth of the clamping groove is the same as the thickness of the signboard to be machined, and a discharging hole is formed in the clamping groove. A punch guide hole is formed in the cover plate; the hole position of the punch guide hole corresponds to the hole position of a blanking hole; the shape of the blanking hole is consistent with that of the special-shaped round hole of the signboard; and the peripheral shape of the lower end of the punch is consistent with the shape of the special-shaped round hole of the signboard. When the machining device is used for machining the special-shaped round hole of the aluminum signboard, the signboard to be machined only needs to be placed on the clamping groove of the base and then covered with the cover plate, the punch is used for conducting punching operation, machining of the special-shaped round hole can be completed, the structure is simple, and operation is fast and convenient.

Owner:CHINA HANGFA GUIZHOU LIYANG AVIATION POWER CO LTD

Diversion damper slowly-closed check valve

ActiveCN103133729APlay the role of diversionPlay a sealing roleCheck valvesValve members for absorbing fluid energyCheck valveDamper

The invention discloses a diversion damper slowly-closed check valve which comprises a valve body provided with medium circulation tubes at two ends. A valve seat is arranged in the valve body. The diversion damper slowly-closed check valve further comprises a diversion body check valve core arranged in the valve body, a support moving structure for supporting the diversion body check valve core, a sliding block connected with the diversion body check valve core, a sliding rod connected with the sliding block, and a non-return driving structure with one end contacted with the sliding block and used for driving the sliding block to perform non-return movement. The other end of the sliding rod is connected with a moving damper structure. The diversion body check valve core in the diversion damper slowly-closed check valve adopts a movable structure, namely the diversion effect and the sealing effect are played, the whole structure is convenient to install, the support moving structure is used for supporting the diversion body check valve core, the supporting is stable, and operation is stable. The moving damper structure can produce resistance to movement of the sliding block and the diversion body check valve core, quick movement is avoided, and dismantle of a pipeline water hammer and protection of a pipeline and a water pump are achieved through slow closing.

Owner:WUHAN DAYU VALVE

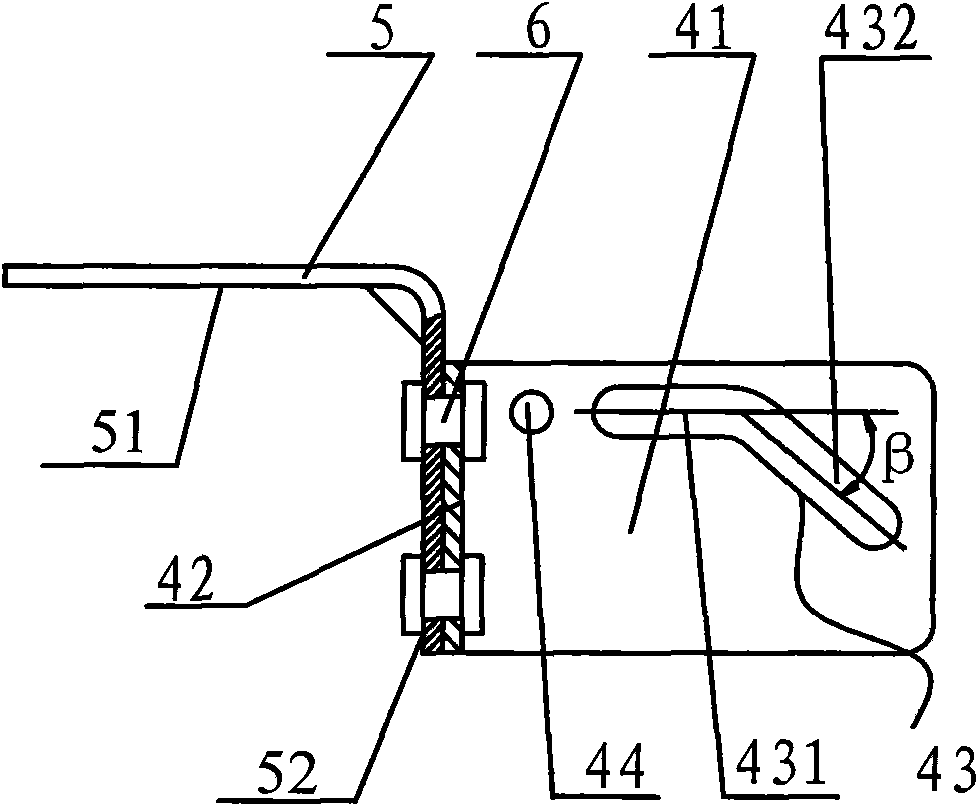

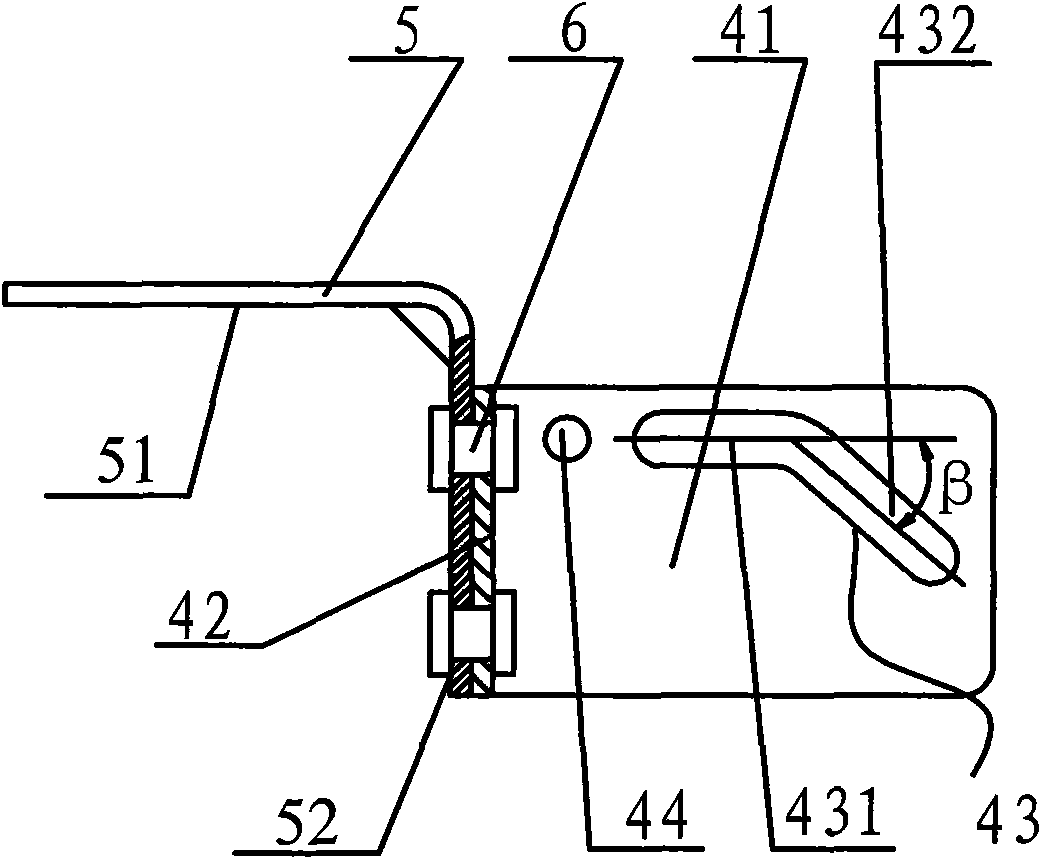

Guide structure in switching mechanism of drop-out type fuse

InactiveCN101937803AGuaranteed accuracyImprove performanceProtective switch operating/release mechanismsEngineeringFront and back ends

The invention discloses a guide structure in the switching mechanism of a drop-out type fuse. The switching mechanism comprises a releasing device, a fastening device, a resetting device and the guide structure. The guide structure comprises a guide rail bracket and a supporting bracket, wherein the guide rail bracket has a pair of front and back end plates which are arranged in parallel and a mounting bottom plate vertically connected with the left ends of the end plates, a plurality of rivet holes are formed in the mounting plate, the pair of end plates has guide holes which are opposite, and each guide hole consists of a horizontal slot and a downward-bent oblique slot which forms an included angle beta with the horizontal slot; and the supporting bracket consists of a horizontal part and a vertical part connected with the right end of the horizontal part, the side face of the vertical part also has rivet holes corresponding to the rivet holes on the guide bracket and also has mounting holes for mounting the resetting device. The guide structure is mainly used for limiting the motion tracks of a contact seat and the resetting device.

Owner:浙江赛菲特电气有限公司

Double-break isolating switch

PendingCN114783813AMove fastQuick responseContact driving mechanismsAir-break switch detailsCrankDrive shaft

The invention relates to a double-break disconnecting switch which comprises a shell, a first static contact seat and a second static contact seat are relatively fixed in the shell, a movable contact seat is arranged between the first static contact seat and the second static contact seat, a first movable contact and a second movable contact are assembled on the movable contact seat in a guiding and sliding mode, and a driving structure comprises a transmission shaft and an operating mechanism. The transmission shaft drives the first moving contact and the second moving contact to synchronously act through a transmission structure in the shell to achieve opening and closing, the transmission structure in the shell comprises a main crank arm, the transmission shaft is connected to the middle of the main crank arm in a rotation stopping mode, the two ends of the main crank arm are in linkage with two transmission assemblies respectively, and each transmission assembly comprises a connecting rod. One end of the connecting rod is hinged to the moving contact, a guide structure used for guiding the other end of the connecting rod is arranged in the shell, the guide direction of the guide structure is perpendicular to the guide moving direction of the moving contact, the moving requirement of the moving contact can be met when the main crank arm rotates less than one circle, and the response speed of opening and closing can be improved.

Owner:PINGGAO GRP +3

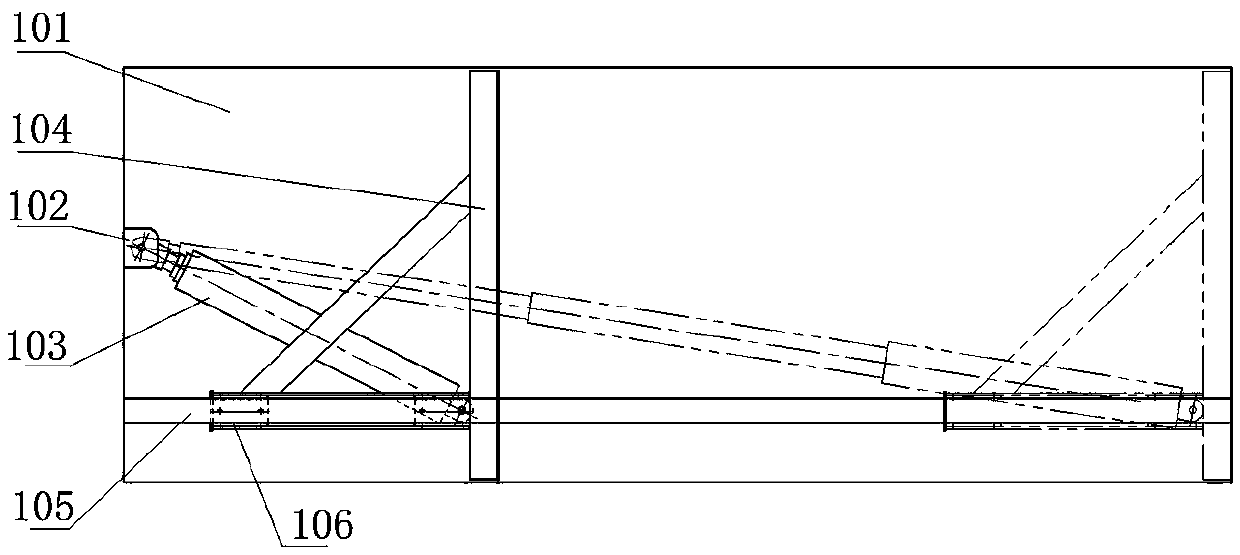

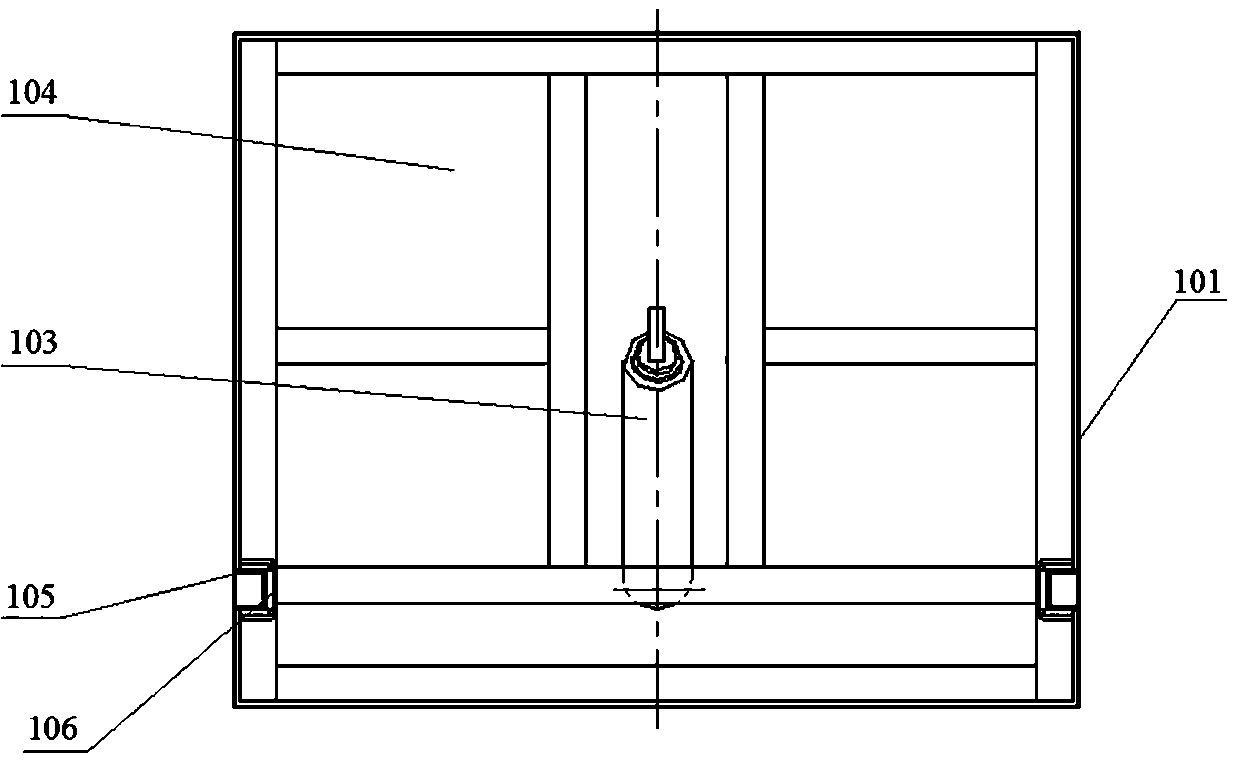

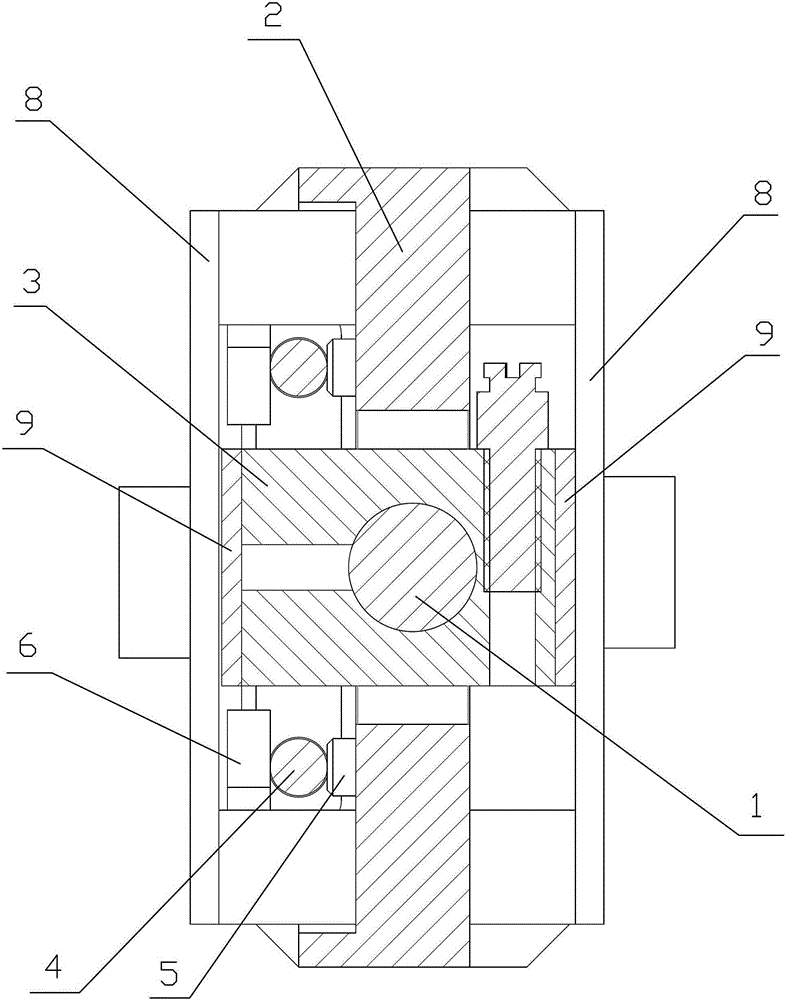

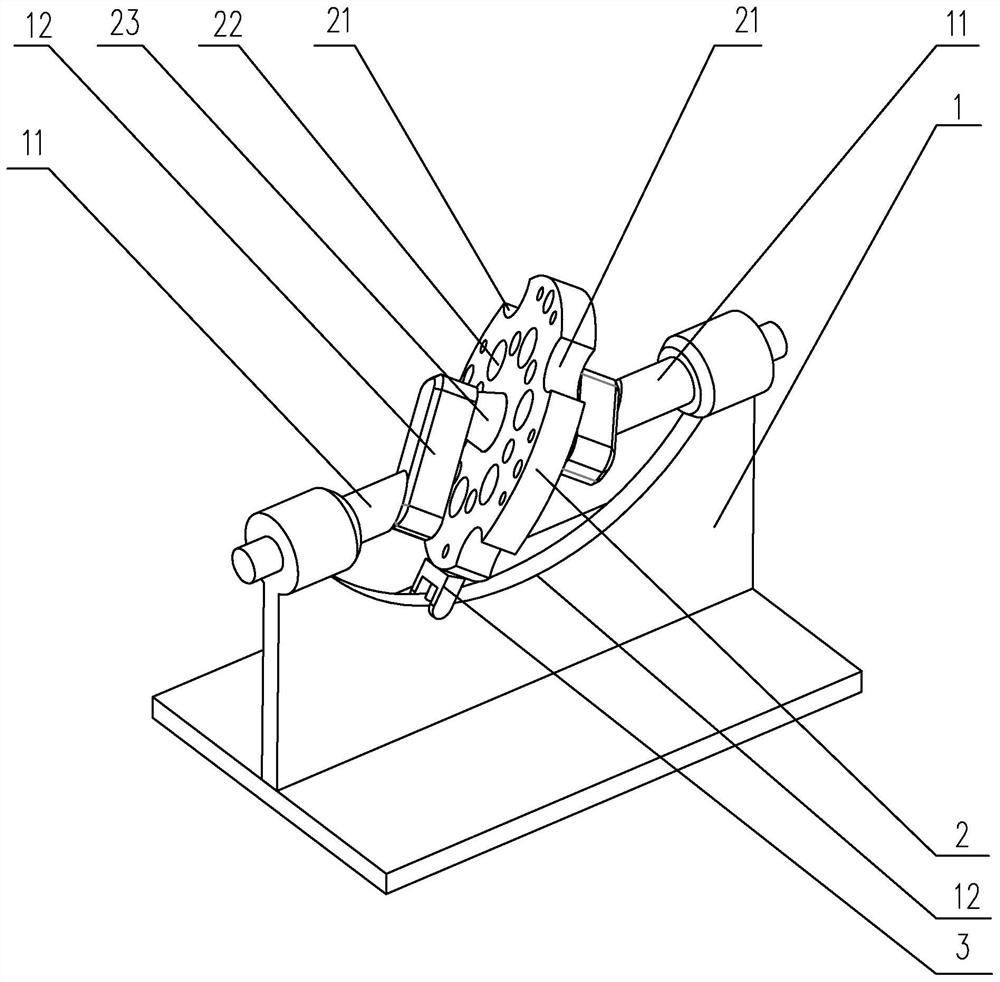

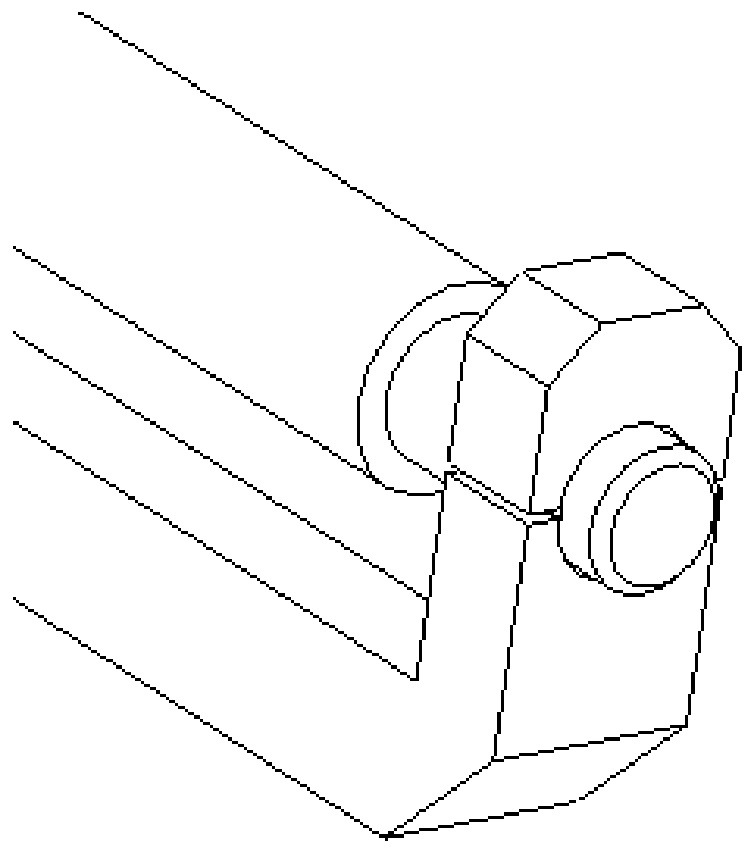

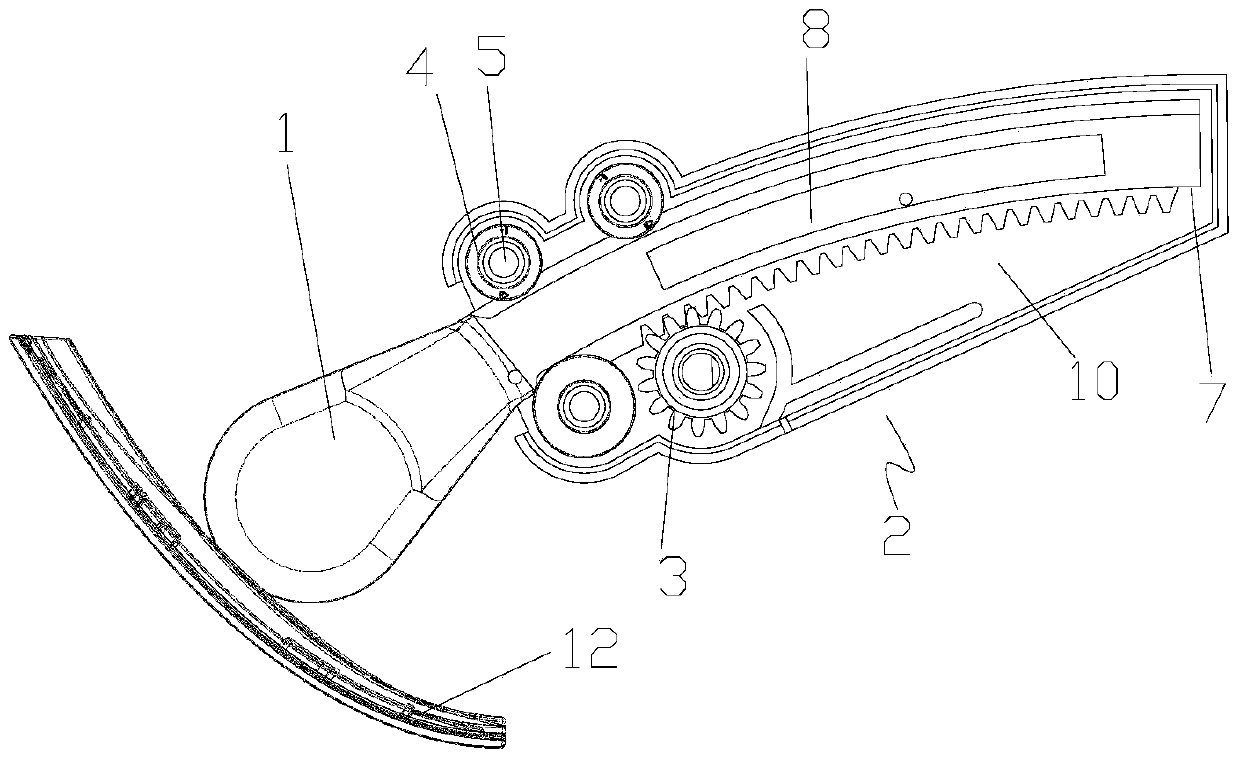

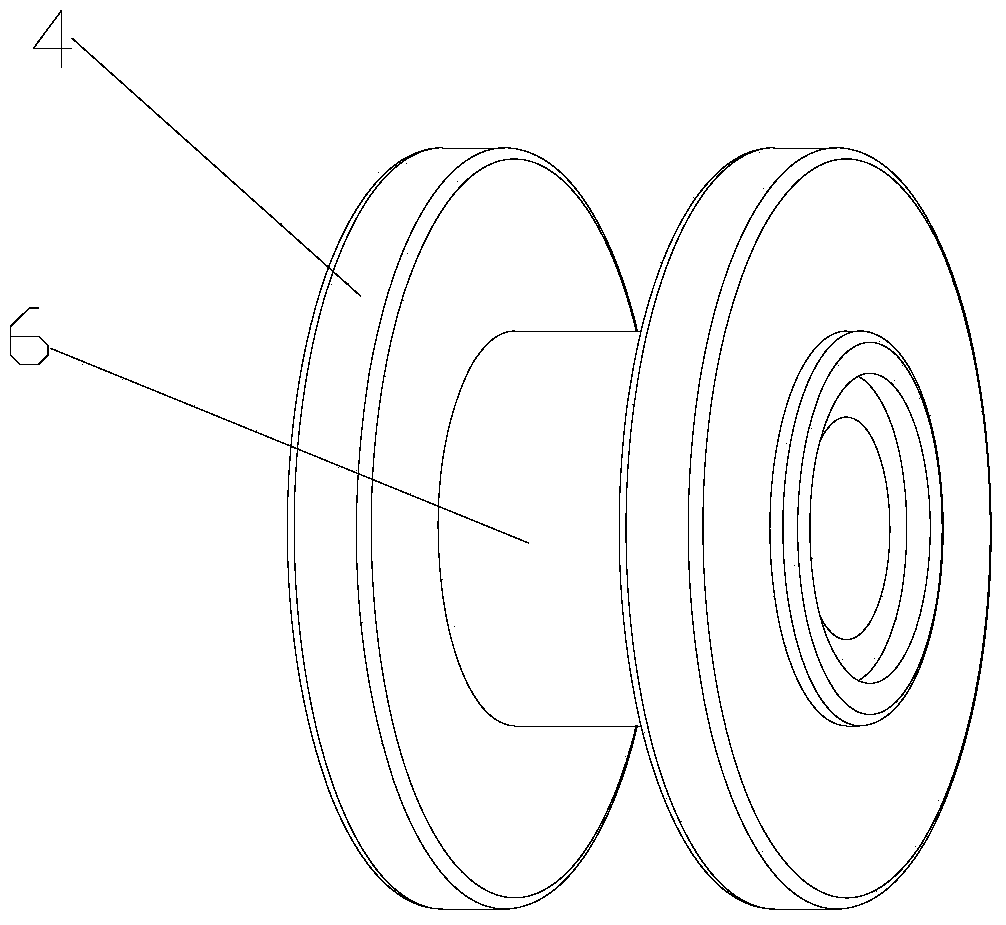

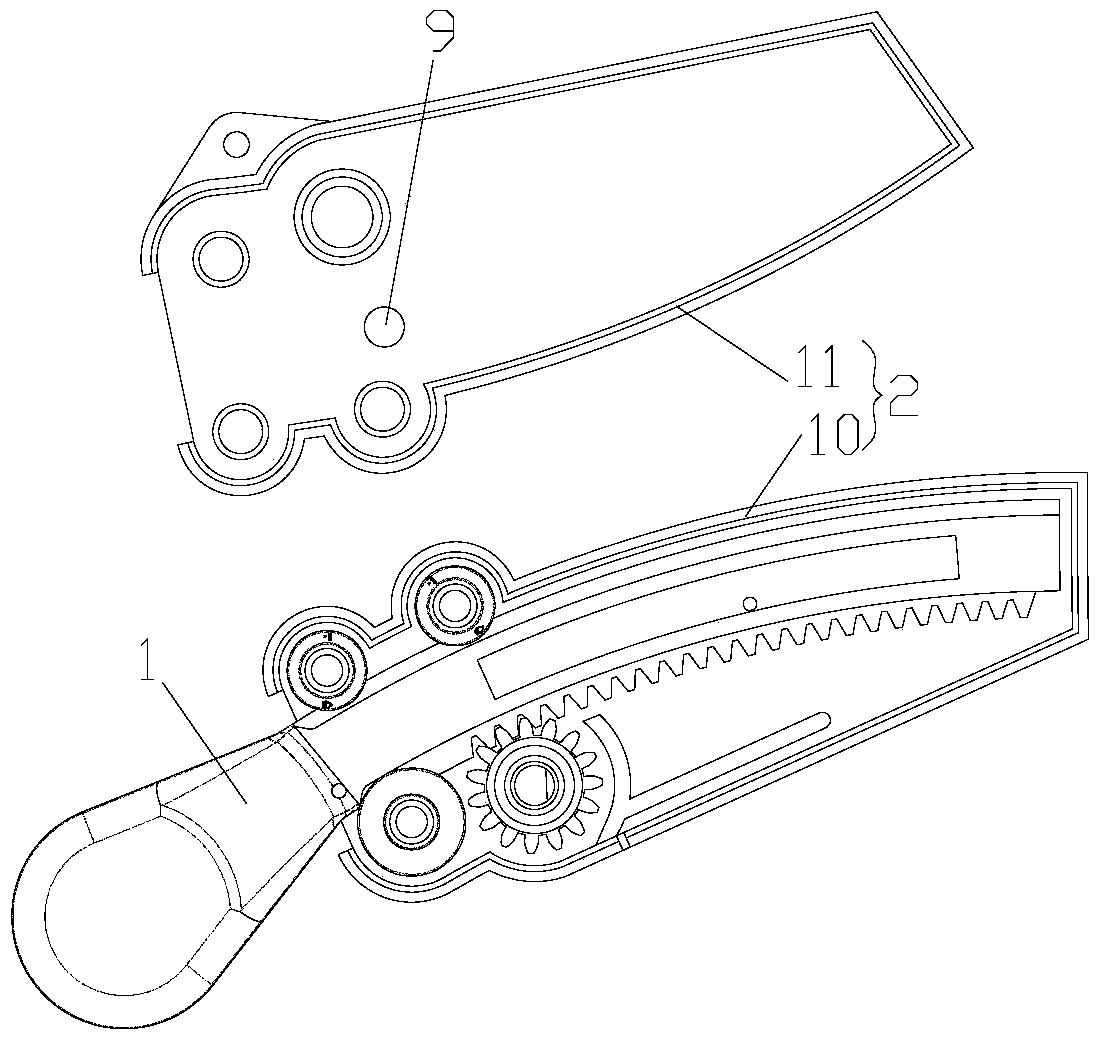

Wind deflector drive mechanism and air conditioner wall-mounted unit

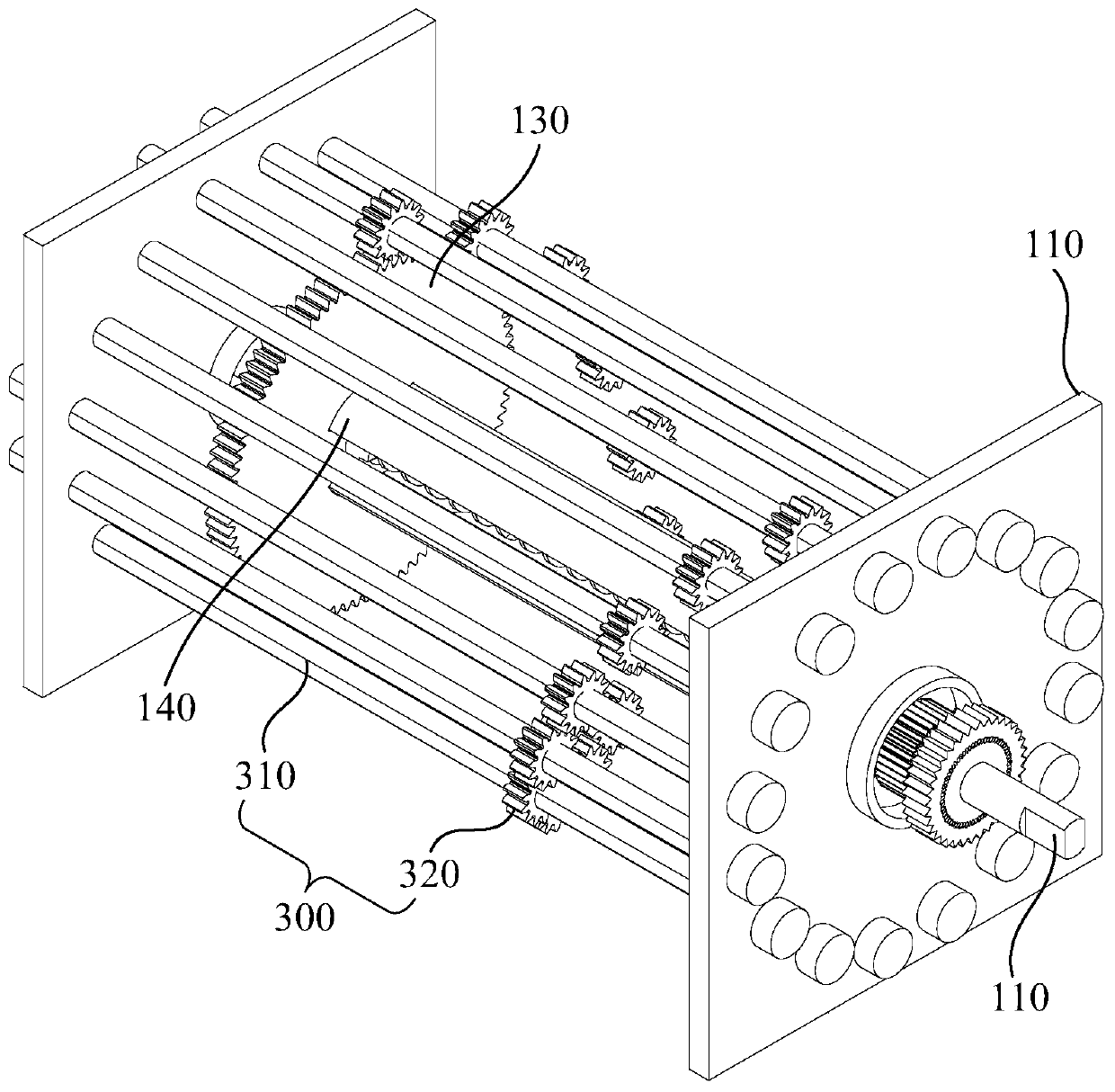

ActiveCN105402873BCompact structureOrientation structure is simpleAir-flow control membersGear wheelEngineering

A driving mechanism for an air-guiding plate comprises: a drive gear rack (1); a drive cartridge shell (2); a drive gear (3) disposed inside the drive cartridge shell (2); and multiple bearing pads (4). The multiple bearing pads form a guiding channel. The drive gear rack (1) is slidably disposed inside the guiding channel. The drive gear (3) is disposed inside the drive cartridge shell (2) and engages with the drive gear rack (1). Also provided is a wall-mounted air conditioner comprising the driving mechanism for an air-guiding plate. The driving mechanism for an air-guiding plate has a simple structure and can be assembled efficiently.

Owner:GREE ELECTRIC APPLIANCES INC

Unbonded steel strand oil removal device

ActiveCN113089350AScrape off quicklyAchieve removalRope making machinesCleaning using toolsMining engineeringStructural engineering

Owner:CHINA CONSTR FIFTH ENG DIV CORP LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com