Diversion damper slowly-closed check valve

A check valve and damping technology, which is applied in the field of water supply pipeline control valves, can solve the problems that the valve cannot be closed slowly, affects the normal operation of the valve, and the valve flow coefficient is small, so as to reduce parts, facilitate installation and layout, and prolong the service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

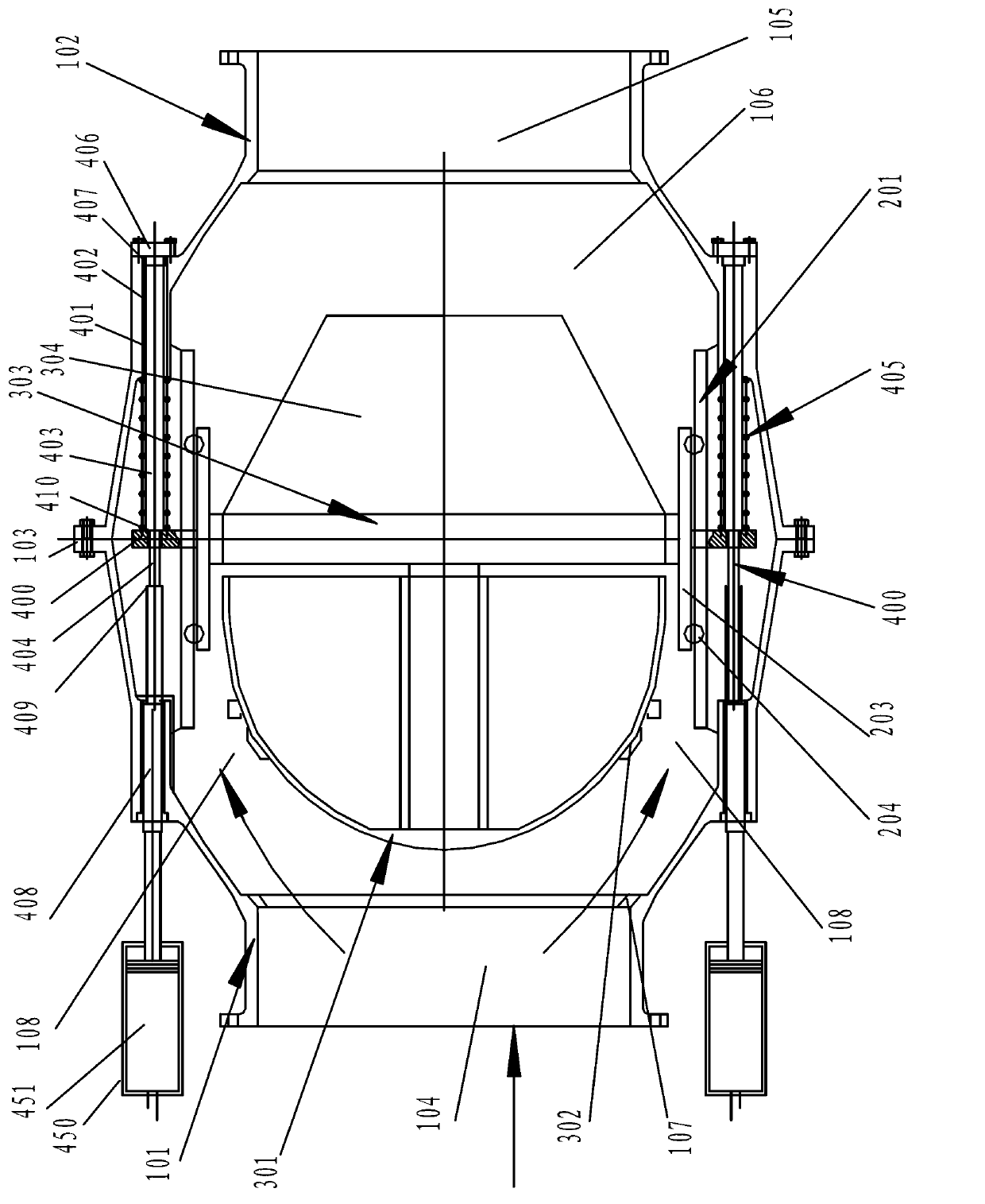

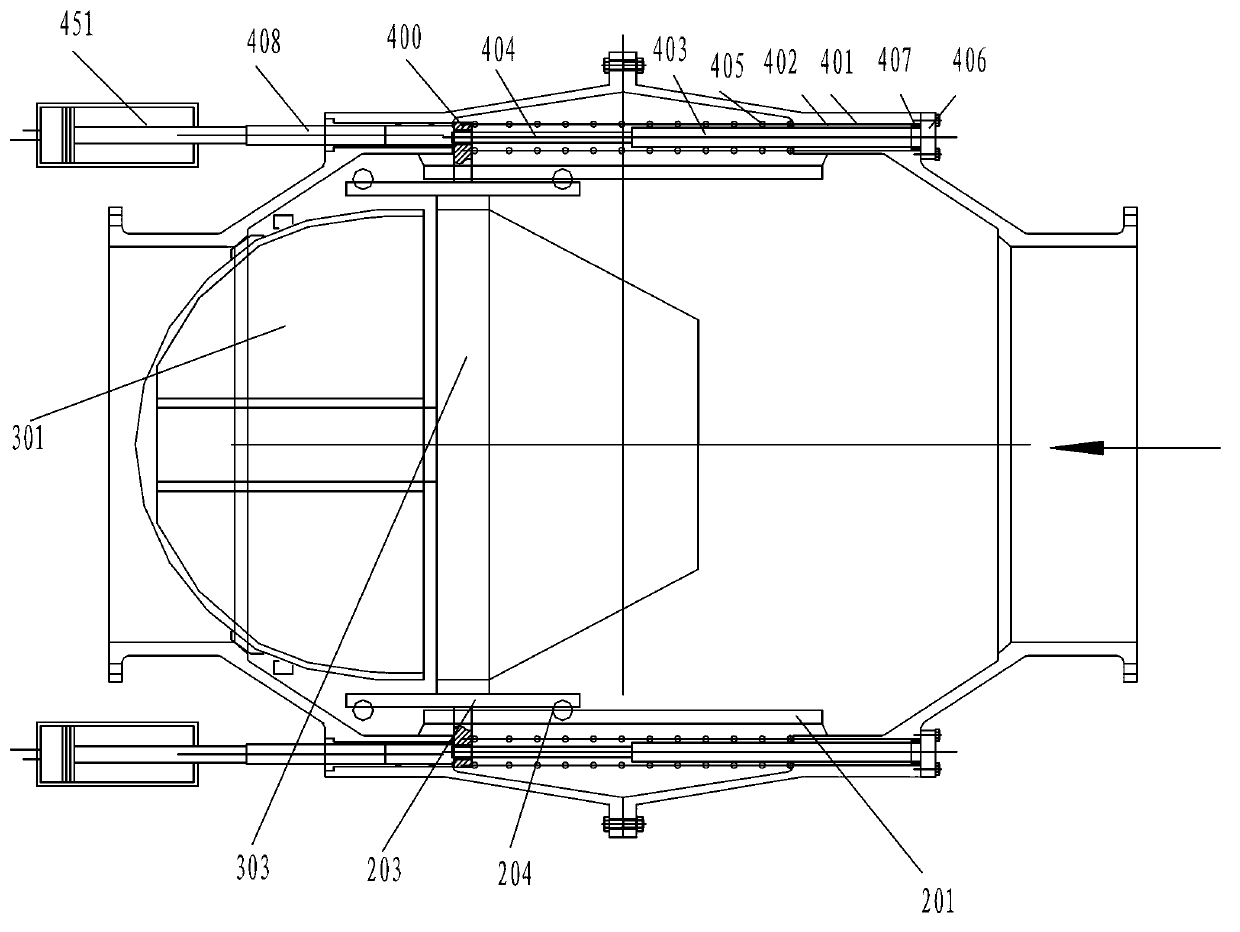

[0037] Such as figure 1 , 2 As shown, the valve body includes a front valve body 101 and a rear valve body 102 , and the front valve body 101 and the rear valve body 102 are connected and sealed by a flange structure 103 provided on the front valve body 101 and the rear valve body 102 . The front valve body 101 includes a facility medium (water) inlet conduit section 104 at the front end, and the rear valve body 102 includes a facility medium (water) outlet conduit section 105 at the rear end. The rear end of the front valve body 101 and the front section of the rear valve body 102 form an installation cavity 106 of the valve internal structure.

[0038] Check direction of the valve body In this embodiment, a valve seat 107 is provided at the end of the medium (water) entering conduit section 104 of the valve body 101 in this embodiment.

[0039] The installation cavity 106 is provided with a supporting mobile structure. In this embodiment, according to the pipe diameter and...

Embodiment 2

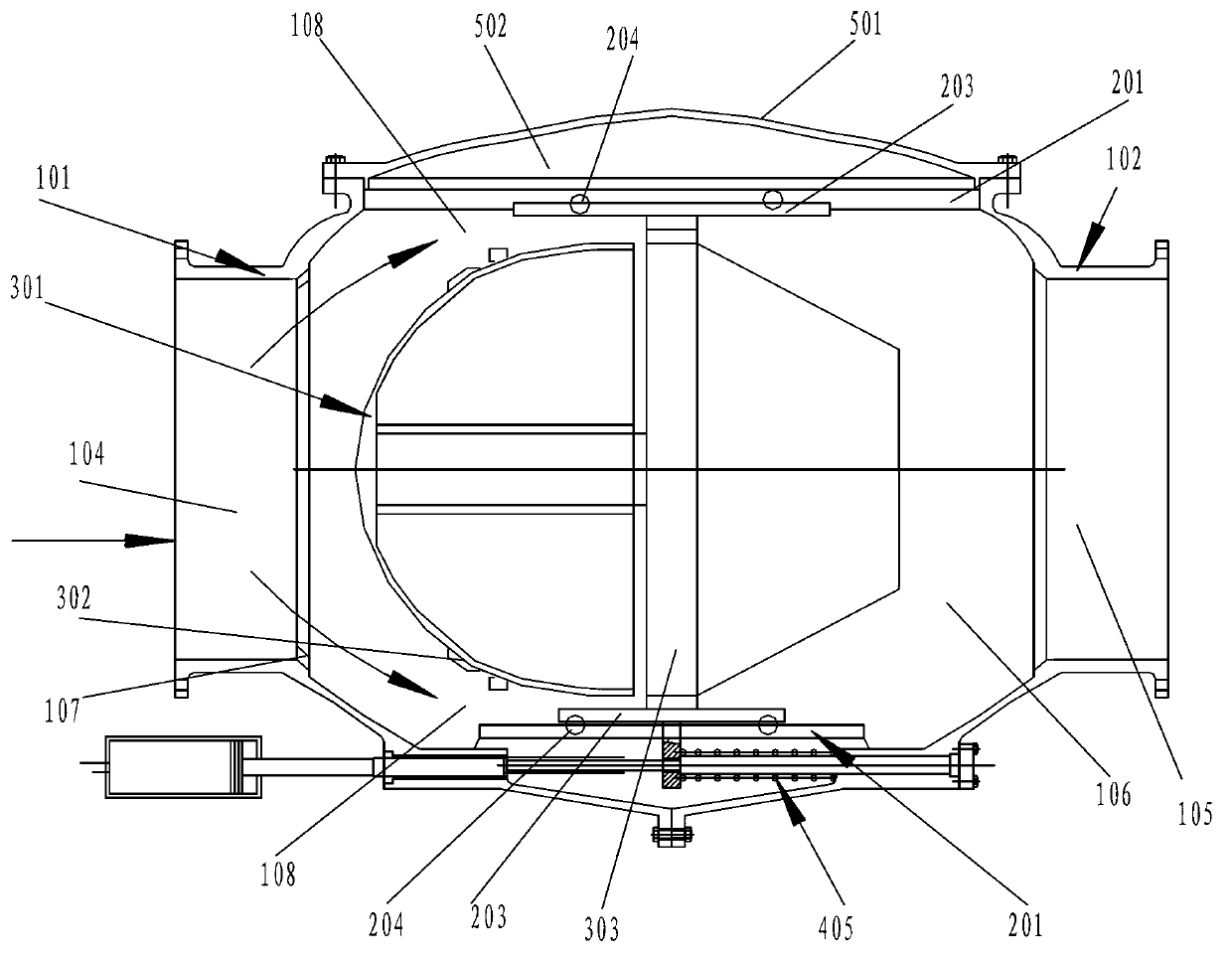

[0052] Such as image 3 As shown, the valve body is provided with an installation hole 501 of the valve body structure, and the installation hole is connected and sealed with the valve cover 502; Form a diversion channel. The shape formed by the inner wall of the valve body shell and the inner wall of the bonnet at the guide channel corresponds to the shape of the check valve core of the guide body, which is a part of an ellipsoid shape; or is formed by tangency of multiple arc segments The shape of the rotating body; or the rotating body formed by the tangency of multiple arc segments, the shape formed by the end of the rotating body tangent to the cylinder or the frustum of the cone; or the shape of the spherical crown; or the shape of the spherical crown and the A shape formed tangentially to a cylinder or frustum of a cone. The structure in the valve body is the same as that in Embodiment 1, and will not be repeated here.

[0053] The working principle of the large-diam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com