Liquid ethane conveying pipeline pressure protection system and method

A technology for transmission pipelines and protection systems, applied in pipeline systems, gas/liquid distribution and storage, mechanical equipment, etc., can solve problems such as increased pipeline costs, increased difficulty and cost of storage tank manufacturing, and few researches on water hammer release , to achieve the effect of eliminating fire prevention, saving manpower, and eliminating water hammer overpressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

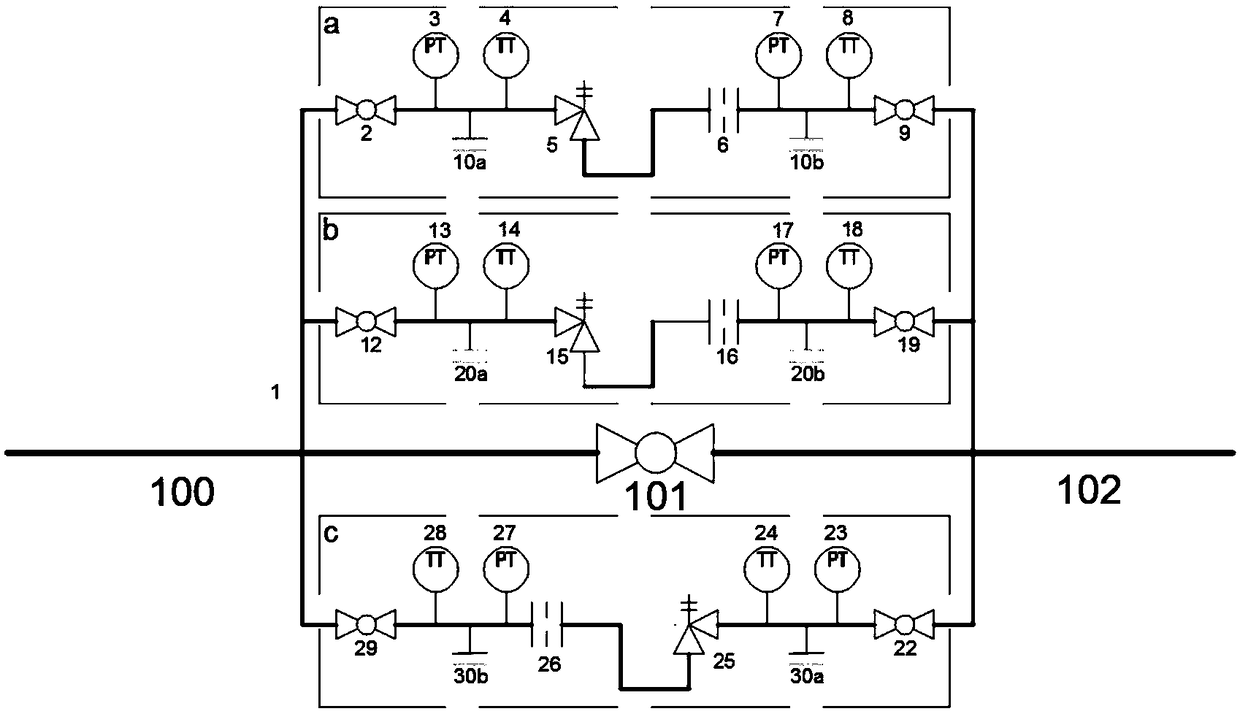

[0031] A liquid ethane pipeline pressure protection system, such as figure 1 As shown, it includes: bypass nipple 1, ball valve 2, pressure transmitter 3, temperature transmitter 4, positive pressure relief valve 5 in the first column, flow limiting orifice plate 6, pressure transmitter 7, temperature Transmitter 8, ball valve 9, drain valve group 10, ball valve 12, pressure transmitter 13, temperature transmitter 14, positive second column pressure relief valve 15, flow limiting orifice 16, pressure transmitter 17. Temperature transmitter 18, ball valve 19, drain valve group 20, ball valve 22, pressure transmitter 23, temperature transmitter 24, reverse pressure relief valve 25, flow limiting orifice 26, pressure transmitter 27. Temperature transmitter 28, ball valve 29, drain valve group 30.

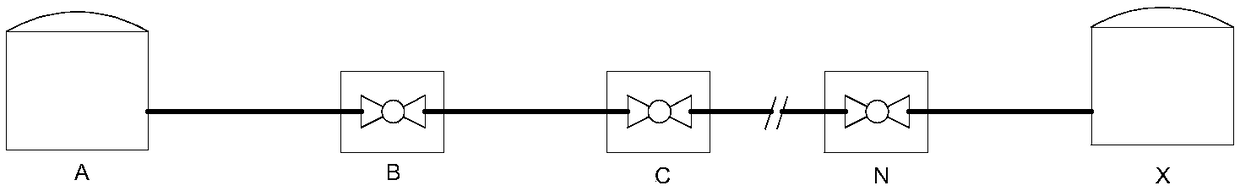

[0032] The schematic diagram of the pressure protection of the whole system of the liquid ethane delivery pipeline of the present invention is as follows figure 2 As shown, such for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com