Driving mechanism for gas blowing cover of core-making machine

A technology of driving mechanism and blowing hood, which is applied in the direction of cores, molding machines, manufacturing tools, etc., can solve the problems of large space required for equipment layout, impact, and high structural cost, so as to achieve no impact in place, reduce rotation speed, The effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

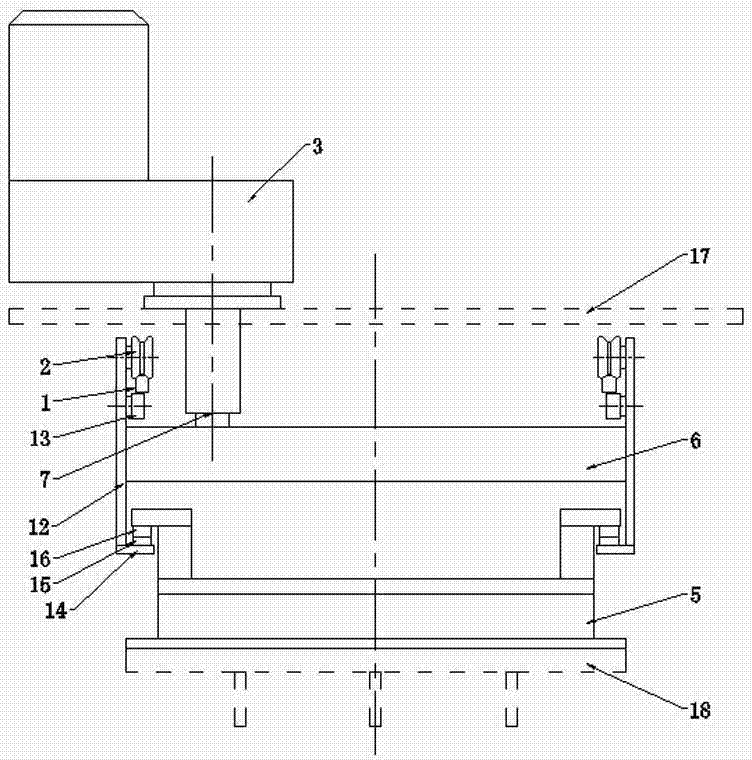

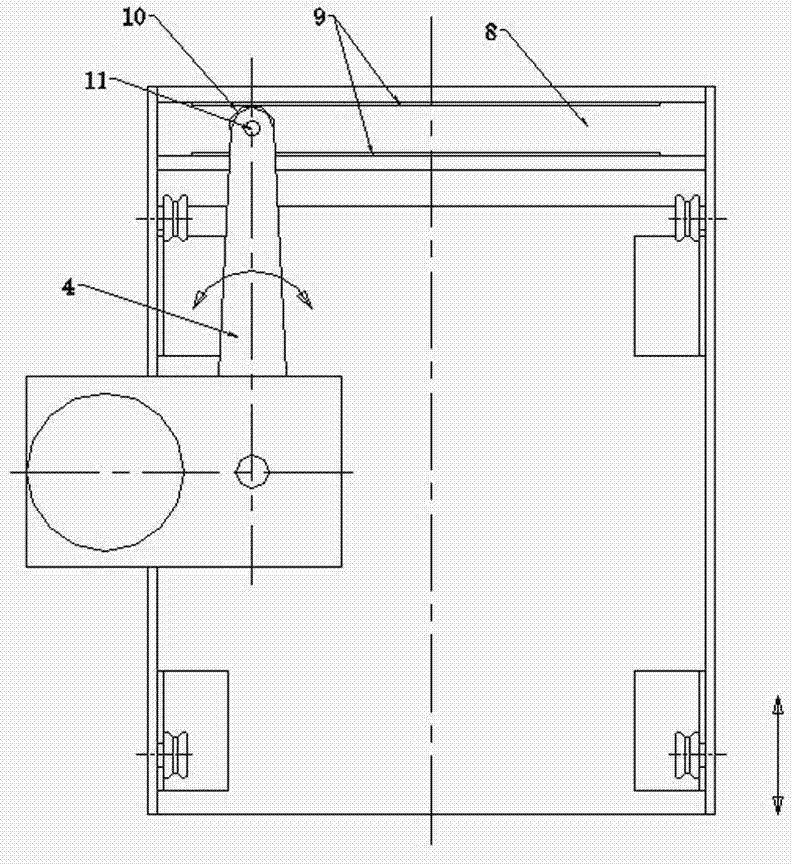

[0027] Embodiment one: see attached figure 1 And attached figure 2 As shown, a blowing hood driving mechanism of a core making machine is composed of a driving device and a guiding device. The guiding device includes a pair of guide rails 1 arranged in parallel along the moving direction of the blowing hood 5 and guide wheels matched with the guide rails. , the driving device includes a geared motor 3 installed on the upper frame of the core making machine, a swing arm 4 fixedly connected to the output shaft of the geared motor 3 at one end via a connecting shaft 7, and a blowing trolley 6 connected to the blowing cover 5; The output shaft of the reduction motor 3 is vertically arranged, and one end of the blowing trolley 6 is provided with a guide groove 8 arranged perpendicularly to the direction of the guide rail 1, and the guide groove 8 is formed by a pair of guide plates 9 arranged in parallel, and the swing arm 4 is arranged in parallel. One end is rotatably connected...

Embodiment 2

[0032] Embodiment 2: A blowing hood driving mechanism of a core making machine, the basic structure of which is the same as that of Embodiment 1, wherein the rotating power output mechanism is a rotating hydraulic cylinder or a hydraulic motor. In this embodiment, since the rotary power output mechanism adopts a hydraulic mechanism, the hydraulic oil output of the ready-made hydraulic station of the core making machine can be used for output, and no additional power source is needed, which is easy to implement.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com