Crushing beam combined structure of double-tooth roller crusher

A combined structure and crushing beam technology, applied in grain processing and other directions, can solve the problems of long maintenance time, poor stress state of crushing tooth caps, and affecting production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

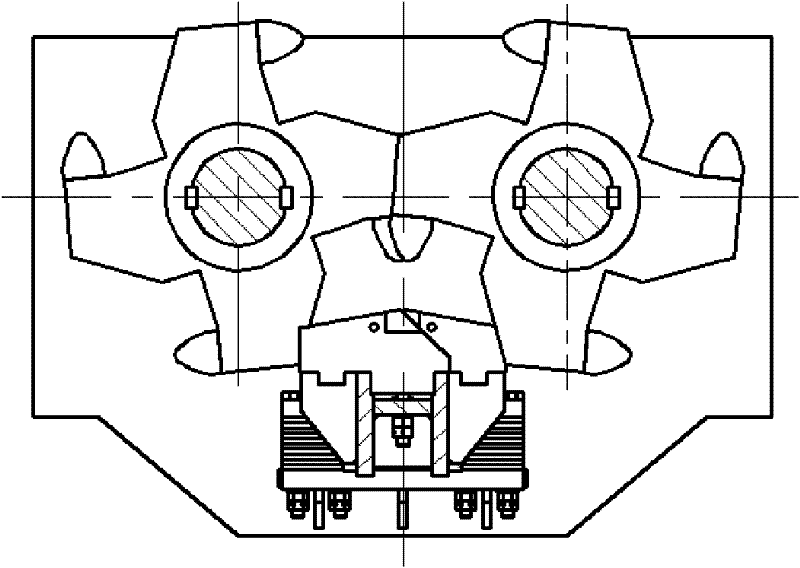

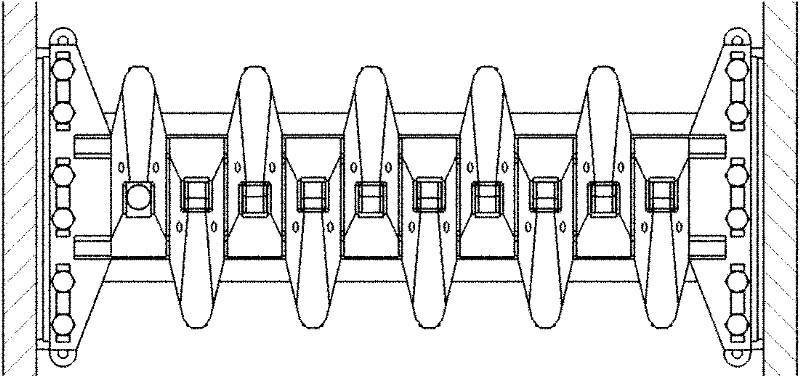

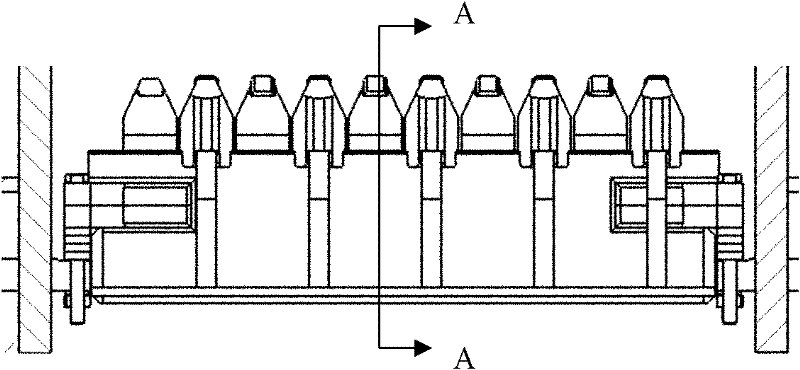

[0021]Referring to the accompanying drawings, a combined structure of a crushing beam of a double-toothed roller crusher consists of a frame 1, an adjusting gasket 2, a bolt 3, a crushing beam 4, a crushing tooth cap 5, a tooth cap 6, a guide 7, and a stopper 8. The stopper is composed of bolts 9 and 10. It is a broken beam combination of a double-toothed roller crusher, which is located under the two crushing toothed rollers of the crusher. A guide groove C and a groove D are set at both ends of the beam 4, and a guide piece 7 is set on the frame 1. The broken beam combination is placed on the frame 1 along the guide groove C and groove D, and the bolts are used to close them, and the gasket is adjusted. There are several U-shaped grooves on the 2, and the opening direction of the U-shaped grooves is at an inclined angle to the side of the adjusting gasket 2, and a notch parallel to the opening direction of the U-shaped grooves is provided on the side of the inclined direction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com