Guide structure in switching mechanism of drop-out type fuse

A drop-type fuse and guide structure technology, applied in the direction of protection switch operation/release mechanism, electrical components, circuits, etc., can solve problems such as large operating force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

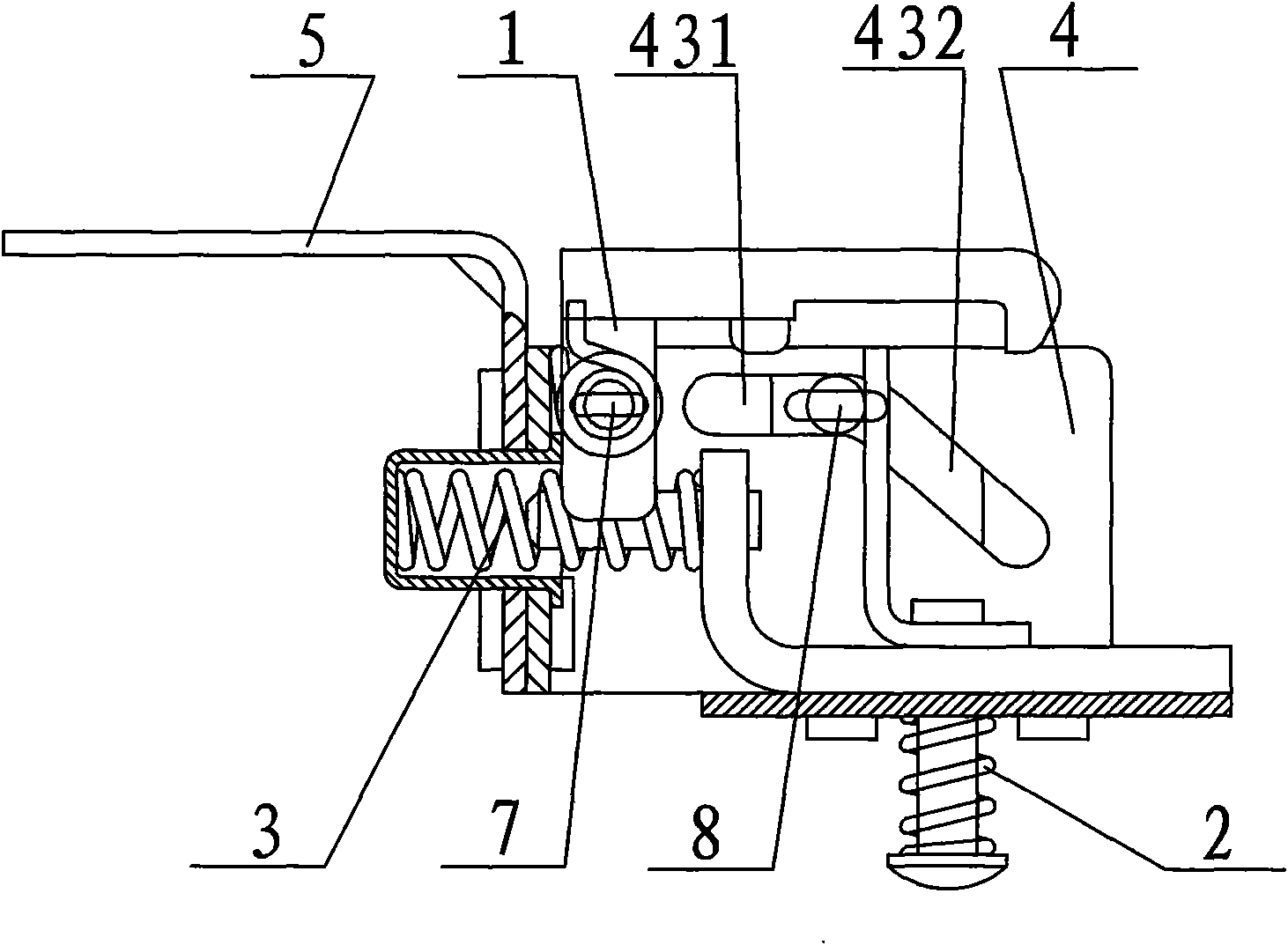

[0013] The technical solution of the present invention is described below by specific embodiments in conjunction with the accompanying drawings:

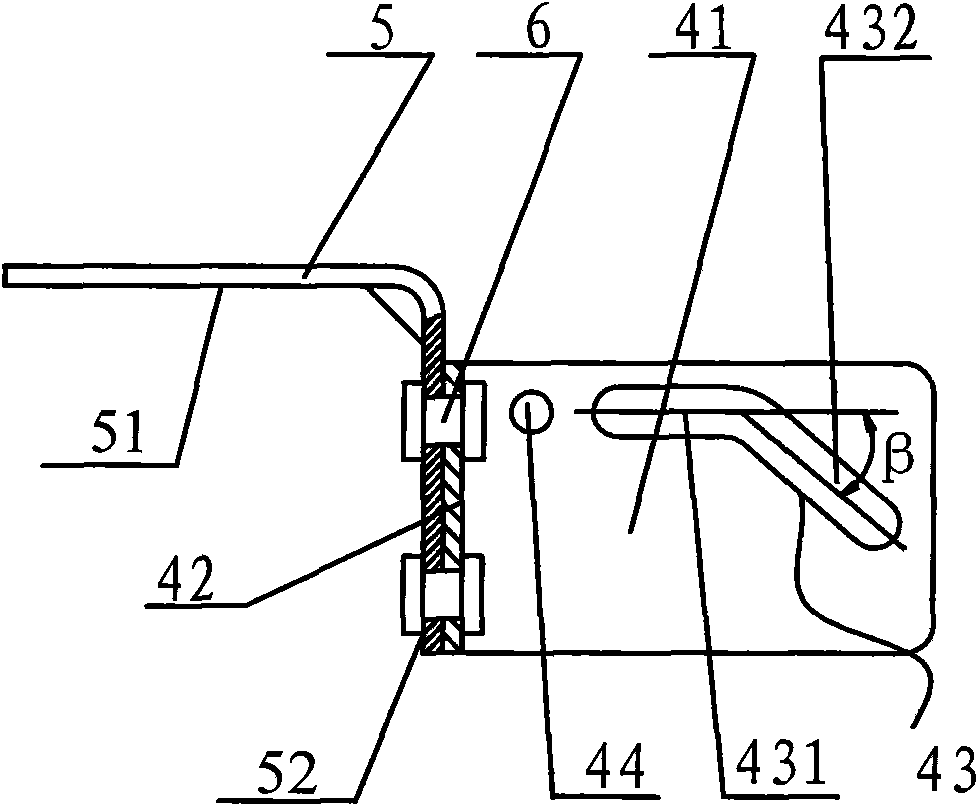

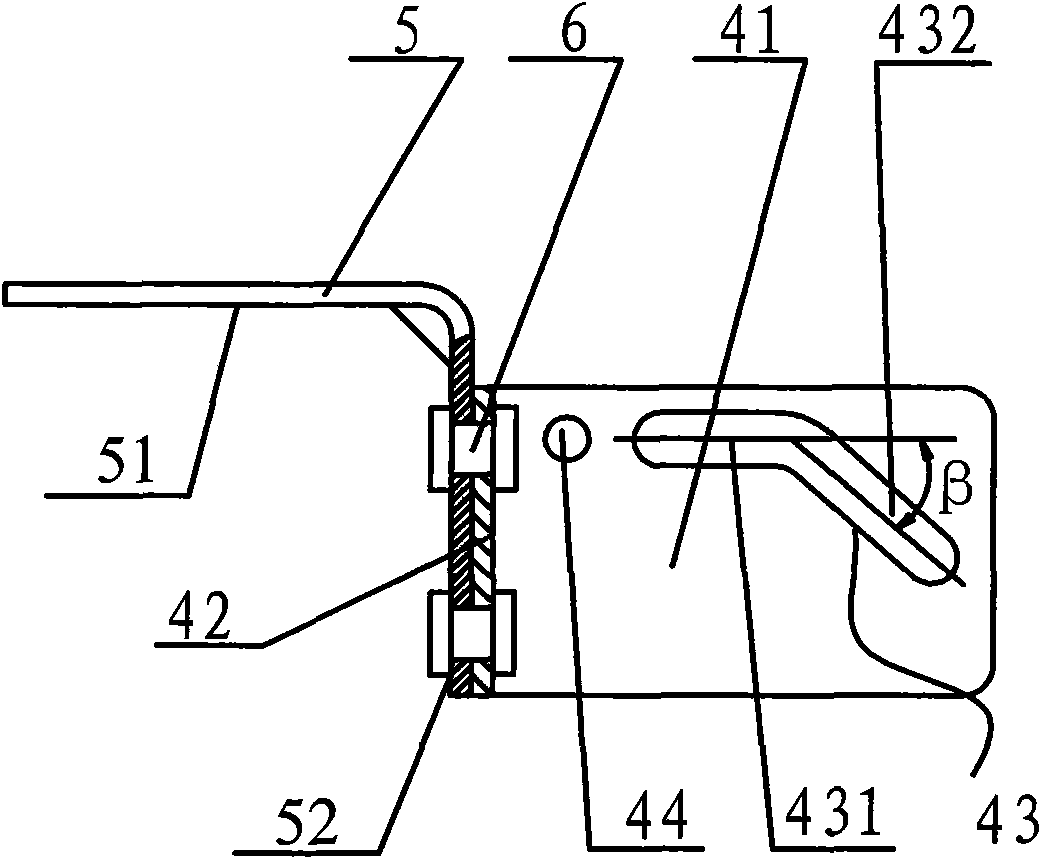

[0014] see figure 1 , the guide structure used in the opening and closing mechanism of the drop-out fuse of the present invention includes a guide rail frame 4 and a bracket 5, wherein,

[0015] The guide rail frame 4 has a pair of end plates 41 arranged parallel to the front and rear and a mounting base plate 42 vertically connected to the left end of the end plate 41. Several rivet holes are provided on the mounting base plate 42; A guide slot 43, the guide slot 43 is composed of a connected section of horizontal slot 431 and a section of oblique slot 432 that is bent downward and forms an angle with the horizontal slot 431 and is β=30°~40°; A pair of end plates 41 are respectively provided with a locking pin hole 44 at the left front of the guide slot 43;

[0016] Bracket 5 is made of a horizontal part 51 and a vertical part 52...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com