Double-break isolating switch

A isolating switch and double-break technology, which is applied in the field of double-break isolating switches, can solve the problems of high production cost of parts, slow opening and closing response speed, etc., and achieve the effect of large moving distance, improved response speed, and guaranteed opening distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

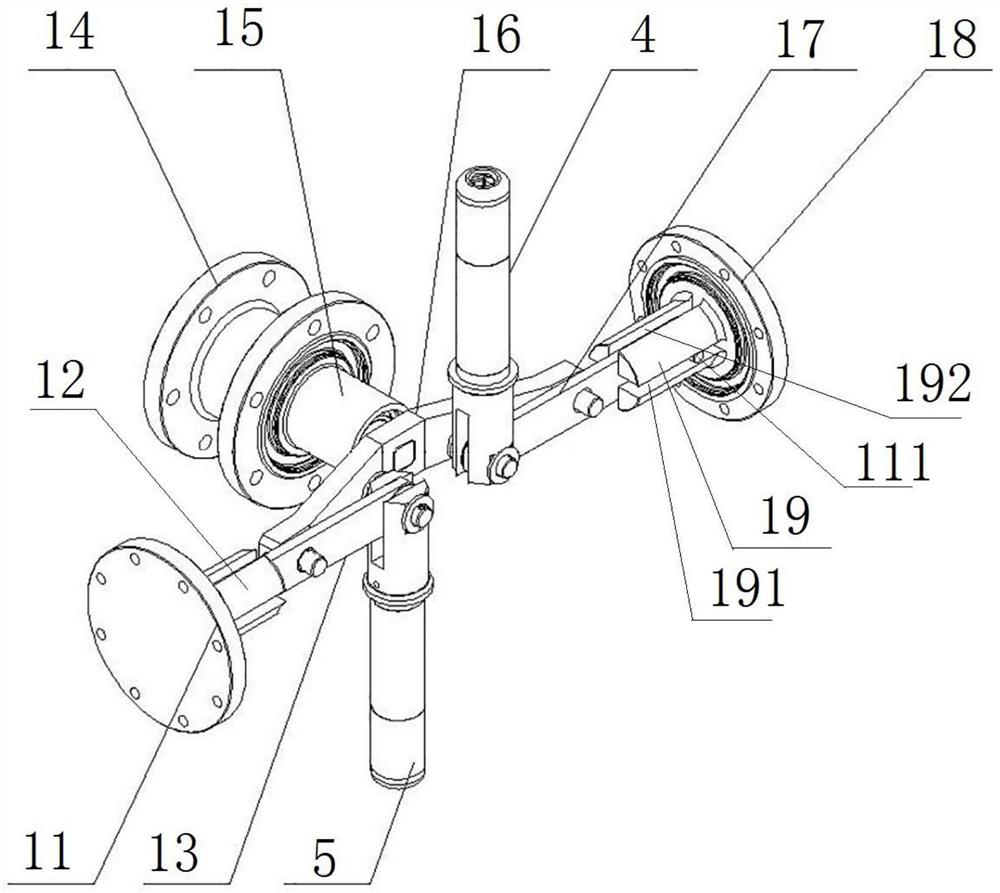

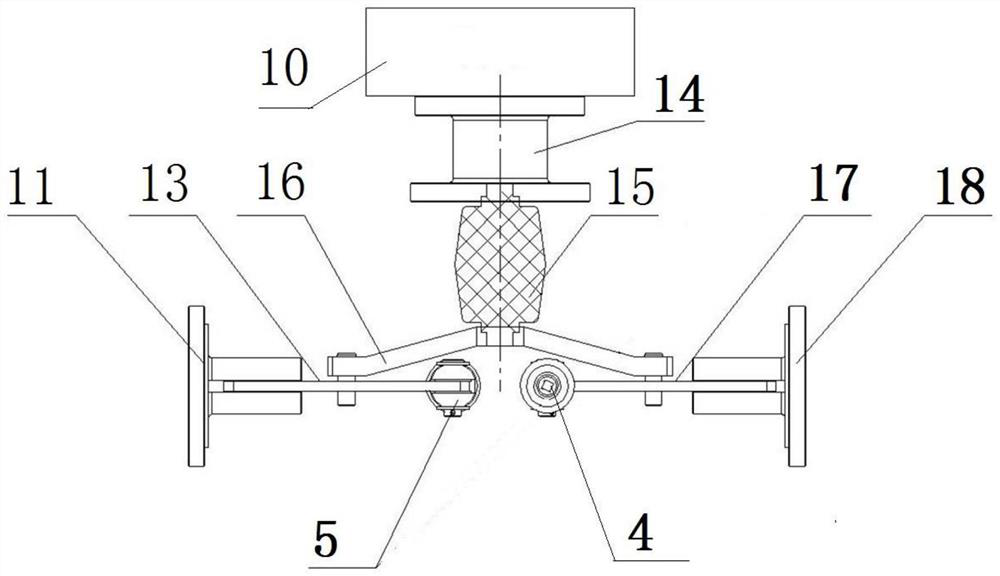

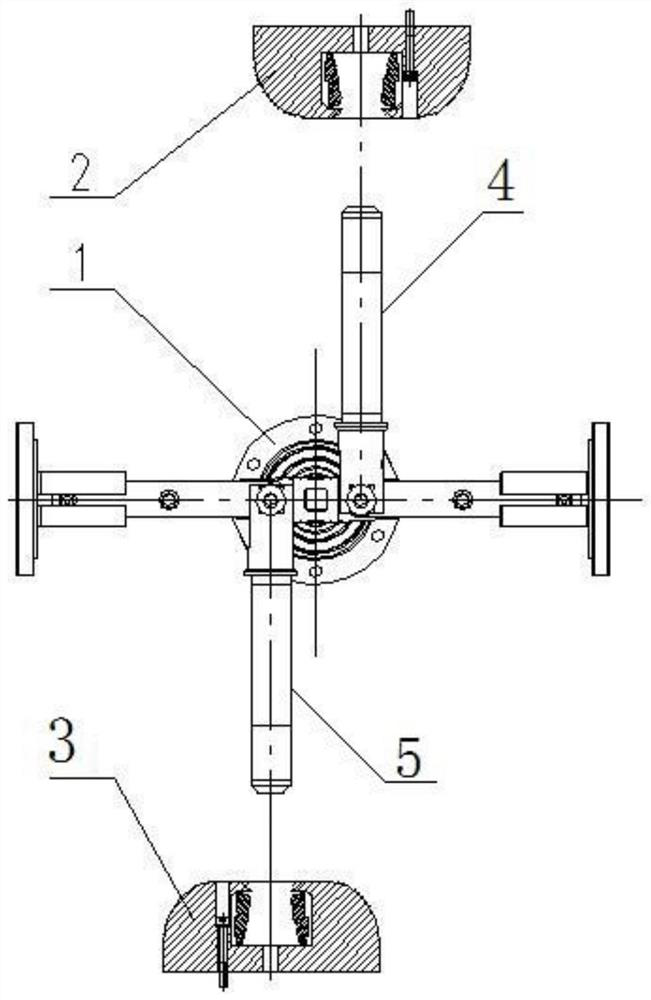

[0044] The double-break isolating switch includes a casing, the inner cavity of the casing forms a sealed air chamber, two supporting insulators arranged oppositely are arranged on the casing, and a static contact seat is arranged on the supporting insulator, and the static contact seats on the two supporting insulators respectively constitute the first static contact seat. The contact seat and the second static contact seat, the first static contact seat is provided with a first static contact 2, the second static contact seat is provided with a second static contact 3, the first static contact 2 and the second static contact The heads 3 are arranged in a staggered manner, and the oppositely arranged first stationary contacts 2 are parallel to the central axes of the second stationary contacts 3; the housing is also provided with a movable contact seat (not shown in the figure), and the movable contact seat passes through the insulating support Fixed in the air chamber, the mo...

Embodiment 2

[0057] The difference between this embodiment and Embodiment 1 is that the guiding moving paths of the first moving contact and the second moving contact in Embodiment 1 are parallel to each other and spaced in a direction perpendicular to the moving paths. In this embodiment, as Image 6 and Figure 7 As shown in the figure, the guiding movement paths of the first movable contact 04 and the second movable contact 03 are collinear, and correspondingly, the first stationary contact and the second stationary contact are on the same axis, so that the entire movable end can be assembled on the same axis. Whether it is perpendicular to the direction of the moving contact guide movement or which structure is more compact is suitable for different use requirements.

Embodiment 3

[0059] The difference between this embodiment and Embodiment 1 is that the main arm in Embodiment 1 is arched. In this embodiment, the main arm is U-shaped, and the two opposite arms of the U-shape are used for hinged connection with the two connecting rods, or in other embodiments, the main arm is a straight plate structure, and the movable contact is hinged on the connection. side of the rod.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com