Unbonded steel strand oil removal device

A steel strand, unbonded technology, applied in the field of unbonded steel strand degreasing devices, can solve the problems of poor cleaning effect, scratches by workers, oil stains on the surface of steel strands and stubborn debris residues, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

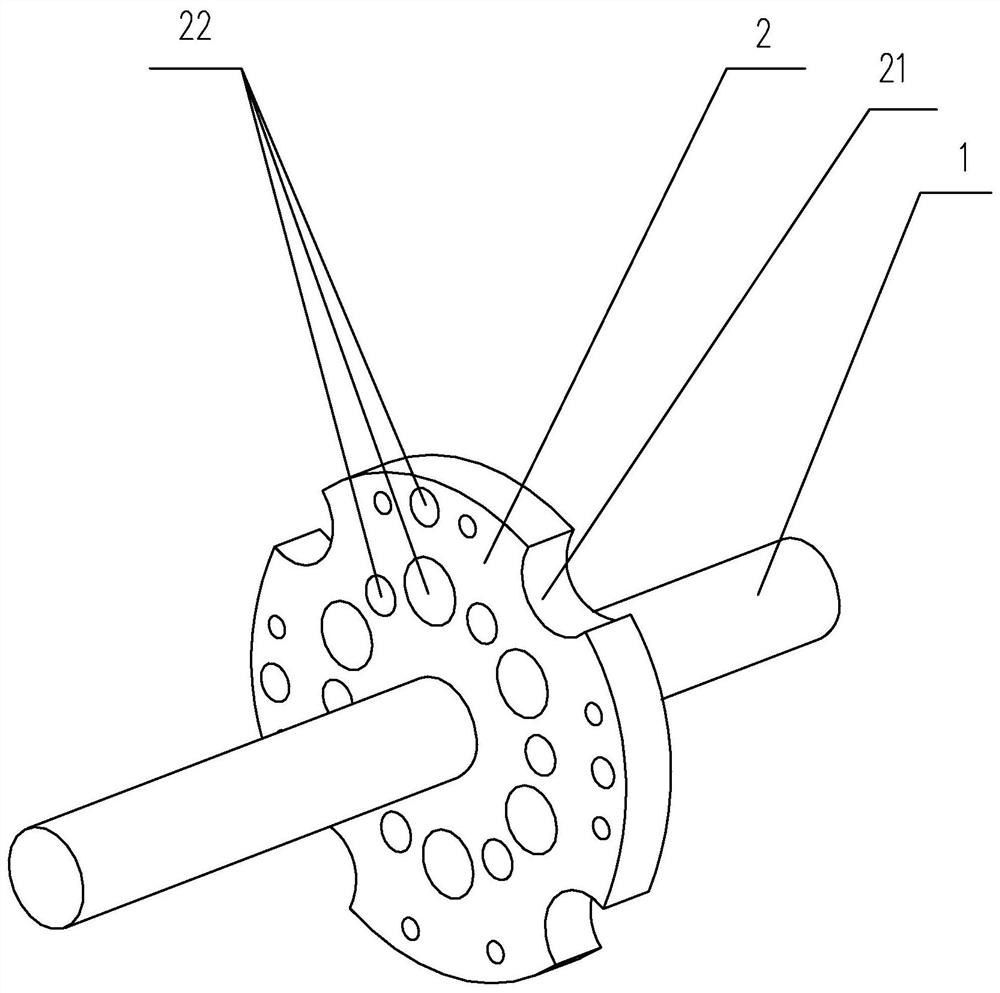

[0024] The first embodiment of the unbonded steel strand degreasing device of the present invention is as figure 1 As shown: it includes a support piece 1 and a work piece 2, the work piece 2 is arranged on the support piece 1, and several groups of snap-in grooves are evenly distributed on the work piece 2, and each set of snap-in grooves includes a number of different sizes. A slot hole 22 arranged on the work piece 2 and an arc-shaped groove 21 arranged on the edge of the work piece 2 .

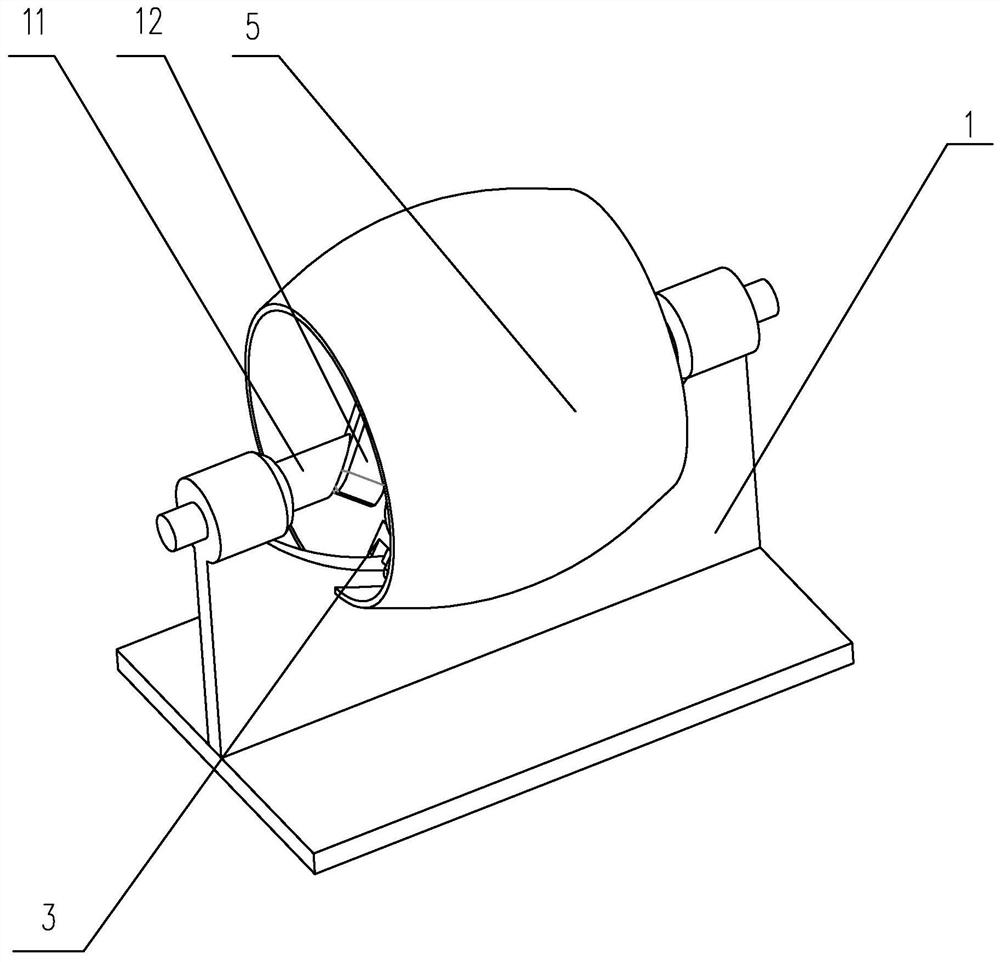

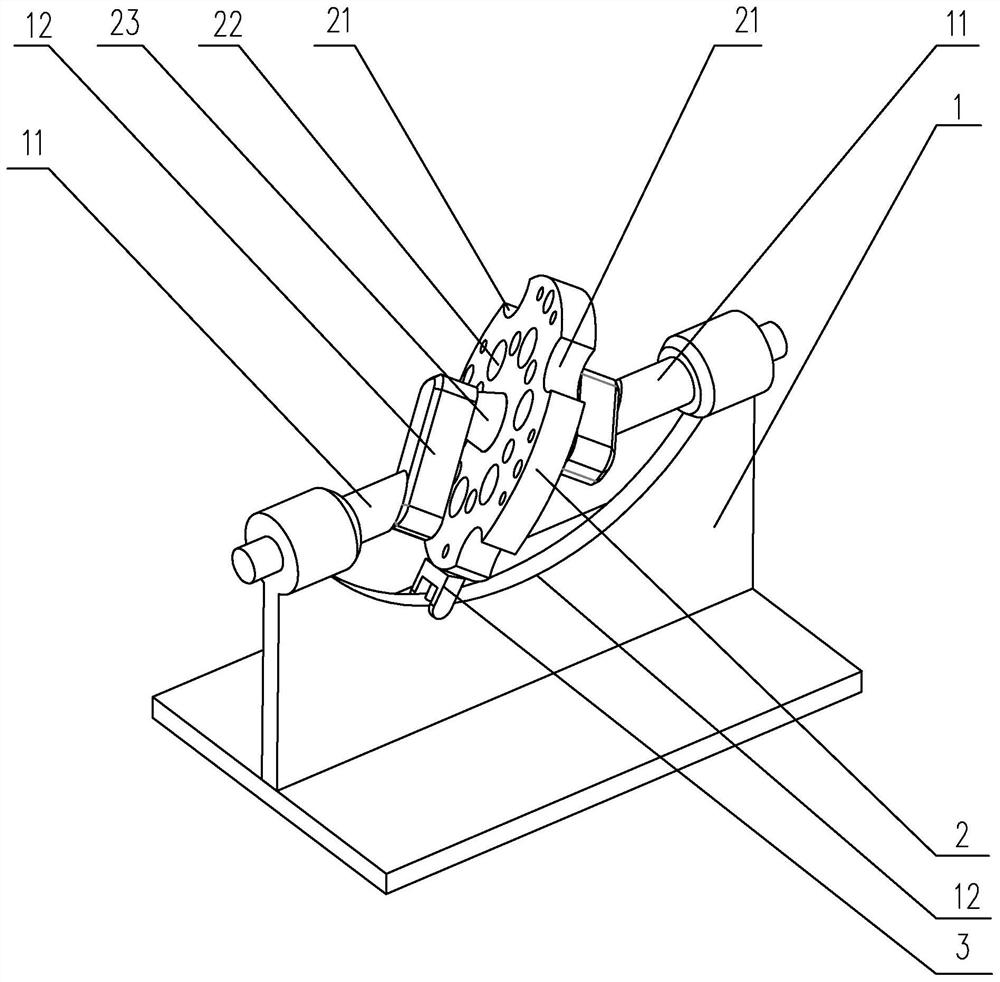

[0025] The second embodiment of the unbonded steel strand degreasing device of the present invention is as figure 2 and image 3 As shown: it includes a support piece 1 and a work piece 2, the work piece 2 is arranged on the support piece 1, and several groups of snap-in grooves are evenly distributed on the work piece 2, and each set of snap-in grooves includes a number of different sizes. A slot hole 22 arranged on the work piece 2 and an arc-shaped groove 21 arranged on the edge of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com