High-precision powder filling mechanism

A high-precision, powder technology, used in packaging, solid materials, transportation and packaging, etc., can solve the problems of inability to increase processing speed, high production cost, low production efficiency of production lines, etc., to meet the needs of large-scale industrial production and production efficiency. High, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

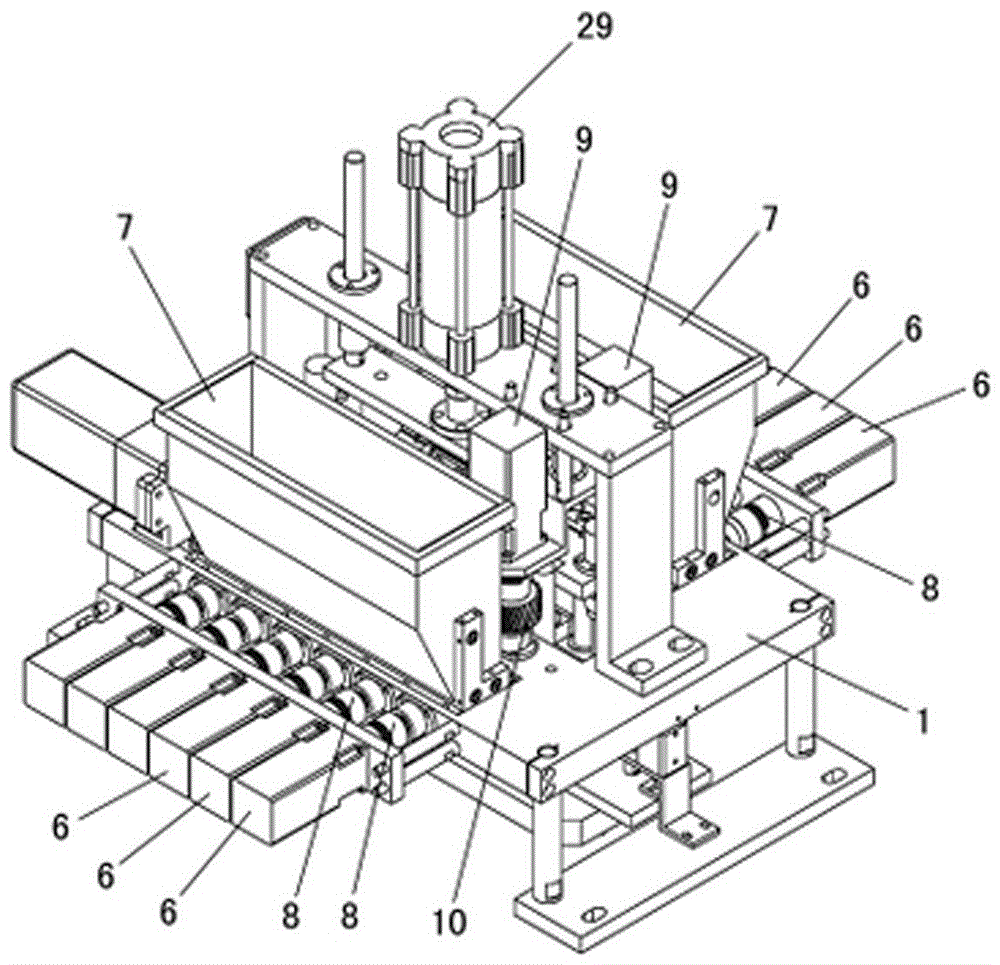

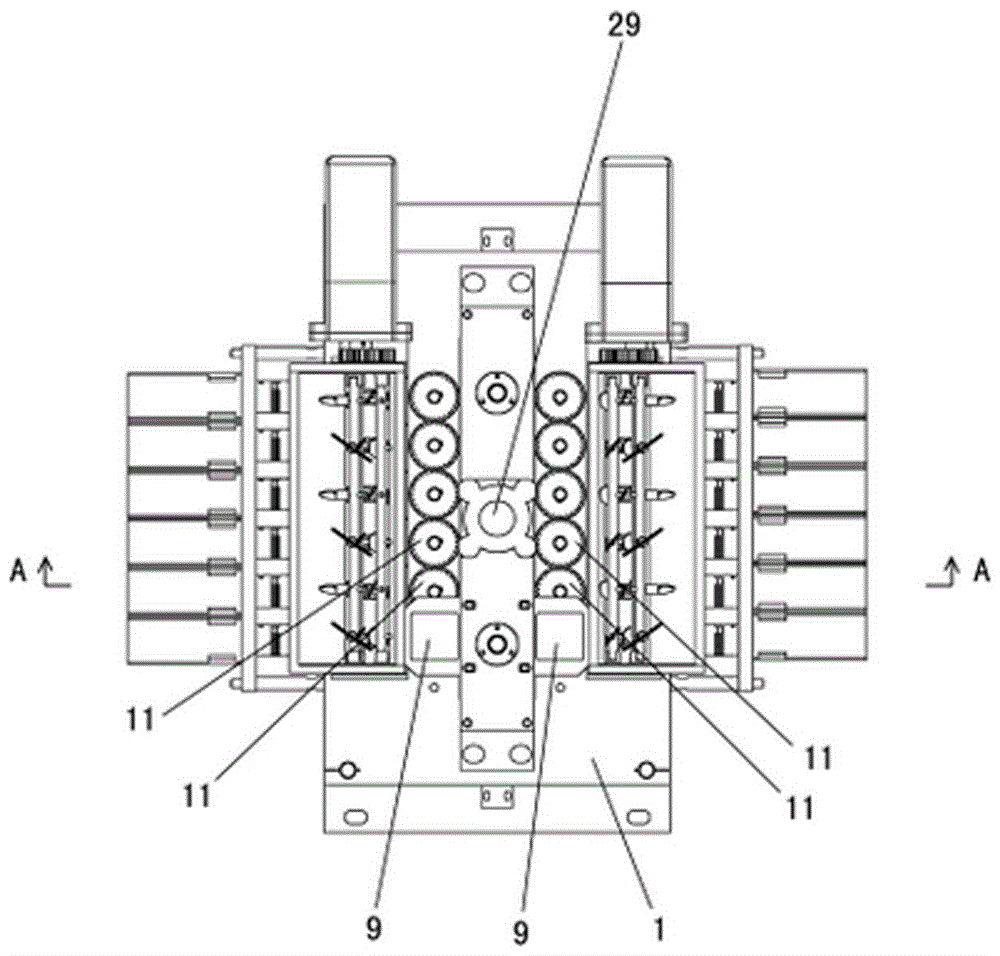

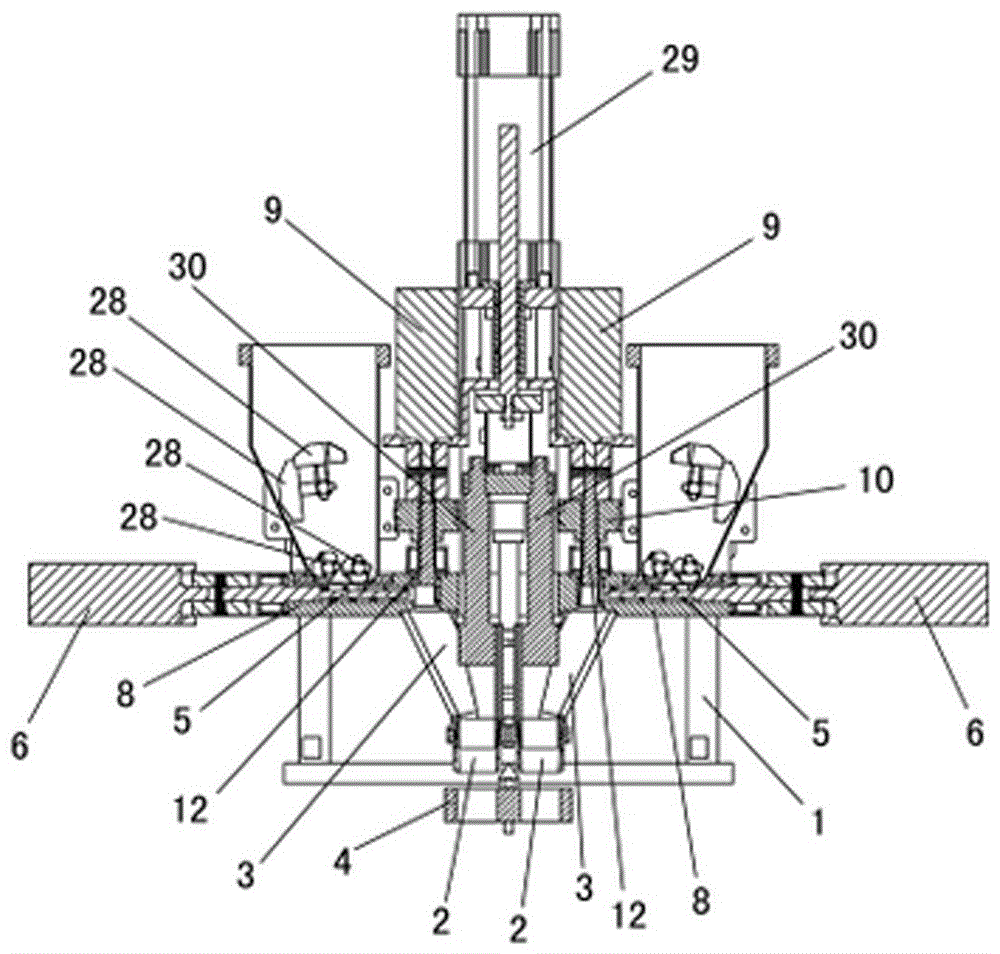

[0025] Such as Figure 1-5 As shown, the high-precision powder filling mechanism in this embodiment includes a support frame 1 and 12 high-precision filling devices, and the high-precision filling device includes a filling head 2, a blanking trough 3, a mold 4, Screw 5, first motor 6, hopper 7, discharge pipe 8, feed rod and feed rod drive device, the hopper 7, filling head 2, discharge pipe 8 are respectively installed on the support frame 1, the The top of the discharge pipe 8 is communicated with the outlet at the bottom of the hopper 7, the screw 5 is located in the discharge pipe 8, the first motor 6 is installed on the outer opening of the discharge pipe 8, and the first motor 6 is connected with the screw 5, The filling head 2 is located below the inner opening of the discharge pipe 8, the top of the blanking chute 3 is connected to the inner opening of the discharge pipe 8, the bottom end of the blanking chute 3 is connected to the filling head 2, and the filling head ...

Embodiment 2

[0043] The difference between the high-precision powder filling mechanism in this embodiment and Embodiment 1 is:

[0044] A transition gear is added between the driving gear 10 and the adjacent driven gear 11 , and a transition gear is also added between the driven gear 11 and the adjacent driven gear 11 . This design makes the feed rods all turn in the same direction: counterclockwise. Therefore, the feeding rods can adopt the same structure without using the reverse feeding rod 13, which can effectively reduce the types of components and reduce the cost of production and maintenance.

Embodiment 3

[0046] The difference between the high-precision powder filling mechanism in this embodiment and Embodiment 1 is:

[0047] The number of the high-precision filling device is one. Therefore, the driving gear 10, the driven gear 11, the reverse scraper bar 21, etc. all need not be used.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com